Garages are often used not only for their intended purpose — car storage but also as a kind of storeroom. It includes seasonal items, oversized items that do not fit into apartments, and even canned products.

That is why garages need waterproofing that can protect against flooding, and destruction under the influence of groundwater, no less than cellars. In this article, we will talk about how to properly perform waterproofing of the garage from the inside and from the outside, as well as what materials are best used for this.

Why is waterproofing necessary and what problems it solves

For the garage, the things stored in it, and the vehicle, not only flooding is dangerous, but also other phenomena caused by the impact of groundwater. Such phenomena include, for example, increased humidity or dampness, as well as the formation of mold and mildew on the floor and walls of the room. As a result, metal products and elements of the car suffer from corrosion, which can be very difficult to solve later. Waterproofing of the garage, even in cases when it is not planned to be equipped with a basement, helps to avoid many problems with transport.

First of all, the base of the garage, or its foundation, needs hydrophobic protection. Work on the installation of waterproofing of the floor should ideally be carried out at the stage of the construction of the garage, and it is important to avoid mistakes that can manifest themselves only after several years of operation of the premises. Moreover, the danger is not only groundwater, but also precipitation, and capillary moisture that can penetrate into the room through walls or floor. the garage becomes especially vulnerable in the spring — the thaw season, during which snow melts, puddles are formed on the ground, and moisture penetrates the base of the garage, provoking the destruction of materials.

Experts recommend approaching the waterproofing of the garage from all sides at once, that is, to treat the floor and walls of the room both inside and outside, to protect the garage ceiling, be sure to waterproof the basement and inspection pit, if any. With the right approach to waterproofing, you can avoid problems such as the accumulation of condensate inside the garage, the proliferation of fungus and mold, the destruction of the screed when moisture accumulated in it freezes, as well as a significant reduction in the service life of the room. Therefore, the right approach to the selection of hydrophobic materials and their installation will allow you to forget about the problems with dampness inside the garage for many years.

Read more about proper waterproofing in the following articles:

— How to make a basement recess properly below the sole of the foundation

— Foundation waterproofing arrangement: Methods, materials, prices, and recommendations of specialists

Types of waterproofing materials:

For work, you can choose:

- pasting,

- coating,

- sprayed,

- painting,

- injectable

- or penetrating materials.

For the treatment of the floor, ceiling and walls of the garage you can use exactly the same materials as for waterproofing of residential and non-residential structures. However, when working with specific materials, it is necessary to take into account some nuances, for example, the peculiarity of the interaction of compounds with groundwater. Let’s consider the types of hydrophobic materials in more detail.

Roll waterproofing

Inexpensive roll-type materials which are made on the basis of petroleum products, are excellent for waterproofing of garages. Any types of roofing material, pergamine, roofing will be excellent options.

Among the advantages of rolled materials, the following points can be distinguished:

- Easy installation and repair.

- Low cost.

- The possibility of using patches to restore the coating.

- High degree of adhesion to various materials.

Roll materials of the surfaced and self-adhesive types are distinguished. The disadvantages of working with such compositions include the fire hazard of working with a gas burner necessary for the installation of surfaced materials. Also, roll waterproofing when heated begins to emit toxic substances, and when working it is necessary to ventilate the garage.

The materials in question are allowed to be used for both external and internal processing of the garage. The necessary tools include a primer, a construction knife, a tape measure, a paint brush, equipment: bitumen mastic – for self-adhesive materials or a gas burner – for surfaced materials. Before starting work with roll waterproofing, it is important to prepare the surface qualitatively, rid it of dirt and any irregularities.

Often, a primer is applied to the base, designed to strengthen the top layer of concrete. You can start hydrophobic surface treatment after the primer has completely dried. In the absence of a basement in the garage, the optimal solution will be the installation of waterproofing from rolled material. Waterproofing is laid on the garage floor even before the construction of the walls. This approach allows you to forget about the problem of penetration of capillary moisture into the room for many years.

