Table of Contents

- What is a blind area and why is it necessary?

- Types of the blind area around the house and building

- How to make a blind area around a house or building: detailed installation technology by types of blind area

- Individual constructs and nuances when laying the blind area

- The price of a blind area arrangement

The blind area performs many functions necessary for the long-term operation of administrative buildings or private houses.

Here are some of them:

- Protects the foundation from various influences;

- Serves as a thermal insulation layer for the base of the house;

- Protects the façade of the building from the effects of precipitation;

- Depending on the design, it can be used as a pedestrian walkway;

- Many options of finishing materials help to create an attractive decorative view.

What is a blind area and why is it necessary?

Let’s take a closer look at what a blind area is. Blind area – a protective structure around a building or a private house, the arrangement of which is made along the perimeter of the entire building along the exterior walls. The blind area is a mandatory part of the construction, regardless of the purpose of the building – residential, public, industrial, etc.

The main function of the blind area is — to protect the ground base from precipitation and sewage from the roof of the house. Also, a high-quality blind area arrangement allows you to extend the bearing capacity of the foundation. The foundation -is the base of any building that has a high load-bearing capacity.

Even the most accurate calculation will not protect the foundation in conditions of constant exposure to groundwater. The foundation is designed in such a way that it has high waterproofing characteristics, but it can only partially protect the foundation from the constant impact of groundwater and its destructive effects. To remove moisture after precipitation, a high-quality blind area arrangement is necessary.

For the arrangement of a high-quality blind area, it is necessary to pay attention to:

- The materials used, necessary for the arrangement of each layer of the blind area;

- Location – the arrangement is made around the entire perimeter of the building;

- The thickness of the protective layer;

- Ground base;

- The angle of the slope, ensures the removal of water from the foundation.

The arrangement of the blind spots around the building is regulated in regulatory documents, which should be adhered to within the period of the building’s construction. Let’s consider the most common mistakes in the construction of blind spots, which will not protect the structure, but on the contrary, will contribute to the destruction:

- Blind area arrangement without the installation of the angle of inclination. This leads to the fact that the sewage will be retained on the base, and during operation destroy it.

- The arrangement of the angle of the blind area slope to the outer walls of the house, such a structure will destroy the socle and the load-bearing walls of the building.

- Blind area arrangement after commissioning of the building, if soil erosion has occurred, then the foundation structure has already been destroyed, and the blind area arrangement will not fulfill its main purpose.

Consequences of untimely blind area arrangement:

- The formation of cracks on the external structures of the building, which perform a bearing function;

- Dampness in basements;

- Formation of mold and mildew in the interior of the building;

- Destruction of building cladding materials;

If you neglect the arrangement of the blind area of the arrangement of some of its layers, then the base of the foundation will remain without high-quality insulation, and the building without an attractive architectural appearance.

Read more about the construction and waterproofing of the foundation in the articles:

— Foundation waterproofing arrangement: Methods, materials, prices, and recommendations of specialists;

— Waterproofing of foundation blocks and walls;

— Waterproofing of the foundation slab: Methods and materials;

— Waterproofing of the ribbon foundation: Technology and materials;

— Cracks in the foundation of the house: Causes and methods of their repair.

Types of the blind area around the house and building

Before setting up the blind area, it is necessary to study the geological indicators of the soil in the construction area. Soils are divided into 2 types:

- With slight shrinkage – these are types of soils that sink for small distances, no more than 5 sm.

- With strong shrinkage– these are types of soils whose shrinkage exceeds 5 sm, and in this case, it is worth paying more attention to the arrangement of the blind area.

Blind areas are divided according to the method of arrangement, the type of coating, and the materials used. The main classifications of the types of blind areas will be considered below.

