Table of Contents

- Types of seams, joints, and abutments

-

What materials are used for waterproofing seams and joints?

- The technology of waterproofing and sealing of various types of joints and the materials used for this

- Sealing and waterproofing of concrete joints and joints in concrete

- Sealing and waterproofing of expansion and temperature joints

- Technology of sealing and waterproofing of expansion joints – How and with what materials can these works be performed:

- Waterproofing of cold joints and concreting joints

- Waterproofing of interlock joints

- Waterproofing of balcony and mounting seams

- Waterproofing of seams from the inside

- Waterproofing of foundation joints, walls, and basement

- Waterproofing of foundation joints

- Waterproofing of wall seams

- Waterproofing of basement seams

- Work on sealing and waterproofing of joints

The weakest points in any construction are seams. No building is complete without certain seams since it is impossible to build a house or a building without a single seam.

Seams are different. There are working, cold, temperature, expansion, control, sedimentary, interlock and interpolate joints.

Seams require special attention during construction because they can let in water or moisture if not done properly. When erecting a particular structure below ground level, for example, a basement, or other structures made of concrete, blocks or bricks, it is very important to use the technology of sealing joints correctly; otherwise, moisture and water can subsequently penetrate these places. To seal various types of joints during construction, there are many materials, such as sealants, mastics, bentonite profiles, swelling cords and tapes.

Types of seams, joints, and abutments

Concrete is an essential building material. It has durability and strength and can be shaped into various architectural forms. Design considerations are necessary to ensure proper operation of the structure. As a rule, any structure that is expected to be deeper than 6 meters underground will experience movement and dynamics.

Concrete should be designed and constructed in such a way as to adapt it to dynamics and movement:

Types of dynamic loading and movement:

- Shrinkage – initially rapid, less expressed as the concrete ages.

- Creep is a phenomenon that causes a redistribution of stresses away from the intensity points.

- Thermal motion – expansion, and contraction of the structure when the temperature changes.

- In order to adapt the design to movement, the structures are designed with “joints”. These joints are laid in concrete slabs at regular intervals to prevent the further development of cracks.

The design of the joint is important for the functioning of the overall structure — sealing these joints is a necessity.

Based on the above, various seams are formed in concrete and other structures.

There are various types of seams and joints:

- Expansion joints – separation between adjacent parts of the structure to allow movement during the dynamics of the structure.

- Control seams – designed to prevent accidental concrete cracks and facilitate filling after solidification.

- Construction, cold, process joints, or concreting joints – stopping points in the construction process where new concrete is poured over the existing concrete.

- Mounting seams – mounting gaps or junctions that need to be filled with insulating materials.

What materials are used for waterproofing seams and joints?

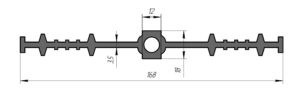

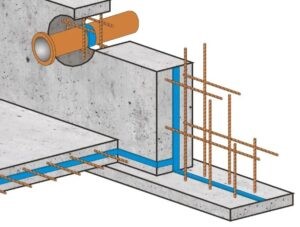

- A waterstop is a special waterproofing tape made of plasticized PVC or polymer materials. The waterstop is used mainly in monolithic construction and is laid in cold and expansion joints in order to serve as waterproofing.

- Bentonite swelling seam is a flexible rubber or rubber waterproofing profile that swells when water or moisture gets on it. When swelling, the bentonite seam serves as a waterproofing barrier that prevents water from passing. Bentonite or swelling seam is designed for waterproofing cold concreting joints.

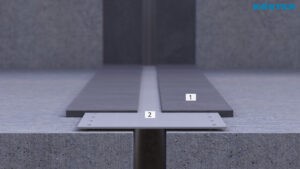

- Waterproofing tape – waterproofing TPO tapes withstand the dynamics and movements of the walls of joints in various directions while maintaining a high degree of sealing.

- Sealants – when it comes to sealing joints, non-shrinking and expanding sealants are mainly used here. When moisture enters, expanding sealants have the properties to expand, preventing moisture from passing through.

