Soft roofing has a lot of advantages – it is high-temperature resistance, wear resistance, excellent plasticity, good sound insulation, and long service life. The coating of a soft roof, subject to the rules of operation, can serve from 15 to 60 years or even more. In this article, we will talk about the technology of installation of one of the varieties of such a roof— a roof made of soft tiles and the cost of work on its laying.

What is a soft roof made of soft tiles?

The subspecies of soft roofs include various flexible materials, such as bitumen flexible tiles, membrane roofs, and roll-on compositions of the surfaced type. The latter two types are suitable for the arrangement of flat roofs, and flexible tiles –are suitable for pitched structures. Soft materials are sold in the form of shingles.

The basis for such shingle is usually fiberglass, and bitumen is used as an impregnation. Stone sprinkling is responsible for the appearance and wears resistance of a soft roof. The flexibility of soft tiles allows you to use them for the design of roofs, even the most complex configuration, including conical, domed ones.

The covering of a soft roof can consist of one or several layers. The thickness of the coating depends on this: from 3 mm for single-layer and up to 9-10 mm for multi-layer. Experts recommend installing a multi-layer coating– it is more reliable, and it lasts longer. The optimal angle of inclination of the pitched roof, for which geometric tile covering can be arranged, is 12 degrees. If the slope is less, it is better to give preference to other roofing materials: for example, rolled surfaced or membrane.

Types of soft shingles

Shingles, from which flexible shingles are obtained, combine the qualities of classic shingles and rolled roofing materials. They have a strong, but elastic base, water-repellent impregnation, and sprinkling, which plays the role of both decorative and protective layer.

There are various types of soft tiles. Let’s consider the main criteria.

Depending on the shape of the shingle cutting, there are:

- hexagonal,

- trapezoidal,

- rectangular,

- semicircular,

- asymmetric,

- diamond-shaped soft shingles

- and slate.

The choice of one or another type depends only on the wishes of the roof design. The most popular are hexagonal, semicircular, and rectangular tiles.

By layering:

The coating based on flexible tiles can be single- or multi-layered. The simplest in installation, operation, and repair is considered to be a single-layer tile, but its service life is 15-25 years. Double- and three-layered coatings are more difficult to install and replace, but their service life reaches 60 years, and among the qualities of operation –are increased wind resistance, tightness, and interesting and embossed design.

There are also coatings with a 3D texture, they allow you to create the illusion of a three-dimensional tile.

Soft shingles are divided into types depending on the base:

- Glass wool is obtained by heating quartz sand. It is an environmentally friendly material resistant to rot, and fire and has excellent sound insulation ability.

- Fiberglass. It is characterized by a higher density, but less strength than fiberglass.

As a moisture-resistant impregnation, bitumen varieties are used, the main properties of which are presented in the table below:

| Property | Oxidized bitumen | APP (Atactic polypropylene)-modified bitumen | SBS-modified bitumen |

| Flexibility | low | low | high |

| Endurance | high | high | high |

| Heat resistance | medium | high | medium |

| Frost resistance | high | low | high |

| Resistance to UV | medium | high | low |

| Moisture resistance | high | high | high |

| Durability | high | high | high |

Oxidized bitumen is obtained as a result of heating oil bitumen and is characterized by excellent thermal stability, and the ability to maintain its appearance for a long time. Installation of soft tiles impregnated with oxidized bitumen can be carried out at temperatures above zero. This material is suitable for temperate climates.

Modified bitumen is obtained by mixing bitumen with additives SBS, APP, and other polymers.

The last criterion is the type of sprinkling for the protective layer

It can be granulated, basalt and shale chips, anthracite, or slag. The granulate one reflects the sun’s rays and withstands mechanical influences, and the slag has excellent strength and a high degree of adhesion to bitumen. The slate crumb is colored only by chemical means and because of this it fades over time, and anthracite is mixed with colored basalt granules to give it color. The most budgetary and widespread is considered to be a sprinkling of basalt crumbs.

The main manufacturers of soft shingles

Each manufacturer offers a material with unique properties and different prices. Let’s analyze the products of popular brands.

