Table of Contents

- What is a seam roof?

-

Installation instructions for the seam roof

- Tool for installation of a seam roof

- Installation of a counter-lathing and lathing

- Waterproofing arrangement

- Laying of a seam roof — installation of sheetings

- Installation of the ridge of the seam roof

- Arrangement of chimneys and other abutments

- Installation of snow holders on a seam roof

- The scheme of installation of a seam roof

- Video instructions for installation of a seam roof

- Maintenance of the seam roof

- Features of installation of a seam roof made of copper:

- Tides and parapet fold

- Installation of seam roof prices for work:

- Services for installation of a seam roof

What is a seam roof?

The seam roof is metal sheets bonded together by a connecting seam, which allows for maximum tightness of the roof. Due to this, the seam roof has found a wide application in the construction of public residential and administrative buildings. It is excellent for covering the roof of a building and provides protection for internal structures from atmospheric influences.

Types of seam roof

In modern construction, several types of seam roofing are used in the construction of the roof:

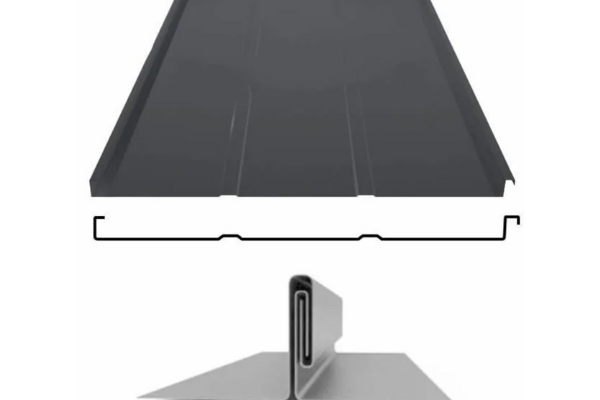

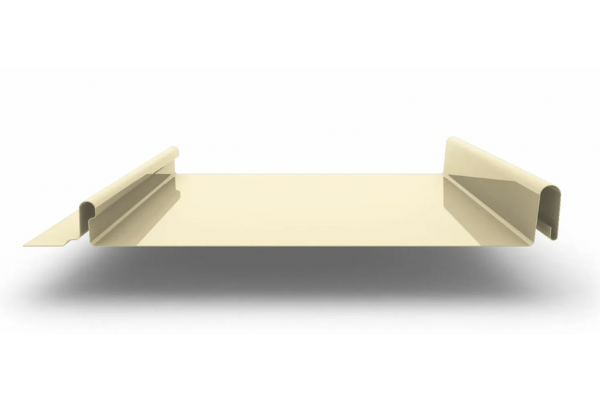

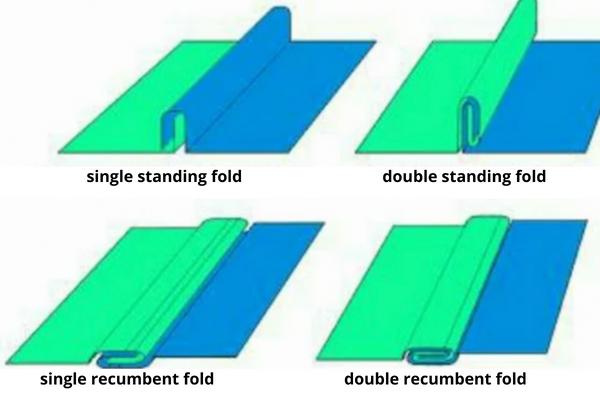

- Clickfalts – are the most common type of seam roof connection, due to perforation on a special shelf, it is securely fixed to the lathing and creates a sealed coating for a long time, significantly increasing the operational properties of the roof, while being mounted in a relatively simple way.

- Double folding roof lock – this type of connection has proven to be one of the most hermetic types of folding roof connection and has found wide application in regions with increased precipitation.

- A single-standing lock – is a less common type of connection, as it is suitable for installation in places with moderate precipitation.

Advantages and disadvantages of a seam roof

Advantages of a seam roof:

- The low weight of metal sheets allows you to mount the roof covering with high quality without much effort and create a sealed sheeting resistant to various types of precipitation.

