Table of Contents

- Advantages and disadvantages of copper roofing

- Varieties of copper roofing and materials used

- Technologies of installation of copper roofing with classification by types: nodes and schemes

- The price of installing a copper roof

- Repair of copper roof

One of the most common roofing options is a copper roof, which is based on copper and its alloys. Such materials have their own features of installation and operation, as well as unique properties, for which they are valued in the circles of builders. This article will focus on the features of the copper roof and all the issues that may arise during its installation, operation, and repair.

Advantages and disadvantages of copper roofing

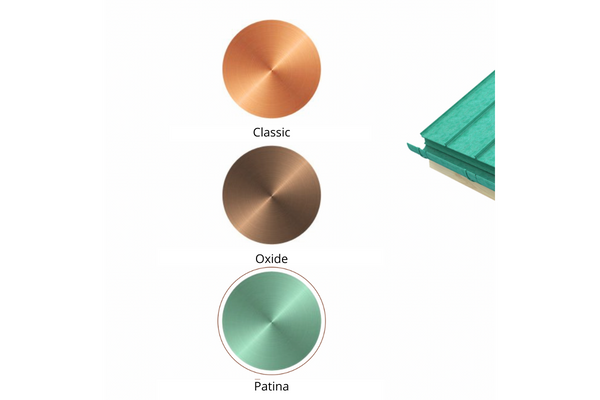

Copper roofing has one unique feature that may not appeal to those who appreciate the attractive appearance of the roofing. We are talking about the oxidation of the material, that is, the loss of its original properties under the influence of oxygen and moisture.

During oxidation, the copper roof loses its original color over time and acquires a darker, often greenish hue. The luster characteristic of the copper coating during the first time of its operation is also lost. Often, in order to avoid the loss of copper color shade, the material is immediately made in green or brown colors. In this case, the oxidation results will be practically invisible externally.

The main advantages of a copper roof include the following points:

- Easy installation, processing, reshaping, and repair;

- The high degree of resistance of the material to moisture, temperature changes, and corrosion processes;

- The high degree of fire safety;

- Long service life;

- Environmental safety of the material, the absence of toxic substances in the composition.

However, this type of roofing has its drawbacks.

Among them are:

- High cost of copper roofing (this coating is considered one of the most expensive among all types of roofing structures);

- The necessity to equip lightning protection and noise insulation;

- High thermal conductivity of copper in connection with which copper roofing is used only for the arrangement of cold roofs;

- The property of copper coating is very hot in the warm season, as a result of which the temperature rises in the attic space.

Varieties of copper roofing and materials used

Let’s consider the main types of copper roofing in more detail.

Folded copper roof

The seam roof is made on the basis of a roll-type material, which is cut into strips and laid along the entire length of the roof slopes. The edges of the roofing structure are bent, thereby forming so-called folds. On one side of the strip of rolled material, the edge is set perpendicular to the roof surface, on the other side, a hook is formed.

The first edge of the material is mounted in the second, after which the connections are carefully fixed. This leads to the formation of a reliable joint, impervious to the effects of moisture and various atmospheric phenomena.

