Snow holders ensure safe snow removal from the roof, in most cases, the installation of a snow holder is necessary to prevent damage to the roof. Here are the main reasons for installing a snow holder:

- The roofing has a smooth surface;

- A large amount of snow precipitation;

- The length of the roof slopes has large size;

- The angle of inclination of the roof is more than 50 degrees.

Installation of snow holders is necessary for all regions with even minor snow precipitation and is suitable for roofs with different configurations. In some cases, the installation of snow holders is not necessary:

- The angle of inclination of the roof is less than 30 degrees;

- In a region with little snow precipitation;

- For household premises with a building height of no more than 2 meters;

- In the presence of a roof fence that partially performs the function of a snow holder.

Read more about the roof structure in these articles:

— Reconstruction of the roof of the building and the roof of a private house;

What is a snow holder and why it is necessary?

Snow holders – are an element of a roofing structure that holds snow cover over the entire roof area, or divides snow layers into smaller ones, and also ensures the safety of being on and under the roof.

Now there is a large selection of various snow holders, snow supports, and snow cutters, when choosing a suitable barrier system, it is necessary to study carefully the functions of each type and take into account the features of the roof design, as well as the region of construction.

Functions of snow-holding devices:

- Separates snow layers, and provides a small amount of snowfall;

- Keeps the snow cover on the roofing for a long time;

- Prevents deformation of the drainage system due to the severity of the snow cover;

- Does not allow injuries to passers-by and damage to property after snowfall;

- Ensures safe operation during roof maintenance;

- Saves time and finances on snow cleaning.

Types of snow holders

Different snow holders have different purposes and different bearing capacities, the choice of any type of snow-retaining system is carried out depending on the configuration of the roof and its coating. Let’s consider the main types of snow-retaining systems:

- Tubular snow cutters are the most common type of snow-holding installation – a universal barrier that fits most roofing materials is installed in various regions and has a good load-bearing capacity, the design allows you to cut large layers of snow into smaller parts.

- Corner snowshoes – very affordably priced. As an independent element, it is installed on flatter roofs, mainly used as an auxiliary part of other types of snow-retaining facilities.

- Lattice snow holders – have a different configuration and attractive appearance, at the same time they have a high load-bearing capacity and are used as an independent type of snow-holding facility.

- Tow snow holders – also have the purpose of point snow holders, are suitable for dividing a large amount of snow cover into smaller ones, practically have no bearing capacity, and are mainly used as an auxiliary element.

Tubular snow cutters

Tubular snow cutters are one of the most reliable and effective structures for retaining snow cover on the roof surface, its main advantage is the separation of snow cover into several parts, which makes snow coming off the roof safer. They are installed in one row along the entire perimeter of the roof, which saves time for the installation of snow cutters on the roof.

Tubular snow cutters have an external resemblance to corners, where there are two rows of metal pipes, the fastening of which is installed to the elements of the truss system or lathing. This design can withstand heavy loads in winter, it is able to hold a significant amount of snow precipitation on the roof surface.

The main function of snow cutters – is the division of a large layer of snow mass into smaller ones, which reduces the size and mass of snow that comes off the roof.

If the roofing sheet has a smooth surface that is unable to retain the snow mass on its surface, then the installation of strong snow collectors is absolutely necessary.

Basically, tubular snow cutters are installed on metal roofs: seam roofs, roofs made of corrugated board, or metal tiles. They do allow not to accumulate of a large mass of snow but provide the snow flow gradually in small volumes. If you neglect this rule, then during the period of operation, the metal sheet may deform and lead to leakage and the cost of repairing the roof.