- Injection waterproofing – is supplied to the seam, under pressure using equipment, through a packer or pre-prepared tubes inside the seam. It is used to fill all hollows, micro cracks, and pores of the concrete.

You can find out more about Injection waterproofing here – Injection waterproofing.

The technology of waterproofing and sealing of various types of joints and the materials used for this

Construction seams and joints are the most common cause of leaks in structures below ground level. Therefore, the protection of joints in concrete is vital, especially considering the catastrophic consequences if they are ignored or if the wrong material is used to seal the joints. For each type of seam, there is its own sealing technology.

Next, we will study all the methods of waterproofing joints, junctions and seams and the materials used in this case.

Sealing and waterproofing of concrete joints and joints in concrete

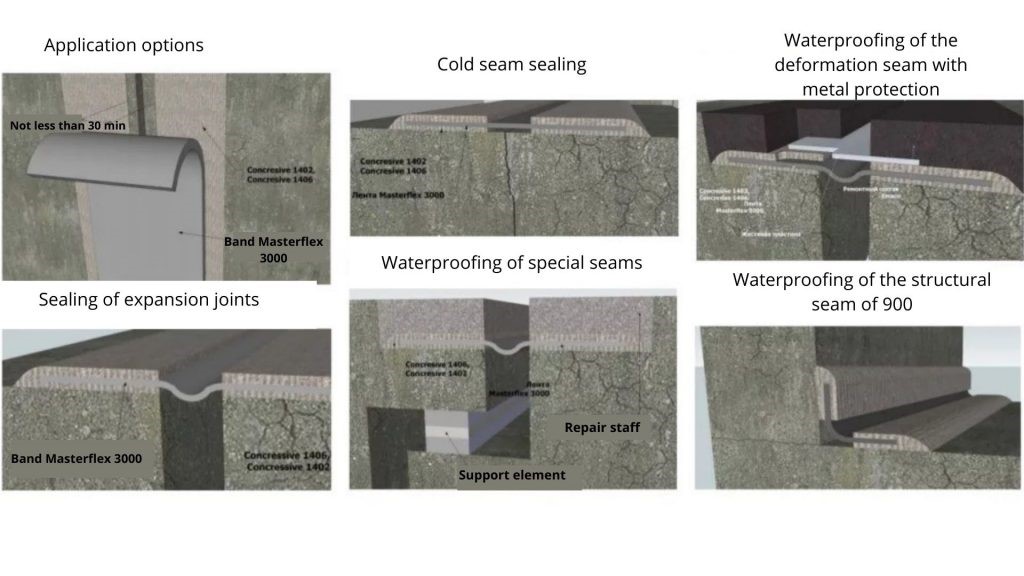

For a concrete structure to be completely waterproof, all its elements, including construction, cold and temperature joints, should be protected. The necessary waterproofing systems are usually supplemented in the technical specifications for the project. To seal concrete abutments, swelling seams, waterproofing tapes and sealants are usually used. If the builders did not pay due attention to the seams and joints during the construction of the building, they might leak later.

Sealing and waterproofing of expansion and temperature joints

Although buildings are often constructed using flexible materials, large building sizes require structural compensators called expansion joints. These seams are needed so that the constructed structure does not crack since the constructed building is exposed to various influences during its service life, such as:

* Ambient temperature during construction and expected temperature range during the life of the building;

* Seismic phenomena;

* Uneven soil precipitation and other impacts can cause dangerous loads that reduce structures’ bearing capacity.

Expansion joints are:

- Periodic breaks in the structure of buildings.

- The gap in the structure of the building is provided by the project architect or engineer to ensure the movement of the building due to temperature changes, soil precipitation, etc.

- A unit designed to safely absorb thermal expansion and compression of various building materials.

Expansion joints are usually found between sections of slabs, bridges and other structures. “Assembly” can be as simple as a freckled separation between two sections of the same materials. In the construction of concrete and concrete blocks, the term “control connection” is used, it serves similar purposes. Throughout the year, building facades and concrete slabs will expand and contract due to warming and cooling during the seasons. Structures will crack under thermal expansion and compression stress if expansion gaps are not provided.

