Table of Contents

- Types of waterproofing materials to protect the cellar from water

- What is the best way to make waterproof the cellar — from the inside or from the outside?

- Waterproofing of the cellar from the outside — an integrated approach

- Waterproofing of a brick cellar: features and technical recommendations

- Waterproofing of the cellar from the inside from groundwater: features and technical recommendations

- Price for the performance of works

Waterproofing of a cellar — is a complex of works related to the installation of waterproofing materials that prevent the occurrence of flooding, and excessive humidity in a buried room.

In order to avoid spoilage of stored products, as well as the destruction of the cellar itself under the influence of excess moisture, waterproofing of the cellar is carried out. The choice of insulation materials depends on various factors, including the material from which the cellar is made (concrete, brick, FBS blocks, etc.) and the place of work (inside or outside).

Types of waterproofing materials to protect the cellar from water

One of the reasons leading to a reduction in the service life of the cellar structure is the impact of ground and meltwater, precipitation, which tend to soak into the soil, saturate it with moisture, and, thus, affect the walls and foundation of the cellar. The correct choice of waterproofing materials depends on various factors; with this in mind, the following types of waterproofing are used:

Bitumen mastics

Bitumen mastics: coating material of viscous consistency, made on the basis of bitumen. Organic and synthetic components are used as additives, allowing the mixture to be used in a wide temperature range.

After application to the surface, the mixture hardens, forming dense impermeable base. Depending on the composition of the mixture, bitumen mastics can be:

- Bitumen-rubber, with the addition of synthetic rubber, rubber powder, mineral oil.

- Bitumen-oil. Consist of bitumen, polymers and technical oil.

- Bitumen-latex. They are made with the addition of slate varnish and synthetic latex.

- Bitumen-polymer. The basis of the mixture — is bitumen and polymer materials, using additives and fillers.

- Bitumen-mineral. The mixture includes mineral components: it can be limestone, ash, quartz, and other components, plasticizing substances.

Due to its high elasticity and density, the material is widely used for sealing joints and seams in rooms for various purposes, including those with high humidity, for example, in a cellar.

You can read more about bitumen mastics in the article – “Bitumen waterproofing: types, characteristics, and technology of the installation“.

Roll waterproofing

Roll waterproofing is used to protect cellars made of stone, reinforced concrete, or prefabricated building materials.

Regardless of the type of construction material, it is necessary to clean the surface from old coatings, dirt, fungus, and mold before use.

Varieties of roll waterproofing:

- Surfaced. As a rule, the basis is fiberglass, the inner surface of which is covered with a layer of bitumen and a protective film. During installation using a burner, the film melts, and the bitumen becomes soft. This ensures that the waterproofing is glued to the surface of the wall in the cellar.

- Pasting. It is made on the basis of fiberglass or polymers. Installation on the surface of the project is carried out using epoxy adhesive mixtures, bitumen-based mastics, or tar.

- Membrane. These types of roll waterproofing are made of polyvinyl chloride or polyethylene. They are mounted to the surface using slats and fasteners.

Any type of roll waterproofing is used for application from the outside, as they work on clamping, not on separation. When performing work using rolled materials from inside the room, waterproofing should be pressed with a screed (floor) and a pressure wall (on the walls).

You can read more about roll waterproofing in the article – “Roll waterproofing installation with detailed installation instructions“.

You can read more about membrane waterproofing in the article – “Membrane waterproofing: Types of materials and methods of their installation“.

Cement and polymer cement waterproofing

Cement and polymer-cement types of waterproofing are made on a cement basis; polymer-cement mixtures include cement and polymers as the main components. Depending on the additional additives, the following types of waterproofing mixtures are distinguished:

- Cement-sand. It consists of high-quality Portland cement, which provides a mixture of viscosity, high strength, and water resistance, with a filler of sifted quartz sand.

- Cement-latex. The addition of latex contributes to the high plasticity and water resistance of the mixture, and its resistance to temperature changes. When working, it is necessary to bring the material to a hot condition.

- With liquid glass. It improves the performance characteristics of the cement-sand mixture: increases fire resistance, the quality of adhesion to the surface, and antiseptic properties.

- Cement-polymer. The composition includes Portland cement, polymers, sand, and plasticizers. The combination of cement and polymers gives a high resistance of the material under tensile and tensile loads, to the appearance of cracks.