- Shingles Technonicol “Shinglass”

Flexible shingles Shinglas have been produced since 2003 and the demand for it is only getting higher every year. The main plant for the production of such tiles is located in Lithuania, smaller production facilities are also open in our country, for example, in Ryazan. Shingles “Shinglass” is characterized by low cost and is suitable for use in temperate climates. The basis for such a tile is fiberglass impregnated with bitumen, and the service life of the material is at least 30-50 years.

- Tile “Tegola”

The Italian brand Tegola is popular in 70 countries around the world, and one of the factories is located near Moscow. In hardware stores, you can choose from more than 100 options for the colors of flexible Tegola tiles. As a base, it has fiberglass with a density of more than 80g/sq.meter, and among the positive properties of the tile are its resistance to significant temperature fluctuations, high strength, and water resistance.

- Soft tile “Doke”

Russian manufacturer Docke has been operating in the country since 2005 and produces more than 12 million square meters of tiles per year. The impregnation for the Doke tile is oxidized or SBS-modified bitumen. Among the main properties of the material– are resistance to UV and temperature, elasticity, and water resistance. The manufacturer offers two lines of roofing materials: budget (20 years warranty) and elite (50 years warranty).

- Flexible roof tiles “Katepal”

The Finnish brand Katepal has been producing high-quality building materials since the 50s of the XX century. The main emphasis is on the quality of bitumen for impregnation. Bitumen withstands significant temperature changes and is suitable for areas with different climates, for the south and north: for example, for Scandinavia and the Mediterranean countries.

Buyers can choose a tile from five lines. The most popular variant of the Katepal is the two-layer soft Mansion tile, for which SBS-modified bitumen is used as impregnation.

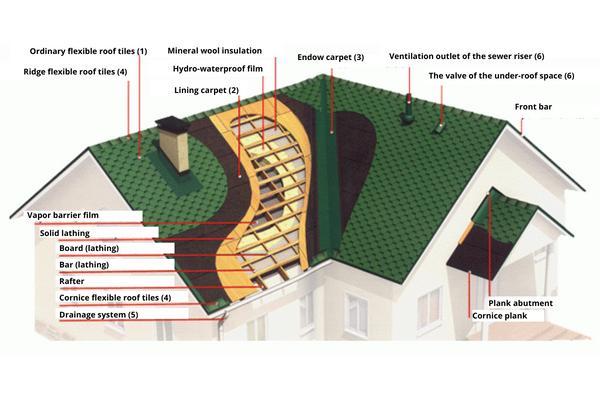

Layers of a soft roof on the scheme of its installation

When laying, the sequence of installation of the elements of the roofing layers is observed. The main tasks of the roofing structure – are protected from heat loss, and noise insulation, as well as prevention of the formation and accumulation of condensate in the under-roof space. If an insulated roof is insulated for a house or building, then the roof layers includes the elements.

If an insulated is installed for a house or building, then the layers includes the following elements:

- Thermal insulation material – most often in the form of mineral wool slabs. The installation of the insulation is carried out by surprise between elements of the truss system, and the thickness of the insulation is no more than 15-20 sm.

- Vapor barrier – protects the insulation from steam rising up from the living quarters and getting wet. Installation of the vapor barrier is carried out from the side of the living room. It is extremely important to lay the sheets overlapping from 10 sm on top of each other, fixing tools– construction stapler and double-sided tape.

- Waterproofing of the coating, pasting, or surfaced type – to protect the insulation, the under-roof space, and residential premises from moisture. Installation of hydrophobic compounds is carried out from the outside of the roof.

Soft roof technology: step-by-step instructions, diagrams, and videos for performing work with your own hands

Let’s consider each of the stages of installation in more detail.

Counter-lathing and lathing for a soft roof

It is necessary to provide high-quality natural ventilation in the under-roof space. Only in this case, it will be possible to avoid the formation and accumulation of condensate inside the structure. Properly equipped ventilation will prevent swelling of the flooring, wetting of the insulation, violation of the integrity of the waterproofing, and other problems. To do this, parallel to the rafters, counter-laths with a thickness of about 5 sm are fixed.

The next step is the installation of a lathing, which will serve as the basis for laying solid flooring. The lathing is most often represented by wooden boards, the width of which- is 10-15 sm, and the thickness is – 2,5-3 sm. The step of the lathing is about 20-40 sm. The pitch value depends on the slope angle of the pitched roof: the smaller the slope, the smaller the distance between the boards should be.