When designing a building, it is very important to take into account expansion joints and their proper sealing and waterproofing since they are one of the weakest points in the structure of the building, If improperly sealed, they will skip a large amount of water into the structure.

Today, many builders and designers ignore the very expansion joints and do not pay due attention to their sealing, as a result, most of the rooms are put into operation where the same seams pass, leak, and need waterproofing.

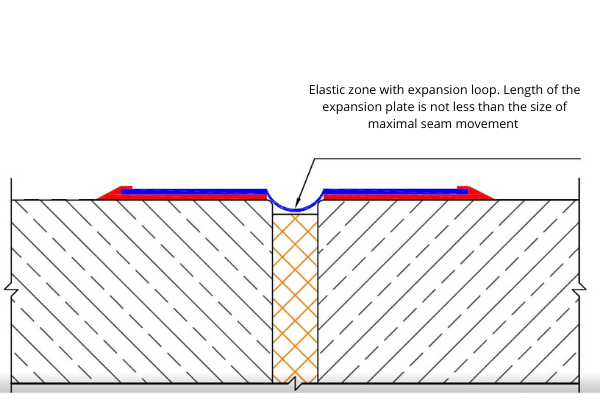

Technology of sealing and waterproofing of expansion joints – How and with what materials can these works be performed:

Outside:

Suppose there is access to this unit from the outside. In that case, it is best to use a system of special elastic tape for waterproofing expansion joints and epoxy glue (for fixing it), like the Sikadur-Combiflex system, which consists of a waterproofing TPO tape (Thermoplastic Polyphenols) and a specially developed Sikadur epoxy adhesive compound. This tape withstands significant and uneven movements of the seam walls in various directions while maintaining a high degree of sealing.

From the inside:

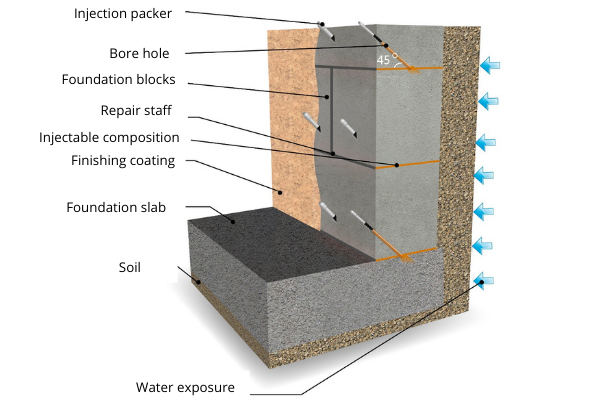

If there is no access to expansion joint or a cold joint from the outside, then its sealing must be performed from inside the room. For this purpose, it is better to use a combination of methods and materials:

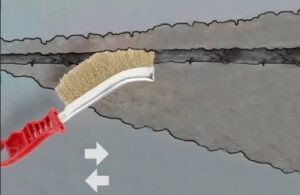

- Embroider and clean the seam;

- Seal the inside of the seam, the swelling profile according to the vilaterm type – this is done in order not to fill the seam to its entire height, but only its marginal zone;

- Seal another swelling profile;

- Seal the remaining gap with a special non-shrink compound or an expanding sealant;

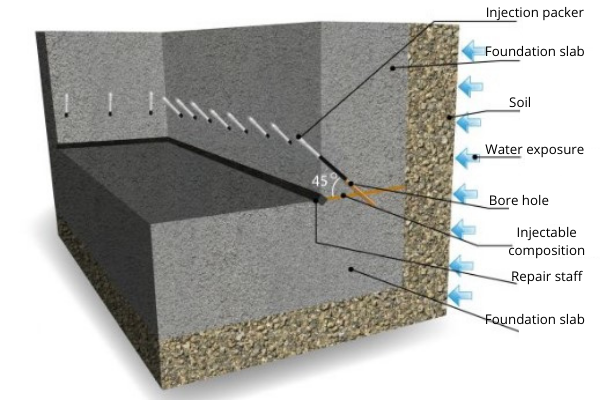

- Make the holes and install the packer around the perimeter of the seam so that, when performing the injection, the injected composition falls between the two installed seals;

- Perform injection waterproofing with the help of special equipment through the installed packers, a gel composition of the Hydroinject type (injection waterproofing from the German company Hydro) is fed into the seam, which spreads throughout the seam, hardens (without losing elasticity) and prevents water from entering the room;

- Install waterproofing TPO (Thermoplastic Polyphenols) tape on epoxy glue, according to the type of Sikadur-Combiflex system.