Design features:

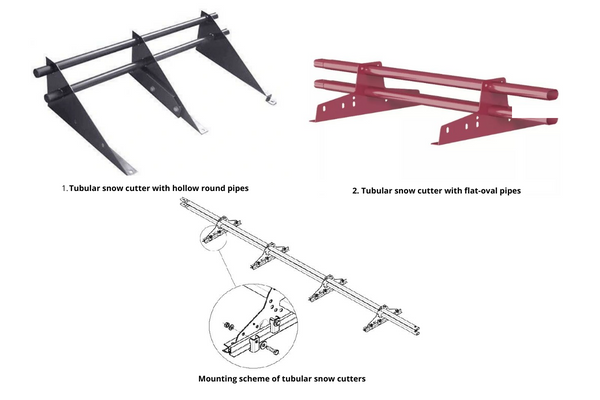

Tubular snow cutters consist of two pipes that are fixed parallel to the edge of the roof using a bracket. For the manufacture of this type of snow cutter, mainly galvanized steel is used, which is painted to protect against corrosion, but there are also structures made of aluminum and copper. By design, snow cutters are divided into:

- With hollow pipes – the diameter of such pipes is 3-4 sm, installation is carried out on a bracket in two rows.

- With flat-oval pipes – the size of such pipes is 4х2 sm or 4,5х2,5 sm, special brackets are used for such pipes and they are installed in one or more rows.

Characteristics of tubular snow cutters:

The modern market offers a wide range of products of this type and different price categories. Snow cutters of low cost will last a short period of time due to poor-quality manufacturing materials to choose a high-quality snow cutter, you need to pay attention to the following characteristics:

- The thickness and quality of the metal – are the main indicators that determine the strength of the entire structure and its bearing capacity. The best metal is galvanized steel with different thicknesses. Zinc is applied to the surface in two ways: hot or cold, the thickness of the application will depend on the method of application, the method of hot application consists in applying to the finished product and excludes applying a thin layer in hard-to-reach places.

- Coating – the most reliable coating to prevent corrosion damage is a polymer coating that is not broken down under the influence of precipitation and protects the metal from corrosion for a long time. Paints based on other components are also widely used.

- Structure – a complex configuration of the snow cutter allows you to create additional structural strength and increase the load-bearing capacity, simpler configurations are produced to reduce the cost, which entails a loss of strength characteristics. When choosing the shape of the pipe, it is worth considering that the oval shape is considered to be stronger than round pipes.

- The number of brackets – to create a reliable structure, it is worth considering that the maximum step of the bracket should be no more than 70 sm, a greater distance between the supports can provoke a fracture of the tubular elements under load, which can subsequently lead to an accident.

It is important to take into account all factors that can affect the strength of the structure and the fracture of the bearing elements, this will ensure safety and increase the service life of the roofing.

Metals, used for the manufacture of tubular snow cutters:

- Rough metals are in the lowest price category and have a low load-bearing capacity, they are also more susceptible to corrosion than other types, which can subsequently negatively affect the roofing fabric.

- Galvanized metal – is a good value for money, is less susceptible to corrosion, has a high load-bearing capacity, designed for a long period of operation.

- Aluminum – the main advantage of this metal is that it is not subject to corrosion and has a low weight, while aluminum structures significantly exceed the cost of other types of tubular snow cutters at the price.

- Copper – this type of metal is used only on roofs with copper coating. When copper interacts with other types of metals, corrosive lesions occur at the junction.

Instructions for the arrangement of a tubular snow cutter:

As already discussed earlier, the design of a tubular snow cutter is considered one of the most durable, which allows them to be installed on a roof with a large slope, long slope size, and smooth roofing.

- At the stage of project creation, it is necessary to calculate the load at the installation sites of the snow cutter and mark the locations of the snow cutter on the plan, indicating the dimensions. Calculate the required number of installation elements and the distance between the mounting system.

When calculating the distance between the supports, it is necessary to take into account the load, and the installation region. Distribute the calculated load on the load-bearing structures to prevent damage to the roofing sheet. - The installation of a snow-retaining system is carried out along the entire perimeter of the roof, without breaks. With a slope length of more than 5.5 m, the number of tubular rows can be increased to three, maintaining a gap of about two meters.

- Installation of tubular snow cutters on metal roofs is carried out at the same level as the load-bearing elements so that the load from the snow cover is transferred to the load-bearing parts of the structure.

