Table of Contents

- Application of waterproofing by injection – when and where should it be applied?

- Injection materials for waterproofing

- Injection waterproofing price

- Injection technology – how the injection process takes place

- Injection waterproofing of the foundation

- Injection waterproofing of the basement from the inside

- Injection waterproofing of concrete

- Waterproofing by injection – advantages, and disadvantages

This is a method in which special mixtures are injected into brick or concrete using pressure and certain equipment. With this method, all voids, pores and cracks are filled, squeezing out existing moisture and water from them. In addition to the fact that the water is squeezed out, all these voids are filled with this injection compound, which prevents further leaks in the room.

The main difference between this method of waterproofing is the penetration of material into the structure. Sometimes there are situations when the injection is made not inside concrete or a brick base, but behind it – this method of insulation is called veil waterproofing.

Application of waterproofing by injection – when and where should it be applied?

If there is moisture in the room, it means that the protective coating on the outside is broken.

It would be ideal to fix the shortcomings of waterproofing from the outside, but, unfortunately, this is not always possible for economic and other reasons. This method of combating penetrating moisture is mainly used in the underground part of buildings (below level 0), when there is no access to the place from the outside.

For example, when it comes to a building in the center of Moscow, where there is a leak in the basement, but due to the fact that there are other buildings nearby, communications, or a road pass, it is impossible to dig out one side or the other, and the defect should be eliminated.

Waterproofing by injection is also used in private homes, where the owner of the house cannot or does not want to dig out the building from the outside.

The injection waterproofing method is suitable for eliminating leaks in structures made of concrete or brick:

- Foundations

- Basements

- Ground floors

- Walls

- Tanks

- Swimming pools

- Places where communications are entered

- Cold seams

- Expansion joints

- Cracks

- Interstory floors

- Pits

- Roofing floors

It is important to note that for each type of repair and coating (concrete, brick, cold, or deformation seam), its own injection composition of suitable viscosity and other qualities is used. For example, for most brick walls, it is necessary to use helium injection mixtures, since they do not have a strong coefficient of expansion and will not destroy brittle bricks.

Also, helium compounds are most suitable for dynamic nodes, since polyurethane resins crack quickly during dynamics. In any case, when choosing a component for a particular structure, it is best to call a representative of the contractor company who will perform such work, since it is he who, after looking at your object and the place of leakage, will be able to determine what is needed to maximize the protection of your premises.

Injection materials for waterproofing

Injection materials of various modifications successfully cope with a number of the most difficult waterproofing problems.

Among them are leaks in places such as:

- Underground tunnels;

- Metro stations;

- Desalination plants;

- Structures are built in areas with high groundwater.

Injection materials are based on a combination of unique technologies and innovative components that are injected using special equipment.

Today, mainly specialized firms use the following materials:

- Polyurethane resins under high and low pressure;

- Polyurethane hydrophobic and hydrophilic resins;

- Single-component and double-component materials with specialized additives;

- Injection resins with high-speed reaction, to block the active flow of water;

- Acrylic gels

- Polyurethane gels;

- Cement materials;

- Epoxy resins;

- Injection against the capillary rise of water.

Attributes of Polyurethane (PU) resin

Liquid components that react to water and have different viscosity and expansion coefficients penetrate into the smallest pores, cavities, voids, and cracks of the concrete structure. Special equipment and high-pressure hydraulic hoses are used for polyurethane injections, which are crucial when access to the repair area is limited. As a rule, injection materials of different viscosity are used in different situations and with different types of leaks. The selection of the right materials is best trusted by specialists, namely field engineers (who were at your facility and got acquainted with all possible nuances) and those companies that you want to attract to perform these responsible works.

Injection waterproofing price

Today, there are a lot of different companies in the injection components market, both domestic and foreign, the most famous and high-quality of them are BASF plant materials and the HydroInject injection components line of the HYDRO plant. All these manufacturers have their own price segment, and the price of materials where imported components are present will be significantly higher than their Russian counterparts. But here it is important to look not only at prices but also at quality since in most cases a shoddy construction will be of poor quality and will last no more than 1-3 years, after which leaks may start again.

