Table of Contents

- What is a blind area and why it is necessary?

- The technology of the blind area arrangement and at what stage it is necessary to perform its waterproofing

- Types of materials for waterproofing the blind area

- Prices for blind area arrangements and its waterproofing

- Waterproofing the blind area around the house with your own hands: Video instruction

Moisture contained in the soil or falling on the ground’s surface with atmospheric precipitation can have a destructive effect on structures for various purposes. In order to avoid negative consequences, it is extremely important to carry out high-quality waterproofing of all elements of the house.

At the same time, it is necessary to purchase suitable materials, choose the right technology and perform the process in accordance with all the rules of construction work. In this article, we will talk about the waterproofing of the blind area, which can protect the foundation and walls of the building from the effects of moisture accumulating in the ground.

What is a blind area and why it is necessary?

A blind area is a strip bordering the basement of a building, which, as a rule, is made of concrete. The blind area around the house is made at the stage of construction of the structure or at the stage of its operation. Most often, the blind area is lined with tiles, asphalt, concrete, or paving stones made of stone. Due to its low cost and excellent strength indicators, concrete is the most common material among those that are designed to perform a blind area.

The considered element of the house has several important functions that it would be more correct to study in detail:

- Decorative element. First of all, we are talking about a decorative function, that is, decorating a building by installing a blind area around it. Such a design solution will give completeness to the appearance of the building.

- Thermal insulation. Also, the blind area can positively affect the thermal insulation of the base of the house, since it prevents the freezing of the foundation in the cold season. However, the real contribution of the blind area to thermal insulation is so minimal that its absence in fact will not affect the condition of the house or the foundation in any way.

- Removal of water from the foundation of a building or house. Protection of the foundation from direct contact with water that enters the area near the foundation from the roof.

However, in order for the blind area to fully cope with its tasks, it is necessary to meet the following requirements:

- The width of the building should exceed the width of the ledge of the cornice by about 20 sm;

- It is recommended to perform a blind area with a small angle of inclination in the direction of the building (as a rule, one and a half degrees is enough);

- Blind area is mandatorily performed around the building.

Important: It is worth noticing that, if necessary, to increase the degree of protection of the foundation from moisture (for example, in areas with high humidity or heavy precipitation), the width of the blind area needs to be made larger than the standard one.

Is it necessary to do waterproofing of the blind area?

It is worth noticing that there are several types of blind area, and the choice of the desired option is based primarily on the amount of precipitation that falls on the territory of a particular area each season. In addition, it is necessary to provide for the nature of drains located on the roof of the building, since they are able to provide undesirable regular contact of the blind area with water.

The blindfold protective tape includes a base and a coating. The blind area itself can be made in various variations: standard bulk (made of clay and crushed stone), bulk with installation of waterproofing for the structure, concrete or reinforced concrete in the form of ready-made slabs.

Each of the types has its advantages, but it is not recommended to install several types at the same time, for example, bulk with clay or concrete. High-quality waterproofing of the blind area around the house will save its residents from the destruction of the blind area under the influence of ground, thawed or rainwater.

High-quality waterproofing of the blind area around the house will save its residents from the destruction of the blind area under the influence of ground, thawed or rainwater.

Important: A blind area — is an auxiliary element that helps to divert water from the foundation of a building or a private house and its absence can in no way be the cause of leaks in the building, since waterproofing of the foundation and walls of the building itself should be responsible for protecting the building from water and moisture penetration. Waterproofing of the blind area cannot affect the building itself or its foundation in any way and, accordingly, it is needed solely to protect the concrete blind area itself.

The technology of the blind area arrangement and at what stage it is necessary to perform its waterproofing

The technology of installation of the blind area depends on the selected type of the blind area. It is also important to take into account the presence or absence of a basement in the building. If such a room is present, then it is recommended to make the blind area double- or multi-leveled.

