Table of Contents

- When and why is it necessary to replace the roof and not repair it?

- Features of replacing a flat roof

- Features of pitched roof replacement

- Roof replacement technology: Stages of work

- Prices for work on the replacement of the roof of the house

- Replacing the roof with your own hands

- Turnkey roof replacement services

Damage to the roof, such as for example, leaks, violation of the integrity of the roofing, rotted support beams, and other problems associated with the installation of additional roof elements, can lead to serious consequences.

In cases where the repair of the roof is no longer feasible, resort to a complete replacement of the roofing, which, as a rule, is accompanied by the reinstallation of thermal insulation, waterproofing of the truss system, or a screed with a slope, if we are talking about flat roofs. In this article we will talk about what materials and technologies are used to replace the roof of the house, as well as in what price range, as a rule, such works are carried out.

When and why is it necessary to replace the roof and not repair it?

To understand whether the dismantling of the old roofing is required, it is necessary to conduct a thorough visual inspection of the roof, as well as invite specialists who examine the roof for both old and new damage. Most often, the roofing installed more than 20 years ago needs to be replaced, because the materials are worn out over time and lose their operational properties. A problem not detected in time can lead to serious consequences.

For pitched roofs:

An indicator of the imperfection of the old coating can be a leak or loss of color characteristics, known as fading of the roof. However, in such cases, it is also necessary to look at the severity of the problem. It is likely that only a few coating elements that do not touch most of the roof and do not threaten its destruction need to be replaced or patches to be installed. In case of local damage, the dismantling of damaged elements, for example, tile sheets will help prevent further leakage of the structure and in this case, work on the capital replacement of the roof of the building is not required.

A more serious indicator is the cracks that occur on the roofing. The damage, especially deep, indicates the deterioration of the roof and, accordingly, the need for its complete replacement. Such damage means that the roof has already begun to collapse rapidly. Practically the most serious problem— the sagging of the roof – suggests that the entire structure is under threat. The root of such a problem, as a rule, lies in a rotten or incorrectly installed rafter system or lathing and serves as a direct indicator of the need to replace the structure.

For flat roofs:

The following points serve as an indicator of the completion of work on the complete replacement of the roofing layers:

- Broken slopes, thanks to which water does not drain from the roof into the drainage system, but stagnates on it, thereby destroying the protective waterproofing coating 5 times faster;

- More than 40% of damage to the waterproofing layer;

- Problems with thermal insulation inside the roofing layers. If there is a broken or missing thermal insulation from the outside of the roof, located above a heated room in a private house or an administrative building, due to the difference in temperatures inside the room, condensation will be formed, which can lead to increased humidity, fungus and mold, dangerous to human health;

Is it possible to install a new roof without dismantling the old one

It is not always necessary to carry out a complete replacement of the roofing. In some cases, partial installation works are carried out. This is relevant when there is no major damage to the truss system or roofing layers both in a pitched and in a flat structure.

Partial replacement of the roof avoids the process of disassembling the old structure and significantly reduces the cost of construction work. However, not all materials are combined with new coatings. For example, it will not be possible to lay material or ceramic tiles on top of a coating of wavy slate. It is also not recommended to use soft shingles as a new coating, since problems may arise with its fixation to the roof surface.

Due to the lack of costs for dismantling the roofing, the cost of partial replacement of the roof is significantly less than the price of complete works. However, before starting to install a new coating on top of the old one, it is necessary to make sure that the underlying surface corresponds and that a new coating can be installed on it.

For pitched roofs:

- Compatibility of the existing coating with the new roof.

- A flat surface, for example, metal tiles, the application of which on a curved base is fraught with a violation of the pattern of waves and the need for additional repair work.

For flat roofs:

- The old surface should not contain defects that can negatively affect the quality of the new roofing. For example, if the roof is made of rolled surfaced materials, then there should be no swelling or other damage to it.

- The new roofing material should be compatible with the previous one, so, it is impossible to apply the surfaced roll waterproofing on the PVC membrane roof.