A distance of 60-100 sm should be maintained between the bearing element and the cornice line. It is necessary to install snow cutters above the dormer windows on a solid lathing. When installing a snow cutter on a roof with a slope of more than 30 degrees and a load of more than 180kg/m2, it is better to install two or more pipes. - Mounting brackets – depending on the roofing fabric, the mounting brackets will vary, for example, on a roof made on corrugated board, the brackets will be fixed to the elements of the lathing, if the roof is covered with ceramic tiles, then it is necessary to install support bars in advance and mount them already. Mounting is carried out through the roofing sheet, using roofing screws with a rubberized gasket.

At the first stage of installing the brackets, the extreme supports are mounted, and the intermediate brackets are fixed after the installation of the extreme ones, so as not to make a mistake with the dimensions and not to make unnecessary holes, which then have to be sealed. If you do not fix the bracket to the elements of the lathing, then under the weight of the snow cover, the entire structure will collapse. - Sealing – ll connecting parts of the bracket adjacent to the roofing sheet should be carefully sealed to prevent moisture from entering the roofing layers.

Corner snow-stoppers

Corner snow stoppers are an obstacle blocking the descent of snow cover to a certain thickness, this type of snow holder is subject to the formation of ice on the cornice bar, as well as the accumulation of a large array of snow cover on the roof surface, which, in this regard, is subject to disruption from the base of the roofing sheet. To install this type of snow support, it is necessary to calculate the load on the truss elements and the supporting structure.

The arrangement of corner snow supports on the roof is made if:

- The roof slope has a slope angle not exceeding 20 degrees;

- As an auxiliary element for tubular snow cutters or lattice snow holders.

Design features:

Corner snow supports represent a V-shaped bar, which is fixed to the roof due to shelves in the base. The maximum height is up to 10 sm, the installation is carried out vertically with respect to the ridge and placed parallel to the cornice bar.

The arrangement of corner snow holders is made depending on the functions performed:

- The main snow-holding installation. Installation is staggered, adhering to the distance between the rows of 50-100 sm. On average, the length of one snowplow is 30 sm.

- Auxiliary snow-holding installation. The arrangement is carried out along the entire perimeter of the roof, the arrangement is produced in one line with a minimum gap between them.

Snow blowers of this type are not mounted in one line, if they are the only snow-retaining installation, then this leads to the breakdown of the entire structure and a large descent of snow cover from the roof. The only exception: is regions with minimal rainfall and sloping roofs.

The material for the manufacture of corner snow stoppers is mainly thin-sheet steel with a polymer coating which gives high-quality corrosion protection.

Instructions for the arrangement of a corner snow stopper:

Installation of snow stoppers is carried out in full accordance with the design scheme, taking into account the calculated snow loads, without allowing deviations. Before the start of installation work, the place of installation of snow stoppers is marked on the roofing sheet.

- The fastening is carried out depending on the function of the corner snow stopper:

- The main installation – the fastening is made by a self-tapping screw with a length of 5 sm, the fastening is made in each wave of the metal roof, and the installation is carried out parallel to the upper vertical edge and is fixed to the lathing.

- Auxiliary installation – fastening is carried out with a short self-tapping screw into the upper part of the profile of the metal roof.2. To ensure tightness, it is better to use roofing screws with a rubber gasket, it protects the fixation point from wet precipitation, and subsequently from corrosion.

Lattice snow holders

The design of lattice snow holders is similar to the design of tubular snow cutters, the difference is that not pipes, but grilles are mounted on brackets. The size and shape of the gratings varies in a large range, it all depends on the functions performed.

Lattice snow holders are distinguished by the type of cells:

- Rectangular cells — are the most common type of lattice snow holders. This type of construction delays more snow cover and works as a snow-cutting facility. The arrangement of snow holders of this type allows you to reduce the load on the roof elements. The width of the cell is 5-10 sm.

- Triangular cells – perform a function of a barrier, meltwater, and small ice chips are passed through the cells.