Classification according to the rigidity of the base:

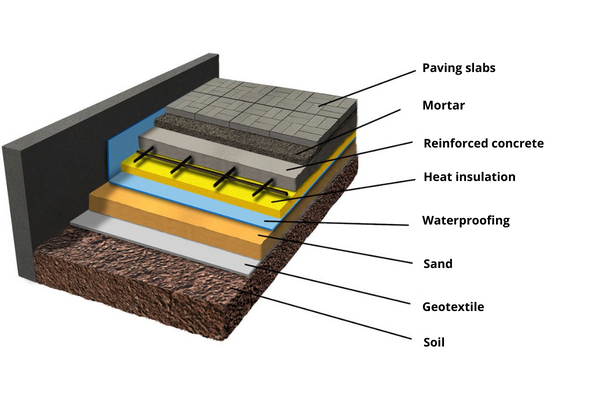

- Rigid – they are made of rigid materials: concrete or asphalt concrete laid on a compacted crushed-sand base, if desired, they are covered with various types of paving slabs to give a decorative effect. The waterproofing barrier is formed due to the concrete base.

- Soft – the arrangement of this type of blind area does not require large financial investments, while the design performs the main functions efficiently and has a number of advantages. Such blind areas are made of clay or bulk materials (crushed stone, gravel, granite chips).

Hard blind area or concrete blind area

A hard blind area has a high strength index and is able to perform a protective function more efficiently than a soft one.

Advantages of hard blind spots:

- It is not exposed to moisture, maintaining a stable temperature during the change of season.

- It does not allow weeds and other plants to germinate.

- It is able to withstand pressure and heavy loads, which allows it to be operated as pedestrian path.

- The possibility of a deep foundation arrangement that protects the ground base from freezing.

- Used in the construction of residential, public, industrial, and auxiliary buildings.

The negative side:

- During long-term operation, cracks and chips appear, which require timely repair work.

The size of the blind area is chosen depending on the design solution. To calculate the required width, the protruding part of the roof above the outer wall is taken into account, in this case, the width of the blind area is 20 cm wider than the protrusion of the roof, this calculation method is suitable for soils with slight shrinkage. If the soils are able to shrink strongly, then the width of the blind area is laid by 60 sm more than the protrusion of the roof.

If the blind area is planned to be used as a pedestrian path, then the thickness of the blind area made of paving slabs is at least 4-6 sm, with a sand layer of 3 sm, the width of the structure is at least 1,5 m.

Soft blind area

The simplest type of protective coating arrangement can be performed without the help of specialists and expensive equipment.

The main advantages of soft blind spots:

- Resistance to temperature changes, capable of not being destroyed during the physical movement of the soil base with the onset of winter or summer. Retains all its original properties, under the influence of different temperatures.

- Does not require maintenance and repair.

- In plastic, there are no materials in the composition that are destroyed by moisture and are subject to corrosion.

- A large selection of finishing coatings makes it possible to create an attractive appearance and various decorative combinations.

- The low-price category does not require expensive financial investments when setting up a blind area.

- Does not require the creation of a trench and has a high thermal insulation index.

Negative sides:

- Periodic cleaning of the coating is required, it is necessary to treat the appearance of parasites and other microorganisms.

- Short service life, requires systematic renewal of the coating. Types of finishing coating of a soft blind area.

Types of finishing coating of a soft blind area:

- Hidden layer – when the blind area is decorated for lawns, flower beds, shrubs or create various decorative compositions of stone or rubble.

- Clay layer – perfectly performs a protective function if the material is selected qualitatively and all stages of the arrangement are observed.

How to make a blind area around a house or building: detailed installation technology by types of blind area

The technology of the blind area arrangement varies depending on the type and materials used, but there are rules that should be followed, regardless of the design of the blind area:

- The blind area arrangement is made tightly to the building, leaving no gap;

- The slope angle is constructed at no more than 10%;

- Be sure to align each stacked layer;

- Use high-quality materials, preferably certified or having a quality document;

- The ground base should be thoroughly compacted;

- Between the outer walls and the blind area around the perimeter, it is necessary to arrange a pliable seam, which will allow cushioning during the movement of soils in the off-season period;

Soft blind area arrangement

The arrangement of a soft blind area is produced in several stages:

- Trench preparation: a vegetation layer of 30 sm is removed for the entire width of the blind area, for heaving soils, it is better to make a trench up to 40 sm. The width is approximately 80-100 sm, a slope is arranged, and the higher side of the blind area should be adjacent to the outside of the building, for the drainage of wastewater after precipitation. the base of the trench should be leveled and compacted.

- It is poured off with clay about 10 cm thick, in which there are no impurities, and the layer is leveled and compacted.

- Then, a waterproofing layer is made, and roofing material or membrane material is used. It will prevent moisture from passing through the foundation and will not allow the clay and sand layer to be mixed.