Features of replacing a flat roof

In the course of work on the replacement of the roofing structure, only the final waterproofing coating or the entire layers under it, namely the screed, thermal insulation, and waterproofing, can be replaced. An indicator of the replacement of

In the course of work on the replacement of the roofing structure, only the final waterproofing coating or the entire layersunder it, namely the screed, thermal insulation, and waterproofing, can be replaced. An indicator of the replacement of

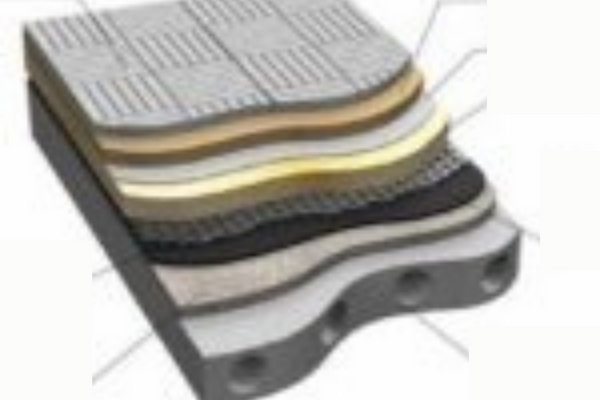

In the course of work on the replacement of the roofing structure, only the final waterproofing coating or the entire layersunder it, namely the screed, thermal insulation, and waterproofing, can be replaced. An indicator of the replacement of layers elements is the degree of destruction of these elements or a violation in their initial installation. For example, if the existing foundation does not have a slope according to the standard, then it should be replaced.

elements is the degree of destruction of these elements or a violation in their initial installation. For example, if the existing foundation does not have a slope according to the standard, then it should be replaced.

elements is the degree of destruction of these elements or a violation in their initial installation. For example, if the existing foundation does not have a slope according to the standard, then it should be replaced.

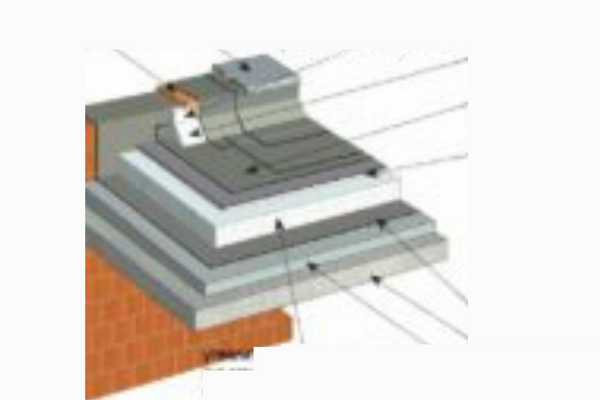

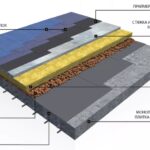

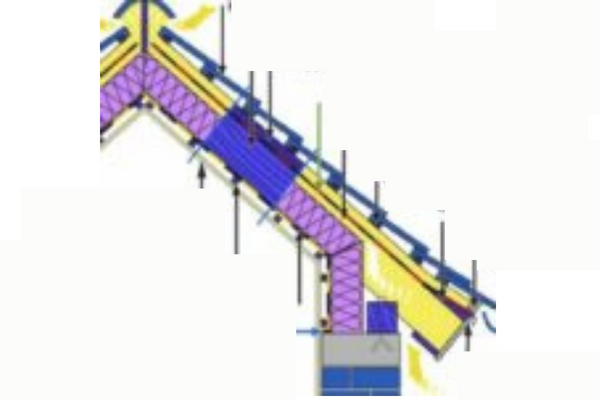

If we talk about the technology of work in standard flat structures, the following process should be noted:

- The process begins with the removal of the damaged coating, namely waterproofing, screed, and thermal insulation. The tools used for this are determined by the type of old roofing materials.

- At the next stage, a visual inspection of the surface is carried out, and the presence of damage is determined, in the presence of which additional repair work is carried out.

- The first waterproofing contour is applied to the base of the concrete floor slab using selected materials.

- Through the separation layer, thermal insulation is placed on the completed protection and there’s a vapor barrier on it;

- Further, linear guides are fixed on the surface with a slope of 3-5%, along which the screed is subsequently performed with a slope towards the drainage system. If there is a large area, the slope for the future screed is performed using expanded clay.

- Dismantling of linear guides and laying of the following roof elements are carried out only after 14 days after filling the screed.

- Waterproofing is applied on top of the frozen screed, which is designed to protect the screed from destruction and from water ingress into the roofing.

You can read more about the flat roof in the following articles:

- Flat roof arrangement: Installation technologies of various types and prices for complex construction

- Waterproofing of a flat roof. Recommended materials, methods of their installation, and prices for work

Schemes for replacing various elements of a flat roof:

Features of pitched roof replacement

A pitched roof, as well as a flat one, can be subject to significant damage. Serious leaks that make themselves felt during the rainy season, as well as other equally significant problems are recommended to be eliminated by completely replacing the pitched roof or its overhaul. Another problem can be considered as a feature of a pitched roof, which consists in the fact that the depressurization of the roof and the place of leakage can be located in completely different places.

