Table of Contents

- Types of paint waterproofing and their characteristics

- Advantages and disadvantages o paint waterproofing

- Technology of the paint waterproofing arrangement

- Features of paint waterproofing of foundation walls

- The arrangement of paint waterproofing of the roof

- Prices for the paint waterproofing arrangement

- The arrangement of painting waterproofing with your own hands

In modern construction, there are several types of waterproofing, each of which is designed for a certain type of materials, surface structures, and operating conditions.

Paint waterproofing is used both for buildings located above the ground and for buried parts of buildings and structures, such as basements, underpasses, and parking lots, hydraulic structures such as swimming pools and reservoirs, which are located below ground level and may be direct contact with groundwater and aggressive environment.

This type of waterproofing is widespread due to a fairly large selection of materials, ease of application, and easy accessibility.

Types of paint waterproofing and their characteristics

There are several types of paint waterproofing. The basis for their differentiation is primarily the material used for the protective painting of structures, as well as a number of the following features:

- According to the composition of the binder, they are:

- organic;

- organo-mineral.

In the organic class, the following stand out:

- bituminous;

- bitumen-polymer – bitumen properties are modified by a polymer component;

- polymer – may consist of synthetic resins and paint compositions.

Organo-mineral compositions are presented

2. To strengthen the strength, various components are added to the paint waterproofing. On this basis, waterproofing is distinguished:

- reinforced;

- non-reinforced

3. According to the structure and condition of the components, they are distinguished:

- emulsions;

- mastics;

- pastes.

Let’s take a closer look at the most popular types of waterproofing by the painting method.

Bituminous

Most often, bitumen compounds, such as emulsions, mastics, or pastes, are used to process parts of suburban and multi-story buildings. They are applied in several layers, the number of which is regulated by the operating conditions of the waterproofing. As a rule, from 2 to 4 layers of the composition are applied to the work surface, and the total thickness of the applied material (all layers together) is 0.2-0.6 sm.

Bitumen mixtures are able to adhere perfectly to the surface and are therefore characterized by strength and resistance to external influences of any kind. In some cases, for example, when the working surface is located at an incline, it is necessary to install additional protective structures or a reinforcing frame, which will alternate with layers of bitumen material. Additional elements in places of corners or faces are especially relevant.

Often, the composition of bitumen material is supplemented with various additives that improve its properties, such as elasticity a d resistance to low temperatures. In situations where the operating conditions of waterproofing imply a significant increase in temperature in the working area, the elasticity of bitumen compounds, on the contrary, is reduced by adding fibrous or finely dispersed pulverized substances to them.

The best indicators of water resistance and thermal stability are characterized by bitumen mastics created using hot and cold preparation technologies. The worst options in this case can be considered compositions in the form of emulsions, since, firstly, the drain from the work surface at the installation stage, and secondly, they begin to crack when exposed to cold temperatures.

Bitumen-polymer compositions, which differ from standard variants by the addition of polymers, are also considered as a type of bitumen materials. This is done to achieve the best physical and chemical characteristics of the material. The most popular are rubber-like polymer additives. By introducing this substance and it’s like into the initial composition, materials intended for:

- bitumen-rubber,

- bitumen-latex,

- bitumen-polyethylene,

- bitumen-epoxy

and other numerous types of bitumen paint waterproofing.

You can read more about bitumen waterproofing in the article – “Bitumen waterproofing: types, characteristics, and technology of the installation“.

Polymer

Polymer paint materials differ from bituminous ones primarily by a higher cost. The main compositions representing the type of polymer materials are considered to be epoxy mixtures, as well as mixtures based on epoxy resin with the addition of tar, furfural, or phenol. The epoxy layer is considered sufficiently stable and protects the treated surface well from moisture.

However, like any other material, epoxy compounds have their drawbacks. These include, for example:

- noticeable shrinkage of the layer over time,

- tendency to detach the material from the base

- and a tendency to crack.

Also, a significant problem with polymer compositions is that they are quite difficult to apply, and it takes a lot of time for solidification. For these reasons, it is best to trust the application of polymer-based materials to professionals.

Due to their disadvantages, polymer mixtures are less and less used in modern construction.