- Round or oval cells allow melt water to pass through and prevent the snow cover from coming off the roof, in this regard, the load formed by the mass of the snow cover affects the roof structure.

Also, this type of snow holder is divided by the height of the barrier and installed depending on the roof structure.

- Small models are installed on flatter roofs in regions with little precipitation.

- High models are installed to hold a large volume of snow cover on steep roof slopes.

Instructions for the arrangement of lattice snow holders:

For the arrangement of this type of snow-retaining system, it is worth considering that it is able to hold a large mass of snow, the main load from the mass falls on the load-bearing elements of the roof, therefore, it is better to mount a solid lathing in places where snow-holders are installed.

- The mounting of the grilles is made on the brackets with bolts of size М8х16, the connection of the snow holders with each other is made with bolts М8х25.

- If the snow holder is with an adjustable angle of inclination, then the two-part brackets are included, the first part is mounted on the roof, and the second one is fixed depending on the angle of inclination, for this purpose several holes are provided, and located around the circle.

- The maximum step of installing brackets between snow holders of this type should not exceed 120 sm, to prevent deformations of the roof canvas and the disruption of the grilles under the weight of the snow mass.

Towed snow holders

This type of snow holders is presented in the form of corners or slats, the installation of which is carried out in several rows, in compliance with the staggered order. They do not delay the snow cover on the roof, but cut the layers of snow into smaller ones.

Due to the fact that the towed snow holders do not have a snow-retaining function, they are also called point snow cutters. This type of snow holder is ineffective for areas with increased precipitation.

Towed snow holders as an independent type of snow-retaining system are allowed to be installed only in regions with a small amount of snow precipitation and a slope angle of less than 15 degrees.

Basically, the towed snow holders have a triangular shape with a width of 3 sm and a long fastening facility. Installation of this type of snow holders should be carried out only on a solid lathing with a tight fixation to its parts, preventing the disruption of snow holders and damage to the roofing.

Towed snow holders are more often used as an auxiliary snow-retaining system and are divided into two types:

- The first type of spot snow cutter has the form of a metal bar, the fastening of which is made on metal roofs. This type is fixed mainly to metal tiles, mounted on the crests of neighboring waves, fasted with screws to the metal cloth, and installed in staggered order in several rows around the perimeter of the roof.

- The second type of point snow cutter also has the form of a metal bar, the fastening is made with long screws under the step in the lower part of the wave, due to this, a strong element of the snow-retaining system is obtained. When choosing a towed snow holder of this type, it is important to choose a structure with a recess height in the lower part greater than the wave of the metal sheet in order to prevent deformation of the roofing sheet at the fixation point.

How to choose the snow holder correctly?

When choosing a snow holder, in order for it to perform its functions at 100%, it is necessary to consider all the characteristics and take into account the load in winter.

The main indicator for the snow holder– is the amount of snow that the snow-retaining installation is able to withstand. Snow holders of a low-price category are able to cope with their function if the roof slope is arranged at a small angle and the region is located in a zone of low snow precipitation, but at the same time they will not be able to fully perform their functions under other conditions, for example, in the winter season with large precipitation, this type of snow holders will simply roofs, damaging the roofing at the same time.

Depending on the load that the snow holder is able to withstand, it is installed in one or more rows. If the estimated load on the snow holders is about 200 kg, then the snow holder with a bearing capacity of up to 75 kg should be installed in several rows (at least two or more), and if you choose a model with a bearing capacity of 300 kg, then you can install it in one row.

The surface of the roofing is also taken into account, for example, smooth surfaces are in great need of installing snow holders, since they are more rapidly disappearing snow cover.

It is better to increase the estimated number of snow holders for a more uniform snow cover on the roof structure and in case of unforeseen factors.

For regions with snowy winters and a large amount of snowfall, it is better to install combined barrier installations.

How to install properly snow holders depending on the type of roof: step-by-step instructions and installation diagrams

Before installing snow holders, it is necessary at the stage of creating a design scheme to note the location of snow holders on the roof structure and adhere to this scheme during installation work.