Read also: Roll waterproofing arrangement with detailed instructions for its installation

Membrane waterproofing

The next type of waterproofing – protective membranes – is excellent for processing various residential and non-residential structures, as well as floors, walls and ceilings of garages and basements. Depending on the specifics of the operation of the membrane and the budget calculated for it, either expensive polymer materials or ordinary construction films of small thickness are chosen.

Like more traditional pasting materials, membranes are characterized by ease of installation and repair, and also have a small mass, which significantly simplifies the transportation and operation of materials. Moreover, the installation of the membrane is carried out very quickly, especially if the width of the materials is enough for the entire work surface. Otherwise, the membrane is laid in sheets with an overlap of 20 sm.

Very often waterproofing membranes are used in combination with expanded polystyrene, which acts as thermal insulation. In the absence of a basement or an inspection pit in the garage, the protective membrane can be laid directly on the floor of the room and a reinforcing mesh and a concrete screed can be mounted on top of it.

The sides of the membrane are not the same: one is – waterproof, and another one is intended for vapor transmission. Do not confuse during installation!

Read also: Membrane waterproofing: Types of materials and methods of their arrangement

Bitumen coating waterproofing

The coating materials are made on the basis of a budget petroleum product – bitumen. Often these mastics are supplemented with additives: plasticizers, polymer and mineral substances, oils.

There are a lot of advantages of bitumen waterproofing of the coating type:

- Forms a seamless coating, without pores and other micro-holes.

- Low cost, economical consumption.

- Easy to use and repair.

- High elasticity and light weight – do not weigh down the design.

- The ability to change the color of the mastic by adding a dye of the desired color to the finished solution.

Coating waterproofing is divided into compositions of cold and hot application. When it comes to waterproofing of garages, they often make a choice in favor of cold mastics, since their preparation does not require heating.

The technology of preparing the work surface for the installation of waterproofing is similar to work with rolled material. The mastics themselves, both cold and hot, are applied using a roller or a wide paint brush. The difference is that hot compositions need to be heated to the desired temperature before use.

Sometimes mastic is applied in several layers, both inside and outside the room. Each next layer is applied only after the previous one has completely dried!

It is better to choose a coating waterproofing with additives, since bitumen mastics are afraid of low temperatures, begin to crack, and plasticizers make them stronger.

Read also: Bitumen waterproofing: types, characteristics and technology of installation

Sprayed liquid rubber

A material perfectly suitable for waterproofing a garage and basement, if present, is considered as liquid rubber, which is applied to the work surface suing special sprayers. such a hydrophobic composition is also perfect for hydrophobic treatment of a flat roof of a garage structure. Distribution of the composition under pressure with the use of an air compressor makes it possible to achieve a uniform hydrophobic coating, and also provides an economical consumption of waterproofing material.

The liquid rubber coating does not contain seams and holes, is absolutely waterproof, perfectly withstands moisture, contact with chemicals and testing both high and low temperatures. However, this material also has several disadvantages:

- Application of liquid rubber is allowed only if the ambient temperature exceeds +5 degrees Celsius;

- The sprayed coating can be damaged by a puncture, but the repair of waterproofing is carried out very simply and in the shortest possible time;

- It is quite expensive to work with liquid rubber: both the material itself and its application services cost customers a decent amount;

- The material in question is extremely demanding on the quality of the surface, which should necessarily be clean, smooth and dry;

- Sprayed waterproofing is suitable only for the external treatment of garage structures.

The use of liquid rubber for waterproofing of garage floors and walls is fraught with negative consequences. The thing is that the material in question is able to withstand only such moisture pressure, which is directed “from the above”. If the liquid presses on the coating from the treated base, then, most likely, the liquid rubber will be simply peeled off from the working surface. The optimal solution will be the use of such material for waterproofing roofs of garage structures.

Read also:

— Liquid waterproofing: Types of materials, their characteristics and prices

Polyurethane compounds

Polymer materials are quite expensive, especially suitable for waterproofing of concrete surfaces. In hardware stores, you can buy ready-made single-component compositions that are mixed before use.