Polyurethane

Polyurethane compositions — are materials, where polyurethane is the main component. This type of insulation, depending on the specific material, can also be considered painting. Polyurethane can be applied by spraying or manually depending on the surface and the situation.

The main difference between polyurethane paint systems from bitumen and cement is that most of these materials can be tinted in almost any color and that, if desired, they can be applied as a final coating on roofs and balconies, since they are resistant to ultraviolet solar radiation or a special protective varnish can be applied to them.

You can read more about polyurethane waterproofing in the article – “Polyurethane waterproofing“.

Polymer concrete and polymer-soluble

The following type of paint waterproofing is in many ways similar to bitumen compositions since it is also applied in several layers (from 2 to 4) and has high moisture resistance. However, unlike bitumen, polymer concrete coatings are distributed over a thickness of approximately 3 to 6 mm.

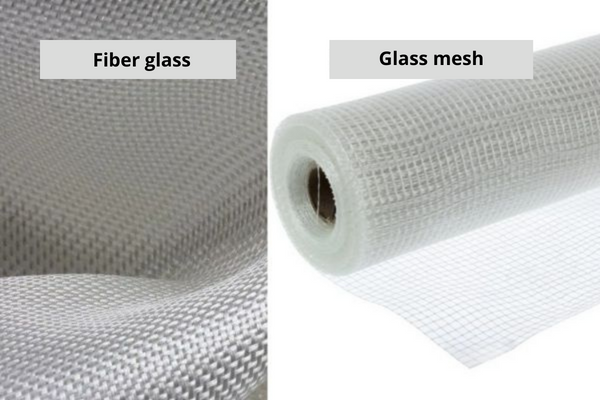

Difficult moments of the working surface, for example, angles of rotation and margins are necessarily equipped with burlap, fiberglass, or glass mesh. But it should be understood that for structures characterized by the opening of cracks over 0.2 mm, it is recommended to use other types of sealing rather than paint waterproofing.

Paint waterproofing with polymer concrete or polymer-soluble compounds is used to protect structures from capillary moisture, as well as minor effects of precipitation.

The pressure of the liquid for paint waterproofing should not exceed two meters. If there is a risk of flooding of a particular territory, or it is regularly exposed to aggressive precipitation, it is best to make a choice in favor of pasting, coating or roll waterproofing.

Polymer concrete and polymer-soluble compounds can be used both from the inside and from the outside of the structure.

Epoxy-tar

Sometimes, as a separate type of paint waterproofing, the most common polymer composition is distinguished, namely, an epoxy-tar mixture. We can safely say that this material has the widest range of applications.

It is recommended to use it to protect those parts of the structure that are constantly exposed to moisture. Epoxy-tar composition is also used for the hydrophobic treatment of monolithic structures and load-bearing structures for industrial purposes.

Polymer cement

This type of waterproofing belongs to the organo-mineral class of compounds.

The most common type is cement-latex. The mixture is applied in 5 or more layers to achieve the desired effect, the total thickness of the layer should be at least 2mm. In places where the surface bends, the layer is additionally reinforced with fabric.

You can read more about cement waterproofing in the article – “Cement-based waterproofing: Features, types, and methods of its application”

Polymer cement waterproofing

Advantages and disadvantages o paint waterproofing

All types of waterproofing, although they have a lot in common, still have their own advantages and disadvantages that need to be considered at the stage of material selection. For some structures, paint waterproofing may not be suitable in many ways, and it is important to understand this. Below we will consider the main parameters on the basis of which you need to make a choice in favor of a particular material.

Comparison table between paint waterproofing, pasting, membrane, and roll one

| Painting | Roll surfaced | Roll pasting | PVC membrane | |

| Mounting method | Non-firing | Firing with the burner | Non-firing | With the drier and mechanical fixation |

| Availability of seams | Not available | Available | Available | Available |

| Adhesion (adhesion) to the concrete base | 100 % | 20 % | 30 % | No adhesion |

| Adhesion (adhesion) to the metal base | 100 % | Not available | No adhesion | No adhesion |

| Complete repetition of the surface relief | Available | Not available. There will be voids | Not available. There will be voids | Not available. There will be voids |

| Coefficient of elasticity | 600-800% | 10-20% | 10-20% | 10-20% |

| The ability to apply mechanized | Available | Not available | Not available | Not available |

| Warranty period for works | 5-7 years | 2-4 years | 1-2 years | 1-3 years |

Technology of the paint waterproofing arrangement

The arrangement of paint waterproofing regardless of what compositions are used for it, has a common technology, which is followed by representatives of all construction companies.