Any repair work should begin with an inspection of the roof, both external and internal. One of the main indicators of roof quality is the condition of the attic room located directly under the roof. This room should be inspected for mold, fungus, damp areas, and other problems.

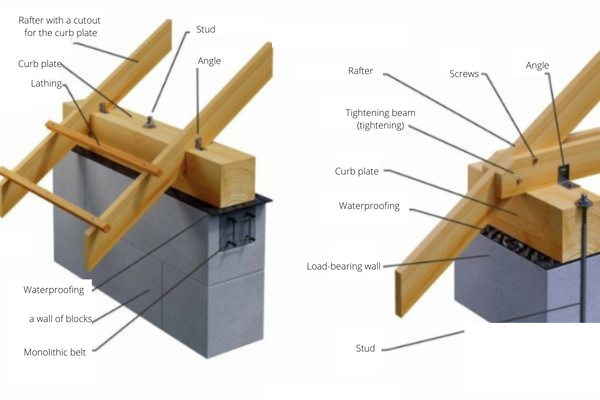

Cracks or holes in the roof, violation of the tightness of the coating and the connection points of the roof with the places of entry of communications, as well as some other problems can lead to roof leaks. It is worth noting that with an increase in the slope of the roof, the distance from the leak site to the actual damage also increases. For help in detecting the problem, you can contact the representatives of the construction company. If the rafter system is damaged, it is recommended to replace the damaged elements as soon as possible and make sure that the system does not need a complete update. Metal linings or rafter brackets can be used as amplifiers of the rafter system.

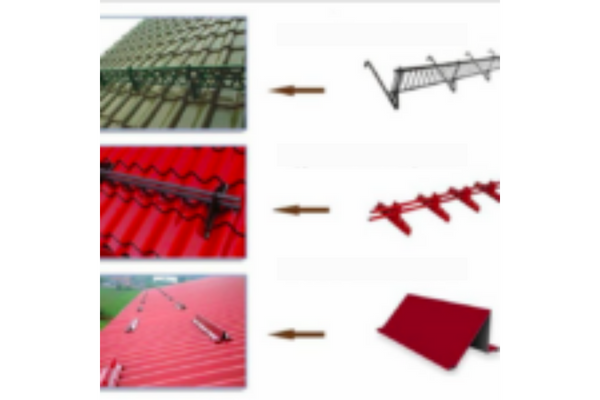

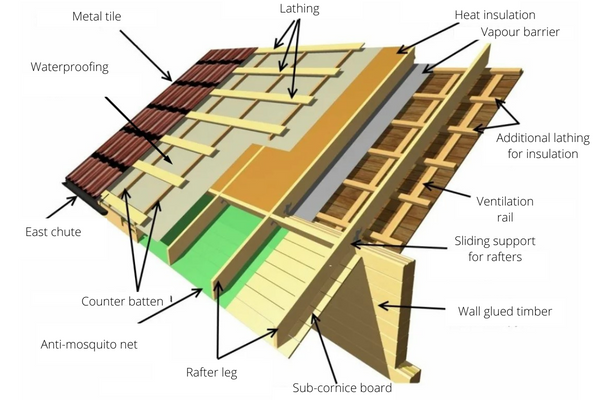

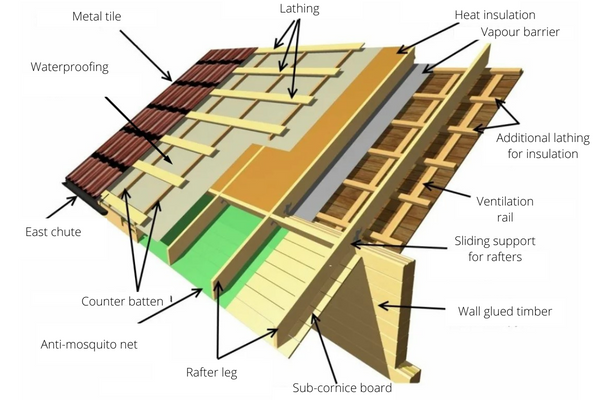

Also, cleaning and processing of elements of the rafter system with antiseptic solutions can have a positive effect. The dismantling of the pitched roof includes the removal of insulation and waterproofing. The new roofing layers will be represented by such components as steam, heat and waterproofing, a new lathing, a new roofing, and additional roof elements, for example, chimneys, vents, snow holders, or gutters.