Stages of the standard blind area:

- Before installation, the top layer of the ground is removed;

- A layer of sand, at least 10 sm thick, is laid on the formed surface and carefully tamped;

- Next comes the separation layer of geotextile;

- The arrangement of a crushed stone cushion with a thickness of at least 10 sm;

- At this stage, waterproofing is fixed, for example, membrane;

- Then the geotextile is laid;

- Installation of thermal insulation;

- Separation layer and polyethylene film;

- Binding of the reinforced frame of the blind area;

- Pouring cement;

- The final stage is the laying of facing materials, for example, paving stones.

the slope under which the blind area is performed should be directed from the structure to the ground area. Thanks to the correct installation, it is possible to achieve such effects as ensuring the removal of excess fluid from the building, preventing subsidence and swelling of the soil, protecting against penetration of roots of various vegetation to the base of the structure.

Due to the fact that the blind area around the house plays a very important role in the operation of the structure, as well as is constantly exposed to external atmospheric influences, it should be installed in accordance with all regulatory requirements, as well as provided with reliable and durable waterproofing.

The layout of all nodes and elements of the blind area when it is installed

Is it necessary to insulate the blind area?

There are several answers to the question whether it is necessary to insulate the blind area. Insulation, for example, allows you to keep warm in the basement or on the socle floor, and also has a positive effect on the condition of the blind area, increasing its service life. If the house is built on stilts or it is characterized by an extensive foundation and the absence of basements, then there is no need to install thermal insulation materials.

It is also recommended to install insulation in places where there is a heaving of soils, since the absence of thermal insulation, the blind area may deform and collapse over time.

Styrofoam is considered as an excellent insulation option. This material is characterized by strength, long service life, good hydrophobic properties and low weight. To insulate the blind area with expanded polystyrene, one layer of material with a thickness of at least 10 sm will be enough.

Types of materials for waterproofing the blind area

Currently, many modern hydrophobic materials are used for waterproofing the blind area. Let’s take a closer look at their features, advantages and disadvantages, as well as technologies for working with materials.

Rolled materials

Some of the most common compositions — are materials, stored in the form of rolls. The process of installation of rolled materials includes a preliminary thorough preparation of the base on which it is planned to lay the surfaced or self-adhesive sheets.

To date, there are two types of roll-type waterproofing: bitumen and polymer materials, and the second option is considered more reliable and durable, but also more expensive. You can also recall the standard roll composition based on cardboard — roofing material, which is allowed to be used for hydrophobic treatment of the blind area. Roofing material is characterized by high strength indicators, and the composition made on the basis of glass wool is perfect even for those areas characterized by an increased groundwater content.

However, do not forget that each type of waterproofing has its own installation features. Laying of the material is carried out in compliance with fly fishing in 10-15 sm. At the same time, in order to achieve the best results, it would be best to lay the roll waterproofing in several layers.

You can read more about roll waterproofing in the article – “Roll waterproofing arrangement with detailed installation instructions“.

PVC membranes and films

Waterproofing films and PVC membranes are able to provide reliable and durable protection of the base of the structure from moisture. However, at the same time, such materials cannot withstand the effects of sunlight and strong mechanical loads. However, the ability of films to cope with loads is affected by their quality: the better the material, the greater its stability.

In addition to PVC membranes and standard films, additionally reinforced materials are also distinguished. The films are perfectly combined with any kind of blind area, and are also mounted in places characterized by high humidity or an increased content of salts and minerals. With the help of membranes and films, it will be possible to protect even those sections of the structure that have a complex geotechnical structure.

You can read more about membrane waterproofing in the article – “Membrane waterproofing: types of materials and methods of their installation“.

Coating bitumen mastic

Bitumen mastics, a type of coating materials, traditionally differ in the simplicity of application, the ability to apply them to structures of different shapes and complexity, as well as high resistance to various influences.

The materials in question are of two types: cold and hot application. The second type, as a rule, is used only by specialists, since in this case bitumen mastic is heated to high temperatures and it is necessary to work with it only with the help of special protective equipment.