When it’s to the price of the injection component, it is also important to pay attention to its consumption per 1 running meter or 1 m2, since, perhaps, its price is low. Still, at the same time it has a large consumption, respectively, the price per m2 or 1 running meter, will be collectively higher than the material, whose cost per 1 kg is cheaper.

If we talk about the price or cost of injection waterproofing in general – material + work, then it is important to make sure that when specifying the total cost of work, prices are fixed and indicated for 1m2 or 1 meter running, and not for 1 kg of material. Since if the prices are indicated per kg, then when performing waterproofing actions, contractors can go to the trick, putting in the estimated less kg of material than necessary and when using the specified amount, request additional money, which in the end may exceed the initial calculation by 2 times.

| Works description | Unit of measurement | Price in dollars |

| Waterproofing of cold joints: -the installation of indent -clearing the indent -layer-by-layer sealing of non-shrinkable mixture | running meter | 200 |

| Waterproofing of interblock joints: -the installation of indent -clearing the indent -layer-by-layer sealing of non-shrinkable mixture | running meter | 100 |

| Waterproofing of expansion joints: -the installation of indent -clearing the indent -sealing of the elastic profile -sealing of non-shrinkable mixture -complex of works on injection | running meter | 700 |

| Injection waterproofing of seams / cut-off waterproofing -the installation of indent -clearing the indent -layer-by-layer sealing of non-shrinkable mixture -the installation of bores and the installation of packers -a complex of works on injection -dismantling of packers and sealing of injection holes | running meter | 300 |

| Injection waterproofing into the concrete body -marking, the installation of holes and installation of packers -a complex of works on injection -dismantling of packers and sealing of injection holes | m2 | 400 |

| Injection waterproofing into the brick body -marking, arrangement of holes and installation of packers – complex of works on injection – dismantling of packers and sealing of injection holes | m2 | 400 |

| Cement-mineral waterproofing | m2 | 180 |

| Penetrating waterproofing | m2 | 180 |

| Waterproofing of places of entry of communications: -the installation of indent -clearing the indent -layer-by-layer sealing of non-shrinkable mixture -the installation of bores and the installation of packers -a complex of works on injection -dismantling of packers and sealing of injection holes | piece | 1900 |

Calculator of the cost of injection waterproofing

Calculation of the cost of injection and suture waterproofing

The total cost of waterproofing

Injection technology – how the injection process takes place

The injection process depends on what exactly needs to be injected. Accordingly, there is a difference between injecting concrete into the body, cold seams, deformation seams, or places of entry of communications.

Works sequence:

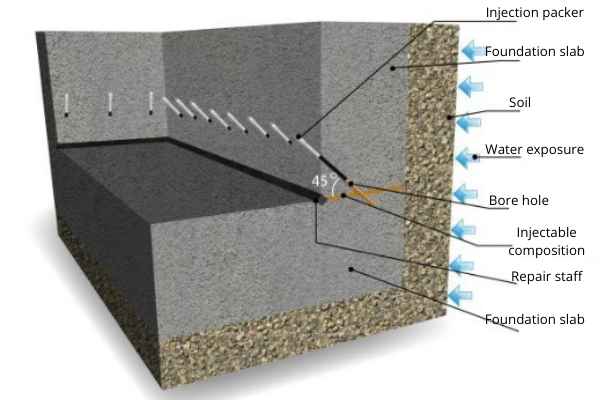

The process of injection into the body of the structure:

- First of all, you need to make a markup to install packers. After that, we drill holes about 4 inches deep on one side of the crack or seam and at an angle, so that when the hole crosses the crack, it does so in the center. For example, on an 8-inch-thick wall, we drill so that the hole intersects 4 inches inside the wall. We drill approximately every 5sm from one end of the seam to the other, and then we install injection ports or packers, they can be plastic or metal.

- Then we use a high-pressure pump to pump water and acid, this cleans the injection area and squeezes out the existing moisture from the pores of the base of the building.