You can read more about the pitched roof in the following articles:

- Waterproofing and repair of pitched roofs

- Installation of pitched roof: Types of pitched roofs and technologies of their installation

Roof replacement technology: Stages of work

The process of replacing the roof includes many stages, none of which can be neglected. First, you need to carefully inspect the roof for any damage. At this stage, you can find out how much time the construction work will take and what price range you can count on. In other words, it all starts with the preparatory stage. Let’s consider it, as well as other mandatory steps necessary to replace the roof of a private house or an administrative building, in a little more detail.

The replacement technology includes several stages:

- Preparatory;

- Dismantling works;

- Installation of the truss system and elements of roof layers

- The arrangement of the finishing coating of the roof

Further, we will study each stage in more detail.

Preparatory stage

As a rule, at the preparatory stage, when the decision to complete the replacement of the roof has already been made, and new roofing material has been selected, calculations are carried out designed to reduce the final cost of replacing the roof of the building. The materials of the lathing and the truss system are being examined to see if they can be reused. For example, if it is planned to install a heavier coating instead of the old roofing material, then it is necessary to replace or strengthen the elements of the rafter system. It is important that the load exerted on the rafters is designed for additional pressure.

In some cases, special online calculators are used to calculate the load. At this stage, a project is often drawn up to replace the roof of a building, which, however, is not always necessary. The project specifies the timing of the work, the stages of the process that were clarified during the inspection of the roof and its individual elements, the approximate cost of the work, and some other data. In order for the project to be complete and exactly correspond to reality, it would be best to entrust its compilation to professionals.

Then, as a rule, the calculation of the amount of the materials that will be needed for the work, as well as their purchase, is carried out. With the help of online calculators, you can determine the number of roofing materials, scaffolding, insulation, steam, and waterproofing, as well as other elements necessary to replace the old roofing. On their official websites, manufacturers usually help to calculate the necessary materials in the number of sheets, boards, rolls, or packages. In case of errors during installation or other inaccuracies, materials should be purchased with a margin of 10% of the total quantity. if the stock is not needed, most hardware stores will be able to take it back (upon presentation of the receipt).

Also, the preparatory stage includes the purchase or rental of all the necessary tools, including protective clothing, shoes, glasses, and gloves. If the work is carried out at a dangerous height, then it is obligatory to use a safety belt. All stairs and scaffolding should be designed for the pressure that is planned to be exerted on them. It is not allowed to work with the use of random support surfaces.

The final stage of the preparatory work is considered to be the installation of scaffolding, which is necessarily fixed in cases when construction work is carried out on the roof. The complexity and size of the scaffolding depend on the nature of the work, which is determined during the inspection of the roof and when drafting the project. The installation of scaffolding has a positive effect on the efficiency of work, and also allows you to significantly save time.

Important: In order to carry out high-quality work, it is necessary to create safe conditions for craftsmen who will work on replacing the roof.

Dismantling works

Dismantling of the old roofing should begin from the end, removing the material row by row. The resulting parts of the material are carefully sent down and immediately after the dismantling of the coating is completed, they are sent to the landfill. Disassembly of the truss system is also carried out in the top-down direction. In cases where the elements of the truss system and the lathing have been rotted, it is necessary to use them as supports for stairs or scaffolding.

The space located under the ramp is fenced since its destruction can harm random passers-by. Do not forget that some of the removed materials can be reused. They should be separated from those compositions that are planned to be sent to the landfill. Dismantling works constitute an important stage of the roof replacement process, so it should be carried out very carefully. It is quite possible that you will have to work with some elements of the coating separately. Upon completion of the removal of the old coating, it is obligatory to clean and level the base, on which a new material will soon be applied.

Work on the installation of a new roof on the existing truss system

Cases in which the dismantling of the truss system is not required, and new elements of roofing layers are installed on ready-made supports can be considered easy. In such situations, the building itself does not need restoration: only the roof is being updated. It is worth nothing that if the reason for replacing the roof of a private house was the sagging of the structure, then the elements of the truss system should be replaced. Such a dangerous phenomenon indicates the imperfection of the supports on which the roof is installed.

In the case of installation of a new coating on an already installed rafter system, it is necessary to install waterproofing, vapor barrier, and thermal insulation sequentially.

What are the main features of these processes?

- Waterproofing membranes are designed to protect the insulation and other components of roof layers from the effects of moisture and water leaks. The membranes are mounted with an overlap of 10-15 cm and are also necessarily glued with double-sided tape or special tape. The most popular domestic manufacturer of vapor barriers is the company Izospan. Also, good materials are made by Juta, Tyvek, Delta, Folder, and others.