Before starting the process, the working surface:

- is sanded;

- is cleaned;

- is dried.

It is important to remove all dirt from the surface, especially greasy stains. It is also necessary to remove the surges and protruding fittings, and existing sinks and other recesses need to be sealed.

To perform high-quality surface cleaning, steel brushes, scrapers, and sandpaper circles are used. Greasy stains are removed using the white spirit of gasoline. to apply the listed solutions to the work surface, a rag soaked in any of the liquids considered usually helps. During the installation of waterproofing, deformation seams are necessarily sealed with sealants and sealed with special tapes. after a high-quality and thorough cleaning and surface preparation, the masters can proceed directly to the application of paint waterproofing.

Important application rules:

- When arranging to waterproof, the main thing should be to create a uniform solid integral coating in thickness, for which it is necessary to apply several layers. There should be no defects in it: swelling, cracks, surges, drips, etc.

- A primer (back paint) should be applied under the paint layer.

- Waterproofing is worn after the primer has completely dried, as well as each subsequent layer is applied after the previous one has completely dried.

- If reinforcing materials are used, they should be overlapped with an overlap of at least 12 sm.

- The adhesion strength to the surface should be at least 0.5 MPa.

- Most compounds need protection from solar radiation.

Now let’s look at the most common application technologies.

Manual application

Most often, the paint waterproofing is distributed over the surface manually. This work is quite simple in performance and it can be entrusted even to the most experienced builder. For manual application, brushes and rollers are used, which, however, are not always able to fill all existing voids.

Since the paint material is applied in several layers, the holes and irregularities formed during the distribution of the first layer can be compensated by the following layers of material. A noticeable advantage, in this case, is possessed by compositions made on the basis of bitumen, since they are able to spread evenly over the working surface, eventually filling all holes and voids.

At industrial facilities and large buildings, spray equipment designed for applying waterproofing materials is most often used. Spraying of compositions takes place under high pressure and from the very beginning does not allow the formation of irregularities and voids, however, it is much more expensive than the “manual” laying technology.

Despite the undoubted advantage of spray equipment, it is not worth using it without a reasonable purpose. After all, it is much easier to carry out waterproofing of a private house or non-residential premises located on a private territory with the help of a brush or roller.

Features of paint waterproofing of foundation walls

Often the foundations of private houses and apartment buildings are flooded with groundwater. In such cases, it is best to use paint insulation compounds that can withstand severe water pressure, for example, such as liquid rubber.

Paint mastics, pastes or emulsions are applied to the foundation in several layers, and the degree of elasticity of the material is individually selected for each structure, depending on the improving substances added to it. It is possible to process the foundation with the help of paint waterproofing both inside and outside the building, thereby compensating for cracks and other defects.

At the stage of purchasing the material, it is extremely important to take into account the characteristics of the soil with which the foundation contacts. This is due to the fact that some types of soil contain chemicals that destroy specific compounds. It is necessary to choose a material that will be resistant to any influences in the right operating conditions.

The characteristics of the soil include, among others:

- Its composition,

- “behavior” depending on the season,

- swelling in the cold,

- freezing depth,

- глубина промерзания,

- composition of groundwater,

- aggressiveness of the environment.

It is also necessary to take into account the climatic features of the area, the type of foundation and the arrangement of the drainage system, installed on the territory in question.

Another feature of the paint waterproofing of the foundation is that one-sided surface treatment is ineffective: it is important to apply a sealing material both outside and inside the building. It is not difficult to process residential premises from the inside with the help of polymer cement compositions working on negative water pressure (from outside to inside), protecting not only owners of private houses, for example, from foundation leaks, but also apartment residents— from flooding from neighbors.

