Table of Contents

- When and why it is necessary to do vertical waterproofing

- Materials and methods of vertical waterproofing installation

- Recommendations: The optimal method of vertical waterproofing of the foundation and walls

- Prices for vertical waterproofing

- Calculator for self-calculation of the cost of waterproofing

Waterproofing — is a protective barrier that protects your home or building from the effects of water and moisture. If we talk about vertical insulation, then its meaning is to protect the vertical surface of the foundation and the walls of the basement or basement (if they are below ground level) from water, aggressive underground environment and moisture.

When and why it is necessary to do vertical waterproofing

Vertical insulation is necessary for all buried parts of buildings and structures, and not only when there is high groundwater around the house, but always, since the soil around the house absorbs moisture from rains and melting snow, and then gives it to unprotected surfaces of walls or foundations.

Waterproofing should be done regardless of the material from which your foundation or buried walls are made, since concrete, blocks, bricks and other similar materials absorb water and moisture like a sponge, as a result of which, over time, due to temperature differences (freezing of moisture and its thawing), microcracks and pores appear in them, and they are being destroyed.

Such buried parts of buildings are the following structures:

- Ribbon or slab foundation;

- Socle walls;

- Basement walls;

What can lead to poor-quality vertical protection from water or its absence:

- Cracks in the foundation;

- Cracks in the walls;

- Increased humidity in the basement;

- Mold and mildew in the basement of a building or its socle, affecting human health;

- Flooding of the basement or residential basement.

When designing and constructing a building, it is necessary to take into account measures related to its protection from water, while it is important not only to perform waterproofing work, but also to do it efficiently by choosing the right waterproofing method and material. If the waterproofing of the elements of the house located underground was performed poorly, then for its repair or replacement, you will need to perform the following expensive measures:

- Dig out the building around the perimeter and break the blind area (if available);

- Dismantle the vertical external layers, made on the walls and foundation – a spike-shaped membrane, insulation (if there is basement) and an old waterproofing coating;

- Prepare the walls and the vertical part of the foundation;

- Installation of a new waterproofing coating;

- Re-mount the insulation and the spiked membrane (if any) on a vertical base;

- Perform backfilling.

Important: Waterproofing works should be carried out at the construction stage of a house or building. If they are not taken into account or are performed poorly, then for the above reasons, they will have to be redone at the time of operation of the building, which will cost 2 times more expensive. "

Materials and methods of vertical waterproofing installation

Waterproofing works on the vertical part of the buried parts of the house can be performed with different materials and technologies. The main methods can be found below.

Coating waterproofing

Coating insulation is a different kind of mastics based on bitumen, polymers, polyurethanes, etc. This type of protection involves applying a brush or roller in the form of a solid one, two or three layers, which, after solidification, form a seamless, sealed layer that reliably isolates the treated surface, including all places of interfaces with other building elements.

Depending on the quality of the material, the resulting coating will be able to withstand chemically active media and moisture for a certain period of time. Due to the high coefficient of elasticity (depending on the type of mastic and its components), the coating composition will be able to prevent cracking under the influence of temperature changes and possible shrinkage of a house or building.

You can read more about bitumen waterproofing in the article – “Bitumen waterproofing: types, characteristics and technology of the installation“.

Pasting waterproofing

This material is supplied in the form of sheets mainly on a bituminous basis according to the type of roofing material. The pasting insulation is applied to the surface by hot soldering or cold method using bitumen mastic and a special roller. Pasting waterproofing is quite easy to install, however, it has major drawbacks associated with the presence of many joints (seams) and their short-lived tightness.

Membrane waterproofing

Membrane insulation is an additionally reinforced film material that can withstand a high degree of load. The advantage of such a system over a pasted or surfaced roll system is the possibility of its use in any, even the most difficult conditions, and therefore there are practically no restrictions on the scope of membrane insulation. However, the reliability of this material is in great question, since it has seams and absolutely has no adhesion to the surface, which means that if water passes through a microcrack in the seam, it will freely walk under the membrane leaving the room in the weakest place.

The main types of membranes:

- Polymer membrane – based on polyvinyl chloride, having several layers.

- Profiled membrane is a high-strength waterproofing material made of polyethylene.

You can read more about membrane waterproofing in the article – “Membrane waterproofing: Types of materials and methods of their installation“.

Roll-on and surfaced waterproofing

Surfaced insulation is a multilayer rolled material on a bitumen base with water—repellent characteristics. Installation of the deposited insulation coatings occurs under the influence of high temperature, mainly fire.

The main disadvantage of the deposited rolls is, of course, the presence of many seams formed when the rolls are joined. Failure to follow clear instructions and technology when the material is deposited on the surface leads to overexposure of the fire at the joint and damage to the bitumen adhesive layer, which in turn leads to a weakening of the seam and the passage of water through it under the waterproofing carpet.

Liquid rubber

Liquid rubber is one of the best and most modern materials for application on the vertical and horizontal surface of the foundation or underground parts of buildings and structures. Liquid rubber, when sprayed, forms an elastic seamless rubber membrane with full adhesion to the base.

The main advantages of LR:

- Due to its elasticity, liquid rubber does not tear or crack, but stretches even with severe shrinkage of the building.

- Due to the absence of seams and joints the rubber coating creates an ideal waterproof barrier without the presence of seams and other weak points through which water can pass.

- Full adhesion to the base does not allow water to walk under the membrane, entering through a hole in one place and leaving in the form of a wet spot or a leak in a completely different place.

You can read more about liquid rubber in the article – “Waterproofing with liquid rubber“.