- Vapor barrier. Such materials are designed to relieve the under-roof space from the effects of excess moisture.

- Thermal insulation. Installation of thermal insulation begins with the selection of material for insulation, the width of which should coincide with the pitch of the rafter system. As a rule, this indicator is approximately 60 sm. Panels of thermal insulation composition, for example, mineral wool, are tightly laid between the roof supports. any joints, junctions, holes, and leaks that are formed during operation are necessarily filled with insulation scraps.

This is necessary so that the thermal insulation layer is evenly distributed over the entire surface of a flat or pitched roof. If polystyrene foam was chosen as the insulation, then all seams, joints, junctions, and gaps should be filled with construction foam. Among the most common insulation options are mineral wool, foam plastic, expanded polystyrene, and also sprayed compositions.

The arrangement of the roof finishing coating, types of materials, and technology of their arrangement

In modern construction, roofing can be made of various materials. In most cases, the owners of private houses decide to replace the old roof with another material that surpasses the previous version in quality, performance, and some other indicators. Let’s consider the roofing materials that are in the greatest demand today.

Slate:

Materials such as wave and flat slate are excellent roofing material options for residential buildings. Slate is able to perform the function of heat preservation, as well as reliably protect the premises from the effects of environmental factors. Slate is based on the use of clay-slate with the addition of various useful substances. This material is useful not only as a roof but also in the construction of fences, enclosures, and other structures.

Wave slate is most often used as a roofing material. It is characterized by a long service life (up to 50 years), ease of installation, excellent water-repellent properties, resistance to temperature changes and mechanical loads, almost complete fire safety, high noise absorption characteristics, as well as an acceptable cost.

Among the disadvantages of slate is its fragility, which makes it difficult to store and transport the material, the ability to lose waterproofing properties in the absence of proper care, the tendency to form lichens and mosses (especially if the roof is located in the shade), as well as the instability of the color characteristics of the material. However, the advantages of the material outweigh its disadvantages, which is why slate is often chosen as a working material.

The slate sheets are laid in the direction from bottom to top with an obligatory overlap of at least 10 sm. If necessary, the sheets of material are cut off in order to ensure that the correct shape of the roof is observed. In some cases, especially when the roof is dominated by a horizontal slope, the laying of the slate is carried out with an offset. Sheets of the roofing material are fixed to the work surface using self-tapping screws covered with a thin layer of zinc, which are twisted tightly enough.

It is not also worth forgetting that before cutting the slate sheet, it should be moistened with water to prevent the destruction of the material. The process itself is carried out using a hacksaw or an angle grinder (the disc should have a small diameter). The final stage of slate installation is the sealing of all joints and junctions using mounting foam. After that, drainpipes and other additional elements are installed on the roof.

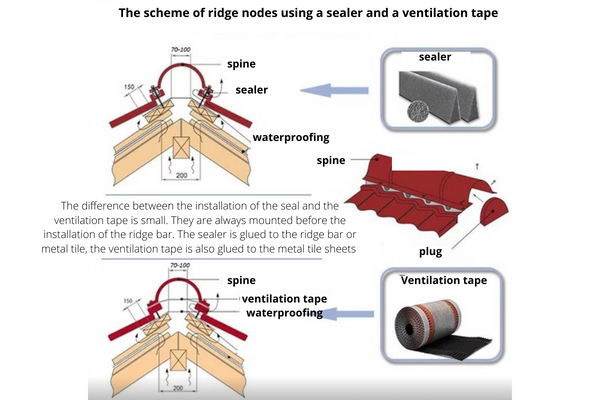

Metal tile:

The metal tile is based on thin-sheet rolled steel, the width and thickness of which vary, respectively, from 0.9 to 1.2 m and from 0.35 to 0.6 mm. as it is known, metal is capable of being exposed to corrosion, therefore, in order to avoid damage, the metal tile is covered with a protective layer based on zinc or an allow of zinc and aluminum. In its form, this material resembles a natural tile and also has a pleasant appearance, because it is covered with paint that can withstand serious atmospheric influences.

The advantages of metal tiles include a long service life, high strength indicators, as well as an attractive appearance. If we talk about the shortcomings of the material, then we can single out high requirements for other elements of roofing layers, such as for example, a lathing and a rafter system. Also, with the help of metal tiles, it is difficult to process structures of non-standard shape. In such cases, a much larger amount of material is used than would be used for simple structures, and there is also a lot of construction waste left after the completion of the work. Despite this, metal tiles are often used for the decoration of roofs made of wood and brick.