- The durability of the material used is the most important advantage, due to the long operating time, without additional repairs.

- Environmental friendliness – the materials, used in the manufacture of seam roof parts are non-toxic and suitable for use in buildings of various purposes, and are safe during installation work and after commissioning of the building.

- Versatility – this type of roof is great for installing a roof with a complex configuration (gazebos, rotundas, pavilions, etc.).

- Maintenance – the simplest possible cleaning of the seam roof from snow and dirt, and repair work on individual sections of the roof is a labor-intensive and fairly fast process.

The disadvantages of a seam roof include noise in rainy weather, but this disadvantage is easily eliminated by a well-chosen design solution with the use of sound insulation materials.

Also, the disadvantage is that the installation work of the seam roof is carried out only by qualified specialists with professional equipment.

Installation instructions for the seam roof

- Depending on the design solution the need to install thermal insulation layer, thermal insulation, and vapor barrier layers are installed at the initial stage of the folding roofing arrangement. The most common thermal insulation material is mineral wool, due to its good thermal insulation properties and reasonable price.

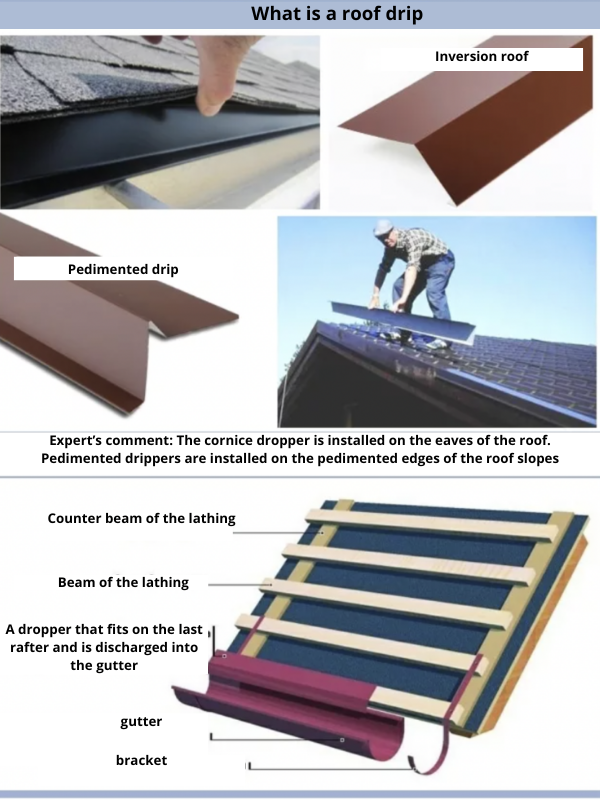

- An important step is the installation of a drip tray along the entire perimeter of the cornice, the installation is carried out along the entire edge of the roof, avoiding distortions and gaps at the joints.

- The next stage — is the application of a waterproofing layer. Various roll materials are often used. The waterproofing material is fixed to the roof rafter’s overlap, in order to avoid gaps, it is also necessary to fix the waterproofing material on the drip.

- Next, a counter-lathing and lathing arrangement is made, and the installation is carried out in accordance with the technological scheme of the placement of bars or boards and is fixed with screws with a certain step.

- The advantage of a seam roof is the use of roofs of different configurations, it is possible to mount full-size panels, as well as a panel trimmed to a certain size. to ensure smooth laying of the panels, it is necessary to start work from the end of the roof, this will make it easier to set a right angle relative to the edge line of the roof, which will further facilitate the work and alignment of the panels. Installation of folding panels depends on the type of connection seam.

- After installing the panels of the seam roof, connecting elements are installed: a roof valley (endow) is installed at the junction of two ramps, ensuring tightness and reliability of the connection, to facilitate work, a template can be used to trim the panels adjacent to the endow.