In the manufacture of such types of protective coatings, high-strength, crack-resistant cement grades are used.

You can read more about cement compositions in the article – “Cement-based waterproofing: Features, types, and methods of its application“.

Penetrating compounds

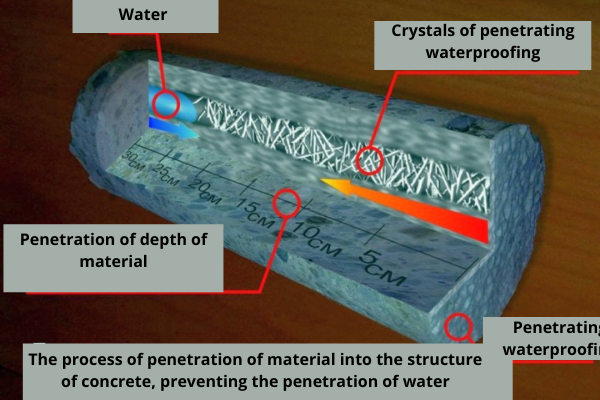

Waterproofing with a penetrating composition during the application process tends to penetrate into the structure of concrete, forming something like a protective membrane inside it. The penetration and growth of the so-called protective crystals of concrete occur due to the entry of the mixture into a chemical reaction with the alkalis inside the building material.

Thus, penetrating compounds contribute to strengthening the water resistance of building materials, including in cellars and other rooms with high humidity. As a rule, these materials are applied to good concrete that does not have large defects, microcracks, capillaries, and pores.

Important: Penetrating types of waterproofing very often do not solve the problem with leaks, since most leaks occur in places where concrete has pores and voids (as a result of poor vibration and ramming when filling), capillaries and microcracks, and penetrating compounds do not work there.

You can read more about penetrating waterproofing in the article – “Penetrating waterproofing: A detailed description of its work on concrete, types of materials and application technologies“.

The scheme of the penetrating types of waterproofing:

Injection method

For waterproofing of the cellar and other objects of high humidity, an injection method is used, which is characterized by the injection of insulating material with special pumping equipment into the structure under strong pressure. As a result of the injection, the water inside the concrete or brick is pushed out, and the voids are filled with the injection composition. A waterproof surface is created that prevents moisture from entering the room.

The method of pressing in the injection is a waterproofing mixture that is often used inside a structure made of the concrete, gas block, or brick, it is impossible to approach from the outside.

Injections can be carried out both after the completion of construction works and during their implementation.

You can read more about the injection method of waterproofing in the following article – “Injection waterproofing“.

Liquid rubber

Liquid rubber — is a product of bitumen processing, to which polymers, latex, and other modifying additives are added to ensure high-quality waterproofing. Most often, the main component of the mixture — is bitumen, in some modifications rubber is used. After application to the surface, the liquid rubber instantly freezes.

Depending on the modification, liquid rubber can be applied to the surface in various ways. It is divided into the following types:

- Sprayed. It is applied to the base by spraying, using the equipment.

- Coating. It is applied to the base manually with a roller and brush.

Modification of liquid rubber is selected, depending on the base and purpose of the building. For external waterproofing of the cellar and other underground rooms, this is an ideal choice, as it provides maximum adhesion to the surface of the base, and high-quality sealing of joints and seams. In addition, the material has a tensile coefficient of up to 800%, which prevents the occurrence of cracks in it.

You can read more about liquid rubber in the article – “Waterproofing with liquid rubber“.

Comparative table between the main properties of materials

Depending on the types and methods of applying waterproofing materials, each of them has certain properties, advantages, and disadvantages.

| Coating | Rubber | Penetrating | Pasting | |

| Application | Manually | With a device | Manually | Gas, burner |

| Layers | 2-3 | 1-2 | 2 | 2-3 |

| Preliminary preparation | Available | Available | Not available | Available |

| Adhesion with base | Complete | Complete | Complete | 10-20% |

| The availability of seams | Not available | Not available | Not available | Available |

| Elasticity | 50-300% | 500-700% | 0 % | 10-30% |

| Amount of work per day | 30-100m2 | 400-600m2 | 40-100m2 | 30-60m2 |

| Warranty period | 3 years | 7 years | 1 year | 3 year |

What is the best way to make waterproof the cellar — from the inside or from the outside?