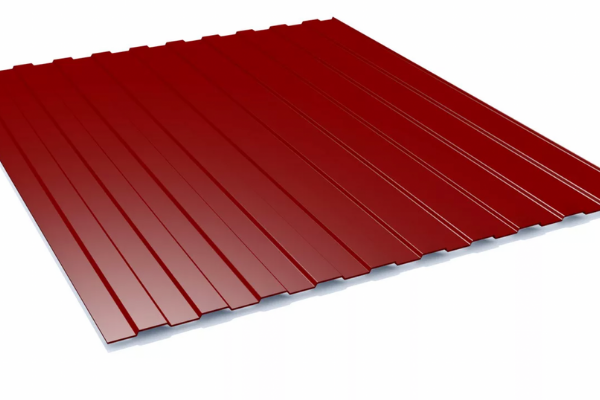

Profiled sheet:

At the heart of the production of the profiled sheet is a technology similar to the technology of manufacturing metal tiles. However, in this case, the formation of individual tiles of the tile does not occur: protrusions and cavities are rolled in the material in the longitudinal direction, which will act as stiffeners. Such sheets of roofing material are characterized by high strength and resistance to snow and wind loads.

Also, the profiled sheet is characterized by an acceptance cost, long service life, and ease of installation., which, if you have the proper experience, you can handle yourself. However, such a coating cannot be called refined: it has an incomplete appearance. In addition, the profiled sheet has low noise insulation. Nevertheless, with the help of this material, the roofs of small and medium-sized private houses are often decorated.

Flexible shingles:

Another type of shingles — soft or flexible shingles contain dense construction cardboard or fiberglass. The base of the tile is necessarily impregnated with bitumen and treated with a sprinkling of fine crumbs, for example, basalt. In construction shops, soft tiles come in the form of sheets, the size of which is approximately 100 x 300 sm. The fastening of the tile sheets to the base is carried out with the help of bitumen mastic and special roofing nails, and each subsequent layer of material should overlap and close the nails fixed on the previous layer. Neglect of this rule can lead to a violation of the tightness of the roofing.

Flexible shingles are characterized by reliability, strength, and durability, as well as attractive appearance, high noise and thermal insulation, and excellent elasticity, allowing the material in question to be used for roofs of complex shapes. The negative features of such coating include its rather high cost, heaviness, and low mechanical strength.

In addition, the mastic used to fix tile sheets to the surface has a limited service life (no more than 6-7 months). With the help of flexible tiles, both non-residential structures (gazebos, greenhouses, baths) and residential.

Flexible shingles:

Another type of shingles — soft or flexible shingles contain dense construction cardboard or fiberglass. The base of the tile is necessarily impregnated with bitumen and treated with a sprinkling of fine crumbs, for example, basalt. In construction shops, soft tiles come in the form of sheets, the size of which is approximately 100 x 300 sm. The fastening of the tile sheets to the base is carried out with the help of bitumen mastic and special roofing nails, and each subsequent layer of material should overlap and close the nails fixed on the previous layer. Neglect of this rule can lead to a violation of the tightness of the roofing.

Flexible shingles are characterized by reliability, strength, and durability, as well as attractive appearance, high noise and thermal insulation, and excellent elasticity, allowing the material in question to be used for roofs of complex shapes. The negative features of such coating include its rather high cost, heaviness, and low mechanical strength.

In addition, the mastic used to fix tile sheets to the surface has a limited service life (no more than 6-7 months). With the help of flexible tiles, both non-residential structures (gazebos, greenhouses, baths) and residential buildings (private houses, cottages) are traditionally decorated. This material is especially well combined with stone and wooden coverings. If there is no need to replace the old lathing, soft shingles can be used as a new coating, which is replaced by the worn roofing material.

Profiled flooring:

Modern profiled flooring is made on the basis of sheet steel coated with a thick layer of zinc. Such a coating can prevent the destruction of the roof under the influence of corrosion. As a rule, the protective composition is sufficient for at least 15-20 years, even in harsh operating conditions. Currently, profiled flooring is mainly used for the design of non-residential and economic structures, as well as temporary buildings. The thickness of the material sheet varies from 0.45 to 0.5 mm. today, profiled flooring is in fashion, which imitates wood or another natural coating in color. However, this coloring does not go too well with decorative elements that are usually installed on the roof.

The technology of laying profiled flooring depends on which type of roof is characteristic of a particular structure (single- and double-pitched, hip, attic, and others). Today two main methods are used for laying profiled flooring – three-blocked and four-blocked. The first option does not involve the installation of capillary grooves, the second one involves the installation of capillary grooves designed to drain excess fluid at the joints. There is also another method — ordinal, in which sheets of roofing material are stacked in rows with respect to overlap.