General installation steps that are important to perform:

- The choice of the fixation point – the arrangement of the snow-retaining system is made parallel to the cornice bar. The first barrier is mounted above the load-bearing structural element, it will have the main load-bearing capacity, the rest are located at a distance of 1.5-2 m from the previous one.

- Arrangement of snow-retaining elements. Depending on the purpose of the snow holder: tubular or lattice elements are mounted in one row, and corner and tow elements— are staggering.

- The number of rows and the distance between the elements is calculated depending on the length of the roof slope and the angle of inclination. The greater the angle of inclination, the smaller the distance between the brackets.

- Mounting. Fastening is carried out by roofing screws in the lower part of the wave of metal roofs.

- Sealing. The fixation points are qualitatively sealed with rubber gaskets. Basically, they come in complete with roofing screws.

- It is better to install a snow-retaining system immediately on the roofing sheet, without waiting for snow precipitation.

Seam roof

The seam roof is one of the varieties of metal roofing, it is distinguished by a connecting element — a seam, which allows you to create a sealed sheeting.

The surface of the seam roof is smooth, without any bends or waves, taking into account this characteristic, a snow-retaining system is necessary, it will ensure safety during operation.

Installation of the blocking system is carried out along the entire perimeter of the building and all protruding parts of the roof.

The arrangement of the snow-retaining system is carried out without damaging the integrity of the roofing sheet, and without violating the tightness of the sheeting.

The facilities of the snow-retaining system can be different depending on the design solution. Two types of snow-retaining facilities are considered more suitable for the arrangement of snow-holders on folding roofs:

- Tubular snow cutters;

- Latticed snow holders.

They are easy to install on a seam roof and practical to operate, have a large load-bearing capacity, and are also available in a large color range, which allows you to choose a shade in accordance with the shade of the roofing sheet. The most common type is considered to be a tubular snow cutter, to choose a snow cutter for a seam roof, pay attention to the following indicators:

- Equipment of the snow-retaining facility – the complete set should include pipes of about 3 m long (2 pieces), four brackets, and fasteners;

- Shape – there are two types of flat-oval or round pipes with a diameter of 2-3 sm. And have an L-shaped or T-shaped form;

- Mounting – the complete set should include brackets with holes corresponding to the diameter of the pipe and bolts for tightening all structural elements, as well as roofing screws with rubber gaskets, with which the bracket is fixed to the roofing, hermetically sealed shelter of the connection point;

- Functions– corrosion resistance and load-bearing capacity of the structure;

- Appearance – to create an attractive architectural appearance of the roof, it is worth considering this parameter when choosing a snow-retaining installation;

- Protective coating – to prevent the interaction of the metal with water, it is necessary to create a high-quality coating, there are models in which, in addition to a galvanized coating, the facility is covered with a second layer of paint or polymer, which creates double protection and gives an attractive appearance;

- Quality – the quality of all snow-retaining facilities should be confirmed by a quality certificate, and the structures should have a passport indicating technical characteristics, as well as instructions for installation.

