Various impacts from natural phenomena, which include, for example, ground and surface water, temperature changes, or precipitation, negatively affect the condition of modern buildings. Water and moisture in a fairly short time destroy the material from which the structure, price house, or building is made, which not only violates the appearance of the structure but also its reliability.

Therefore, both at the construction stage and at the stage of restoration of buildings, it is extremely important to carry out high-quality waterproofing of the foundation, walls, roof, terrace, balcony, and other structural elements. To protect buildings from moisture, the method of pasting waterproofing is often used. What it is, where and with what materials it is performed, will be discussed in this article.

Important: The concrete from which most foundations and houses are made, — is a porous structure that, with prolonged contact with water, absorbs it like a sponge, passing it inside, which can lead not only to leaks inside the basement/socle or premises located under the roof of the building, but also to gradual destruction of concrete: — From the effects of temperature changes in winter. Water that has soaked into concrete and frozen there, and thawed in the spring, leads to the formation of microcracks and an increase in capillaries and pores of concrete; — From salts and minerals in groundwater. Without proper protection of the underground part of the structure, these elements gradually destroy the concrete.

What is taped waterproofing and its main characteristics?

The pasting type of waterproofing is an effective method of protecting structures made of various materials from water. It is a multi-layer coating made of a special material that is fixed with a layer of adhesive composition. According to the technical characteristics, materials for pasting calculation can be compared with materials from the category of roll waterproofing.

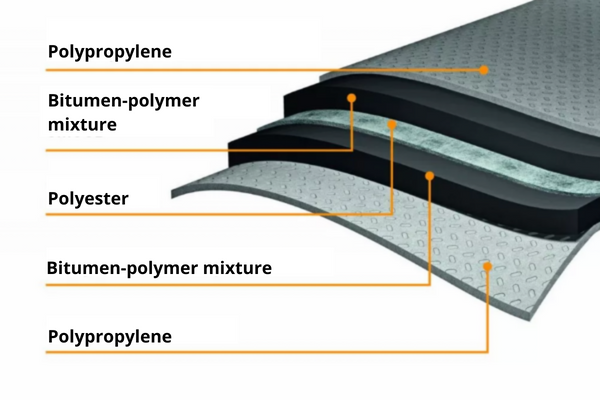

Pasting hydrophobic products, with the help of which modern buildings are protected from water, consist of:

- Adhesive base — the lower layer of the material used for more reliable fastening of the composition to the work surface;

- Substrate — a part of the product, which is a frame on which a hydrophobic material is applied;

- A waterproofing layer made of bitumen or various polymers, a material that is located on the top and protects the structure from moisture penetration.

Advantages and disadvantages of pasting materials

Advantages:

In the modern construction market, the materials of the pasting type are in great demand. This is explained by a number of their positive characteristics:

- Affordable price: in addition to the fact that the purchase of adhesive membranes will not cost the customer so much (relative to higher-quality and expensive systems), you can also find this material in almost any construction store, for example, in the “Petrovich” construction materials hypermarket.

- Safety for the human body and for the environment: pasting products are manufactured in accordance with all norms and requirements and therefore do not pose a threat to human life and health.

- Resistance to water: the products in question do not just protect the structure from moisture, they are able to withstand significant water pressure and at the same time maintain the integrity of the structure. This indicator depends, among other things, on the number of layers applied at the construction stage.

Disadvantages:

However, like other materials, pasting and roll types have their drawbacks.

- The presence of seams between the sheets. Seams — are the weakest points in any waterproofing system.

- Lack of adhesion or cohesion to the base, since in places this type of insulation will not fit tightly to the surface and have cavities under which water can walk if it passes through a weak or poorly glued seam.

- In most cases, before installation, the waterproofing material should be heated using a gas burner. This is a rather dangerous process, especially for those who undertake the performance of waterproofing in the absence of sufficient experience.

- For high-quality installation of adhesive materials, it is important that the working surface is perfectly flat. Poor-quality grinding can lead to the fact that the material will not be able to be fixed on the base or it will not be fixed securely enough.