To trim the elements of profiled flooring, it is recommended to use a hacksaw or special scissors designed to work with metal. The protective paint will help to eliminate various surface damages such as scratches and chips that appear during the installation of the roof. The sheets themselves are fixed to the base using galvanized screws, which necessarily include a sealing rubber gasket, a drill bit, and ahead of the desired color.

At the same time, the length of the screws is determined by the thickness of the lathing: the screws should not pass through it. It is worth noting that for each square meter of profiled flooring, as a rule, from 6 to 8 standard screws are required. At the stage of installation of fasteners, it is important not to twist or finish them, because the quality of the roofing depends on it.

Prices for work on the replacement of the roof of the house

The cost of replacing the roof of a building, as a rule, is determined by the roof area, the degree of disassembly required in a particular case, the planned timing of the work, as well as the condition of the load-bearing elements of the building, the dismantling of which may be optional. Another important factor affecting the price of work on replacing the roof of a private house is the natural conditions in which the process will be carried out.

Below is a table with an example of prices for work to replace the roof of a building. The cost is indicated on 1m2 of the area.

| Name of roofing material | Metal shingles in $ | Flexible shingles in $ | Composite shingles in $ |

| Dismantling of the old roof | 10 | 10 | 10 |

| Arrangement of waterproofing | 10 | 10 | 10 |

| Installing of counter-lathing | 10 | 10 | 10 |

| Installing of lathing | 12 | 12 | 12 |

| Installation of a lining carpet | Not required | 10 | Not required |

| Installation of a new roof | 36 | 45 | 57 |

| Roof replacement | 78 | 109 | 99 |

| Installing the inner lathing | 7 | 7 | 7 |

| Installation of vapor barrier | 7 | 7 | 7 |

| Installation of thermal insulation | 13 | 13 | 13 |

| Roof insulation | 27 | 27 | 27 |

| The arrangement of finishing coatings of the pitched roof | ||

| Name of the material | Unit of measurement | Price |

| Laying of metal tiles | m2 | starting from 60 |

| Laying of ceramic tiles | m2 | starting from 80 |

| Installing a ceramic ridge | running meter | starting from 120 |

| Installation of flexible roof tiles | m2 | starting from 60 |

| Installation of profiled flooring | m2 | starting from 60 |

| Installation of composite tiles | m2 | starting from 50 |

| Laying of cement-sand screed | m2 | starting from 70 |

| Laying of natural tiles Braas (Braas) | m2 | starting from 45 |

| Installation of a profiled sheet | m2 | starting from 40 |

| Installation of slate | m2 | starting from 35 |

| Installation of a copper sheet | m2 | starting from 60 |

| Installation of euro slate | m2 | starting from 46 |

| Installation of a seam covering | m2 | starting from 80 |

| Installation of a copper coating | m2 | starting from 150 |

| Installation of zinc-titanium coating | m2 | starting from 150 |

| Installation of a slate roof | m2 | starting from 160 |

| Installation of a drainage system | ||

| Installation of a gutter with a funnel and a pipe | running meter | starting from 120 |

| Installation of a storm drain pipe D=100 | running meter | starting from 190 |

| Installing the funnel | piece | starting from 140 |

| Installation of a drip tray with an inset into the wall | running meter | starting from 90 |

| The arrangement of snow holders | running meter | starting from 40 |

Estimate for roof replacement

To prepare a detailed estimate for the replacement of the roof of a building or a private house, you can contact specialists.

The estimate is not just a certain total amount, the estimate — is a document detailing all the work and materials used, their volumes, and their costs. The estimate for the replacement of the roof of the building includes all possible data on the process of work. The estimate should include the following items:

- A detailed list of all works performed, the volume of these works, and prices;

- A detailed list of all materials used, their volume, and prices;

- Prices and number of shifts and construction equipment;

- The cost of disposal of construction debris;

- Prices for the construction of auxiliary building structures, for example, scaffolding;

- Prices for delivery of construction materials;

- Overhead costs.

Online calculator for calculating the price of work on the reconstruction of the roof

Расчет стоимости устройства плоской кровли под ключ

Итоговая стоимость

Расчет стоимости устройства скатной кровли под ключ

Итоговая стоимость работ

Replacing the roof with your own hands

It is quite possible to cope with the work of replacing the roof of a private house on your own, the main thing is – to be carefully prepared for this process. It is necessary to study the condition of the roof, detect all damages and assess their degree, investigate the nature of damage to the load-bearing structural elements or make sure that they can be used again. It is important to be 100% sure that the elements of the truss system will withstand the pressure from the new layers of hydro, heat, and vapor barriers, as well as from the updated roofing.