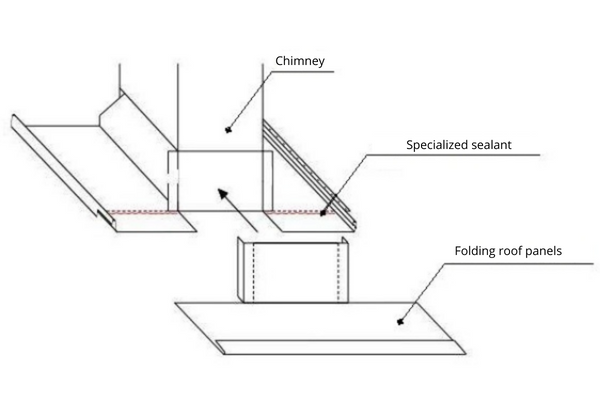

- To assemble the chimney bypass structure, it is necessary to use a pre-prepared scheme, according to the scheme, to make the structural elements of the bypass, trim the adjacent seam panels, fix the beam and install mounting strips, ensure the tightness of the structure with specialized roofing sealants. Then install the lower bar and gradually build up the side panels into a hook.

- The final stage will be the installation of a finishing strip around the entire perimeter of the chimney, the connecting sections should be sealed with a specialized roofing sealant.

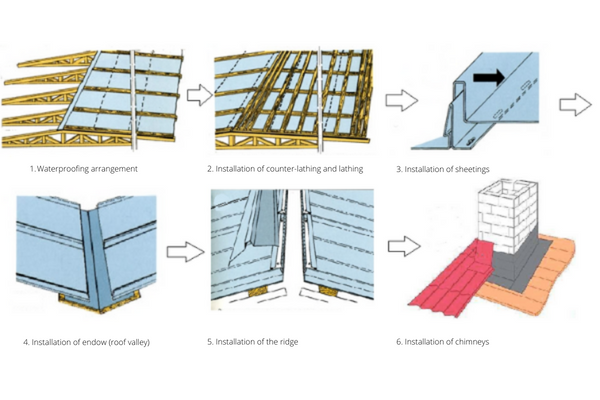

Briefly, we can specify the main stages of the installation of a seam roof:

- Installation of thermal insulation and vapor barrier material (if necessary);

- Fixing the dropper around the perimeter of the cornice

- Application of waterproofing coating

- Installation of counter-lathing and lathing

- Installation of folding roof panels

- Fastening of additional elements.

- Assembly of the chimney bypass structure

Tool for installation of a seam roof

For high-quality work on the installation of a seam roof, it is necessary to use professional equipment that will ensure simplicity and high productivity of installation work.

Depending on the type of connecting seam, the set of tools may vary, but the main tools are listed below:

- Metal shears – necessary for cutting panels of various configurations;

- Scissors of the Pelican type – used to create an even cut of the folding panels;

- Curved roofing pliers with an angle of 45 ̊, a mallet– to create connecting nodes;

- Shlyazen– a device for arranging locks in places of adjacency;

- Tools for deflections of nodes and cornice;

- Construction level measuring tools and fixtures;

- For a roof with a double seam joint, a specialized tool of two types is used: automatic and mechanical.

- The installation of a roof with a two-finger joint can be carried out without a specialized installation, but by simply pressing the foot on the edge or using a mallet.