- Next, an injection compound, polyurethane, is injected into the installed ports under pressure. As polyurethane mixes with moisture, inside the wall and in the pores of the material, it begins to expand into foam rubber, and the mixed product (polyurethane foam) begins to penetrate into all pores and voids, expand and seal it. The injection should be performed from one end of the injected surface and continue every 5 sm to the other end. As a result, all voids and weak areas will be filled with polyurethane injection composition from groundwater. If we are talking about a crack in the basement, then its upper part is visible from the outside, and with proper injection, you will see that foam rubber oozes out of it, in fact, the seal passes right through it. This is good protection from groundwater.

Waterproofing of cold concreting joints or cut-off waterproofing by injection:

- First, an indent is made.

- Then this fine is sealed with a special expanding sealant or repair compound so that the injection resin goes inside (into the thickness of the wall) and does not come out in a weak cold seam back.

- The rest of the process is identical to the injection into the body described above.

Injection waterproofing of the foundation

When moisture appears in your house, the cause of which is a problem in the waterproofing of the foundation, the most correct method to solve this problem is to dig out the building from the outside and restore the protective waterproofing. If for some reason it is impossible to do this, then it is necessary to perform waterproofing work from the inside. To date, this is the most highly effective repair method used to eliminate leaks in basements and foundations from the inside.

Injection waterproofing of foundations and walls with polyurethane

This type of injection is perhaps the most common method used to repair water intake leaks in general, due to its versatility. It is used exclusively to stop leaks in concrete structures, foundations, subway tunnels, and mines.

Waterproofing of the foundation by injection method

Polyurethane injection involves the injection of activated polyurethane resin under pressure through packers hammered into holes drilled in the concrete. The injected resin passes through the entire thickness of the foundation wall or slab (usually 8 inches), expands, and solidifies in the cavity, thereby eliminating cavities and voids, and preventing water from entering your basement. The polyurethane injection waterproofing system is the introduction of a compound into concrete, by drilling and injection under pressure, of a double-component polyurethane resin using specialized equipment, thus filling voids and cavities inside. It is a safe and environmentally friendly solution to stop the penetration of water through foundations, basements, elevator shafts, walls, and concrete joints.

For what types of foundation leaks, injection insulation is suitable:

- in cold seams formed when pouring the foundation and walls of the basement;

- in the expansion joints;

- moisture on the surface of the foundation plate, floor, or foundation walls;

- cracks that have formed in the basement;

- places where communications are entered. Underground pipe penetrations in the wall for electrical pipelines, gas pipelines, air conditioning lines, and pipes.

Important: To perform work on the injection waterproofing of the foundation, you should not choose cheap polyurethane compounds, since in most cases they have poor elasticity, adhesion and resistance to water and aggressive environment. The use of cheap injection resins is fraught with a recurrence of leakage in a year or two. As a recommendation: it is best to use materials from such well-known manufacturers as BASF, CGI or HYDRO with its line of HydroInject polyurethane resins.

You can read more about the waterproofing of the foundation in the following articles:

- Installation of waterproofing foundation: Methods, materials, prices, and recommendations of specialists

- Horizontal waterproofing of the foundation: The technology of installation and the materials necessary for this

- Waterproofing of the tape foundation: Technology and materials

- Waterproofing of foundation blocks and walls

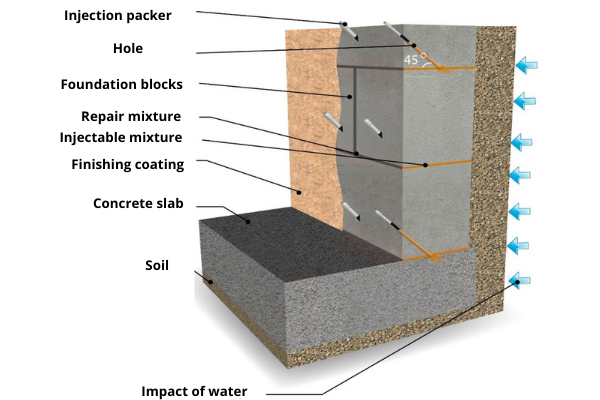

Injection waterproofing of the basement from the inside

Groundwater often washes away the soil. Waterproofing of the basement is always best done from the outside, not from the inside so that it works for clamping, not for separation. This is great protection from groundwater. But there are situations when there is no access to the basement from the outside since the house or building has already been built and in order to get to the walls of the lower room or foundation, you need to dig out the building or house from the outside, which is not always possible.