Cold mastic is recommended to be combined with a solvent first, which will allow the bitumen mastic to acquire its operational properties and harden after application. Bitumen-polymer mastics have a higher quality than standard bitumen compositions, which can be perfectly fixed to any type of surfaces, for example, to metal, brick, concrete, stone and not only.

You can read more about bitumen mastics in the article – “Bitumen waterproofing: types, characteristics and technology of the installation“

Liquid rubber

One of the most high-quality waterproofing coatings is considered to be a coating made of liquid rubber. This is due to the fact that this material has a huge number of advantages. For example, it is applied very quickly and hardens, so working with liquid rubber, as a rule, does not take much time. In addition, the composition in question does not emit toxic fumes and poses absolutely no danger to human life and health.

Liquid rubber is able to withstand the effects of negative temperatures, mechanical loads, vibrations and chemicals, does not ignite, has strength, elasticity and a long service life than can last 40 years.

However, this material does not always withstand the effects of ultraviolet radiation and therefore it is not recommended to use for external structural elements that are constantly exposed to sunlight. If such a need is still present, then you can buy a special protective paint in a hardware store that can protect the hydrophobic coating from UV exposure. paints are available on the market in a wide variety of colors.

Do not forget that improved compositions that are resistant to UV radiation are not always necessary.

You can read more about liquid rubber in the article – “Waterproofing with liquid rubber“

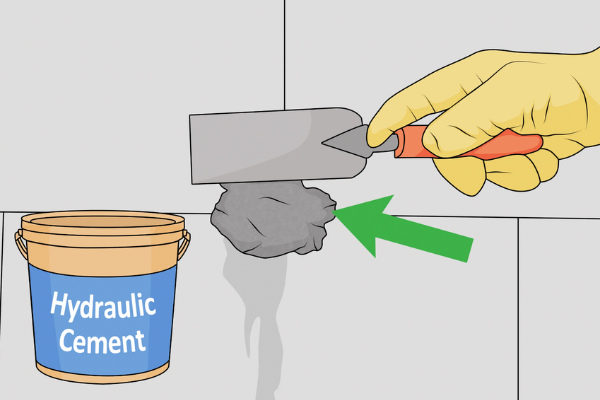

Hydraulic cement

Hydraulic concrete is usually made from such a material as hydraulic cement. This composition is an improved version of standard concrete with a porous structure. Moisture easily penetrates into the pore of concrete, which causes the material to deteriorate and collapse. Hydro concrete is a concrete supplemented with various waterproofing additives, which provide reliable water resistance of the blind area.

Hydraulic cement is characterized by high strength and resistance to various kinds of influences, such as mechanical loads, precipitation, chemicals and moisture. Another advantage of hydraulic cement is that it is perfectly combined with any type of blind area, for example, with products made of sand, crushed stone and other materials.

Liquid glass

Such a waterproofing material as liquid glass is often used for hydrophobic treatment of the blind area around the building. Among the positive properties of liquid glass — are resistance to moisture, fire and chemicals, low thermal conductivity, environmental safety, antiseptic effect, excellent compatibility with a large number of types of surfaces, durability and more. In addition, the material in question is often used to work with bases that have a porous structure. These include concrete, wood and plaster.

However, liquid glass also has a number of disadvantages. For example, this material dries up quite quickly, so it is important to knead it in a small volume and carefully distribute it over the surface. Also, liquid glass is characterized by fragility and the ability to collapse under the influence of strong mechanical loads. For this reason, such waterproofing is sometimes covered with rolled materials to provide additional protection of the coating. Other disadvantages of liquid glass — are its incompatibility with various solvents, as well as the impossibility of applying it to a brick base.