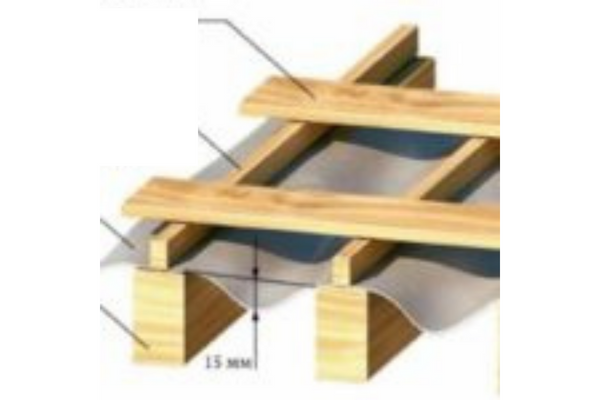

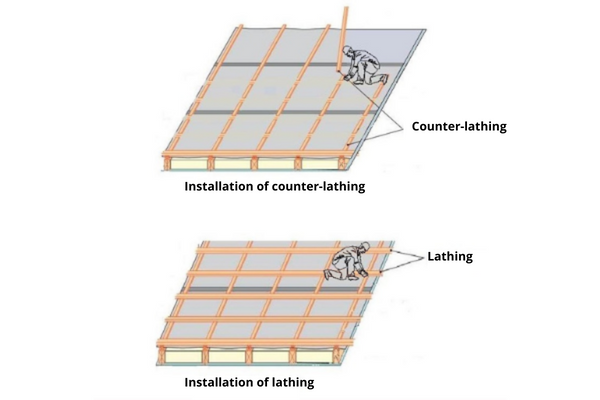

Installation of a counter-lathing and lathing

It is better to mount a solid lathing in the base of the seam roof, unlike a discharged one, it allows you to avoid unevenness of the base and subsequently prevent bending and deformation of the metal sheet. It is better to pre-process wooden products used for the installation of counter-laths and lathing with a specialized composition to increase the durability of the structure.

Let’s take a closer look at the installation process of the counter-lattice and lathing:

- The counter-lathing is mounted from a beam with a square section of 5,0х5,0 sm, it is more convenient to mount with self-tapping screws with a set pitch, work should be carried out along the rafters.

- The installation of the lathing begins along the edge line of the roof, using boards with a thickness of 2,5-3,5 sm, the installation is carried out perpendicular to the counter-lathing. Laying is carried out in the direction of the ridge, keeping a certain distance (not more than 40 sm).

- In more vulnerable places, for example, endowments, it is better to perform a solid boardwalk (up to 70 sm on each ramp).

Installation scheme of the counter-lathing and lathing:

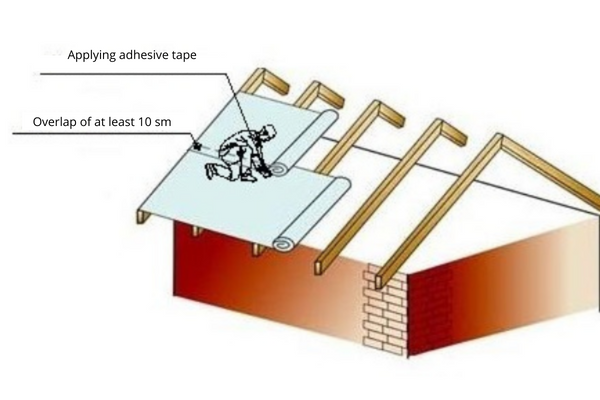

Waterproofing arrangement

When installing a waterproofing membrane, it is important to lay the coating so as to avoid gaps and leaks. It is better to lay the material in an overlap, the upper strips are laid on the lower ones with an overlap of at least 10 sm, and the joint of the two strips is closed with self-adhesive tape. The membrane is fixed to the rafters and the dropper with small nails with a wide cap or a construction stapler.

The scheme of laying a waterproofing membrane:

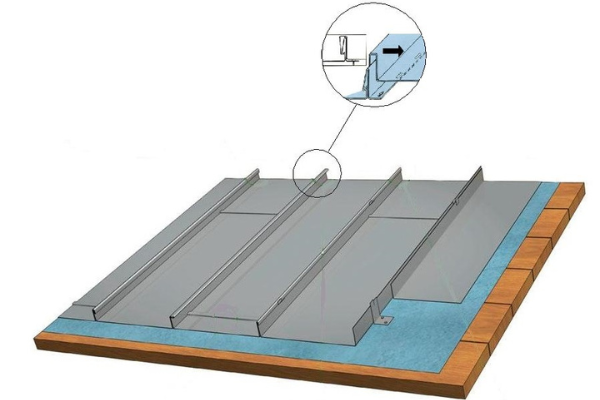

Laying of a seam roof — installation of sheetings

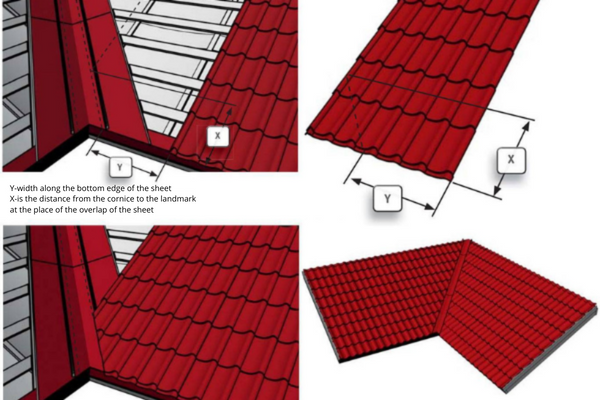

Depending on the configuration of the roof, the panels are cut to the required size or use full-size panels. Work begins from the end of the roof, for this, it is necessary to prepare the cornice node, which begins with the installation of drippers, to which the waterproofing material is fixed. After the arrangement of the cornice node, the installation of sheetings begins, and a right angle is clearly displayed relative to the edge of the roof.

Near the lower edge of the locks, the panels are cut with a depth of no more than 2.5 sm bent down with a specialized tool, and the protruding part of the lock is cut off. The panel is fixed to the lathing (depending on the type of seam connection), and the end plate is also fixed with screws to the end board and bent down. After the installation of the starting sheeting, the rest of the roof is installed.

The scheme of laying sheeting:

Installation of the end of the seam roof

The fastening of the lower endowment is made in overlap with a size of 10-20 sm, the edge of the endowment is fixed to the folding sheeting and the cornice, it is necessary to seal the joints to prevent moisture ingress. It is necessary to cut according to the pattern of the picture with an allowance of 2.5 sm, which are adjacent to the endow, the allowance is left for bending and subsequently reliable adhesion to the fastening bar.

The scheme of the endow arrangement:

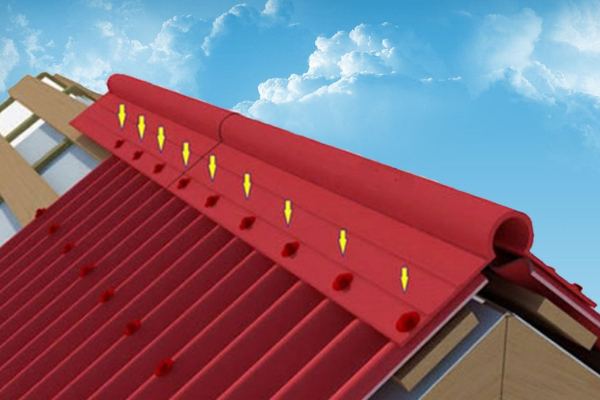

Installation of the ridge of the seam roof

The installation of the ridge is one of the final stages in the construction of a seam roof. The installation of the ridge takes place on mounted folding sheetings. The ridge comes complete with an aero element to ensure natural ventilation. The fastening of the ridge elements is made by roofing screws to the upper face of the folding lock.

Ridge installation scheme:

Arrangement of chimneys and other abutments

Previously, for the arrangement of chimneys and wall abutments, the structural elements are prepared in accordance with the design solution. Parts with locks are cut off from the folding panels. They form the abutment bars (side aprons), which, on the one hand, are adjacent to the wall of the pipe, and on the other– snap with adjacent sheeting.

The space between the side aprons is closed by the abutment bars (upper and lower), which do not have a latch. A hook is made on the upper bar, on which a sheeting fits the chimney from above. The lower bar with a hook falls on the lower picture. The aprons adjacent to the walls of the pipe are closed with a roofing sealant.

The scheme of installation of chimneys:

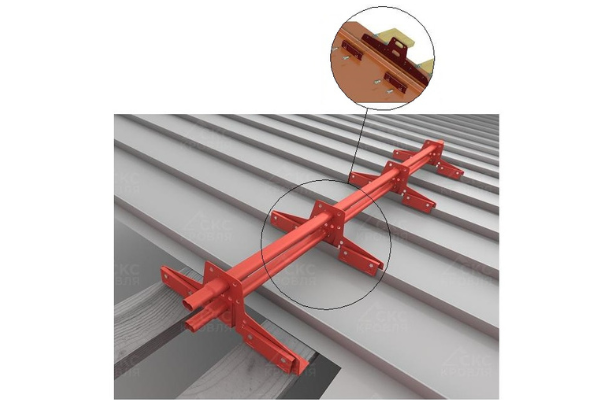

Installation of snow holders on a seam roof

Snow holders are mainly installed in regions with traditional winters. The parameters that should be observed when installing snow holders –are the slope angle, which should not exceed 50 ̊.