The positive features of polyurethane materials include:

- Waterproof seamless coating.

- High tensile coefficient and excellent elasticity.

- High degree of adhesion to various surfaces.

- Rich color scheme, wear resistance.

- Long service life, resistance to atmospheric precipitation and ultraviolet.

- High speed of installation and repair work.

Manufacturers always indicate the nuances of working with the manufactured composition. Before starting work with polyurethane waterproofing (if it is applied to a concrete surface), the base should be thoroughly cleaned, and any damage, for example, cracks – should be eliminated. After that, the surface is treated with a polymer, on which waterproofing is applied, and most often in 2-3 layers, each of which should be dry before applying the next one.

Experts recommend using paint brushes, rollers or spatulas as tools. To speed up the installation of polymer mastics, you can order services for spraying mastics using special equipment.

If the type of waterproofing in question is applied to the basement floor, the coating should be continued at least 15 sm up the walls. This is necessary to achieve the best effect from the hydrophobic protection of the structure.

In some cases, the finished coating is also sprinkled with sand, the volume of which is not less than 300 microns.

See also:

Penetrating

Penetrating materials are made on the basis of cement, which is supplement with fine quartz sand, polymer and mineral additives. Penetrating waterproofing is mounted on the same principle as the coating materials.

Advantages of penetrating waterproofing:

- Easy installation.

- Light weight.

- Safety.

- The ability to penetrate deep into the pores of the material.

- Low requirements for the condition of the treated surface.

- Can be used both outside and inside the room.

Before starting the installation of penetrating waterproofing, it is necessary to clean the base from salts. For this purpose, chemical salt neutralizers or mini-car washes are used, which direct a jet of water under high pressure to the surface.

Then, to achieve the effect, the concrete base should be moistened. This ensures high-quality interaction of the hydrophobic material with the liquid right inside the pores of the material. Compositions of the penetrating type are rubbed into the work surface with a stiff brush, and subsequent layers of material, if necessary, are applied perpendicular to the first layer (in the other direction). To apply the second and next layers, you can use a spatula. Since the penetrating waterproofing does not cope with the protection of garage elements from moisture by 100%, a layer of rolled material is laid on the base after the composition dry out.

Comparison table

Below is a table of the main characteristics of the materials considered:

| Indicators | Rolled | Membrane | Bitumen | Liquid rubber | Polyurethane | Penetrating rubber |

| Expenditure, kg/m2 | 2 sq. m. | 1 sq.m. | 3 kg | 2 kg | 0,8 kg | 0,8-1,2 kg |

| The presence of seams on the coating | + | + | – | – | – | – |

| Relative elongation at break, not less than % | 2 % | 20 % | 500 % | 700 % | 100 % | 200 % |

| Water absorption in 1 day, not more than | 2 % | 2 % | 0,4 % | 0,5 % | 0,5 % | 5 % |

| Operating temperature, °С | from -40 to +70 | from -40 to +60 | from -20 to +30 | from -35 to +70 | from -25 to +50 | from -50 to +70 |

| Flexibility, °С, not lower than | 5 | 5 | -5 | -25 | -15 | -10 |

| Chemical resistance | High | High | Medium | Medium | Medium | Medium |

| Resistance to UV | Not available | Available | Available | Available | Available | Available |

| Primer application | Required | Required | Required | Not required | Required | Not required |

| Surface humidity | Not allowed | Not allowed | Not allowed | Allowed | Not allowed | Allowed |

| Service life | 2-3 years | 20 years | 25 years | 3 years | 15 years | from 30 years |

Technology and features of garage waterproofing from inside and outside

Garage waterproofing includes several important steps, including the treatment of the basement or inspection pit, if any. Let’s consider the features of each type of work separately.

Waterproofing of the garage basement from the inside

Internal waterproofing of the garage basement is aimed at processing joints between the floor and walls, concreting joints, joints between blocks (if the floor or walls have a block structure), cracks formed in the concrete coating or brickwork, and so on. Often the waterproofing of the basement from the inside is not carried out at the construction stage, but only after the detection of leaks and other damages.