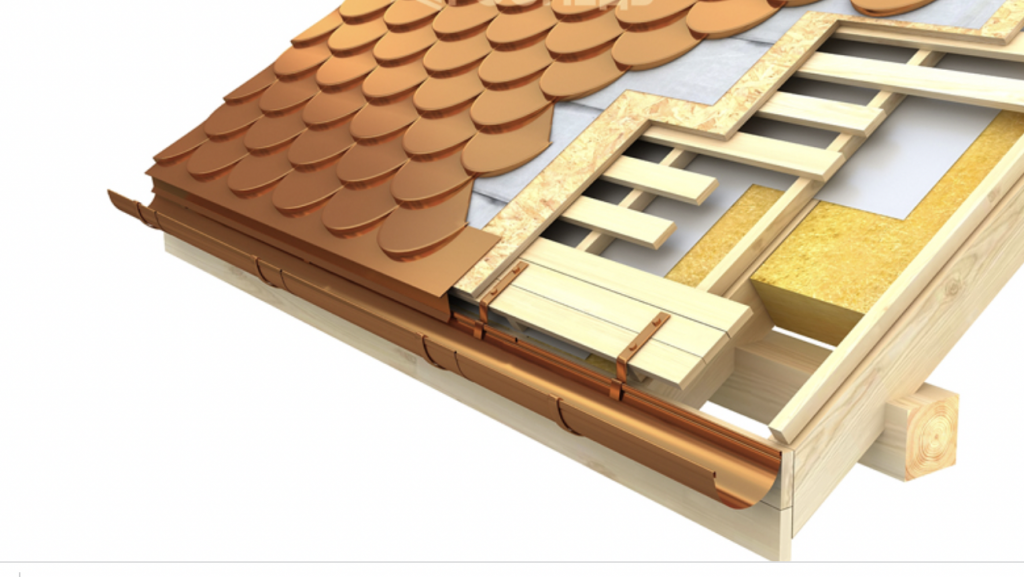

Tiled

A tiles copper roof in its appearance and purpose does not differ from a standard metal tile. The only feature of such a roof is the use of copper and its alloys as the basis for tiles. In terms of useful properties, copper sheets are very similar to steel elements of roofing, however, unlike copper, steel needs additional protective coating with paint or polymer materials. Copper tiles are most often not treated with protective compounds, since they have a high degree of resistance to external influences. This also explains the high price of a copper tile roof.

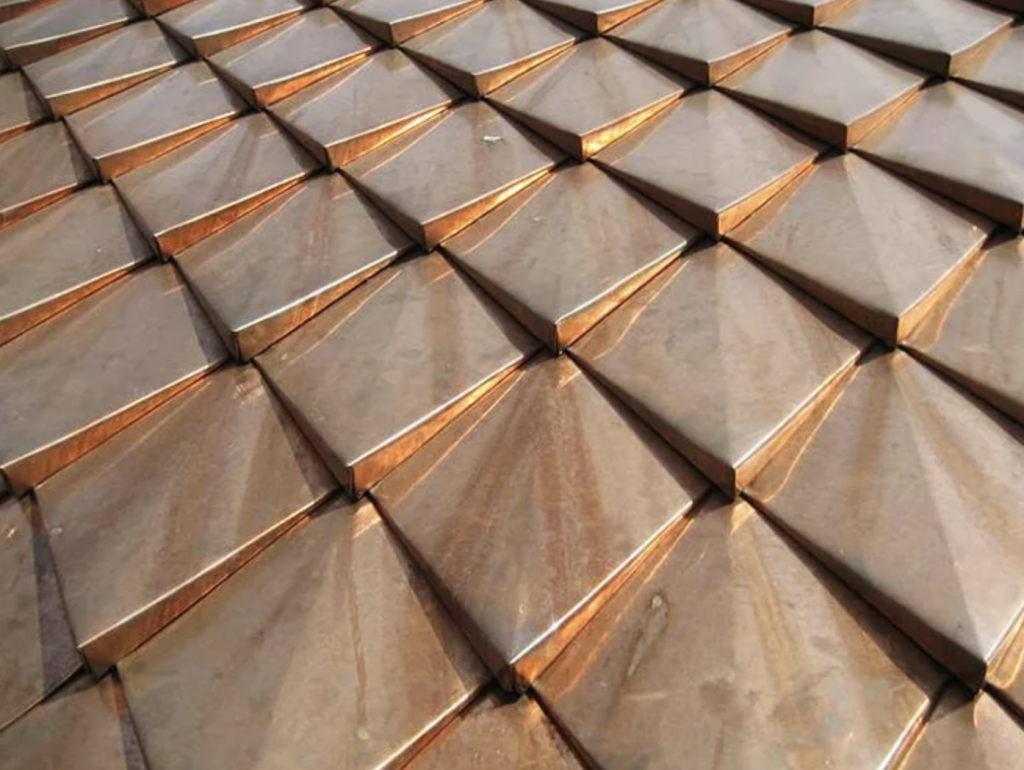

Checkers

Elements of a checkered copper roof can be made in the form of rhombuses, rectangles, or trapezoids. They are laid on the roof surface in a staggered manner. The joints of the coating elements are often treated with special compounds: this ensures a high degree of tightness of the roof structure. Lock connections installed between the roof elements are also responsible for tightness. It was the lock joints that made it possible to distinguish the checkered roof as a separate type of copper roof. Otherwise, the checker-type coating is noticeably similar to copper shingles.