Flooring arrangement

After the installation of the counter-lath and the lathing, the flooring is mounted, which plays the role of solid formation for a soft roof. The height differences over the entire area of the solid flooring are no more than 1-2 mm. As flooring, experts recommend using plywood of the FSF type, as well as edged boards made of wood. The latter are arranged so that the convex parts of the annual rings “look” inside the living room.

The sheets are mounted on self-tapping screws or ruffled nails. A small gap should be left between the flooring elements, which will compensate for the deformation of the coating in the warm season. The gap between the plywood sheets should be at least 3-5 mm, 1-3 mm is enough for flooring made of wooden boards.

When using sheet materials, the thickness of the flooring turns out to be at least 0,9 sm – if the coating is single-layered, and 1,2 sm – for multi-layered coating. The thickness of the flooring from the edged boards is most often at least 2,5 sm.

After preparing the foundation, the installation of the roof begins – from the cornice.

The direct installation of a soft roof includes two main types of work – the preparation of the roofing structure and the direct laying of coating materials. We will consider both preparatory and basic work in stages.

Installation of a cornice overhang

In the first stage, it is necessary to install and strengthen the eaves overhang. This is due to the fact that the fixation of the lining carpet to achieve the tightness of the roofing structure should be carried out on top of the reinforcement element. The cornice overhang itself is made of wooden fillies, which are fixed to the side parts of the elements of the rafter system. Nails should be used for work, but you need to approach this process very carefully because nails that are too wide can split the rafter legs.

The installation of a number of fillies begins with the first and last element, through which a strong rope is stretched. Along this rope, the remaining elements of the row are aligned, which are also fixed to the rafters with nails. After the fillies have been secured, they are sheathed using a lathing around the perimeter of the roofing structure.

Reinforcement of the cornice overhang is done with the help of special cornice slats made of thin-sheet metal. The slats are fixed to the edge of the flooring with the rid side in staggered order. For the installation of slats, the usual roofing nails are used. The pitch of such slats is 12-15 sm. They overlap with each other in 3-5 sm.

Installation of a dropper

The drip tray is made of a steel sheet covered with a thin layer of zinc and is a corner up to 3 meters long. The dropper strengthens the cornice overhang and serves to divert water: it redirects water flowing from the roof so that it does not fall under the lathing and does not lead to wetting of the under-roof space. The installation of the drip tray on the lathing is carried out with the help of roofing nails, which are hammered in a staggered manner with a step of 15 sm.

Lining carpet flooring

A soft roof requires flooring of a solid lining carpet. The option in which the carpet is mounted only on dangerous areas of the roof is not rational. The most vulnerable areas of the roof include eaves overhangs, abutments of roof elements to its surface, endowments, and not only. The best option for the lining carpet material will be self-adhesive materials or materials that can be fixed to roofing nails.

The flooring of the lining carpet begins with the ends, while it is extremely important the carpet is laid evenly on both adjacent slopes. Experts recommend mounting the carpet near the ridge and the ends without seams, and in the absence of such an opportunity – observe an overlap of 30 sm, smearing the fixation points of materials with mastic.

On flat sections of the roof, it is important to provide overlaps in both longitudinal and transverse directions. The carpet is mounted from the bottom up, and the dimensions of the overlaps are 10 sm and 15 sm, respectively. Bitumen mastic is used to smear the connected areas.

Mounting the bar

Now we are doing the installation of the end plank on the pediment overhangs. This bar protects the ends of the room from snow, rain, and strong wind. The slats are installed immediately after the lining of carpet flooring and are connected to each other with a minimum overlap of 3-5 mm. Roofing nails are used to fix the slats, the mounting pitch is 12-15 mm. The nails should be fixed in a staggered manner. In places where the end slats are fixed, the soft roof is mounted with a preliminary treatment of the slats with bitumen mastic, as well as with a slight trimming of the upper corner of the shingle.

Marking of the roof slope

The marking of the roof slope allows you to properly align the shingles at the stage of their installation, as well as to observe the geometricity of the roof covering. Marking lines significantly simplify the task for specialists, but lines alone are often not enough, so it is important to check the correctness of the coating during the installation of shingles.

The marking of the ramp is performed as follows: vertical lines are marked at a distance equal to the width of the shingles, and horizontal lines are marked at a distance of 80 sm, that is, 5 rows wide of standard flexible tiles.