Waterproofing of cold joints and concreting joints

Cold joints in concrete are formed when there is a break in the concreting process.

For example:

- First, we fill the foundation slab, and then we begin to fill the walls – a cold seam is formed at the junction of the foundation slab and the wall.

- When pouring concrete walls, a break is made in the work – here, a cold seam is formed at the junction of the old and new concrete pouring.

Cold seams are weak points in the structure, and in the absence of good external waterproofing, they will skip water through in the first place. To protect cold seams during construction, it is necessary to lay a so-called swelling cord at the joints, following the established norms and technology of its laying.

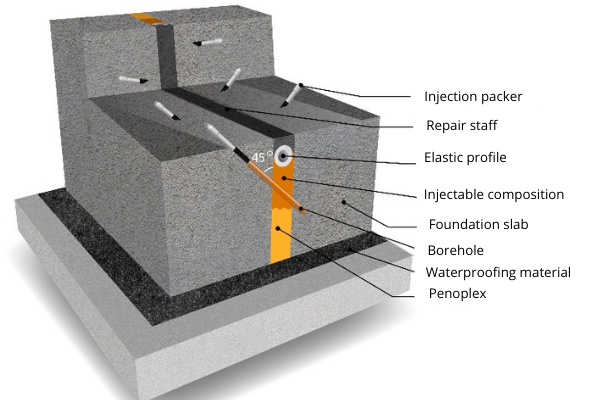

- Suppose violations were committed during concreting, the technology of sealing cold seams, as a result of which it is necessary to eliminate leaks at the joints of the cold seam from the inside of the room. In that case, the following stages of work should be followed:

The cold should be embroidered (make a small 3x2cm strobe) in the shape of a swallow;

2. The made wall chase should be cleaned and dust-free;

3. Layer-by-layer seal the non-shrink compound or expanding sealant, according to the HydroExpand type;

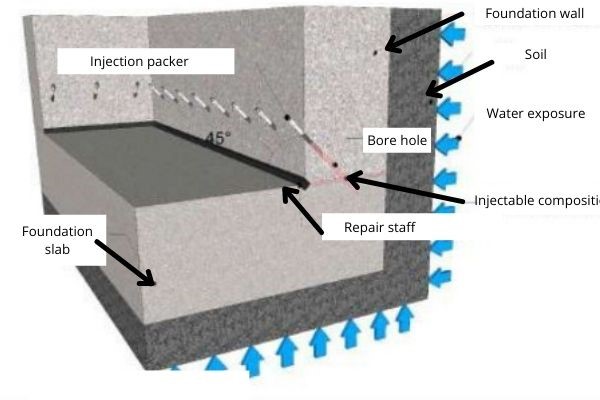

4. Mark the injection centers, along the perimeter of the seam, in steps of 0.20m in staggered order;

5. Drill boreholes-holes and install a packer (hollow tubes for injection composition wire);

6. Injection waterproofing – injection under pressure (using special equipment) of the polyurethane compounds, according to the type of HydroInject into a cold seam;

7. Removing packers;

8. Seal the injection centers with an expanding or non-shrinking sealant.

In addition to sealing the concreting joints with the help of sealants and injection formulations, it is also recommended to apply a special protective membrane of waterproofing compounds operating at negative water pressure (from outside to inside the room), according to the type of cement-mineral two-component waterproofing.

