Table of Contents

- Materials for waterproofing and sealing pipe penetrations into the building

- How to properly seal the inputs of pipe penetrations into a house or building during construction and after it – Modern methods and materials

- Injection of pipe penetrations – Injection waterproofing

- Sealing of inputs. Prices and cost

- Waterproofing of the pipe entry in the basement and sealing technology of all entrances to the basement

- Waterproofing and sealing of cable entries

- Input sealing unit – drawings and design solutions

- Sample act of sealing pipe penetrations in the building unit

Places of pipe penetrations are places where various engineering pipes enter your building or private house from the outside. Pipe penetrations can be of various diameters and for various engineering purposes:

- Sewage system

- Water supply system

- Electricity

- Gas supply

- Heating

- Ventilation and air conditioning

If the holes through which pipes enter the buildings are placed underground (in the basement or plinth) or on the roof, balcony, or open terrace, then it can be a potential hazard of leakages. Places where the pipes, cables, etc., enter your building from the side of the street, are the weak places, through which water and moisture can further penetrate the premises. That is why special attention should be paid to their correct installation and waterproofing.

Materials for waterproofing and sealing pipe penetrations into the building

Materials and ways of pipes and cables protection from penetration of water:

- Special elastic waterproof sealants;

- Fire-fighting polyurethane foam for sealing cable penetrations

- Cable gland seal

- Rubber shock-absorbing seals GPD

- Silicone seals of pipe penetrations

- Pressure flanges

- Hermetic sleeves and insets

- Injection resins

Important: Not all the materials can suit your specific situation and unit. For example, the selected foam or sealant may not have adhesion to the material from which your pipe or sleeve is made. Despite the waterproofing of the input, water will easily penetrate into your basement or technical room.

By choosing a method or a material, it is very important to check that this method of waterproofing and the selected waterproofing material is suitable for you, for this it is better to invite an experienced company whose specialization is waterproofing works directly-this is exactly the organization that can only choose the right material, but also correctly perform all the work according to design standards and units so that everything is guaranteed to be dry.

When choosing a material for sealing pipe penetrations, it is better to choose compositions of the following qualities:

- High adhesion (coupling) to most synthetic and metal materials (of which cases, pipes and sleeves are made);

- Non-shrinkage of compositions or high expansion coefficient;

- High coefficient of elasticity for the prevention of cracks in material (as most of the inputs are the dynamic units);

- Waterproofness.

Sealants and mastics

Today there are quite a lot of different sealants designed to stop water in the area of passing cables and pipes. The main quality that this type of sealant should have, in addition to water resistance, is elasticity.

Elasticity is an important component since the places where different pipes enter are dynamic nodes subject to constant movement. In the absence of the desired coefficient of elasticity, the sealant will simply crack over time.

The most popular sealant for carrying out work to eliminate leaks through the entrance of various pipes into the building on the contact sleeve cable or pipe is Stopaq. Video with detailed instructions and a description of the technology of using sealant as waterproofing:

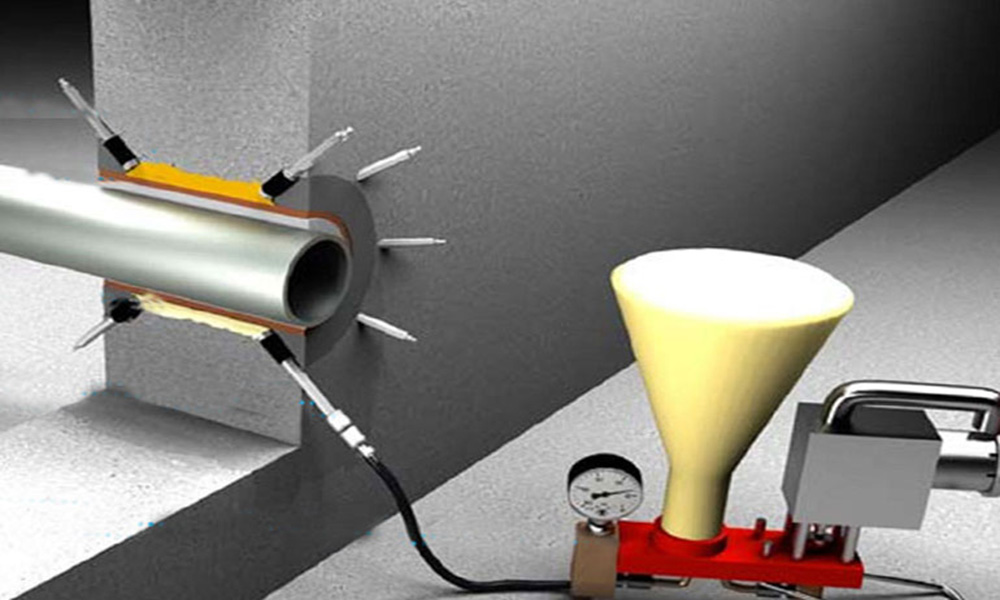

Polyurethane resins

Polyurethane resins are used in the injection method of waterproofing. With the help of a special pump and artificial pressure, polyurethane helium resins are injected through installed injectors into the required space or thickness of concrete, penetrating into all voids, microcracks, and pores expanding there. Thus, a waterproofing barrier is created.

Seals and couplings of various diameters

Various systems by type can serve as seals:

- Cable gland seal

- GPD rubber shock-absorbing seals

- Silicone seals of pipe penetrations

- Thermal boxes and thermal inserts

All these solutions are designed to prevent water and the external environment from entering your building. These solutions are installed mainly at the construction stage of the structure and are not intended for repair work during operation (but there are exceptions).

All these systems are mainly distinguished by the way they are installed:

- Bolting

- Concreting

- Expansion

- Welding

Each system has its own way of installing it. The systems are characterized by tightness, fire resistance, and a suitable base for them (brick, concrete, blocks, etc.).

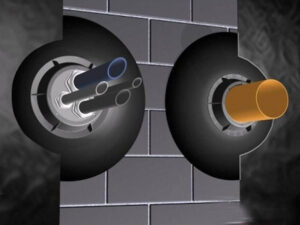

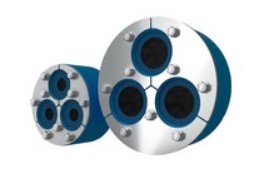

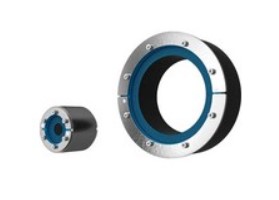

One of the world’s most famous manufacturers and suppliers of adaptable solutions for sealing cable and pipe penetrations is Roxtec. Here are some examples of different seals and couplings:

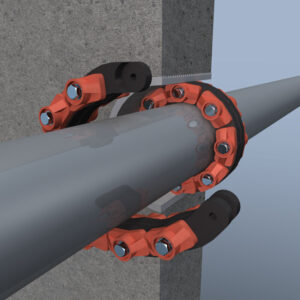

The installation method is an extension. Roxtec coupling Collapsible coupling for sealing existing cables and pipes

Penetration with a sleeve for fastening by welding; designed for single cables or pipes; provides electromagnetic compatibility.

Fastening with bolts. Roxtec input Collapsible coupling for sealing existing cables and pipes

The installation method is concreting. Roxtec penetration Round coupling for single cables and pipes inserted through the foundation.

How to properly seal the inputs of pipe penetrations into a house or building during construction and after it – Modern methods and materials