- The problem for rolled materials is not only uneven but also complex surfaces, including, for example, pipe outlets or ventilation openings. It will not be possible to glue such surfaces qualitatively.

- Short service life.

Alternatives to pasting materials

Taking into account such disadvantages as the presence of seams and the lack of adhesion (cohesion) to the base, which is characteristic of the entire line of rolled waterproofing materials, systems with the following properties can serve as an alternative:

- No seams;

- 100% adhesion to the base;

- High elasticity indicators.

Materials with similar characteristics include the following materials:

- Liquid rubber – This material can be studied in more detail in the article “Waterproofing with liquid rubber”.

- Polyurethane waterproofing – This material can be studied in more detail in the article “Polyurethane waterproofing”.

Types of pasting waterproofing materials

Before starting construction, the material for waterproofing is selected. The choice is based on such indicators as the type of construction, installation conditions, required service life, budget, the presence or absence of groundwater, and the final purpose of waterproofing. After all, for example, industrial and domestic construction put forward absolutely different requirements for building materials.

In general, taped waterproofing refers to rolled types of waterproofing. You can read more about this category in the article – Roll waterproofing arrangement with detailed instructions for its installation.

Below we will consider the most common options and their technical characteristics.

Types of pasting materials by structure

Leafy

You can easily understand what kind of product this type belongs to by its name. the construction store sells sheets that fit the standard dimensions of structures, which are subsequently fixed to the sections of the structure in need of waterproofing. For the most part, sheet products are used to cover concrete, aerated concrete, brick, and some other bases.

Roll-type compositions

The second type of pasting product is considered universal because it can be used in almost any situation. Different manufacturers produce rolls with an average width of one to two to three meters. The customer can choose the length himself since there are no clear boundaries for this. These materials are fixed to the base on an adhesive base and, as a rule, are mounted in a frame that is installed on the work surface.

Roll-up pasting materials include fiberglass impregnated with bitumen, which easily melts. This feature ensures high resistance of the material to temperature, mechanical and weather influences.

Tile structure

Tile types are used for the arrangement of pasting waterproofing much less often than a sheet or other options but still find their application in the construction of multi-storey buildings. The technology of the arrangement of this material and its characteristics are similar to the indicators of the sheet. the main thing when buying such options is to choose the right adhesive composition that is combined with the base of the structure.

Types of pasting materials according to the arrangement method

In addition to the structural classification of pasting materials, there is also their division into pasted and self-adhesive. Let’s talk about the best materials for each of the listed types.

Pasted

The glued compositions include such types of products as roofing material, sealing membrane, and asbestos felt. All these types of insulation should be glued using an adhesive base, which is part of the waterproofing material.

Roofing material

This option is considered as the most budget-friendly of all the materials under consideration. Its composition is based on simple construction cardboard, which has not differed in high cost. You can buy roofing material at any hardware store. At the same time, it is important not to forget that not all adhesive compositions are suitable even for universal materials.

Sealing membrane

Unlike other pasting materials, the sealing membrane does not include a substrate. The only components of its composition — are universal bitumen and several types of rubber. The material is characterized by high performance and is most often used to protect underground structures from moisture and dampness.

Asbestos felt

Asbestos felt is made of fiberglass or contains a base of asbestos on mastic, which includes oxidized bitumen. Such a material has a higher cost than other subspecies of pasted materials. It is available in the form of a composition coated with a sprinkling or double-sided protective layer based on a polymer.

Self-adhesive

These are the types that have their own adhesive layer and do not require additional heating for their arrangement. Among the self-adhesive options, the materials produced by “Technoelast” are considered as the highest quality.

Technoelast

Technoelast has different modifications and is suitable for use both outside and inside the building, depending on the modification. For the installation of most types of Technoelast, it is enough to remove the protective film and glue it to the prepared surface.