- Sand is poured off the reconciliation, also with subsequent leveling and compaction. It protects the waterproofing coating from mechanical damage.

- The advantage will be the installation of a layer of geotextile. Geotextile – is a material with a fibrous structure, it is used to remove moisture from the top layer of the soil and prevent the erosion of the sand layer and mixing with the crushed stone layer.

- Then, a crushed stone base with a thickness of 12 sm or a base made of other bulk material is laid.

- The decoration of the blind area is made depending on the preferences of the customer.

- If a thermal insulation layer is required, then this layer is laid after the waterproofing layer is installed.

Diagram and nodes for soft blind area arrangement

The main node in the arrangement of a soft blind area — is the construction of a drainage system. This is necessary to drain the collected water after precipitation into the drainage layer, while the finished coating will not be destroyed, and the soil will not give strong precipitation. Specialized perforated pipes are used for the installation of the drainage system. Pipe elements are pre-insulated with geotextile. It will not allow soil or bulk materials to clog the perforation.

Installation of each layer of the blind area:

When installing a soft blind area, it is necessary to adhere to certain technology for the arrangement of each layer so that the drainage and filtration system of wastewater works properly.

Technological scheme of the arrangement of each layer:

- Waterproofing materials – a qualitatively laid layer should cover the entire clay layer, and it is also necessary to make an overlap of 10 sm on the vertical parts of the trench. It is better to use modern membrane materials.

- Insulation layer – to protect the insulation, another layer of waterproofing material is laid. This stage is performed on the condition that the system needs additional insulation of the structure.

- Crushed stone base – the crushed stone layer is laid already 15 cm thick, but it is worth considering the total depth of the trench.

- Geotextile – is a separating material that has a fibrous or fabric structure. Performs the function of a separating material that does not allow layers to be mixed.

- Sand layer – a 10 sm cushion arrangement is made, the layer should be leveled, with mandatory compaction and moistening.

- Geotextile – at this stage, the geotextile layer performs the function of filtering the interlayer, after its arrangement, a system of drainage pipes is installed, which are connected by a tee.

- Sandy-grave mixture – this layer is the finishing layer, its thickness is on average of 4 sm, sometimes more, it is laid to the upper edge of the trench. If a decorative layer is laid on top, then it is necessary to separate them with geotextile. Most often, this layer is the finishing one, since it is able to withstand mechanical impact and significant pressure.

- If desired, you can lay a decorative layer that will improve the architectural appearance of the structure.

Let’s consider the types of finishing coatings for a soft blind area:

- The arrangement of the natural lawn– is the simplest architectural solution that does not require large financial investments. With this type of decoration, it is necessary to lay an additional layer between the sandy and vegetable layer so that the roots of the plant do not destroy the construction of the blind area.

- Artificial lawn service– the artificial lawn service does not require additional measures to prevent the destruction of the blind area, and has a well-groomed appearance.

- Bulk coating – most often made of colored granite chips or pebble coating, this type of coating is suitable for decoration in various styles, for example, chalet or country.

- Paving slabs – laying is done on a layer of sand, which it is poured on top of geotextile, also this kind of blind area is decorated with the installation of curbs.

This type of blind area can be put into operation immediately, without waiting for the strength of concrete to set, as in rigid blind areas.

Concreting of the blind area

The arrangement of a concrete blind area is made in several layers:

- Preparation of the trench – the entire width of the blind area is removed from the vegetation layer to a depth of 20-30sm. Then, a small slope is constructed and the soil base is compacted, paying special attention to the area near the foundation with backfill, while adding soil so that the thickness of the compacted layer is at least 15 sm. the depth of the trench is calculated taking into account that they fit: a rigid base, a pliable layer by the thickness of about 10-15 sm and a layer of insulation. If the depth is greater than the calculated depth, then the difference is poured with local or clay soil, with mandatory compaction.

- The arrangement of a pliable layer – the soil base is poured with a crushed stone layer, and the crushed stone layer is leveled and compacted. The first layer is poured with crushed stone of a fraction of 40-70 mm, then a smaller fraction of crushed stone of 5-10 mm is used. A smaller layer of crushed stone is necessary to fill the voids formed in the layer with larger crushed stone. Compaction should be carried out to such an extent that waves of crushed stone are not formed under the roller. The next layer of filling is river sand, it is also leveled and compacted qualitatively. The permissible deviations for a crushed stone base are 1.5 sm for every 2 meters, and for a sandy base– 1,0 sm for every 3 meters of filling.

