Table of Contents

- Types of roll insulation

- Recommendations on the choice of rolled materials

- Methods of installation of roll waterproofing depending on its type

- The installation of roll waterproofing of the foundation

- Roll waterproofing for the floor

- Prices for the installation of roll waterproofing

Everyone knows about the need to install waterproofing of buildings and structures. Roll waterproofing provides reliable protection of private homes and commercial buildings from the negative effects of groundwater, low temperatures, salts and other aggressive chemicals. As a result, properly made waterproofing significantly extends the service life of the building and prevents its destruction. The market offers a large selection of rolled waterproofing materials of universal or special purpose for solving specific tasks.

Types of roll insulation

For various purposes and constructions, various materials with certain characteristics are used.

Rolled materials may differ among themselves by such parameters as:

- The basis of the material is Polyether, Polyester, Fiberglass, Glass fiber-mat, Unsupported;

- Type of coating of the upper side – grit, non-woven fabric, film, basalt, sand, slate, foil, polypropylene;

- Type of coating of the surfaced side – ventilated coating, film;

- Thickness in mm – 1.5mm-4mm;

- Type of structure on which waterproofing can be applied – foundation, roof, walls, floor, universal use;

- Installation method – pasting, surfacing, mechanical fixation, free laying, laying on mastic and combined options;

- Service life;

- Temperature conditions of use.

Depending on the method of fixing to the base, the rolled products are divided into the following types:

- Torch-welded;

- Mounted;

- Membrane.

Torch-welded waterproofing

It consists of two layers. The lower base can be polyethylene, fiberglass, glass-fiber mat. An astringent coating is applied to the base, which melts during heating and is firmly fixed on the working surface. Bitumen mastics with various improving additives are used as binders for installation. Most often, surfaced waterproofing compounds are used for roofing work. The material is widely distributed due to its affordable price, ease of application and excellent waterproofing properties. With proper application, a high-quality monolithic surface is obtained, resistant to negative external factors.

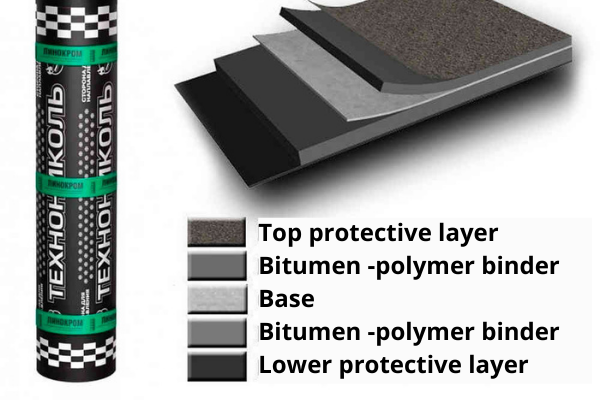

What the torch-welded waterproofing consists of:

- Top protective layer

- Bituminous polymer binder

- The basis

- Bitumen-polymer binders

- Lower protective layer

Standard characteristics of torch-welded materials depending on their brand and quality:

| Indicator description | Unit of measurement | Value |

| Maximum tensile load | Н | +/- 100-200 |

| Weight of the binder from the torch-welded side | kg/m² | not less than 2 |

| Water absorption during 24 hours | % by weight | not more than 1 |

| Temperature of radius of curvature R=15 mm and R=25 mm | 0C | not higher than -25 |

| Water penetration under a pressure of 10kPa | withstands | |

| Water penetration under a pressure of 0,2 Mpa during 2 hours | withstands | |

| Resistance to dynamic pressing-through | mm | not less than 500-2000 |

| Resistance to static pressing-through | kg | not less than 10-20 |

| Weight | kg/m2 | 3-6 |

Roll waterproofing with mechanical fixation

This type of rolled product is attached to the base using special slats or screws, that is why it is classified as mounted

Basic materials of this type are:

- PVC membranes – a multilayer polymer membrane based on plasticized polyvinyl chloride (PVC). This membrane has internal reinforcement with polyester mesh and UV resistance. In addition, the sheets are additionally treated with fire-retardant agents for waterproofing.

- TPO Membrane is a rolled waterproofing membrane reinforced with fiberglass made of thermoplastic polyolefins based on polyethylene (TPO).

The main disadvantages of this material are not very effective protection of the base from moisture due to the presence of numerous seams, lack of adhesion to the surface and the complexity of installation.