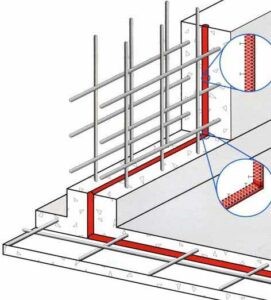

Waterproofing of interlock joints

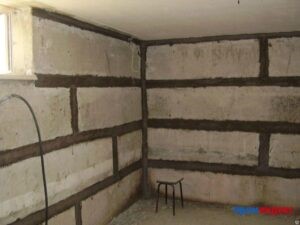

If the walls of the house are made of blocks, then they have interlocking seams that require special attention. Interlocking seams are those seams that are located between concrete blocks.

When erecting the walls of a basement or basement of blocks, it is very difficult to lay the blocks so that the solution under them lays everywhere evenly and perfectly, respectively, when conducting external waterproofing with surfaced or rolled materials, most likely in places where the solution lay unevenly, a hollow may form, which will be a weak spot for moisture and water to penetrate the room, through the interlocking seams.

If the house is already standing, and the interlocking seams leak moisture and water, then the following technology should be applied to seal them:

- The cold seam should be embroidered (make a small 3x2cm strobe);

- The made chase should be cleaned and dust-free.

- Layer-by-layer seals the non-shrink compound or expanding sealant, according to the HydroExpand type.

- If the interlocking joints are severely destroyed, or there are damages and microcracks in the blocks themselves, then the interlocking seams can be additionally injected.

In addition to sealing the interlock joints of concreting with the help of expanding and non-shrink sealants, it is also recommended to apply a waterproofing composition of water working at negative pressure, according to the type of cement-mineral two-component waterproofing.

Waterproofing of balcony and mounting seams

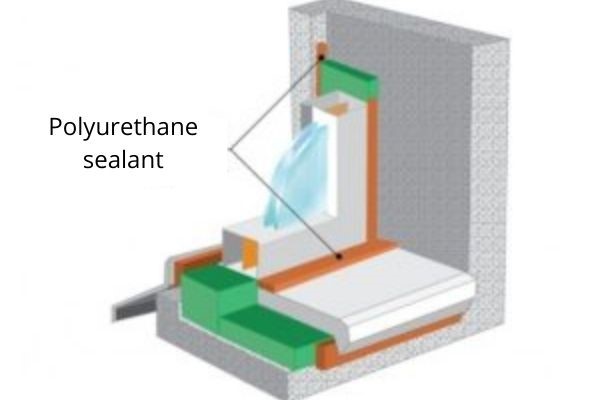

When installing windows or balconies, so-called mounting seams are formed. If these seams are not sealed in time with sealants or mounting foams, water may go through them in the future.

Waterproofing of seams from the inside

If we are talking about sealing seams from the inside, then most likely, we are talking about repairing and eliminating leaks in places where there are joints, joints, and seams. Waterproofing from the inside is carried out if access to the seam from the outside is impossible.

The work from the inside is carried out mainly by stitching the seams, sealing them with a swelling cord or sealant, and injecting 2-component polyurethane resin or gel (where the dynamics is).

When carrying out work from the inside, certain technological processes should be followed, depending on which joint we are dealing with. For each type of seam, different sealing and waterproofing technologies are used, you can read more about each in the continuation of this article.

Waterproofing of foundation joints, walls, and basement

As mentioned earlier, seams are one of the weakest points in any construction. Seams exist in the walls, the foundation, and the basement, and it does not matter what kind of material those very walls of the basement or foundation are made of.

Waterproofing of foundation joints

Foundations are different, but not depending on whether it is a ribbon foundation or a monolithic foundation slab, there may be seams.

There are several types of seams in the foundation:

- Expansion- is used mainly when it comes to a large building or structure.

- Cold or seam concreting – although when pouring the foundation, it is not recommended to take breaks and pour the foundation in several stages, sometimes you have to do concreting work in several stages with interruptions. This scheme is mainly used when working with objects of a large area or complex geometric shape, where continuous concreting in one layer is technically difficult or impossible at all.

The method of sealing these seams has been described above.

Waterproofing of wall seams

During the construction of walls, various types of seams can be formed, depending on how and with what material those walls were erected.

- Monolithic walls – When pouring concrete walls, seams may form if the walls are poured in several stages. When pouring walls from a monolith, at least 1 cold seam is almost always formed – this is the seam of the abutment of the slab wall since the walls are poured separately from the floor of the base.