- Waterproofing layer – the next layer is the installation of a waterproofing film, it protects the concrete base from moisture loss and contributes to the rapid strength gain of concrete. For the arrangement of this layer, a polyethylene film with a thickness of about 200 microns is most often used.

- Insulation layer – when installing a blind area on heaving soils, it is better not to neglect the arrangement of this layer. Most often, insulation is made with polystyrene foam materials, installation is carried out in 1-2 layers.

- Shuttering arrangement – wooden shuttering is most often used, which is made of boards and timber, also bridges with a width of 2 sm are mounted and the height should be a quarter greater than the thickness of concrete. Jumpers are necessary for the arrangement of deformation seams. for easy removal of the formwork elements, the elements are pre-lubricated with separating lubricants.

- Reinforcement arrangement – grids with a cell size of 10 х10 sm are most often used, the diameter of the rod is 0,4 sm, the mesh is installed in an overlap, the overlap is produced in the size of a cell and secured with a wire.

- The arrangement of the concrete base – for the arrangement of the concrete base, a concrete mixture of a class not lower than B15 is used. After laying the concrete mix, it is necessary to provide high-quality care for the concrete. Prior to the set of the release strength of concrete, not less than 70% of the design strength, the concrete base is abundantly moistened with a plastic film, if the concrete is not cared for, cracks may be formed on the concrete surface and the concrete strength set will go much slower.

- The arrangement of deformation joints – the previously installed lintels are removed from the concrete base and filled with bitumen-based mastic with the addition of mineral filler. This seam dampens, allowing concrete slabs not to collapse when moving in the spring.

- Protection of the finished coating – to increase the wear resistance and durability of the concrete base, the surface is treated with special compounds. This composition reacts with the structure of the concrete base, resulting of the concrete base, resulting in a thin coating with high waterproof characteristics.

Layers of the arrangement of a concrete blind area with nodes

The arrangement of a concrete blind area — is a simple technological process independently.

- stage – cushion arrangement. Before laying the concrete mix, it is necessary to pour a layer of sand with a large fraction or crushed stone, too fine inert material can give a large shrinkage, which will negatively affect the structure. Most often a combined layer is used: first, a layer of crushed stone is leveled and compacted, then a layer of sand that will fill the free space and create a high-quality pliable layer.

- stage – reinforcement. The reinforcement mesh arrangement is capable of giving additional rigidity and structural strength. The diameter of the reinforcement from which the reinforcement frame is created is selected depending on the required load-bearing characteristics.

- stage – the formwork arrangement. The formwork allows you to give a strict geometric shape to the future structure and does not allow the concrete mixture to spread. The formwork should be installed along the entire perimeter of the coating.

- stage – laying of concrete mix. For the construction of a solid foundation, it is necessary to use concrete of a class not lower than 25, which has a strength index of 32.0 Mpa, it is also necessary to provide high-quality care for concrete, especially during the hot period, and to prevent moisture evaporation.

Individual constructs and nuances when laying the blind area

For the arrangement of a high-quality blind area, it is worth considering some indicators:

- Calculation – it is necessary to calculate correctly the necessary layers and take into account their thickness so that when developing a trench, you do not make a mistake with the size. Find out in advance whether a thermal insulation layer is required, and lay on it at least 5-10 sm in addition.

- Drainage arrangement – it is not necessary to allow the drainage system to be removed from the ground base, this contributes to the erosion of the soil and damage to the finish coating, it is also possible to shift the blind area due to the physical movement of the soil.

- The organization of the slope angle – it is important to position the angle correctly and arrange it from the building, also you can not neglect the slope arrangement, it will allow you to remove moisture from the load-bearing structures of the building.

- Crushed stone base – it is important to make this layer of crushed stone of a large fraction of 40-70 mm, such a fraction size will not be mixed with clay soils and will create a more rigid base.

- Sequential laying of layers in accordance with the technological scheme -violation of the technology of the arrangement will not allow the blind area to perform the main protective function.