To create a cellar, concrete, reinforced concrete, blocks or bricks are usually used; the porosity of these materials contributes to their gradual destruction, reducing the service life. The presence of seams between bricks or blocks leads to an increase in potential water leaks inside the built cellar. In order to avoid the destructive effects of groundwater, it is necessary to make waterproofing.

If it is possible to make waterproofing from the outside, of course, it should be done from the outside, since when installing external protection, the very material from which the walls and basement of the cellar are made will be protected from the destructive effects of water.

When the cellar is created already in the finished house, due to the inability to make external protection from water, waterproofing of the buried room from the inside is carried out.

Waterproofing of the cellar from the inside, is an integrated approach, taking into account vertical and horizontal protection.

The cellar of any building needs waterproofing work to avoid water entering it, and the formation of high humidity.

But it often happens that it is impossible to approach the built cellar from the outside, and the external waterproofing of the cellar was not carried out or was done with violations; puddles and drips appear in the room, and floors and walls get wet. This leads to the destruction of the foundation structure, the appearance of fungus and mold, and damage to things stored in the cellar, equipment, and products. In this case, its waterproofing is carried out from the inside.

As a rule, when installing internal protection against water, it is necessary to pay attention to 3 important design elements:

- Seams and joints – are the weakest point.

- Walls

- Floor

You can read more about internal waterproofing in the article – “Basement waterproofing from the inside: Methods, materials, and stages of work“.

Waterproofing of cold joints of the floor slab and walls in the cellar

Seams — are the weakest point in any construction and with broken external waterproofing, it is the seams and cracks that will start to pass water through in the first place.

As a rule, in the built cellars we can find the following types of seams:

- Cold seams – are the joints of the foundation slab or floor and walls, as well as the joints between the floor slab and the wall;

- Concreting seams, as a rule, are formed when concreting took place in several stages;

- Interlocking seams – typical for walls made of blocks;

- Inter-brick seams – typical for walls made of brick.

Before starting work on sealing seams in the cellar, it is necessary to choose the appropriate method, taking into account the following factors:

- Type of seam;

- Seam width and depth;

- Maximum possible loads;

- Features of the purpose and operation of the premises.

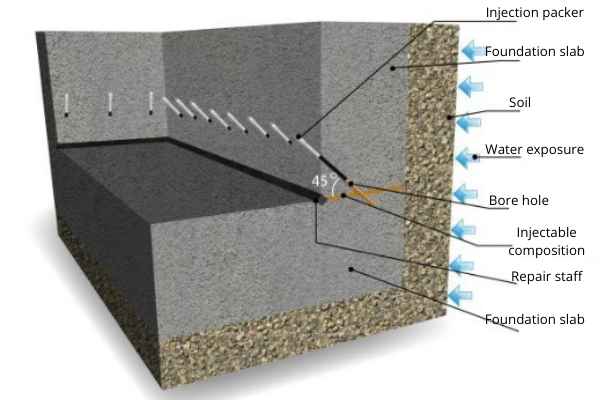

Insulation materials with high elasticity — sealants, polyurethane, or acrylic resins-are chosen to fill concreting joints, and cold and interblock joints. The method of work is– injection:

- Reinforcement of the seam before injection – the installation of small indenting with a layer-by-layer seal of a special expanding sealant, so that during injection, the injection compound passes inside the structure, and does not exit through a weak seam back into the room.

- The injection works – injectors are installed along the perimeter of the seam with a certain step, with the help of which the injection compound is injected into the seam.

You can read more about sealing joints in the article – “Sealing and waterproofing of joints – concrete, cold and deformation ones“.

The scheme of implementation of injection waterproofing in the area of the seam abutment slab-wall:

Scheme of injection during sealing of interblock joints:

Waterproofing of walls

Both concrete and brick, from which buildings are usually built, allow water to pass well. To prevent the destruction of the walls caused by the penetration of moisture into the cellar, waterproofing work should be carried out.