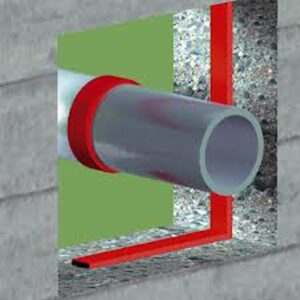

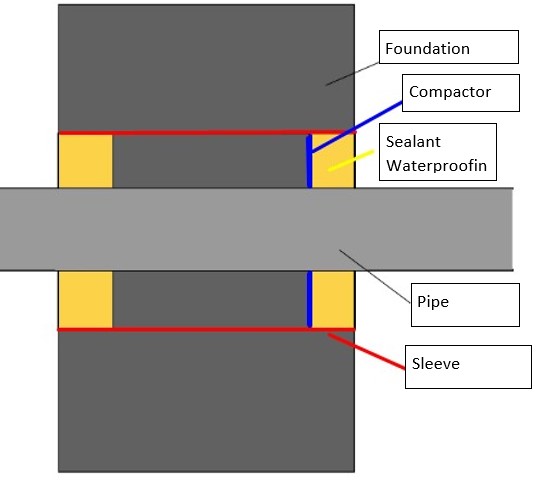

Pipes and cables enter the building through a special sleeve or case. The problem with leaks of the inlets, holes, and places of passage of pipes and electrical cables can occur both at the contact of the concrete sleeve and at the contact of the pipe or cable sleeve (if the pipe or cable passes through the installed sleeve). For maximum protection for pipe penetrations spots, from water penetration, it is recommended to isolate them in the following way:

Waterproofing on the contact sleeve concrete

At the construction stage:

A bentonite profile or a swelling cord is wrapped around the installed sleeve, its task is to protect the cold seam that forms on the contact of concrete and the metal sleeve when concreting the foundation or walls. After the installed cord has contact with the moisture contained in the concrete, it will begin to swell (by 300% or more), thereby blocking the water path through the concrete interface and the sleeve.

At the stage of repair or elimination of leaks:

If a leak is detected after the completion of construction, the following set of measures must be carried out to eliminate it:

- A small fine (3x2cm) is made around the sleeve.

- A non-shrink compound or an expanding sealant is compacted layer by layer into the completed toothing.

- Small holes (holes) are drilled around the installed sleeve into which hollow tubes are installed – the so-called packers (they can be metal or plastic).

- Waterproofing of engineering inputs by injection of the polyurethane resin is injected into the space located between the sleeve and the concrete with the help of equipment supplying the right composition under pressure, to the right place (injection pump).

- Injection material (polyurethane resin), under pressure penetrates into all cracks and voids and fills them thereby preventing water from passing.

Waterproofing on the contact sleeve pipe or sleeve cable

- In the spaces between the outlet of the sleeve or case, it is necessary to install a special sealer, according to the type of vilaterm (sealer), so that when sealing the space between the sleeve and the pipe, the waterproofing material or sealant could not pass along the entire space. This will not give the pipes space for deformation and can subsequently harm them.

- Layer by layer, seal a special waterproof sealant into the remaining opening (between the cable and the sleeve), leaving a small gap for the subsequent composition. If we are talking about an electrical cable, then the sealant should also be fireproof.

- Seal a special non-shrink compound or expand a sealant on top of the sealant.

Waterproofing of holes:

Sometimes there is a situation when pipes penetrate into the house, a hole would be made in the wall through which engineering systems were brought. In this case, this hole should be sealed, and engineering systems should be carried out through special cases or sleeves. The completed hole is filled with special hydrophobic concrete (with waterproofing additives) or sealed with a special non-shrink compound.

When pouring concrete, it is recommended to make a reinforced frame to give the structure additional stability. It is also necessary to consider the cold seams that form around the perimeter of the filling, they will be the weak points for potential water leakage. To protect cold joints before pouring concrete, it is recommended to install a bentonite profile or a so-called swelling cord along their perimeter (when moisture enters, it swells and does not allow water to pass).

Further, the entire surface is treated with a special waterproofing compound operating at negative water pressure, according to the type of Polymer-mineral elastic waterproofing HydroPaz. After these measures are completed, it is necessary to perform injection waterproofing to fill the remaining gap betwenn concrete wall and the pipe.

Injection of pipe penetrations – Injection waterproofing

As mentioned earlier, injection of injections is one of the most effective ways to protect this zone from water since injection formulations are supplied under pressure and have the properties to fill absolutely all voids and spaces. The injection, in fact, enters the space between the concrete and the sleeve, case, cable, pipe and fills it and possible voids and microcracks around it. Thus, injectable formulations or materials block water and prevent it from entering the room.

Injection waterproofing is mainly used when builders don’t pay due attention to the issue of sealing the entry points of engineering networks during construction, which eventually leads to the formation of leaks in the building.