- Walls made of FBS (foundation construction blocks) blocks – here, we are talking about the cold seam of the wall plate, as well as the seams between the blocks forming the walls.

- Brick walls – there will be seams both between the bricks and at the junction of the floor wall.

For waterproofing and protection of cold joints of the wall plate and other joints when installing walls, the method of seam stitching, layer-by-layer sealing of sealant, and injection (if necessary) is used.

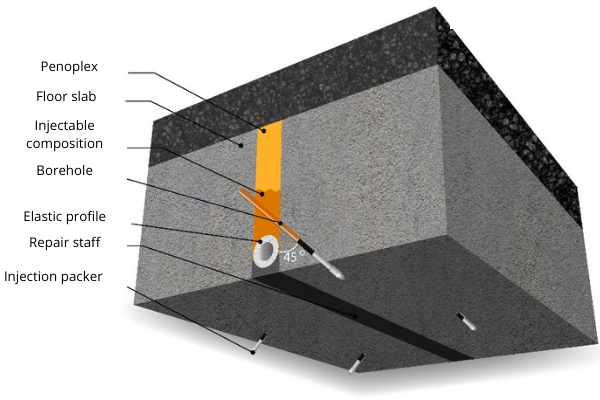

Waterproofing of basement seams

If there are leaks in the basement, then, first of all, it is necessary to determine from which places or seams are in the basement. If the water comes from downstairs, at the seam of the plate-wall junction (this happens in most basements), then it is not easy to embroider the lower seam of the wall-to-plate junction and seal the swelling cord or expanding sealant there, but also to inject it.

It is important: When stitching a cold seam, it is not enough to make a 3-5 sm chase, then seal the swelling cord into it, sealing it with a non-shrink compound, or initially seal a special expanding sealant there in layers – You need to additionally perform an injection (mainly 2-component polyurethane resin, HydroInject type) - this technology will serve as a cut-off and will not allow capillary moisture to rise up the wall. The produced chase is not made for the entire thickness of the wall and, accordingly, in the absence of an injection (as a cut-off), capillary moisture will pass right behind the strobe you made and come out, a wet spot just above your seam.

Work on sealing and waterproofing of joints

For each type of seam, its own set of works and its technology is used, with the help of which it is protected from future leaks. Seams are the most vulnerable places in the construction of your house, respectively, if the work on sealing the seams is performed poorly, in the future, they will leak water or moisture and will require expensive repairs.

Based on the above, in order to perform these works qualitatively, it is necessary to invite a professional waterproofing company with relevant experience and qualifications.

| Works description | Unit of measurement | Price in $ |

| Waterproofing of cold seams: -Work on the installation of the chase -Cleaning the chase -Layer-by-layer sealing of non-shrinkable composition | running meter | 20 |

| Waterproofing of interlock joints: -Work on the installation of the chase -Cleaning the chase -Layer-by-layer sealing of non-shrinkable composition | running meter | 16 |

| Waterproofing of expansion joints: -Work on the installation of the chase -Cleaning the chase -sealing of the elastic profile -Sealing of non-shrinkable composition -Complex works on injection | running meter | 100 |

| Waterproofing of expansion joints with waterproofing TPO (Thermoplastic Polyphenols) tape: Device for sealing the contour of the expansion seam using elastic tape on epoxy glue | running meter | 50 |

| Injection waterproofing of seams / cut-off waterproofing -Work on the installation of the chase -Cleaning the chase -Layer-by-layer sealing of non-shrinkable composition -Work on the installation of boreholes and installation of packers -A complex of works on injection -Dismantling of packers and sealing of injection holes | running meter | 1200 |

| Cement-mineral waterproofing | m2 | 20 |

| Waterproofing of the places of entry of communications: -Work on the installation of the chase -Cleaning the chase -Layer-by-layer sealing of non-shrinkable composition -Work on the installation of boreholes and installation of packers -Complex of works on injection -Dismantling of packers and sealing of injection holes | piece | 300 |