Table of Contents

- What is stylobate and in which buildings it is present?

- Features of the stylobate part of the underground parking

- Prices for waterproofing of the stylobate part of the building from inside and outside

- Cost calculator for self-calculation

The stylobate serves as the foundation of the building and performs not only a supporting but also a decorative function, fiving scope to the architect’s imagination. This building element provides stability and external completeness to the structure and also serves as an essential structural part of the structure.

The stylobate is found in buildings such as shopping malls, business centers, and apartment complexes, where there is an underground parking lot and the stylobate part serves as its roof. In such residential complexes, as a rule, playgrounds, pedestrian paths, surface parking lots, and gardens with various plants are located on the stylobate.

The stylobate needs high-quality waterproofing, and if it is damaged, repairs should be carried out in compliance with all the rules and with the use of the necessary materials. What kind of construction compounds are required for hydrophobic treatment and repair of the stylobate, as well as what technologies of work are most correctly used, will be discussed in this article.

What is stylobate and in which buildings it is present?

In modern construction, a stylobate is a ground part of the structure, acting as a fairly large erected platform. Often the stylobate is made as a multi-tiered element of the building. The platforms are stacked one after another, and in the lower part, they are expanded with the help of stepped ledges.

The stylobate has many variations. For example, stones forming the entrance to the building are added to the ledges. Stylobate can also serve as a basis for gazebos, terraces, playgrounds, and other non-residential structures. If we are talking about multi-storey residential buildings, then the stylobate is a basement, equipped in the interests of residents, or a large slab of concrete mounted on columns. Most often, an underground parking lot if organized under such a slab, is designed to preserve the personal transport of guests.

The use of stylobate allows you to protect children from the dangers associated with the movement of vehicles in the yard. This is due to the fact that the movement of cars takes place on the territory hidden under the stylobate and not connected to the yard. Car owners also benefit from such an organization of the territory, who get the opportunity to leave their vehicles in a guarded closed parking lot, where nothing threatens them.

Often the stylobate is arranged so that the ground floor unites several buildings at once. This is relevant not only for residential buildings located next to each other but also for business centers in which the area under the stylobate is also used to perform various functions. The stylobate allows you to expand the useful space, which is very lacking near busy business complexes, and also ensures the reliability of such structures because they are often characterized by a complex architectural form.

The socle floor can serve as an excellent room for the organization of a retail outlet, a fitness club, an additional office, and not only. However, in order for the stylobate to perform its functions correctly, it is necessary to equip it competently, namely, to select the necessary heat and waterproofing materials, calculate the load on the structure and determine its bearing capacity. Without compliance with these measures, the stylobate may be damaged or even destroyed, and this is fraught with a violation of the integrity of the entire building.

Features of the stylobate part of the underground parking

Underground parking, as the name implies, is located below the level of the ground’s surface and occupies a fairly large area under residential, office, or retail premises. At the stage of parking construction, it is extremely important to carry out high-quality waterproofing of the exterior of the stylobate part, so that precipitation and other sources of water and moisture could not affect the concrete structure. This is necessary to preserve the integrity of the entire building and to ensure normal conditions for the maintenance of vehicles in the parking lot.

Waterproofing of a stylobate is a complex process that includes protection from precipitation and from groundwater, as well as the installation of drainage and discharge systems. At the same time, both the upper and lower surfaces of the underground parking are subjected to hydrophobic treatment. It should also be remembered that parking on a stylobate is not necessarily equipped with insulation and internal partitions. The main part of the structure is considered to be the roof, among the tasks of which– is the ability to withstand the weight of people, transport, various non-residential structures, and so on.

Technologies and materials for the stylobate waterproofing

Due to the fact that the upper surface of the parking lot is located on a stylobate, and accordingly is subjected to the strongest mechanical loads, it is important to ensure the following properties:

- High strength and overload resistance;

- The presence of a drainage system with several levels;

- Waterproofing is characterized by a long service life.

Most often, coatings based on bitumen or polymer substances are used as roofing materials, since they are characterized by excellent operational properties, as well as an acceptable cost.

Waterproofing from the outside

The roof of the building is mounted in compliance with the angle of inclination, so that precipitation and meltwater can flow down the roof surface. However, in order that the liquid does not get into the interior of the room and, as a result, does not harm the load-bearing structural elements, it is important to ensure high-quality external waterproofing of the stylobate.