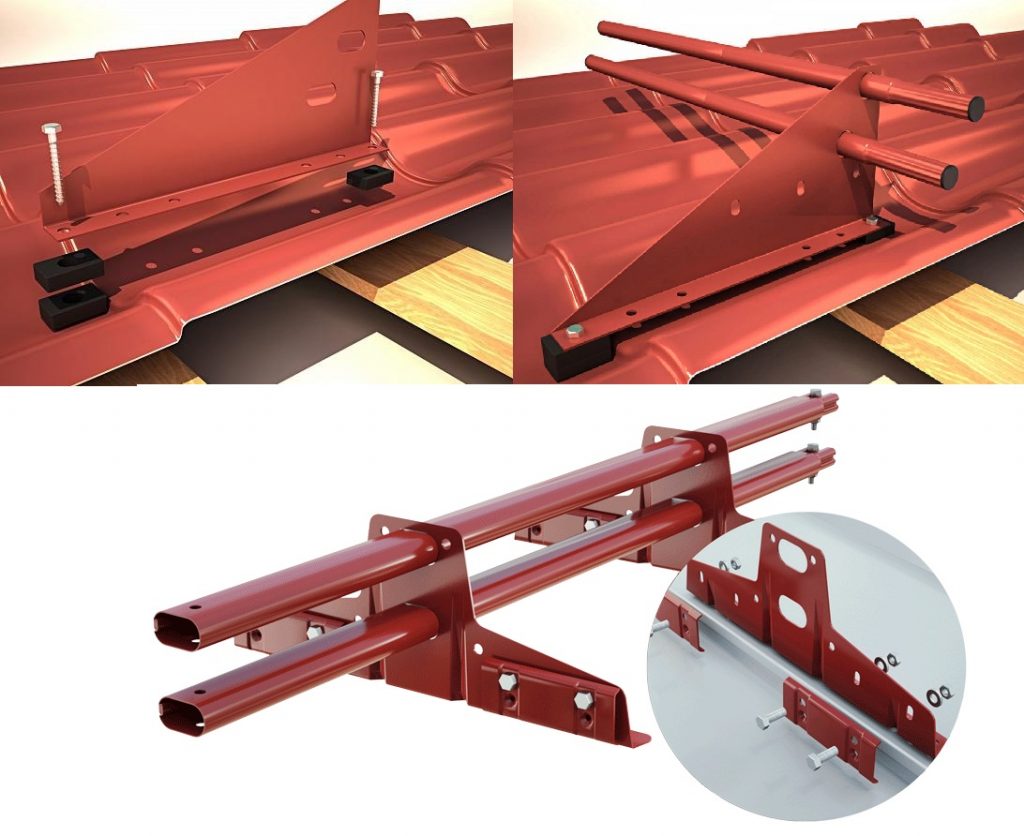

The brackets of the snow-retaining system are fixed only to the folding locks, preserving the integrity of the roofing.

Installation of barrier facilities is carried out without fastening to the elements of the lathing, they are fixed to the folding locks, which allows you to preserve the integrity of the roofing sheet.

Let’s consider the step-by-step installation of a snow holder on a seam roof:

- At the first stage, a clamp is fixed to the folding lock.

- A bolt is installed through the clamp and bracket and the entire structure is tightened;

- Pipes or grilles are stretched through the bracket, fixed, and closed ends with plugs.

Read more about the arrangement of the seam roof in this article:

— Installation of a seam roof: The technology of the arrangement and the materials used.

Roof, made of piece tiles

Piece tile has high performance, an attractive architectural appearance has many shapes and configurations.

Despite the high strength of the piece tiles, it is better to distribute the snow load evenly over the entire surface of the roof to prevent damage to the roofing sheet. Therefore, tubular or lattice snow holders are used as an auxiliary element, installing them above the entrance or parking lot.

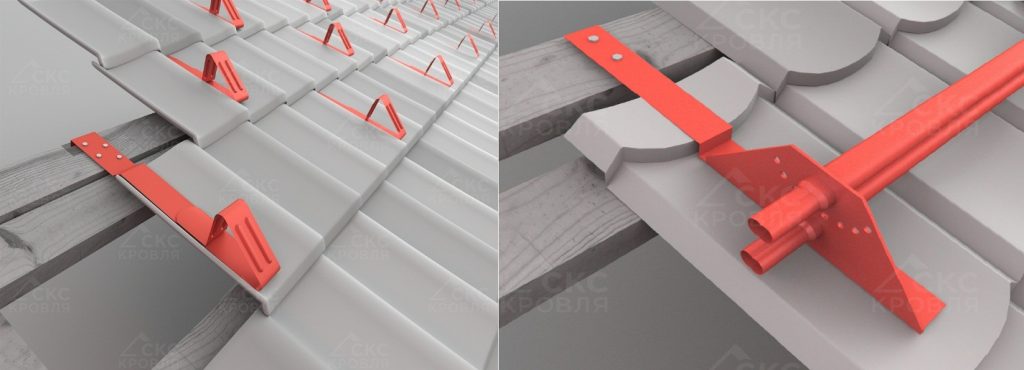

A feature of the installation of the snow-retaining system is the installation of an additional support bar, which is larger in size than the elements of the lathing system.