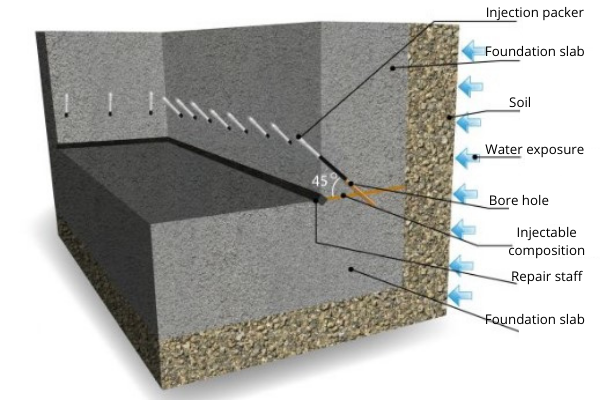

When a leak is detected at the site of a seam, a joint of slabs or a crack, repair work should begin with the stitching of the site. At this stage, a small-sized indenting is installed, which is filled with an expanding sealant. Then you should drill small holes and insert packers into them, through which the repair solution will be supplied using a pump. As soon as the crack or seam is filled, and the leak is eliminated, the packers can be removed, and the holes left after them can be filled with a sealant.

Waterproofing of the room from the inside can only affect the walls if leaks have been found in them. Injection technology is used to restore surfaces, especially if we are talking about several small local leaks. After minor damage is eliminated, a larger-scale waterproofing is mounted on the wall, which can be represented by rolled or coated materials.

A similar technology is used in cases where the walls are made of blocks. Damaged interblock seams are expanded, cleaned and filled with sealant, and roll or coating waterproofing is used as a finishing coating. It is the same with brick walls, where it is important to fill all the voids, which are the main cause of leaks.

Hydrophobic treatment of the pit, located in the floor or foundation of the room and intended for collecting water, also is applied to the waterproofing of the basement of the garage, carried out from the inside. Thanks to the pit, it is possible to pump out the accumulated moisture in a timely manner. However, if the pit is made or processed incorrectly, flooding of the basement may occur. High-quality waterproofing of the pit will avoid possible problems.

The arrangement of the pit should be carried out correctly from the very beginning. The hole created in the floor or foundation is equipped with a formwork and a reinforcing frame, as well as the swelling cord. Hydrophobic additives are added to the concrete, which is planned to be poured into the pit. After the concrete solidifies, the pit is supplemented with waterproofing (most often mineral-based), capable of withstanding moisture from both sides, that is, both negative and positive pressure.

Waterproofing of an already installed pit, which does not perform its function properly, is carried out by injection using mineral compounds that include polymer additives.

Read more:

— Waterproofing and sealing of cracks in concrete, brick and other bases

Waterproofing of the garage basement from the outside

Hydrophobic treatment of the basement from the outside includes several important steps. Let’s consider each of them:

- Cleaning the work surface from dirt, dust, and grease stains, as well as removing excess liquid from it;

- In cases, where it is planned to install the same waterproofing for the foundation and walls (which will be provided with a transition from a horizontal surface to a vertical one), a fillet is necessarily installed, creating a smoother transition angle;

- After cleaning, the working surface is treated with a primer using a roller or paint brush: the primer should dry completely before starting further work;

- At the next stage, waterproofing is applied in accordance with the manufacturer’s recommendations: since the basement is a structure that is constantly in contact with groundwater, repeated hydrophobic treatment may be necessary after 3-5 years;

- The last optional stage — the insulation arrangement will help to protect the installed waterproofing, as well as prevent its destruction in the event of external mechanical influences on the basement. Sometimes a drainage membrane is also used as a finishing coating, which serves as an additional tool for water drainage.