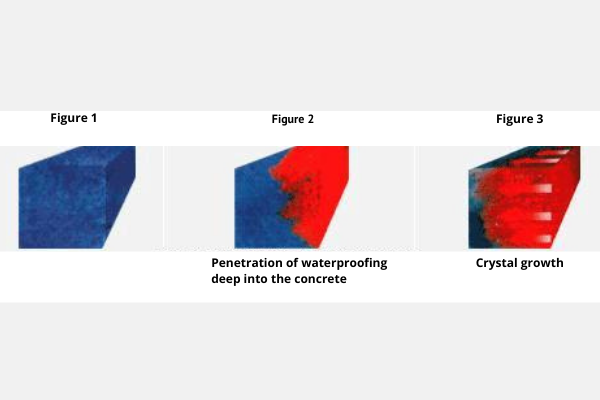

Penetrating

The material works like this: The penetrating compound is applied to the surface using a brush, fills the pores of concrete structures and turns into insoluble crystals that do not allow water to pass. One of the most important components when applying penetrating formulations is abundant moistening of the surface before and after work.

Penetrating insulation consists of several basic elements:

- Portland cement;

- Chemically active additives;

- Alkaline earth metals;

- Polymers.

You can read more about penetrating waterproofing in the article – “Penetrating waterproofing: A detailed description of its work on concrete, types of materials and application technologies“.

Comparison table between the main methods of vertical insulation

This table shows all the advantages and disadvantages of the above waterproofing systems and technologies.

| Liquid rubber | Surfaced and pasting materials based on bitumen PVC membranes | PVC membranes | |

| Mounting method | Without fire By spraying Manually using a roller or brush | Fire burners Pressure rollers | Hot air dryer Mechanical fasteners Special rollers |

| Work on negative water pressure | Not available | Not available | Not available |

| Number of layers | 1 layer for double-component 2 layers for single-component | 2-3 layers | 1 layer |

| The need for pre-priming | Available | Available | Not available |

| Seams and joints in waterproofing coating | Not available | Available | Available |

| Adhesion to the base | 100 % | 20 % | No adhesion |

| Coefficient of elasticity | 600-800% | 10-20% | 10-20% |

| Installation speed m2/per 1 day | 400-600 | 20-50 | 30-60 |

| Warranty period for works | 7 years | 3-5 years | 1-2 years |

Recommendations: The optimal method of vertical waterproofing of the foundation and walls

Today, there are many waterproofing materials and methods of waterproofing installations on the market, which makes choosing between them a rather troublesome task, which is best entrusted to professionals working with different materials and different methods. Below are recommendations regarding the optimal methods of vertical protection of the foundation of the house and its walls from water penetration, regardless of whether the house has a basement or not.

Vertical waterproofing of the foundation

When building the foundation of a house, regardless of the type of foundation (ribbon foundation or slab) and the future availability of a basement, it is necessary to perform its waterproofing. These works can be performed using surfaced roll membranes, PVC membranes, polyurethane or cement-polymer materials.

Recommendation:

One of the most popular and high-quality waterproofing materials suitable for waterproofing the foundation is liquid rubber, as it is a seamless coating with 100% adhesion (adhesion to the surface) and a high coefficient of elasticity.

Vertical waterproofing of walls

The installation and assembly of waterproofing on the walls can be performed by the following methods:

- Installation of surfaced insulation on walls and foundation;

- Installation of PVC membrane on walls;

- Application on walls, various types of mastics;

- Spraying or applying liquid rubber on the foundation slab and walls.

Recommendation:

Liquid rubber is the best option for the foundation insulation installation, since it has the following properties:

- No seams;

- 100% adhesion to the concrete, brick and other substances;

- A large coefficient of stretching, which will not allow the material to crack or disperse during shrinkage of the building or its dynamics.

You can read more about vertical and horizontal waterproofing in the following articles:

- Horizontal waterproofing of the foundation: The technology of the installation and the materials necessary for it

- Vertical waterproofing: materials and methods of its installation

Stages of work execution by most of the existing materials:

- Cleaning the base from dust, dirt and flaking particles;

- The fillet installation is at the transition from the horizon to the vertical (if you have a slab foundation), and not at 90 degrees;

- Applying a primer to improve the adhesion of future insulation to the base;

- Waterproofing installation in 1 or 2 layers, depending on the selected material;

- Protection of the work, performed from mechanical damage, for example, using a spiked membrane.

Important: When performing work, it is necessary to follow strictly the instructions of the manufacturer of the waterproofing materials and contact personal companies, since the main reason for most leaks and subsequent complaints is poor quality and incorrectly performed work.

Prices for vertical waterproofing

Below is a price list with prices for a waterproofing device on a vertical surface. This price list takes into account the cost of work per m2, excluding the cost of materials, the cost of overhead and transportation costs. The price of the work may vary depending on the complexity of the execution, seasonality and time constraints (night work may cost more). Unless otherwise indicated, all prices in the price list are indicated for 1 layer of a coating, while some coatings are applied in at least 2 layers.

| Works description | Unit of measurement | Price in $ |

| The installation of surfaced waterproofing on the vertical | m2 | starting from 10 |

| Installation of a self-adhesive membrane on a vertical | m2 | starting from 10 |

| The installation of PVC membrane on the vertical | m2 | starting from 15 |

| Application of polyurea | m2 | starting from 30 |

| Application of mastic waterproofing | m2 | starting from 8 |

| Application of liquid rubber by spraying | m2 | starting from 10 |

| Application of liquid rubber manually | m2 | starting from 9 |

| Application of polymer cement 2-component waterproofing | m2 | starting from 15 |

| Polyurethane waterproofing installation | m2 | starting from 15 |

| Application of penetrating compounds | m2 | starting from 15 |

| Applying the primer | m2 | starting from 8 |