Insulation of the blind area

The thermal insulation layer is necessary to protect the drainage system from freezing in winter, if there is a risk of freezing of the soil, it is better not to neglect the arrangement of this layer. An additional layer will help to increase the period of operation of the drainage system, without additional repairs.

The insulation arrangement is made at the stage of trench preparation. A waterproofing layer is laid on top of the clay layer, then the insulation is laid, all parts of the insulation should be hermetically sealed to prevent the influence of various influences on the insulation material and subsequently its destruction. The insulation layer is calculated individually, taking into account regional peculiarities and the climate in which the blind area will be operated, on average, the thickness of the insulation is mounted at 5 cm.

Materials, used for insulation:

- Extruded polystyrene foam – is a fairly durable material, is not subject to rotting and external influences, has a water-repellent property; it is light in weight and easy to install. The main thing— is to ensure the protection of butt joints with a specialized film.

- Foamed polyurethane – has high frost resistance, withstands low temperatures up to -60 degrees without changing its properties, and is an environmentally friendly material with a high thermal insulation index.

- Foamed foam – a large number of pores allows the material to have high thermal insulation and sound insulation performance. It has low water absorption and low weight. It is also resistant to temperature changes and the appearance of mold and mildew.

You can skip the stage of the insulation arrangement only if the foundation of the house is made of piles or has a large basement.

Waterproofing of the blind area

The waterproofing arrangement is necessary to ensure maximum protection of the foundation from moisture ingress, for the arrangement of a high-quality insulating layer, waterproofing should be installed around the perimeter of the house, leaving no gaps and spaces.

If you do not perform a waterproofing layer on the blind area, then during operation the load-bearing structural elements of the foundation blocks will begin to collapse. Due to the poor-quality arrangement of the insulation layer or its absence, the spread of fungi and mold is possible. Exposure to atmospheric precipitation will lead to the destruction of the foundation of a house or building.

The waterproofing arrangement of the blind area consists of two stages:

- The underlying layer;

- Bulk layer.

Depending on the type of blind area, a waterproofing layer is arranged:

- Soft blind — rolled materials are most often used for soft blinds, for example, polyvinyl chloride films, the use of polyethylene or roofing materials is not able to create 100% protection against moisture penetration to the foundation structure.

- Rigid blind area — to create waterproofing on a blind area of this type, hydraulic cements or asphalt concrete are used, they are able to reliably protect the foundation structure from moisture ingress.

The waterproofing layer is made of various types of materials and is divided into groups:

- Roll material – such type of material is used for buildings that have basements, after the clay layer is installed, roll waterproofing with overlap is installed, the layer is compacted and soil or crushed stone is laid on top.

If the material is laid in several layers, then it is necessary to process each layer with a special mastic.

Most often this type of waterproofing is used for the arrangement of a blind made of crushed stone, the advantages of this type:

- low cost – is one of the most budget materials that has waterproofing properties;

- easy installation – no specialized equipment and qualified personnel are required to install a waterproofing layer.

Disadvantages of this material:

- Careful surface preparation is necessary – in order for this material to perform its functions, it is necessary to lay layers on a prepared surface that will not allow damage to the material.

- If the integrity of the material is damaged, a rather complex process of repair work is required.

Types of rolled materials:

- Bitumen based materials — is the most budget-friendly material among its analogs;

- Polymer-based materials — is a more expensive material, but have a long service life;

- Roofing material — is a denser and more durable material, for the operation of waterproofing on a site with a large amount of wastewater, it is better to use roofing materials based on glass wool.

- Hydroglassizol — this material does not allow moisture to penetrate the foundation structure, and also ensures the passage of wet steam through its thickness.

1.Liquid glass – is the most common material for the blind area arrangement. The material has antiseptic properties and long service life. Also great for processing porous or fibrous materials.

The advantage of this type of material:

- Resistant to atmospheric precipitation and chemical effects;

- Fireproof;

- Has low thermal conductivity;

- Non-toxic during use and operation.

Among the disadvantages can be distinguished:

- The fast setting of the components, so the working mixture should be produced in small portions;

- Fragility – it is better to use in conjunction with a roll type of waterproofing;

- Has no strength indicators – it is destroyed by mechanical action;

- It is important to observe strict proportions when preparing the working solution;

- Can not be used on brick structures.