Table border about the injection method of waterproofing, you can read in the article – “Injection waterproofing“.

Sealing of inputs. Prices and cost

Below there are average prices for the performance of work on sealing pipe penetrations of various pipe penetrations. Prices and the cost of work is depending on the diameter and the list of work performed. The prices listed below do not take into account the cost of the sealants or other materials used.

|

Works description |

Diameter of the input |

Unit of measure ment |

Price in $ |

|

Waterproofing of pipe penetrations: |

50 |

1 piece |

1400 |

|

110 |

1 piece |

1500 |

|

|

160 |

1 piece |

1600 |

|

|

Waterproofing pipe penetrations: |

50 |

1 piece |

2400 |

|

110 |

1 piece |

2700 |

|

|

160 |

1 piece |

2900 |

|

|

Waterproofing opipe penetrations by the Stopaq system with the performance of work on strapping with an elastic profile and its sealing |

180 |

1 piece |

2900 |

|

Sealing pipe penetrations by Injection: – Stitching of the seam of the abutment / the device of the fine |

50 |

1 piece |

3100 |

|

110 |

1 piece |

3400 |

|

|

160 |

1 |

3900 |

Sealing of the inputs the price in the estimate

The above prices do not take into account the complexity of the work and other factors that may affect the prices and the final cost of the work. Suppose you want to get an accurate estimate with the final price per unit and the final cost, taking into account the materials and works used. In that case, you need to call a specialist or engineer from the company that deals specifically with waterproofing to inspect your facility.

An experienced engineer, having familiarized himself with your object and the specific situation with inputs and leaks, will be able to draw up a professional technical task, which he will transfer to the estimating department, which in turn will make you a detailed estimate where you will see not only the final cost of the estimate but also the prices for each position.

Waterproofing of the pipe entry in the basement and sealing technology of all entrances to the basement

When it comes to laying engineering networks, they are mainly brought into the building underground through the foundation, plinth, or basement. In most cases, pipe penetration into the house is carried out through the basement. According to the rules, the laying of engineering wiring in the building is carried out through the installation of a sleeve or case.

This is done in order not to damage the pipe or cable during subsidence of the soil and/or dynamics of movement of the foundation or building. As a rule, the places where engineering systems enter the building are quite weak points in terms of the possible penetration of water or moisture into the basement through them, and particularly this circumstance that makes it necessary to pay special attention to their sealing and waterproofing during construction.

Suppose the technology of installation and sealing of passages for pipes or cable entries into the basement is violated during the construction of a house. In that case, you’ll have a risk of the following consequences:

- Penetration of water into the basement of the house can eventually lead to flooding of the basement and damage to property and decoration.

- The formation of a wet spot around the place of pipe penetrations will eventually lead to the formation of mold and fungus in your basement which is dangerous to human health.

Waterproofing and sealing of cable entries

It is better to install cables into the house through a specially installed sleeve, as this will provide an opportunity to add new cables and repair old ones. The sealing of the cable entries entering the building should be carried out using a non-flammable waterproofing material. In addition to various sealants, there are also many devices on the market for sealing cable entries.

Input sealing unit – drawings and design solutions

Here you can download various design units for sealing pipe passages and various cables into a house or building. It is important to note that each case is individual and may have its own characteristics that require adjustments to standard solutions. That is why it is better to call an experienced specialist at your home or institution before deciding on the waterproofing method.

- Unit for entering engineering water supply systems into a concrete collector

- Unit for entering a water pipe into a concrete

- Collector well in a situation where there is a rigid fixation of the pipe

- Vibration-resistant assembly using a flange cuff

- Repair of units with problematic sealing of the entrance of engineering cables

Sample act of sealing pipe penetrations in the building unit

Suppose you are performing work or you are performing work on sealing various engineering inputs into your structure or building. In that case, you can hand over or accept these works according to the act of sealing the inputs (outputs). On our website, you can download several samples of such acts.

The act of sealing pipe penetrations in the basement.

You can draw up these acts yourself by downloading the necessary samples of acts and filling in the details of the contractor and the customer.