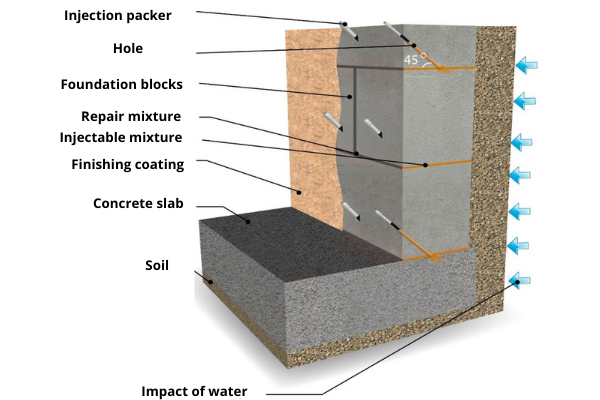

When performing waterproofing of basement walls from the inside, the following materials are selected:

- Insulation mixtures operating at negative water pressure (from outside to inside), for example, Hydro Paz – from the German company HYDRO. It is applied to the surface with a spatula or a trowel, or by spaying, using special equipment. It works with water pressure from the outside to the inside; thus, the material does not need additional fixation with a pressure wall or screed.

- Polyurethane, gel resins. They are used in the injection method of waterproofing. The work is carried out by special pumping equipment that pumps the mixture under high pressure into the body of the structure.

Waterproofing of the cellar walls from the inside, as a rule, is carried out if it is not possible to do it from the outside of the building, using methods of protection from moisture, by filling pores and voids in the walls of the base.

You can read more about the waterproofing of the foundation and walls in the following articles:

- Waterproofing of basement and house walls from outside and inside – Methods, materials, prices, and technology

- Foundation waterproofing installation: Methods, materials, prices, and recommendations of specialists

- Waterproofing of the ribbon foundation: Technology and materials

- Waterproofing of foundation blocks and walls

- Waterproofing of bricks and masonry

The scheme of performing injection waterproofing in the body of the wall:

Waterproofing of the floor

Since the floor in the cellar is below ground level, it is constantly exposed to groundwater, its penetration into the buried room. In this regard, the owners of the houses and commercial buildings conduct waterproofing of the floor in basements and cellars.

When choosing a waterproofing material and the method of its application, it is necessary to take into account such factors as the stage of work: during construction or during operation; base materials; the condition of the floor surface, as well as the presence or absence of a properly executed floor base slab.

2 options for waterproofing the floor in the cellar:

- If the base slab is made without violations, after sealing the seams or joints of the floor and wall slabs, a waterproofing material is applied to the floor with an approach to the walls up to the top (in the event that cellar walls are completely underground).

- If the floor slab is built with violations, then in this case it is recommended to restore completely the slab by destroying the existing one and erecting a new one or by using the existing floor as a so-called concrete base, on which waterproofing will be applied, and then reinforcement is performed, a swelling bentonite cord is laid and a reliable floor slab is filled.

You can read more about the waterproofing of the floor in the following articles:

- Waterproofing of the basement floor of the house: Methods, technologies of the installation, and materials

- Waterproofing of concrete floor in a private house – A detailed guide on how to do this work with your own hands and what materials to use at the same time

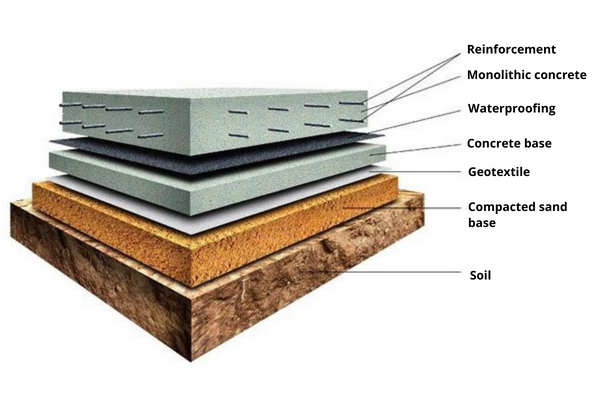

The scheme of the correct arrangement of the floor in the cellar:

Waterproofing of communication entry points

Communication entry points — are areas through which engineering communications are introduced from the outside into premises for various purposes. The entry points have different sizes, depending on the diameter of pipelines or cables.

If the room is underground, for example, a cellar, then from the outside, through the holes for entering communications, there is a high probability of water getting inside. In order to avoid leaks, it is necessary to conduct waterproofing of the communications entry points.

Depending on the size of the holes, operating conditions, and natural and climatic factors, the following waterproofing materials are used:

- Silicone, cable seals for the entrance of communications;

- Elastic waterproof sealants;

- Polyurethane fire-resistant foam, for cable wiring places;

- Shock-absorbing rubber seals;

- Resins for injection;

- In each specific case, certain types and volumes of materials are required for waterproofing work. In order to make a mistake with the choice, you should invite experienced specialists to diagnose the room and consult.