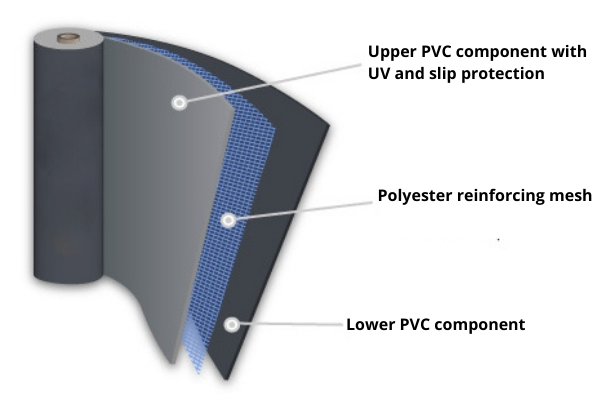

What a rolled PVC membrane consists of:

- Upper PVC component with protection from UV rays of the sun and from possible slipping

- Reinforced polyester mesh

- Lower PVC component

Standard characteristics of roll PVC and Thermoplastic Polyolefin membranes:

| Indicator description | Value |

| Temperature conditions of use | from -10°С up to +50°С |

| Reinforcement | glass-fiber mat |

| Degree of flammability | from G2-G4 |

| Thickness, mm | 1-1,5 |

| Dimensions | 2,10х10 and 2,10х20 |

| Manufacturer | Russia |

| Type of construction for installation | Foundation, roof |

You can read more about membrane waterproofing in the article – “Membrane waterproofing: Types of materials and methods of their installation“.

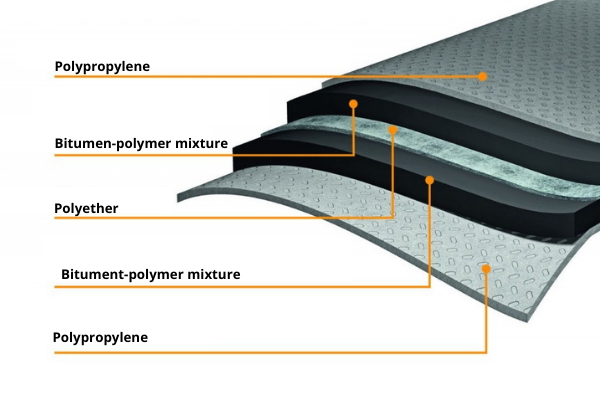

Surface waterproofing

A two-layer material, with a fiberglass or PVC base and a polymer-bitumen composition on top. Epoxy adhesive compositions and mastics are used to fix the pasting products. For the best effect, it is necessary to lay the adhesive compositions in several layers. Adhesive roll sheets are suitable for any bases, they are easy to fit. Work should be carried out in dry weather.

According to the insulating substance included in the composition, the following types of adhesive composites are produced:

- Bitumen waterproofing is based on bitumen mixed with basalt or shale crumbs. The main bitumen-based materials are roofing material, glass roofing material, and roofing.

- Bitumen-polymer insulation – special modifiers (plastic or rubber) are added to bitumen, improving the properties of the adhesive material: resistance to UV radiation and high temperatures.

- Membrane compositions – are made on the basis of PVC, representing a thin coating that effectively protects the work surface. Despite their small thickness, the membranes are strong and durable, safe, and can be used in a wide temperature range.

What surface waterproofing consists of:

Standard characteristics of pasting materials depending on their brand and quality:

| Indicator | Value |

| Mounting method | Self-adhesive |

| Water absorption by volume, % not more | 0,8-1 |

| Temperature conditions of use | +5 |

| Weight of material | from 1,5-2 kg/m2 |

| Static bending strength, not less than, Mpa | not less than 1 |

| Adhesive strength with concrete/metal, Mpa (kgs/sm2), not less | 0,1-0,2 |

| Extension coefficient, %, not less than | not less than 20-60 |

| Temperature of radius of curvature R=25 mm, not higher than, С | 10-25mm |

Recommendations on the choice of rolled materials

Rolled types of materials are very difficult to repair, especially when it comes to waterproofing underground parts of buildings and structures, such as foundations and basement walls located below the planning ground level. The repair of these units in most cases will entail a lot of costs associated with the dismantling of the made blind area, the development of soil, the dismantling of thermal insulation, old waterproofing coating, as well as the costs associated with the return of all these elements.