Replacing the old roofing with a new one begins with working with a lathing. First, this roof element is dismantled and then re-installed. In cases, where partial repair of the lathing is required, only damaged parts are replaced. The size of the step of the lathing is determined by the type of roofing. For example, for asbestos cement, it is 75 sm, and for metal tiles – is about 40 sm. A counter-lattice is fixed to the outer side of the rafters, which serves as the basis for installing steam and waterproofing. In some cases, additional spacers are mounted, designed to strengthen the lathing.

The ends and the cornice overhang also need strengthening, and a solid lathing will help to rid these structural elements of such a dangerous phenomenon as snow stagnation. The load-bearing elements of the building are reinforced with brackets, linings, bolts, and additional racks. Installation of additional ventilation of the roof, preventing the accumulation of moisture in the under-roof space. Thermal insulation in this case can be placed both under the rafters and between them. The vapor barrier is necessarily treated with finishing material. It is important to approach each stage of work responsibly: only in this case, the replacement of the roof of a private house will be possible without the help of professionals.

Regardless of what material is used as a roof, when performing work with your own hands, it is recommended to prepare the tools, which are:

- Nail Clipper,

- Screwdriver,

- Hammer,

- Knife,

- Roulette,

- Level,

- A circular saw.

You can read more information about the replacement of the roof and its reconstruction in the following articles:

- Reconstruction of the roof of the building and the roof of a private house

- Arrangement of the roof of a house and a turnkey building: Types, materials, construction technologies, and installation prices

- Flat roof arrangement: Installation technologies of various types and prices for complex construction

- Arrangement of pitched roof: Types of pitched roofs and technologies of their arrangement

- Repair of the roof of a private house, an apartment building, and an administrative building on a turnkey basis

Scheme of replacement of various elements of a pitched roof:

Tutorial video on replacing the roof with your own hands

Turnkey roof replacement services

Employees of our construction company constantly perform work on replacing the roof of a private house on a turnkey basis. It is profitable to cooperate with a proven company because professionals in their field will be able to advise the customer on all issues, give useful advice, draw up a complete project of work, as well as replace the roof at an acceptable time for a fair price. In order to place an order, it is enough to contact our company specializing in working with roofs of buildings.

Important: The performance of work related to the replacement or repair of the roof by non-professionals can lead to errors in the installation of various elements of the roof. Such errors can eventually lead to the fact that the roof will need to be dismantled and installed again, and this is a double expense of money and time.

Replacement of a flat roof

The process of replacing a turnkey flat roof includes the dismantling of all elements of roof layers, inspection for damage, installation of all necessary components of the roof, as well as the installation of new roofing. During the installation of roofing materials, it is provided:

- Slope according to the standard

- Heat insulation

- Waterproofing

- Working drains capable of diverting water in time

The cost of such work varies depending on the number of roof layers, the need to remove construction debris independently, and some other factors. Our company performs turnkey flat roof replacement work quickly and efficiently.

Replacement of pitched roof

Dismantling of the roof covering of a pitched roof necessarily begins with the ridge of the structure. Roofing materials are removed in rows in the top-down direction. In the process of work, it is extremely important to monitor how much material can be reused. It is also necessary to know exactly where the main damage to the roof is located since they most often indicate violations of the integrity of the rafter system.

Professionals specializing in the replacement of a pitched roof on a turnkey basis perfectly cope with all stages of work. Also, specialists will be able to calculate the materials needed for the work, so that the customer does not have to overpay. When placing an order for the replacement of turnkey roofing, the company provides a guarantee for both construction work and roofing materials.

Replacement of the roof covering

As you know, the current repair of roofing, containing numerous damages, is not always advisable, for this reason, owners of private houses often choose to replace the old roofing with a new one, that is of higher quality, externally attractive, and durable. Moreover, such work may include both complete and partial dismantling of the old coating. However, it is important that the elements of the truss system are able to withstand the pressure from all roofing materials.

Construction companies traditionally replace the roofing on a turnkey basis. The price for dismantling and installation work is determined by the degree of damage to the old coating, the total area of the roof, the required amount of work, as well as the type of materials that specialists will work with. The representatives of the company with which you plan to cooperate will be able to offer you the most high-quality and at the same time budget roof options. It is only important to make sure that the company provides a guarantee for its work and materials, and is also ready to work under the conditions formulated by the customer.