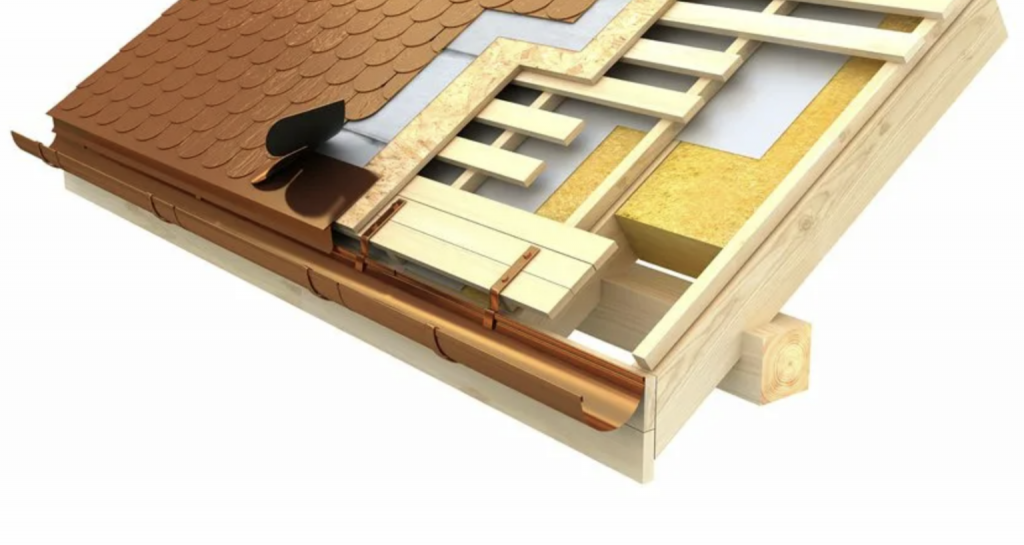

Soft copper roof

The soft copper roof resembles bitumen shingles in its structure. The structure of such a roof looks like this: the material is based on fiberglass, covered with bitumen from the outside and from the inside. On the outside, a slab made of copper is fixed to the base, while a self-adhesive surface is preserved on the inside. To improve the quality of a soft roof, bitumen-polymer compositions supplemented with special useful additives are used instead of the standard modified bitumen. Due to such additives, the useful properties of the copper roof, which were discussed above, are achieved. Fiberglass, bitumen coating, and copper slab together form a flexible material, the thickness of which does not exceed 2-3 mm.

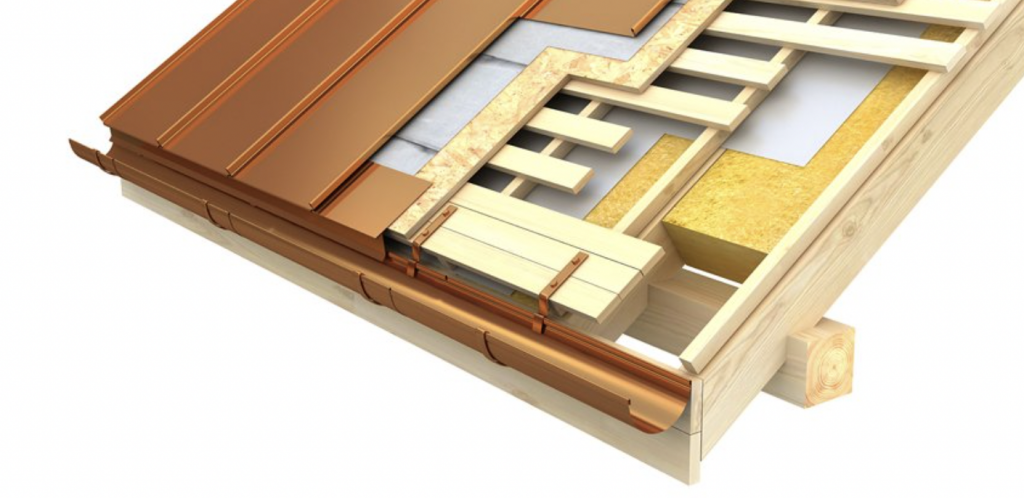

Technologies of installation of copper roofing with classification by types: nodes and schemes

Copper roofing refers to coatings of small thickness: in hardware stores, you can buy copper rolled products with a thickness of from 0,4 to 1,2 mm. The optimal indicators for various types of roofing are considered to be: 0,8 mm for shingles and checkered roofs, and 0,5-1 mm for a seam covering. It should be noted that the copper roof is mounted exclusively on solid lathing and only on those roofs that are not equipped with bitumen-based waterproofing. The best options for hydrophobic compositions in such cases are diffusion membranes, as well as felt.