In this case, waterproofing is performed from the inside. Protection from groundwater from inside the basement is mainly performed by injection waterproofing, by injecting special polyurethane mixtures into the concrete body, seams, and cracks, depending on where leaks are observed. There are different materials for waterproofing, their choice depends on the type of leakage, the material from which the foundation, and the main supporting structures of the basement are made. The most popular injection mixtures are helium compounds (designed mainly for brick walls) and polyurethane compounds (designed mainly for concrete walls, gas blocks, etc.).

Injection waterproofing with polyurethane

Polyurethane injection involves an injection into leaking seams, cracks, and problematic areas of the floor and foundation walls. This type of repair is most suitable for monolithic concrete slabs and concrete blocks of various types, it is from these 2 materials that most basements are built.

Such an injection is very reliable from groundwater and provides long-lasting protection with the correct introduction of the composition by a professional waterproofing specialist from the inside.

For durability and reliability, the injection composition of polyurethane itself is also important. Here, expensive imported materials from BASF or, or a more optimal line of HydroInject polyurethanes from Hydro are best suited.

You can read more about basement waterproofing in the following articles:

- Waterproofing of the basement from the inside: Methods, materials, and stages of work

- How to properly waterproof the basement from the outside

Injection waterproofing of concrete

Concrete is a mixture of sand, stone, cement, and a liquid component. Quite often, water is added to the mixture to help it spill easier with the molds. When this happens, the concrete hardens and begins to harden, this process actually continues for many years (concrete continues to increase compressive strength for many years). In most cases, pores and voids remain in it, including due to poor quality, and due to the fact that the concrete was poorly vibrated during pouring.

Most of the shrinkage occurs during the first 5 years, older houses are less likely to shrink. When walls are injected, polyurethane resin penetrates the pores and voids with high pressure and expands so as to completely close them. It is very important that polyurethane penetrates exactly inside the basement wall itself from the inside in order to fill all the voids as much as possible so that in the future moisture could not pass through these weak points.

Injection waterproofing is the most reliable method of waterproofing the basement from the inside.

Injection into concrete:

If we are talking about injection, it is into the concrete body, then marking is initially done, after which holes are drilled and special hollow tubes made of plastic or metal, called injection packers, are installed. They have a small price. The packer data should be set at a certain step and at a certain slope. After the packers are installed, injection material is injected into the concrete body under pressure with the help of certain equipment. After the work is completed, the installed packers are cut off, and the holes are sealed with a repair compound.

You can read more about concrete waterproofing in the article – “Concrete waterproofing and how to do it: Types of materials and methods of installation”.

Waterproofing by injection – advantages, and disadvantages

Injection waterproofing — Advantages:

- The ability to perform waterproofing of the room from the inside;

- Ability to stop water in difficult areas;

- The long warranty period for works (from 6 years).

Injection waterproofing — Disadvantages:

- High cost;

- It is necessary to have special equipment to carry out the work;

- To carry out the work, you need to have the necessary qualifications and experience;

- It cannot completely replace the external waterproofing, as it does not solve the main problem – water continues to saturate the walls from the outside (since the external waterproofing is broken) and gradually destroy it.

Important: The injection waterproofing method is the most effective method of solving problems with water entering your basement through a foundation slab or walls when there is no access from the outside. It is important to pay attention to the fact that some construction companies and contractors may not offer you to use injection waterproofing to protect your foundation and basement, not because this method is ineffective, but because they do not have the necessary skills and expensive equipment to perform injection work. Accordingly, when choosing the method of waterproofing your foundation from the inside, it is best to use the services of large and reliable companies with an office, their own equipment, a fleet and qualified engineers – in most cases, such companies have a guarantee for these works of at least 6 years.