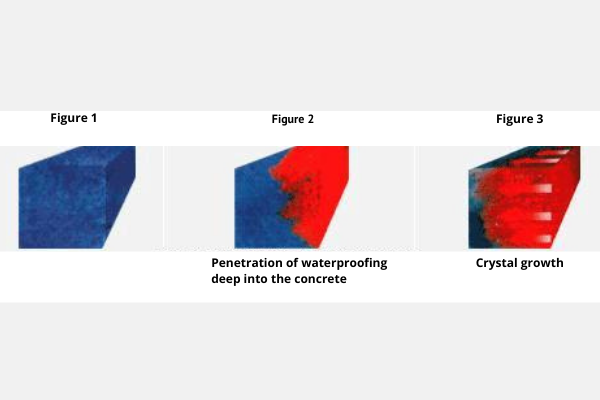

Penetrating

Hydrophobic materials of the penetrating types are made on the basis of cement with the obligatory addition of fine sand and some useful chemicals. Penetrating compounds are excellent for waterproofing basements, foundations of structures, as well as blind areas made of concrete. The materials in question have the property of penetrating into all the smallest holes and irregularities of the working surface, as well as the coating of penetrating waterproofing becomes only stronger upon contact with water due to the “gluing” of the composition.

It is also worth noting that the penetrating type compounds are able to reliably protect the structure from the effects of gasoline, oils and many other combustible substances.

Moreover, for all their features, the materials in question do not clog the base material (for example, concrete) and allow it to breathe.

You can read more about penetrating compounds in the article – “Penetrating waterproofing: A detailed description of its work on concrete, types of materials and application technologies“

The scheme of work of penetrating materials:

Clay

Clay waterproofing of the blind area around the house is considered as the most budget-friendly and at the same time easy-to-use option. Not even the most experienced builder can handle the installation of such a composition. The process of installing waterproofing begins with removing the top layer of soil and filling the resulting space with clay, which should be carefully tamped.

At this stage, the waterproofing slope is also set in the direction away from the house. The places of all formed compounds should be smeared with bitumen composition. For greater reliability of hydrophobic treatment, a strip of rolled material can be fixed to the vertical surface and then the coating can be covered with crushed stone.

What kind of waterproofing to choose for the blind area of the house and building

The choice of waterproofing directly depends on the type of blind area and the location of the waterproofing coating.

If the waterproofing is located on the ground, gravel or sand, which have the appropriate dynamics and movement, then it is best to use a PVC membrane.

If the waterproofing is located on a solid foundation, for example, concrete base or on the concrete blind area itself, which is undoubtedly recommended, then it is best to use seamless, and most importantly— elastic materials with 100% adhesion to the base, for example, liquid rubber, as waterproofing.

Such material as liquid rubber, in addition to its other advantages, has a high coefficient of elasticity, which allows it to stretch during movement or subsidence of the blind area, and not tear, diverge at the seams or crack.

Prices for blind area arrangements and its waterproofing

| Description of work | Unit of measurement. | Price |

| Waterproofing of the blind area | ||

| Laying of profiled membrane | m2 | 10 |

| The arrangement of surfaced waterproofing | m2 | 40 |

| Waterproofing arrangement of PVC membranes | m2 | 36 |

| Application of bitumen mastic | m2 | 10 |

| Application of liquid rubber | m2 | 60 |

| Construction of a blind area | ||

| Installation of formwork | running meter | 20 |

| The arrangement of a solid protective and separating layer of non-woven geotextile material | m2 | 5 |

| Sand cushion arrangement (100mm) with seal | m2 | 90 |

| The arrangement of a pillow made of crushed stone (100mm) with a seal | m2 | 90 |

| Insulation of a blind area with EPPS (Extrusion Foam Polystyrene) slabs | m2 | 30 |

| Reinforcement of the blind area with reinforcement and laying of expansion joints | m2 | 87 |

| Concreting of the blind area | m2 | 80 |

| Paving with a blind area with paving stones / paving slabs on the Cement-Sand Screed base | m2 | 120 |

*The above prices may change depending on the scope of work and their complexity.