The flooring of the end carpet

Soft tiles can be laid in two ways: by the open method or with undercutting. The first method requires the flooring of an additional end carpet. Such a carpet is laid on top of the previously laid lining carpet with an indentation of 2-3 sm in the horizontal direction of the endow axis. 10 sm the edges of the carpet are smeared with bitumen mastic with a layer of up to 2 mm. The front part of the carpet is fixed to roofing nails: they are hammered at a distance of 2-3 sm from the edge of the sheeting in increments of 20-25 sm.

Installation of the starting strip

A special bitumen-based tile is used here for the installation of a ridge-cornice coating. Another option is to use a pattern of shingles, the dimensions of which depend on the shape of the flexible tile cutting. Such strips are fixed to the lining carpet with the help of mastic or special adhesive compositions and necessarily with an indentation of 1-2 sm from the bend of the cornice bar. After gluing the strips, they are additionally reinforced with roofing nails.

Patterns from ordinary shingles are suitable for laying soft tiles of semicircular, rectangular, hexagonal, or asymmetrical shape. The tile is fixed to the shingle strips using bitumen mastic or adhesive composition. Otherwise, the technology of installing a soft roof on the starting strips does not differ from the rules of laying the roof on the rest of the roof area. If we are talking about a trapezoidal tile “dragon tooth”, then it is laid whole, without performing any preparatory work.

The arrangement of a soft ordinary tile

Now you can proceed to the installation of soft tiles. In cases where the roof slope is long enough, the roof laying begins from the center of the slope. At the same time, it is important to observe the horizontal arrangement of the tile sheets, as well as to ensure that the installation of the roof is observed in the same direction and with the same overlap.

If the roof slope is not long, the installation of flexible tiles can be started from the bottom of the structure. The first row is laid in compliance with an indentation of 1-2 sm from the edge. At the same time, it is best to install diagonal strips so that the center of each next tile element is shifted relative to the previous one by half a sheet.

After laying the main volume of the tile, the installation of the very first row is carried out, lubricating the elements with bitumen mastic before laying. It is not necessary to overdo it with the adhesive composition: an additional layer of mastic is applied only where there is no adhesive composition. The flexible tile laid in this way will reliably protect the roof structure from direct and oblique rain.

You can read more about different types of roofs and work with them in the following articles:

The arrangement of a pitched roof: Types of pitched roofs and technologies of their installation

The arrangement of the roof of a house and a turnkey building: Types, materials, construction technologies, and installation prices

Reconstruction of the roof of a building and the roof of a private house

The arrangement of the surfaced roof: Types of rolled surfaced materials and technology of their installation

The arrangement of the endowment

This is a vulnerable area, water accumulates here most often. The endowments are mounted on a pre-prepared area without nails because any holes will help moisture get inside the roof layers. The size of the plot is calculated for the endow itself plus 30 sm on each side of its axis. The module is fixed to the same area: first with nails, and then by smearing the module with bitumen mastic.

At the stage of installation of a soft roof, it is necessary to lay tiles so that the end zone is closed with a gap of 5 sm. Since the use of nails in such areas is contraindicated, tile sheets are fixed to bitumen mastic. During installation, it is important to observe the markings made at the previous stages and to monitor the horizontal laying of the tiles.

Installation of the ridge

The next stage is the installation of the ridge and roof ribs. For this task, a ridge-cornice soft tile is used. The edges are such ordinary shingles that are trimmed so that between the coverings of two (or more) there is a small space of up to 5 mm wide left for the adjacent ramps.

The installation of the ribs involves laying tiles or other soft roofing material in the direction from bottom to top, and each element of the roof is fixed with an overlap of 3-5 mm and with the help of four roofing nails. Each subsequent element of the coating should overlap the place of fixation to the roof surface of the previous element.

As for the ridges, in this case, the installation of the roofing begins from the place that is located opposite the prevailing direction of the winds. For each region, this place will be located from different sides. After that, the same technology is used as when working with roof ribs.

Pipes outlet and connections arrangement

The places of the abutment on any roof need special attention. For example, before starting work with the roof abutting the chimney, a fillet or a wooden beam with a cross-section of 5*5 sm is installed. The brickwork from which the pipe is made should be pre-treated with plaster and primer. For convenience, the arrangement of the abutments is carried out simultaneously with the installation of the roof.