Recommendations for the choice of material

It may not be easy to choose the right material for the arrangement of high-quality waterproofing with today’s variety of products. What is the first thing you need to pay attention to when choosing a suitable composition?

- Each building material has its own operating conditions, which should be carefully studied. For example, there are materials that can withstand regular exposure to groundwater, and there are those that are damaged due to constant contact with liquid. Therefore, it is important to determine in advance the conditions in which waterproofing will be used.

- Also, you need to remember to study the technical characteristics of the purchased pasting insulation. Be sure to pay attention to the components included in the waterproofing and their properties, as well as the types of structures combined with it.

- It is not allowed to ignore the fact that the technology is planned to be used for installation. For example, for vertical installation, it is better to purchase insulation supplemented with abrasive powder as a finishing layer, and horizontal installation requires the use of products coated with polymer additives. If it is known that the pasting layer will be subjected to significant mechanical loads, it is recommended to give preference to a composition improved with fiberglass.

Popular brands of adhesive and self-adhesive membranes:

“Technonicol”

This brand of waterproofing self-adhesive materials is one of the most popular in Russia. For many years, Technonicol has had many factories and supplies its products throughout Russia. Technonicol products are suitable for protecting foundations, roofs, walls, floors, and other structures.

Where it is possible to buy pasting and other insulation at competitive prices

Technonicol products and other waterproofing materials can be bought in almost any construction store, but do not forget that not all stores should be trusted, since there are fakes and low-quality goods on the market.

Important: Most of the pasting systems should be properly stored (in the right position and at the right temperature) and transported, otherwise they may lose their properties and fulfill their purpose less efficiently and durable.

The technology of the arrangement of pasting waterproofing

To date, depending on the requirements for construction, various technologies for installing a waterproofing system are used. The most popular of them are horizontal and vertical mounting types. However, there are other subtleties when choosing installation techniques.

The stages of work include:

First of all, it is important to understand the procedure for performing work on the arrangement of pasting waterproofing.

- The work begins with the grinding of the base. Sometimes the surface is leveled using a cement screed. Grinding and leveling are necessary only if the surface has corresponding defects.

- The next stage — is a primer designed to increase the adhesion properties of the hydrophobic composition to the base. It is necessary that the primer is completely dry before starting further installation.

- Then a pasting or self-adhesive material is applied to the base, which is fixed to the surface using an adhesive base.

It is also worth considering that the pasting waterproofing is performed using a cold or hot technique.

- The cold mounting method involves fixing the hydrophobic material with glue, which is applied to its inner surface. The adhesive composition is designed to destroy the surface layer of the material and turn it into liquid bitumen, with which the sheeting is subsequently fixed.

- The hot installation technique involves heating the adhesive layer with a burner until it reaches a semi-liquid state. Fastening takes place using a roller, in the same way as in the case of cold fixation.

Important: Waterproofing of structures both from the inside and from the outside is prohibited during the frosty season, since the freezing of liquids prevents the qualitative process of installing materials. Also, the weather should be dry, because only in this case the material will be able to stick well to the base and show all the declared performance characteristics.

Installation instructions for pasting types of waterproofing

In order for the pasting waterproofing should work correctly and with a long-term effect, it is necessary to follow the instructions strictly for its installation or invite a qualified organization whose specialists are well familiar with the technology of this type of protection arrangement, otherwise, you risk that the material will not protect the surface at all or to the proper extent, leaks and subsequent expensive repairs will appear.

Horizontal waterproofing

Horizontal technology is most in demand where there is a rise in moisture from the surface of the ground, that is, horizontal accumulation of liquid. The considered technique is used both from the outside and from the inside of the building. However, the process of installing this type of waterproofing should be carried out before the walls are erected, so it is important to plan such work.