You can read more about the sealing of the places of communications entry points in the article – “Sealing and waterproofing of the entrances of communications to the building“

Waterproofing of the cellar from the outside — an integrated approach

In the cellar, located underground, due to the cool temperature, it is possible to store food and drinks. To prevent ground and atmospheric water from getting inside, causing structural destruction, dampness, and mold, waterproofing of the basement should be done outside, during the construction of the house.

With the right choice of materials and methods of waterproofing, various factors are taken into account:

- Building materials used in construction;

- Features of soils, ground, and surface waters;

- Natural-climatic conditions.

To carry out complex works on the external protection of the basement, both vertical and horizontal waterproofing is used, preventing water from entering the cellar through the vertical and horizontal surfaces of the structure.

In order to provide high-quality comprehensive protection of the cellar from the effects of water, it is necessary to choose materials with the following qualities:

- Strong adhesion of the insulating material to the surface, eliminating the penetration of moisture inside.

- The absence of seams, which are the weak point of the protective system.

- Elasticity. The high tensile coefficient of the material allows it to withstand various mechanical influences.

- The durability of the protection — is one of the important qualities of outdoor waterproofing, in conditions of exposure to moisture of various origins.

For the implementation of complex external waterproofing of the cellar, materials made on the basis of polyurethane or liquid rubber are most suitable, providing a high quality of the necessary protection.

You can read more about the different methods of external waterproofing in the following articles:

- How to do properly the waterproofing of the basement from the outside

- Horizontal waterproofing of the foundation: The technology of the installation and the materials necessary for this

- Vertical waterproofing: materials and methods of its installation

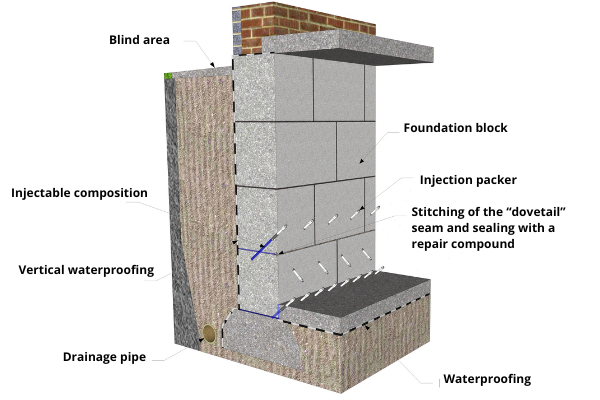

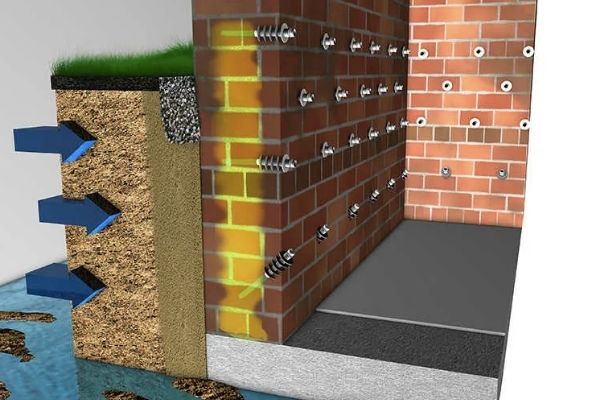

Waterproofing of a brick cellar: features and technical recommendations

All types of waterproofing materials can be used for the external waterproofing of a brick wall.

For internal waterproofing, depending on the condition of the brick structure of the cellar before choosing the material for its waterproofing, a special repair compound should be applied:

- The brickwork is undamaged and in good condition. It is recommended to use polymer-cement materials consisting of liquid polymers and binders. The mixture is applied to the walls in several layers, after which a protective coating is formed on the surface, preventing moisture from entering.

- Brick and masonry mortar loses strength, and crumble. In this case, repair compounds should be used. The main components are Portland cement, quartz sand, and chemical, reinforcing additives. Such compositions should have high strength, wear resistance, high adhesion, and reinforcing ability.

After processing the brick for reliable protection against the penetration of water and moisture, brick walls should be injected with special elastic compounds. An alternative option is to cover brick walls with a special waterproofing material that works on negative water pressure.