Proper processing will not avoid not only leaks but also future structural damage in the form of cracks and other defects. The consequences of leaks can be areas of mold and dampness, as well as a violation of the integrity of the load-bearing structural elements.

Leaks of the stylobate part have a number of reasons:

- Violation of parking construction technology,

- Use of low-quality materials,

- Lack of waterproofing or poor quality

- Lack of drainage and discharge systems.

As a rule, the following materials are used for waterproofing the stylobate part from the outside:

- Surfaced roll

- PVC membranes

- Liquid rubber

Surfaced roll materials

One of the most popular methods of waterproofing is the use of surfaced roll materials. Such compositions are made on the basis of bitumen and have a layer that melts when exposed to high temperatures, thereby being able to stick to the surface.

The application of such waterproofing is carried out quite easily, however, in the context of complete safety, it would be more correct to entrust this work to professionals. They will not heat up the material with a blowtorch or a gas burner and gently connect it to the work surface in 2 or 3 layers.

Most often, with the help of surfaced materials, the horizontal part of the stylobate and its walls are processed, which are often supplemented with a layer of insulation.

The surfaced waterproofing has significant drawbacks:

- Under the influence of strong mechanical loads to which the stylobate is regularly subjected, such materials evenly lose their performance characteristics.

- The waterproofing coating made of rolled materials has many seams, which makes it very vulnerable;

- The material has a low coefficient of elasticity and when the building shrinks, it diverges at the seams and weak points.

You can read more about roll waterproofing in the article – “Roll waterproofing arrangement with detailed installation instructions“.

PVC membranes

Another excellent way of external waterproofing of a stylobate is considered to be the laying of membranes made on the basis of polyvinyl chloride, or PVC. Such materials are laid on the top of the work surface, and the seams between them are processed by welding.

If we talk about the stylobate part of the underground parking, then PVC membranes can be laid on the roof of such structure in several ways – traditional (on top of thermal insulation) and inversion (under thermal insulation and drainage system). The second method is relevant in cases when it is planned to equip a lawn or playground on the roof of the parking lot.

You can read more about membrane waterproofing in the article – “Membrane waterproofing: Types of materials and methods of their arrangement“.

Liquid rubber

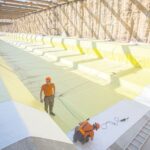

For many years the most effective and at the same time quite expensive method of waterproofing walls, roofs, and foundations of underground parking, including on a stylobate, is the use of liquid rubber.

This waterproofing material is characterized by a high degree of adhesion to any type of base, including concrete slabs, which are an integral part of the stylobate. Liquid rubber penetrates into all the irregularities of the working surface, including the smallest protrusions and holes and forms a seamless coating, which, unlike fused roll materials, simply stretches when the structure shrinks or deforms, and does not diverge at the seams or cracks.

Also, the liquid rubber coating is highly resistant to mechanical loads and therefore does not deform and does not collapse during shrinkage or minor deformations of the structure. The waterproofing material in question has its drawbacks, which are successfully compensated by its positive characteristics. Among the negative properties of liquid rubber — is the complexity of the process of its application and the high cost of high-quality compounds.

You can read more about liquid rubber in the article – “Waterproofing with liquid rubber“.

Repair and waterproofing from the inside of the stylobate part

Restoration of the integrity of the walls, roof, or foundation of the stylobate can also be carried out from inside the room. In this case, various waterproofing and repair compounds are used, which can either penetrate into the structure of a concrete structure or withstand negative water pressure from the outside to the inside.

To eliminate stylobate leaks from the inside, as a rule, the following types of materials are used:

- Polymer-cement

- Mineral-acrylic

- Injection systems

- Sealants and hydraulic seals

Polymer-cement and mineral-acrylic compositions

If waterproofing works need to be carried out from the inside, and not from the outside, then not all cement-based materials are suitable here, namely those that can withstand negative water pressure from the outside to the inside, for example, such compositions such as HydroPaz Prime Acril from the German company HYDRO. As a rule, all these materials are applied manually using brushes, rollers, and spatulas in 1 or 2 layers.

Important: It is important to take into account that even the highest quality polymer cement systems will not withstand water pressure from weak points, such as cracks in the structure or the location of cold joints and concreting joints. In such areas, before applying polymer-cement or mineral-acrylic compositions, it is recommended to make additional reinforcement by injection, so as to fill all the voids with a special hydrophobic composition, and only then apply a waterproofing coating.