Let’s consider the technology of installation of several varieties of copper roofing.

Installation of a copper seam roof

Folding panels-sheetings, made of copper, as a rule, are made to order since they are in much less demand than elements made of galvanized steel. Often, the manufacture of copper panels is carried out directly during construction work. installation of folding sheetings:

- The starting panel is placed at one of the edges of the roof.

- On the side of the pediment, the mounting of the launch pad is carried out with the help of clips. The sheeting is fixed to a solid lathing by using one of the sides of the clip, equipped with a special platform with holes. The other side, equipped with a hook, is used to install a seam responsible for the reliable connection of the panel to the roof structure.

- The second strip of sheeting is fixed next to the starting one, and the edges of the panels are placed on the fold of those paintings that were laid earlier.

- After the arrangement of two rows of panels, all the formed joints are compressed using a special device, called a frame.

Installation of copper roof tiles

Tile — is a kind of copper roof, which can be laid not on a solid, but n a sparse lathing, however, it is extremely important to observe the required step of the lathing. Since in the case of a tiled roof, several sheets of roofing can be located on one panel, the lathing should be present under each row of shingles (that is, not necessarily under each individual shingle). We can say that the step of the sparse lathing corresponds to the step of the rows of tile sheets.

Tile laying begins with the eaves of the roof: the formation of a row is carried out from the middle to the edges. However, there is also an option in which the installation of tiles begins from the edge of the roof and continues toward the middle. It is extremely important to ensure that the first row of tiles is laid exactly on the eaves of the roof.

As fasteners for a copper roof, copper nails are most often used, which are driven into each shingle of the first and last rows of the coating. In the rows located between the first and the last, nails can be installed not on each element, but through one shingle. At the same time, the laying of tile sheets is necessarily carried out in compliance with overlaps in both longitudinal and transverse directions.

The arrangement of a copper soft roof

A copper flexible roof can be mounted exclusively on a solid lathing and necessarily on top of a lining carpet. Such a carpet is made of a cloth covered with protective compounds with the addition of polymeric substances. Since the carpet is not provided with a self-adhesive surface, roofing nails are used to fix it to the lathing, and the installation itself is carried out in strips, each of which is fastened with nails. Carpet laying is also necessarily carried out in compliance with the overlap in the longitudinal or transverse direction. In this case, it is quite enough overlap, the value of which does not exceed 100-150 mm.

The arrangement of a soft roof based on copper alloys begins with the overhang of the roof, and the starting strip of flexible material is laid exactly along the cornice. After laying the starting strip, the installation of the main part of the roofing material begins, which can be started both from the middle of the roof cornice and from any of its edges.

Copper nails are used to fix the soft roof to the lining carpet material. They have driven in evenly: 4 pieces for each individual element of the coating. Each next row of material is laid in such a way that the roof covers the nail caps of the previous row. A variety of forms of shingles are allowed for the installation of a soft roof both vertically and with a slight offset of half a sheet.

The arrangement of a copper checkered roof

The elements of the checkered roof can be rectangular, trapezoidal, or rhombic in shape. The edges of each checker made of the copper sheet are bent in different directions: one goes up, the other down. Bends should necessarily be directed towards platinum. In this way, two locking elements are obtained, which are necessary for the installation of a checkered roof structure.

The formation of a coating based on a checkered roof is carried out as follows: the first row is laid so that the edges of the checkers bent upwards are located on the outside of the roof. These edges will serve as the basis for joining the elements of the second row: the curved edges of the elements of the second row will be wound up by the edges of the already laid row of material. To ensure the tightness of such a coating, additional fastening of the checkers to the lathing is carried out using clamps on self-tapping screws.

The price of installing a copper roof

Prices for some types of work on the installation of a copper roof will be discussed below. Not all types of materials are presented in the tables since the range of coatings is very wide. A full price list, which will specify the prices for any construction work related to the installation of a copper roof, can be provided upon request.