Installation of a tubular or lattice snow-retaining system:

- At the stage of conducting installation work on the arrangement of roofing covering made of piece tiles, a snow-retaining piece tile with a distance of at least 90 sm is mounted at the place of fixation of the snow holder, which is fixed to the bar with two screws.

- Then, a support bracket is fixed to the snow-retaining tile.

- After installing the bracket, pipes or grilles are installed.

- The snow-retaining facility should be installed along the entire perimeter of the roof and above the skylights, also in places of chimneys and other protruding parts.

Installation of a corner or towed snow-retaining system:

- The point installation of the elements of the snow-retaining system is carried out in the right recess of the tile, without preliminary pruning.

- The hidden part is fixed to the support bar, and the lower part of the triangle should be protruded above the plane of the piece tile.

- The installation of such elements will allow you to cut the snow cover into smaller parts.

Read more about the construction of a roof made of tiles in these articles:

— Repair of metal roofing: Technology and prices;

Soft roof

A soft roof is a roofing carpet made on the basis of fiberglass or cardboard, covered with a modified layer based on bitumen. They also include rolled and membrane materials.

This type of coating has a rough surface, which allows, unlike metal coatings, to prevent an avalanche-like descent of the snow layer. But still, the installation of snow holders is necessary, since when a critical mass of snow cover is set, it will still break off from the base of the roofing sheet.

Snow holders allow you to distribute evenly the snow cover along the base of the roof and provide snowfall in small portions.

Soft roofs are mounted mainly on roofs with a slope angle of no more than 15 degrees, snowfall will not be too fast, so the installation of massive snow-retaining installations is not required. Most often, for a snow-retaining system, towed snow-holders are used, which divide the snow mass into smaller parts.

If you ignore the installation of snow holders, then, in addition to the danger of a large mass of snow coming down, there is a risk of snow damage to the surface of the roofing sheet, which leads to rapid wear of the coating and, subsequently, major repairs.

Installation of snow holders on a soft roof is relatively not a complicated process, but it is necessary to follow a clear methodology for the arrangement of any type of snow-holding system:

- Snow holders are mounted on the roofing sheet during installation work on the roof, in accordance with the design scheme.

- Fixing the corners is self-tapping screws to the elements of a solid lathing, while the fixation point is covered with roofing material.

- If the installation of the snow-retaining system is carried out after the installation of the roofing, then the fixation points should be sealed with rubber seals, and the fastening is made into the base, through the roofing sheet.

- Tubular or lattice types are mounted along the line of the cornice bar, minimizing gaps along the entire perimeter of the roof. Fastening is carried out by self-tapping screws to the base of the roof, through the roofing sheet with mandatory sealing of the joints. For uniform load distribution, the barrier system is mounted on load-bearing structural elements.

Read more about the arrangement of a soft roof in these articles:

— Installation of a soft roof: technologies, materials, and prices for work;

— Soft roof repair: technologies and prices.

Prices for the installation of snow holders

The price for the installation of snow holders depends on the type of snow holder and the material of the roofing sheet, they also take into account the period during which the snow holders are installed: during the installation of the roofing sheet or on the mounted sheet.

| Type of work | Unit of measurement | Price in $ |

| Arrangement of a snow holder on a metal tile | running meter | starting from 40 |

| Arrangement of a snow holder on a soft roof | running meter | starting from 40 |

| Arrangement of a snow holder on a piece tile | running meter | starting from 80 |

| Arrangement of a snow holder on a seam roof | running meter | starting from 60 |

| Arrangement of a snow holder on a roof made of profiled sheet | running meter | starting from 60 |

| Arrangement of a snow holder on a mounted roof | running meter | +20 to the price |

| Arrangement of a snow holder bar | running meter | starting from 24 |