Snow holders are mounted strictly on the ridge of the fold, withstanding a certain step of mounting brackets 60, 90, or 120 sm, on average 3-4 brackets are installed on one snow holder.

Installation scheme of snow holders:

The scheme of installation of a seam roof

Video instructions for installation of a seam roof

Maintenance of the seam roof

As mentioned earlier, the seam roof is practical in operation and does not require complex maintenance. Thanks to the smooth surface of the metal sheets, snow or dirt does not linger.

In case of mechanical damage, it is possible to replace entire sheetings by dismantling the old and installing new sheeting.

With small deformations, a patch can be installed, the fastening is done with screws, and the damaged area should be treated with specialized mastic or sealant.

Most of the damage to the roof can be avoided if the folding roof arrangement is performed qualitatively.

Features of installation of a seam roof made of copper:

The peculiarity of the folding roof made of copper is the plasticity of the material, and its pliability during installation work, which significantly reduces the installation time of the roof, while copper is a reliable and environmentally friendly material. An ideal option for installing a roof of a complex configuration (for example, domes at Temples, rotundas, etc.).

At the same time, a folded copper roof looks more aesthetically pleasing and gives a noble architectural appearance.

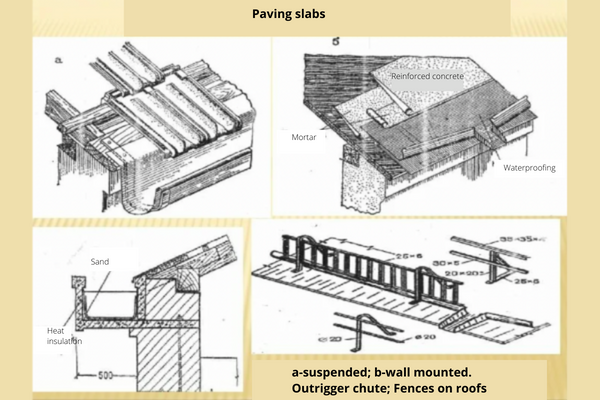

Tides and parapet fold

Low tide installation is necessary to protect the facade elements and the foundation from the effects of hydrostatic load created by snowmelt and rain.

There are two types of low tide systems:

- Wall gutters on the seam roof are mounted on the edge of the slope neat to the overhang;

- It is better to mount hanging gutters using brackets under the overhang of the roof.

The suspension system has the advantage — of being able to collect all the water from the roof, including drops from the cornice.

The parapet is necessary to ensure safety when conducting any type of work (installation of antennas, repair of roof parts, etc.). when installing the parapet on a seam roof, it is necessary to compress the ledge with metal perforated corners and fasten it with bolts for the reliability of the structure and install the fence itself on the corners.

Installation of seam roof prices for work:

| Description of work | Unit of measurement | Price in $ |

| Installation of vapor barrier | m2 | 10 |

| Installation of insulation | m2 | 27 |

| Installation of waterproofing | m2 | 9 |

| Installation of counter-lathing | m2 | 14 |

| Installation of lathing | m2 | 20 |

| Installation of a seam roof | m2 | 120 |

| Installation of additional elements | running meter | 74 |

| Pipe bypass installation | piece. | 750 |

| Installation of snow holders | running meter | 71 |

| Installation of a drainage system | running meter | 55 |

Online calculator for calculating the cost of installing a seam roof in comparison with other coatings

Расчет стоимости устройства скатной кровли под ключ

Итоговая стоимость работ

Services for installation of a seam roof

So for a high-quality arrangement of a seam roof, it is necessary to perform the following works:

- Installation of vapor barrier;

- Installation of insulation;

- Installation of waterproofing;

- Installation of a counter-lathing;

- Installation of the lathing;

- Installation of a seam roof;

- Installation of additional elements;

- Installation of pipe bypass;

- Installation of snow holders;

- Installation of a drainage system.

For a detailed estimate and calculation of the installation, please contact our calculation department.