That is why, when choosing a material, it is best to choose premium quality insulation that can last a long time and not be destroyed by the effects of aggressive environments in the soil and water, such as acids, alkalis, and salts.

Roll types of waterproofing are divided into 4 different categories or classes:

- Premium – the highest resistance to an aggressive environment. The service life is 15-20 years.

- Business – average resistance to aggressive environment. The service life is 10-15 years.

- Standard – Average resistance to external stimuli. The service life is 7-10 years.

- Economy – Very low resistance to salts, alkalis, and acids. The service life is 3-7 years.

High-quality alternatives to roll and membrane waterproofing:

Methods of installation of roll waterproofing depending on its type

Each type of roll waterproofing has its own method of installation. Further, we will study each method separately.

The installation of torch-welded waterproofing

The torch-welded waterproofing is laid on the surface by surfacing the active layer using live fire.

The technology of laying:

- Surface preparation – Removal of dirt and dust;

- Primer – Application of bitumen primer to improve the adhesion of the roll with the base;

- Preparation of the tools – Filling of gas burners with gas;

- Burning-in of the 1st layer – With the help of gas burners and fire, the first layer of roll insulation is deposited. The rolls are overlapped on top of each other in 15sm;

- Fixation – Parallel with the burning-in, the rolls are pressed against the base with a special roller;

- Burning-in of the 2nd layer – Similarly to the first layer, the 2nd layer is burned-in, in so as to overlap the seams of the first layer.

Installation of mounted waterproofing

Mounted types of waterproofing coatings do not have adhesion or adhesion to the base and are attached to the edges with slats and screws.

Installation technology:

- Preparation of the base and cleaning it from dirt;

- The arrangement of a geotextile web with fixation to the base;

- Fastening of the rolls at the edges with special clamping strips and clamps;

- Installation of PVC or TPO rolls with an overlap of 15sm;

- Cross-linking of rolls using a construction hair dryer or a special installation of a heating connection to a temperature of 550-650 degrees. When installing vertical joints or lifts on various structures, it is preferable to use a construction hair dryer.

By clicking on the link, you can download detailed instructions for the installation of rolled PVC membranes from SIKA company:

By clicking on the link, you can download detailed instructions for the installation of rolled TPO membranes from SIKA company:

By clicking on the link, you can download detailed instructions for the installation of rolled PVC materials from Icopal company:

By clicking on the link, you can read more detailed information about this type of waterproofing and about the methods of its installation – Membrane waterproofing: Types of materials and methods of their installation.

Arrangement of surface waterproofing

Surface waterproofing is arranged by gluing it onto the base. Basically, we are talking about self-adhesive rolls.

The technology of laying:

- Cleaning the base;

- Cutting the sheets to the desired size according to the height of the base;

- The installation and application of bitumen primer;

- Sticker rolls on the base by rolling them from the bottom up. The rolls are glued overlapping in 15sm;

- Pressing the rolls to the base;

- When installing additional layers, the surface is again coated with bitumen primer, and then another layer of waterproofing is glued to it in order to overlap the seams of the previous one.

By clicking on the link, you can download detailed instructions for the installation of adhesive membranes from our Icopal company:

The installation of roll waterproofing of the foundation

Roll waterproofing, as a rule, is used in works related to the protection of the foundation and foundation walls from water and moisture, since materials of this type are commercially available and relatively inexpensive.

If we talk about the installation of waterproofing of various types of foundations, then the most common roll insulation is premium quality surfaced products.