The protection of the abutments from winds, rains, and snow can be done with the help of an end carpet, from which patterns are made. The front, side, and back patterns are distinguished. The front, side, and back patterns are distinguished. They are mounted on top of ordinary soft tiles using bitumen mastic. At the same time, an overlap of at least 20 sm on the front side and 8 sm on the sides should be observed.

The front pattern fits with the establishment on the shingles, the side ones – with the launch under the roofing, and the back one – under the flexible shingles. The chimney is closed with patterns of 30 sm high around the perimeter, and a metal apron is fixed on top of the patterns with screws and roofing sealant.

To ensure the tightness of the connection of communications to the roof surface (including the pipe terminals), pass-through elements with mounting on roofing nails allow. At the fixation points of the passage elements, the shingles are trimmed according to the shape of the element and glued to it with bitumen mastic. In most cases, fixing a suitable roof outlet is also a mandatory step.

The price for the installation of a soft roof in m2

| Description of work | Units of measurement | Price for work % |

| Installation of euro slating | m2 | 36 |

| Installation of a soft roof in 2 layers | m2 | 32 |

| Installation of a soft roof in 2 layers (mechanical fastening of the lower layer) with a mineral slab of 200 mm thickness | m2 | 48 |

| Installation of PVC membrane roofing | m2 | 24 |

| Installation of curb plate | running meter | 36 |

| Installation of the rafter system | running meter | 72 |

| Installation of the rough ceiling | running meter | 18 |

| Installation of the lathing | running meter | 36 |

| Roof insulation (mineral slab) | m2 | 36 |

| Vapor barrier arrangement | running meter | 12 |

| Separation of lumber | m2 | 144 |

Online calculator for calculating the cost of installing a soft roof

Расчет стоимости устройства плоской кровли под ключ

Итоговая стоимость

Works on the installation of a soft roof turnkey

Construction companies carry out work on the installation of a soft roof turnkey. Prices depend on the area of the roof, its shape and complexity, the availability of additional elements, on the angle of inclination of the slopes (if present), and other factors.

A competent calculation of the permissible load on the roof will allow you to choose the right roofing material, and will also help to rationally organize construction work.

One of the most important tasks of builders is to prepare a solid foundation, that is, a lining carpet on which the roofing can be laid. The carpet should have high strength and rigidity characteristics, as well as be waterproof and absolutely flat (the maximum permissible deviations are only 1-2 mm). In addition, when installing soft roofing, the following points should be taken into account:

- The optimal pitch of the lathing, is determined depending on the type of roof and its slope.

- The correct slope angle of the slopes, is suitable for laying flexible tiles (for sloping roofs, other types of soft roofs should be chosen, namely membrane and rolled materials).

- Compliance with the requirements for fixing the lining carpet, taking into account all necessary gaps, overlaps, and other features of the coating.

- Solid covering of the roof surface with a lining carpet.

- A competent approach to laying soft tiles, compliance with the geometricity of the coating, and sufficient treatment of the coating elements with adhesive compositions.

- Absolute tightness of the places where chimney, ventilation, roof windows, and other additional roof elements adjoin to the roof surface itself.

When working with construction companies, you may encounter a large number of errors, for example:

- The final cost of services turned out to be more than the one that the representative of the company initially called.

- The timing of the work has been delayed compared to the original plan, and the completion date is unknown.

- The work was done poorly, leaks appeared on the roof after the first rain. And the guarantee for construction work, in which it would be possible to compensate for possible losses, was given orally or not at all.

It is important to sign a contract with a construction company, which will describe the scope of work, the cost of installing a soft roof, and the timing. If one of the parties fails to comply with the terms of the contract, sanctions are imposed on the violator.

The right choice of specialists will help to avoid possible problems with the quality of the work performed. Performers with extensive work experience and certificates confirming their qualifications should be preferred. The contractor should give a guarantee for the work in writing. It is good if the company can show a portfolio of works, and give the contacts of their customers so that you can talk and get personal feedback. You can check the contractor on the FTS website: it should work under one name, without constantly changing addresses and names.

On the arrangement of a roof made of flexible materials, it is better not to save money and choose only those materials that have proven themselves well in the climate of your region. And trust roofs with complex architecture to experienced specialists.