Waterproofing of garage walls

Both monolithic and block garage walls need reliable waterproofing, but it is a little more difficult to work with the second type of surfaces. Both monolithic and block walls can be processed using penetrating materials, however, for walls consisting of blocks, it is also important to carry out additional processing of seams and joints. A sealant of hydrophobic gels will perfectly cope with this task. Plaster materials are mounted on top of the penetrating waterproofing, and polyurethane paint is used as a decorative coating, which is also capable of performing moisture-proof functions.

However, in many cases, the best option is to abandon the expensive installation of penetrating waterproofing. The rental of special equipment, the services of specialists, the purchase of high-quality materials, as a rule, are quite expensive. The budget solution– coating-type materials with polymers in the composition, that is, bitumen-polymer mastics.

Before starting the work, it is important to clen the walls from dirt, grease stains, and dry thoroughly. The seams between the blocks are expanded by at least of 5-10 mm and are filled with sealant. After that, the coating waterproofing is applied to the walls in a continuous layer, there may be several layers. For additional protection, you can use plaster waterproofing.

Waterproofing of the garage floor

Before the construction of the floor, the soil is carefully compacted. Hydrophobic materials are placed on the garage floor at least of 25 sm from the ground level. If seasonal uplifts of ground and flood waters are characteristics, then the waterproofing of the floor should be installed even higher.

The compacted soil is provided with a pillow of sand, and then equipped with geotextile, which serves as the basis for a hydrophobic roll-type material. Only then proceed to the installation of the concrete screed.

At the stage of installation of waterproofing of the floor, the type of soil should be taken into account. If the soils are wet, subsident, then the height of the waterproofing of the floor increases to 30-50 sm, and the selected material should be laid in 2-4 layers. Also, before laying the roll, the concrete base is treated with penetrating waterproofing. It is extremely important to create a solid coating as a result, the seams on which are removed by treating them with glue and heating them to the desired temperature.

Waterproofing of the garage foundation

Waterproofing of the foundation is done from the outside. To do this, a trench with width of 50 sm is formed at the constructions stage of the garage. For waterproofing the foundation, it is recommended to combine 2 hydrophobic materials. For example, you can treat the base with bitumen mastic, and roll material on top of it. At the same time, it is important to lay strips of rlled waterproofing immediately on the mastic, without waiting for it to dry. It is necessary to fasten the strips with an overlap of at least 10 sm, and all overlaps are also treated with bitumen mastic.

If there is no basement in the garage, then the foundation is treated only from the outside. If there is a basement, then waterproofing is also applied from the inside. Penetrating waterproofing will be an excellent solution for the internal treatment of the foundation, a more budget option is coating-type materials (at least 2-3 layers). A good waterproof pillow can serve as roll waterproofing, which is also mounted in several layers.

Read also: Waterproofing of a ribbon foundation: Technology and materials

Waterproofing of the garage roof

For waterproofing the roof of a garage structure, roll-type materials that fit well stretched with an overlap of 10-12 sm are perfect. If the choice was made in favor of roofing material, then before applying it to the roof, as well as on any other surface, it is important to clean the base from dirt and only then proceed to laying the roofing material. Any bulges and kinks present on the hydrophobic coating are necessarily eliminated.

The roofing material itself is laid on the surface using a gas burner. At the same time, the correct temperature regime should be observed, since with insufficient heating of the roofing material, it will not be possible to lay it on the base, and overheating will lead to a loss of elasticity by the material. The heating of the roofing material is stopped at the moment when the logo disappears from the surface of the material. It is not difficult to check the quality of the laid waterproofing: the roof surface is doused with water, after which the inside of the roof is checked for humidity. If no leaks or drops of moisture are detected, then the waterproofing of the roof is well done.

Also, self-adhesive membranes are often used as a waterproof coating, which are connected to the surface using polymer mastics. After laying, the material is smoothed with a conventional roller. Most polymer mastics are perfectly combined with various types of roofs, including concrete, wooden and metal. If all seams and joints between sheets of material are treated with high-quality mastic, then it is possible to reliably protect the garage roof from the effects of atmospheric precipitation for many years.