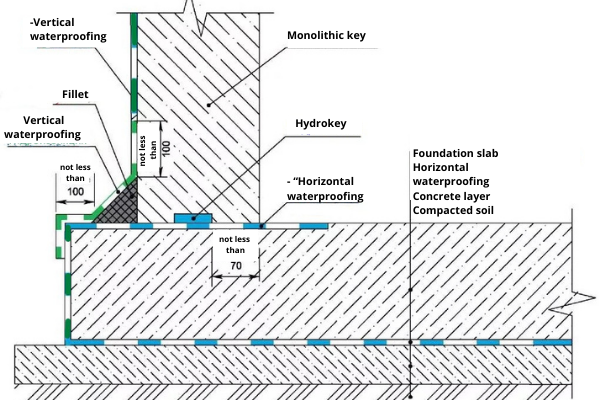

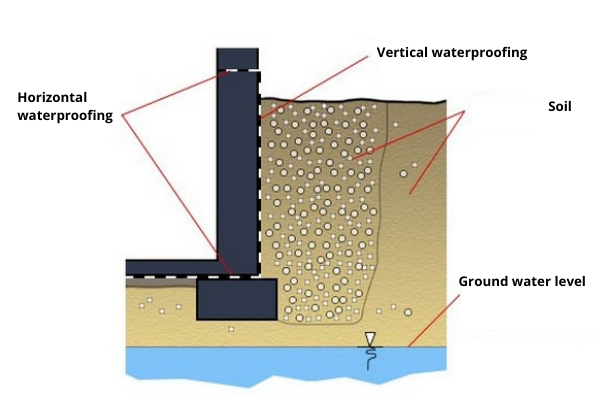

When installing foundation protection, it is necessary to take into account both horizontal and vertical waterproofing.

You can read more about protecting the foundation and walls from water in the following articles:

- Foundation waterproofing device: Methods, materials, prices, and recommendations of specialists

- Waterproofing of the tape foundation: Technology and materials

- Waterproofing of foundation blocks and walls

- Waterproofing of basement and house walls from outside and inside – Methods, materials, prices, and technology

- Waterproofing of bricks and masonry

Horizontal waterproofing

The installation of rolled sheets on a horizontal surface should be performed before pouring the foundation slab by mounting waterproofing under the concrete, as well as on the horizontal base of the slab after pouring it.

Horizontal protection from water is carried out in 1-3 layers when using surfaced and pasting materials and in 1 layer when using PVC and TPO membranes.

When working with tape foundations, waterproofing is performed between the foundation cushion and the blocks, as well as between the blocks and the wall, which in turn serves as a so-called cut-off waterproofing.

You can read more about horizontal insulation in the article – “Horizontal waterproofing“.

Scheme of horizontal waterproofing installation with rolled materials:

Vertical waterproofing

When installing rolled sheets on the vertical base of the walls and foundation, it is worth considering that the insulation should be raised 20-30sm above the design ground level.

The pasted and surfaced rolls are stacked vertically in 2-3 layers. PVC membrane is in 1 layer. During installation, the rolls are attached to the upper point of the vertical surface using special pressure strips.

You can read more about vertical insulation and how to install it in the article – “Vertical waterproofing“.

Scheme of vertical waterproofing installation of roll insulation:

Roll waterproofing for the floor

The floor of a private house or commercial building also needs a high-quality waterproofing installation. For this purpose, roll membranes of various types can be used.

Recommendation: For concrete floors, it is recommended to use premium surfaced sheets, and for wooden floors, flooring and pasting types of insulation.

When installing roll and other waterproofing of the floor, it is necessary to perform several basic steps:

- Prepare the surface in terms of its cleaning from dust and dirt;

- At the junctions of the floor and wall, it is necessary to make a small baseboard from the cement-sand screed or a special tape for a smooth transition of insulation from the horizon to the vertical;

- Apply a bitumen primer to the surface to improve the surfaced and pasted sheet rolls with a base;

- Install the insulation coating in 1-2 layers, so that the second layer overlaps the seams of the previous one.

You can read more about the waterproofing of the floor in the following articles:

- Waterproofing of the basement floor of the house: Methods, technologies of installation, and materials

- Waterproofing of the concrete floor in a private house – A detailed manual on how to do this work with your own hands and what materials to use at the same time

Prices for the installation of roll waterproofing

Below is a table with prices for the installation of various types of waterproofing. When specifying the prices and the price per 1m2, standard indicators of the complexity of the work were taken into account, as well as materials of average quality.

| Works description | Unit of measurement | Price in $ |

| Installation of torch-welded waterproofing horizontally in 1 layer | m2 | 5 |

| Installation of torch-welded waterproofing vertically in 1 layer | m2 | 7 |

| Installation of self-adhesive membrane horizontally in 1 layer | m2 | 5 |

| Installation of self-adhesive membrane vertically in 1 layer | m2 | 6 |

| Installation of PVC membrane horizontally in 1 layer | m2 | 8 |

| Installation of PVC membrane vertically in 1 layer | m2 | 9 |

| Application of bitumen primer | m2 | 2 |