You can read more about brick waterproofing in the article – “Waterproofing of bricks and brickwork”

Waterproofing of the cellar from the inside from groundwater: features and technical recommendations

Maximum waterproofing of the cellar is provided when it is carried out both from the inside and from the outside of the house. In a building in operation mode, as a rule, the protection of a buried room from groundwater is possible only from the inside.

The fact of moisture penetration into the cellar means that waterproofing work is mandatory, in order to avoid the following adverse consequences:

- Destruction of concrete, brick, or other structural foundations of the house;

- The appearance of fungus, mold;

- Peeling of paint, and plaster;

- Constant leaks, flooding;

- The appearance of dampness.

In order to prevent the consequences leading to emergency situations, and damage to the structure and property, it is necessary to use the services of experienced specialists, with the help of which to carry out reliable waterproofing of the basement.

If there is groundwater in the cellar location area, it is also recommended to make a high-quality drainage system located at a level below the floor of the built cellar, so that drainage can relieve the pressure of groundwater not only on the walls of the structure but also on its floor or foundation.

You can read more about the drainage system installation in the article – “Turnkey drainage installation around the house: Proper drainage, its types, installation technologies, materials, schemes, and prices”.

Price for the performance of works

Waterproofing of the cellar — is a complex work, as a result of which the protection of the base of the structure is provided, preventing the penetration of water inside. Properly performed protection contributes to its safety and durability.

To perform waterproofing works, it is necessary to have certain types and qualities of materials, told, and equipment. The cost of waterproofing services consists of the following factors:

- Types, volumes, and cost of materials, and equipment;

- Seasonality;

- Technologies of work;

- Soil features;

- Condition of the room;

- The price level in the local construction market.

| Description of work | Unit of measurement | Price in $ |

| The arrangement of surfaced waterproofing on the horizon | m2 | starting from 36 |

| The arrangement of surfaced waterproofing on the vertical | m2 | starting from 49 |

| Installation of a self-adhesive membrane on the horizon | m2 | starting from 35 |

| Installation of a self-adhesive membrane on a vertical | m2 | starting from 48 |

| PVC membrane arrangement on the horizon | m2 | starting from 58 |

| PVC membrane arrangement on vertical | m2 | starting from 68 |

| Application of polyurea | m2 | starting from 90 |

| Application of mastic waterproofing | m2 | starting from 20 |

| Application of liquid rubber by spraying | m2 | starting from 25 |

| Application of liquid rubber manually | m2 | starting from 33 |

| Application of cement-mineral double-component waterproofing | m2 | starting from 60 |

| Arrangement of polyurethane waterproofing | m2 | starting from 60 |

| Application of penetrating compounds | m2 | starting from 60 |

| Application of primer | m2 | starting from 10 |

| Name of works related to internal waterproofing | Unit of measurement | Price in $ |

| Waterproofing of cold joints: -Works on the arrangement of indenting -clearing the indenting -layer-by-layer sealing of non-shrinkable composition | running meter | starting from 60 |

| Waterproofing of interblock joints: -Works on the arrangement of indenting -clearing the indenting -layer-by-layer sealing of non-shrinkable composition | running meter | starting from 40 |

| Waterproofing of expansion joints: -Work on the arrangement of the indenting -clearing the fines -sealing of the elastic profile -sealing of non-shrinkable composition -complex works on injection | running meter | starting from 490 |

| Injection waterproofing of seams/cut-off waterproofing -Works on the arrangement of indenting -clearing the indenting -layer-by-layer sealing of non-shrinkable composition -Work on the arrangement of boreholes and installation of packers -a complex of works on injection -dismantling of packers and sealing of injection holes | running meter | starting from 120 |

| Injection waterproofing into the concrete body -marking, Work on the arrangement of boreholes and installation of packers -a complex of works on injection -dismantling of packers and sealing of injection holes | m2 | starting from 190 |

| Injection waterproofing into the concrete body -marking, Work on the arrangement of boreholes and installation of packers -a complex of works on injection -dismantling of packers and sealing of injection holes | m2 | starting from 190 |

| Cement-mineral waterproofing | m2 | starting from 60 |

| Penetrating waterproofing | m2 | starting from 60 |

| Waterproofing of entry points of communications: -Works on the arrangement of indenting -clearing the indenting -layer-by-layer sealing of non-shrinkable composition -Work on the arrangement of boreholes and installation of packers -a complex of works on injection -dismantling of packers and sealing of injection holes | piece | starting from 690 |