Waterproofing of the pit in the garage

If there is an observation pit in the garage, it can become another place of accumulation of water. To prevent this, only the installation of waterproofing based on penetrating materials will help. Only in this case, groundwater, precipitation and other types of soil moisture will not have a negative impact on the condition of the observation pit.

Before applying penetrating waterproofing, it is important to moisten the surface well. Only in this case, the composition will be able to effectively perform its function. In addition to the inspection pit, the basement, foundation, floor and even walls can be treated with penetrating materials.

Stages of waterproofing of the inspection pit in the garage:

- Preparation of mortar.

- Surface preparation, removal of old coatings.

- Humidification of the concrete base.

- Applying penetrating waterproofing with a paint brush, roller or spatula.

Waterproofing can be applied in several layers, after drying, the surface is plastered. Especially vulnerable areas can be treated using injection technology with sealants and gels.

What is better to choose, waterproofing outside or inside the garage?

The most effective option in the case of garages is considered to be waterproofing of the structure from the outside. Such treatment blocks the interaction of groundwater with structural elements, and therefore allows you to make sure that the garage is not harmed by temperature and deformation effects.

External waterproofing allows you to increase the service life of the garage structure, however, at the same time, it is much more time-consuming than processing the room from the inside. Internal waterproofing is most often used as an additional protective measure designed to enhance the effect of external hydrophobic treatment.

There are three types of internal waterproofing of the garage

- anti-pressure (this option is relevant at a high groundwater level),

- pressure-free (suitable for regions with heavy precipitation),

- as well as anti-capillary, the basis for which is penetrating waterproofing and various strengthening impregnations.

Both external and internal waterproofing have their advantages, so experts recommend combining both types of hydrophobic garage treatment. However, such work is quite lengthy and time-consuming, so it’s worth making it easier for yourself and entrusting the installation of garage waterproofing to professionals.

Prices for garage waterproofing

Below is a list of prices for some garage waterproofing services:

| Name of the service | Cost of the service |

| Arrangement of surfaced waterproofing (horizontally) | 36 $/sq.meter |

| Arrangement of surfaced waterproofing (vertically) | 49 $/sq.meter |

| Laying of self-adhesive membrane (horizontally) | 35 $/sq.meter |

| Laying of self-adhesive membrane (vertically) | 48 $/sq.meter |

| Arrangement of bitumen mastic | 20 $/sq.meter |

| Arrangement of sprayed liquid rubber | 25 $/sq.meter |

| Arrangement of penetrating waterproofing | 60 $/sq.meter |

| Arrangement of polyurethane compounds | 60 $/sq.meter |

| Applying the primer | 10 $/sq.meter |

| Waterproofing of seams (interblock) | 40 $/sq.meter |

| Waterproofing of seams (deformation) | 490 $/sq.meter |

| Injection waterproofing of seams | 120 $/sq.meter |

Calculator of the cost of work

Calculation of waterproofing cost

The total cost of waterproofing

How to make waterproofing in the garage with your own hands

Despite the complexity and duration of the process, it is not too difficult to install waterproofing in a ready-made garage, but it is necessary to take into account the nuances:

- Before starting work, it is necessary to get rid of signs of dampness: mold, fungus, damaged elements, blisters, leaks, cracks in the base.

- Conduct a thorough inspection of the premises for existing and potential leaks: specialists equipped with the necessary equipment can cope with this task.

- Identify materials and a set of tools, study the manufacturer’s recommendations, purchase additional materials (for example, plaster waterproofing for the arrangement of the finishing coating).

- During work, it is important to pay special attention to all joints, seams of various types, as well as places where walls are connected to the floor and ceiling.

- Do not forget to use strengthening impregnations, protective paints and other useful solutions that are applied before or after waterproofing.

It is not necessary to save on high-quality hydrophobic compounds, on the rental of the required equipment, as well as the installation of reinforcing frames (for example, in the construction of the foundation or pit).

If any, even the smallest cracks in the base are found, it is necessary to seal them with sealants and observe the treated area for a couple of weeks.