2. Bitumen-based mastics – are distinguished by the method of application: hot or cold, the hot application should be performed by qualified specialists, and the cold one can be handled independently.

To prepare the working composition, the mastic is mixed with a solvent, subsequently, the applied mixture hardens and acquires its protective characteristics.

Advantages of this material:

- It is possible to apply the material by yourself;

- Suitable for blind areas with the complex configuration;

- Penetrates into hard-to-reach places;

- Good adhesion to the surface of concrete, bricks, metals, and other materials.

Negative sides:

- Shrinkage of the material may contribute to the destruction of parts of the structure.

3. Film material – provides high-quality protection of the foundation structure from moisture ingress, but at the same time is subject to destruction from mechanical influences and sunlight. To avoid this, it is worth choosing a film that can withstand heavy loads for a long time.

Types of films:

- Membrane;

- With reinforcement;

- Polyvinyl chloride (PVC-film).

The main advantage – is the ease of installation and resistance to salts and minerals, it is also used in places with a complex soil structure.

- Hydraulic cement – it is part of concrete, changing its structure, and reducing the number of pores into which moisture penetrates. Hydraulic cement has high resistance to mechanical influences and impacts from atmospheric precipitation. Perfectly interacts with all materials from which the blind area arrangement is made.

- Penetrating materials– materials made on the basis of cement with the use of active substances and polyfraction sand. Such compositions are used for waterproofing hard blind areas, the main advantage— is resistance to wet conditions, and strength gain in this environment. Such insulation protects the structure not only from moisture but also from all fuels and lubricants. They are laid on different structures.

Read more about the waterproofing of the blind area in the following article:

— Waterproofing of the blind area around the house and building

The arrangement of seams in the blind area

The arrangement of deformation seams — is an important stage in the construction of a concrete blind area, for the arrangement of a high-quality deformation seam, it is necessary to observe the technology of work.

The deformation seam allows you to reduce the load that affects parts of the structure. The causes of any load can be different, their impact can lead to the destruction of concrete.

The choice of the type of deformation seams depends on the impacts that will be imposed on the construction of the blind area. Climatic factors and the region of construction are also taken into account. For the arrangement of the deformation seam, the use of low-plastic materials is not allowed, the main indicator for the quality material used for the arrangement of the deformation seam with a high index of elasticity and resilience.

Types of expansion joints:

- Temperature – seams, that are resistant to different temperatures, when installing such a seam, it is necessary to take into account the lowest negative and the highest positive temperature index.

- Shrinkage – such joints are used at the stage of concrete work, they are necessary to create a strong concrete coating with a high strength index and prevent the formation of cracks on the concrete surface. After the set of the release strength of concrete, the seam should be sealed.

- Sedimentary – this type of seam is considered as the most common, most often used for loose soils and with possible subsidence of foundation blocks.

Method of arrangement of the deformation seam:

- For the arrangement of the deformation seam, the loads imposed are taken into account, and the installation of seams is usually arranged in steps of 2-2,5 cm.

- Temporary seams are installed from wooden slats, lubricated with a specialized lubricant composition, for easy removal from the structure.

- After gaining the release strength of concrete, temporary slats are removed, and the voids formed are sealed with a tape material with a porous structure, most often foamed polyethylene is used. Further, the material is covered with a sealant to protect against moisture ingress.

The price of a blind area arrangement

When calculating the cost of the blind area arrangement, first of all, the area of the building around which the blind area will be installed is taken into account. The cost is also affected by the width of the blind area, and the type, and materials used.

| Type of work | Units of measurement | Price in $ |

| Soft blind area arrangement | m2 | 260 |

| The arrangement of a concrete blind area | m2 | 160 |

| The arrangement of a concrete blind area with a warming layer | m2 | 350 |

| The arrangement of a concrete blind area with paving slabs | m2 | 390 |

Advantages of choosing a “turnkey” blind area arrangement:

- Fast works performance;

- Compliance with the technological scheme of the blind area arrangement;

- Preparation of estimates and settlement documentation;

- With the complexity of the arrangement of the blind area layers, qualified specialists will perform all the stages more efficiently and quickly.

The negative side:

- The high price of works;

- Long documentary process.