You can read more about cement compositions in the article – “Cement-based waterproofing: Features, types, and methods of its application“.

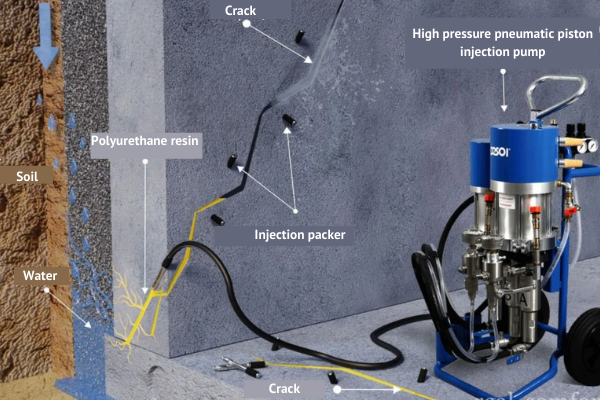

Injection method of waterproofing

When using this method, the waterproofing material is injected under pressure using special equipment, inside the concrete or brick structure filling all microcracks, voids, and capillaries and, thus, does not allow moisture and water to pass.

The arrangement of injection waterproofing in the stylobate part looks like this:

- Weak areas of concrete, cold joints, and places of communications entry are identified, as a rule, these are places where moisture manifests or leaks occur;

- Following a certain step, small holes are made in the concrete, into which injectors are installed;

- An injection pump is connected to the installed injectors, which under pressure supply the desired composition to the body of the structure, thereby squeezing out the moisture existing in the pores and voids and filling these places for their future protection.

The scheme of the injection method of waterproofing

You can read more about the work of injection systems in the following articles:

- Injection waterproofing

- Waterproofing and sealing of cracks in concrete, brick, and other bases

- Sealing and waterproofing of joints – concrete, cold, and deformation ones

Sealants and hydraulic seals

Common repair compounds are also hydraulic seals and sealants. Hydro seals, for example, are special mixtures that set very quickly and acquire a high degree of adhesion to the base material. With the help of such hydrophobic compositions, it is possible to quickly eliminate leaks, even those that affected the load-bearing elements of the structure.

To date, there are several types of hydraulic seals, namely pressure and non-pressure options. Pressure-free hydraulic seals are most often used for preventive purposes and are installed under the main waterproofing material. Pressure materials are suitable for both emergency and major repairs and allow you to eliminate pressure and non-pressure leaks. It is worth nothing that the pressure high-speed hydraulic seal is able to harden in just 30 seconds.

As for sealants, such materials are usually made on the basis of polymer substances or with their addition. Sealants are excellent for sealing cracks and crevices that occur on both the outer and inner surfaces of the stylobate. Before applying the compositions, the working surface is prepared, then the damage is filled with the prepared solution, and the excess repair material is removed with a spatula. After that, it is necessary to wait for the complete drying of the construction composition.

Important: Hydraulic seals and sealant work well in combination with the injection method of waterproofing, which fills the seam or crack not on top, as sealants do, but penetrates into thr structure.

Prices for waterproofing of the stylobate part of the building from inside and outside

Prices may vary depending on the complexity of the work, the volume, and the tasks set.

| Prices for waterproofing arrangement outside | ||

| Description of works | Unit of measurement | Price in $ |

| The arrangement of surfaced waterproofing on the horizon | m2 | 36 |

| The arrangement of surfaced waterproofing on vertical | m2 | 49 |

| Installation of a self-adhesive membrane on the horizon | m2 | 35 |

| Installation of a self-adhesive membrane on a vertical | m2 | 48 |

| PVC membrane arrangement on the horizon | m2 | 58 |

| The arrangement of PVC membrane on the vertical | m2 | 68 |

| Application of polyurea | m2 | 90 |

| Application of mastic waterproofing | m2 | 20 |

| Application of liquid rubber by spraying | m2 | 25 |

| Applying liquid rubber manually | m2 | 33 |

| Application of cement-mineral 2 component -waterproofing | m2 | 60 |

| Polyurethane waterproofing arrangement | m2 | 60 |

| Application of penetrating compounds | m2 | 60 |

| Application a primer | m2 | 10 |