The cost of work on the installation of a copper roof:

| Name of the type of work | Cost of work in $ |

| Production of folding sheeting and other elements | starting from 272 |

| The arrangement of folding sheetings | starting from 41 |

| Installation of the endows (roof valleys) | starting from 57 |

| Installation of the hip | starting from 39 |

| Installation of the ventilated ridge | starting from 46 |

| Vapor barrier arrangement | starting from 7 |

| Waterproofing arrangement | starting from 7 |

| Installation of a solid lathing | starting from 12 |

| Dismantling of roof layers | starting from 20 |

| The arrangement of the drainage system | starting from 35 |

| The arrangement of the snow retention system | starting from 35 |

| Installation of an attic window | starting from 55 |

The cost of the applied copper roof sheets:

| Copper sheet thickness | Sheet size (in mm) | The cost of the material (per 1 kg) in $ |

| 0,5 mm | 1000*2000 | starting from 140 |

| 0,8 mm | 600*1500 | starting from 82 |

| 1 mm | 1000*2000 | starting from 140 |

| 1,5 mm | 1000*2000 | starting from 140 |

| 2 mm | 1000*2000 | starting from 140 |

| 2,5 mm | 1000*2000 | starting from 140 |

| 3 mm | 1000*2000 | starting from 140 |

| 5 mm | 600*1500 | starting from 82 |

| 10 mm | 600*1500 | starting from 82 |

| 15 mm | 600*1500 | starting from 82 |

| 20 mm | 600*1500 | starting from 82 |

| 30 mm | 600*1500 | starting from 82 |

| 50 mm | 600*1500 | starting from 82 |

Repair of copper roof

Any repair work begins with the identification of the causes that led to the occurrence of damage to the copper roof. Among the possible reasons, the following points are highlighted:

- The use of fasteners whose material is not chemically compatible with copper;

- Rigid fastening of the clips, which does not allow them to fight temperature fluctuations (the clammers should be floating);

- Mistakes, made during the installation of the roof: insufficient quality connection of the coating to the roof space, the use of too few fasteners, and other problems;

- Damage to the copper coating during its operation.

It is worth noting that not in all cases the copper roof needs complete dismantling and subsequent replacement. It is often quite enough to make a patch, which should cover the damaged area. The repair of a copper roof is greatly facilitated by the fact that the copper coating does not need sheeting.

The so-called patina, which eventually covers the copper roof, performs a protective function and protects the metal from external influences. The only problem is too long patina formation in natural conditions: on average, its formation takes from 7 to 15-16 years, depending on the climatic features of the area.

If we talk about the causes of damage to various types of roofing, then the considered options it is:

Seam roof:

- Untimely removal of snow from the roof, creating excessive pressure on the roof surface;

- Mistakes, made when laying the coating (choosing the wrong angle if inclination, lack of a wide apron, depressurization of seams, and other moments);

- Too diligent cleaning of the roof surface from snow and various contaminants: this approach can lead to damage to the metal coating:

Tiles roof:

- An illiterate approach to laying the sheets, due to which leaks may occur;

- Coating arrangement without compliance with symmetry requirements;

- Lack of necessary gaps at the junctions, on the eaves of the roof, and on the ridge;

- Mistakes are made when laying the components of the roofing layers (insulation, vapor barrier, waterproofing, and so on).

The repair of the copper roof can be carried out by completely replacing the coating or by eliminating only the defective area. The discrepancy of the folds, for example, is compensated by crimping the joints of the sheetings with a roller nozzle. If holes have formed in the roof, they can be eliminated with the help of pastes that include thermosetting substances and metal particles in their composition. Such material is applied at a distance of 2 cm from the damage and warmed up until it is melted.

In case of repair of a soft copper roof, strips of material are removed from the roof surface, after which wooden slats are mounted under the joint lines of the strips, the thickness of which does not exceed 5-7 mm. further rolling ensures the formation of a ventilation duct, which serves to remove most of the accumulated condensate.

Copper roofing structures are characterized by high resistance to external influences, as well as long service life. Therefore, with a responsible approach to the device, operation, and repair of the copper roof, such a coating can be counted on for at least several decades.