You can read more about horizontal waterproofing in the article

Horizontal pasting waterproofing can be carried out on a horizontal surface and is mainly relevant when installing waterproofing on a foundation slab, floor slab, or flat roof. You can read more about the waterproofing of these structures in the following articles:

- Waterproofing of the foundation slab: Methods and materials

- Waterproofing of floor slabs: Methods and materials

- Waterproofing of a flat roof: Recommended materials, methods of their installation, and prices for work

Vertical waterproofing

This technology is relevant for vertical foundations and walls of an already erected structure. Vertical waterproofing allows you to protect the foundation and basements from the effects of groundwater and rainwater, moisture, temperature changes, and the effects of minerals and salts.

You can read more about vertical waterproofing in the article

– Vertical waterproofing: materials and methods of its arrangement

The application of pasting products on a vertical base is mainly relevant for the construction of walls. You can read more about the waterproofing of these structures in the following articles:

- Waterproofing of basement and house walls from outside and inside – Methods, materials, prices, and technology

- Waterproofing of the ribbon foundation: Technology and materials

- Waterproofing of foundation blocks and walls

Where is the adhesive waterproofing applied

Waterproofing materials, regardless of where they are used, should be applied in several layers, overlapping the seams of the previous layer, in order to provide high-quality protection of the building from water.

Pasting waterproofing of walls

If we are talking about the need to treat the walls with waterproofing materials, then it is best to choose materials whose arrangement is conveniently manufactured in an upright position. In this case, the task of waterproofing — is to protect the wall surfaces that are below ground level from the effects of water, moisture, and chemicals.

You can read more about waterproofing walls in the following article

Waterproofing of the foundation

The foundations of private houses and administrative buildings are exposed to moisture more often than other parts of the building since they are located underground. The task of the hydrophobic material — is to protect the structure from excessive exposure to water, which can spoil both the internal and external parts of the structure when leaks occur.

You can read more about the waterproofing of the foundation in the following articles:

- Foundation waterproofing arrangement: Methods, materials, prices, and recommendations of specialists

- Waterproofing of the foundation slab: Methods and materials

Waterproofing of the basement

Another “consumer” of waterproofing products are basements and socle rooms – these are places of increased exposure to water since they are located underground, where not only groundwater accumulates, but also rainwater (open groundwater). Vertical surface treatment is used for waterproofing basements.

You can read more about the waterproofing of basements in the following articles:

- How to make waterproofing of the basement from the outside properly

- Waterproofing of the basement from the inside: Methods, materials, and stages of work

- Elimination of basement leaks once and forever

- Waterproofing of the basement floor of the house: Methods, technologies of the arrangement and materials

- Fungus and mold in the basement of a private house: Causes and how to get rid of it once and forever?

- How to make properly a basement recess below the sole of the foundation

- Waterproofing of the socle: Recommended materials and technologies

Waterproofing of floors

Protection of floors from excess moisture is relevant in all types of premises. Properly conducted waterproofing will allow you not to think about such unpleasant problems as leaks, the appearance of mold, and the penetration of moisture into the living room. Self-adhesive materials, such as the previously discussed “Technonicol” and “Technoelast”, are best suited for working with floors.

You can read more about the waterproofing of the floor in the following articles:

The price of the arrangement of pasting waterproofing

The cost of work on the waterproofing of various parts of the building is determined by a combination of interrelated factors. Their list includes such data as:

- Location of the facility and complexity of transportation of materials;

- The condition of the structure at the time of waterproofing;

- The amount of work required and, accordingly, the number of materials;

- The time of the year in which the installation is planned;

- Deadlines set by the customer for the performance of works;

- The preferred technology for conducting the pasting waterproofing.

| Description of works | Unit of measurement | Price in $ |

| The arrangement of pasting waterproofing on the horizon in 1 layer | m2 | starting from 36 |

| The arrangement of pasting waterproofing on the vertical in 1 layer | m2 | starting from 49 |

| Arrangement of self-adhesive waterproofing on the horizon in 1 layer | m2 | starting from 36 |

| Arrangement of self-adhesive waterproofing on the vertical in 1 layer | m2 | starting from 49 |

| Application of bitumen primer | m2 | 10 |