It is recommended to carry out paint waterproofing of the floor simultaneously with hydrophobic treatment of the lower part of the walls, since the hydrophobic floor covering should form a solid surface with waterproofing of the walls.

It is important to use only those materials that are absolutely safe for human health, since the residents of the house or apartment will constantly be in contact with substances released by the waterproofing compound. You can easily find such materials in a hardware store: they are marked with the inscription “for interior work” on the label.

The most popular compositions for indoor use today are liquid acrylic mixtures.

You can read more about the waterproofing of the foundation and walls in the following articles:

- Foundation waterproofing arrangement: Methods, materials, prices and recommendations of specialists

- Waterproofing of basement and house walls from the outside and inside – Methods, materials, prices and technology

The arrangement of paint waterproofing of the roof

Due to its consistency, this type of waterproofing is excellent for moisture protection of roofs with a complex surface configuration — with various superstructures, tilt angles, and etc.

On the roof, the paint waterproofing is applied in 3-4 layers, with total thickness of 0.3-0.5 sm, as a paint material you can choose:

- bitumen roofing mastics;

- synthetic resins;

- polyurethane waterproofing;

- waterproofing with polyurea;

- liquid rubber.

To increase protection from solar radiation, a special sparkling or protective varnish is often applied to the top layer.

The advantage of most paint coatings for use on roofs is that they:

- Turn into a waterproof, highly elastic coating;

- Have no seams;

- Have high resistance to temperature changes;

- Do not require heating before application.

You can read more about roof waterproofing in the following articles:

- Waterproofing of the roof: methods of its arrangement and types of materials for performing high-quality work

- Waterproofing of a flat roof. Recommended materials, methods of their installation and prices for work

- Roof waterproofing repair: Methods, materials and prices

- Waterproofing of metal roofing: Materials and technology of their arrangement under metal roofing of cold and warm roofs

Prices for the paint waterproofing arrangement

This price table shows the cost of paint waterproofing, depending on its type and method of application. The prices indicated for the work may vary from those indicated in this price list, as they directly depend on the complexity of the object, its type, the chosen paint system and other individual characteristics of each object.

| Description of work | Unit of measurement | Price in roubles |

| Applying polyurethane waterproofing manually | m2 | starting from 400 |

| Mechanized application of polyurethane waterproofing | m2 | starting from 300 |

| Applying liquid rubber manually | m2 | starting from 400 |

| Mechanized spraying of liquid rubber | m2 | starting from 600 |

| Application of polymer compositions manually | m2 | starting from 400 |

| Mechanized spraying of polymer compositions | m2 | starting from 600 |

| Application of cement-based materials manually | m2 | starting from 600 |

| Mechanized application of cement-based materials | m2 | starting from 900 |

| Arrangement of bitumen waterproofing manually | m2 | starting from 200 |

| Arrangement of bitumen waterproofing mechanized | m2 | starting from 300 |

Online calculator of the cost of waterproofing works

Calculation of waterproofing cost

The total cost of waterproofing

The arrangement of painting waterproofing with your own hands

The application of this type of waterproofing, depending on the composition and surface of the application, can turn out to be both a super-complex high-tech process and a fairly simple matter, subject even to a beginner in construction. As a rule, the more expensive and reliable the waterproofing material is, the more difficult it is to prepare and apply it correctly.

To apply waterproofing with your own hands, you need to follow the following steps of work:

- Choose the right type of waterproofing coating – a material with certain characteristics is suitable for each structure and case;

- Properly prepare the surface – at this stage, 50% of success of the entire waterproofing process is covered. The surface should be cleaned of dust and dirt, remove sharp corners and bumps and, if necessary, degrease (if we are talking about metal);

- Properly prepare the composition – mainly relevant for 2 or 3 component compositions;

- Base priming – most paint systems require pre-priming the base with a special primer or back paint;

- Apply the selected composition strictly following the manufacturer’s instructions – it is necessary to comply with the manufacturer’s recommendations not only in compliance with the rules of application, but also in the number of layers and the drying time of each of them;

- Protection– after application, some paint compositions require a protective coating arrangement designed to protect the work performed from mechanical damage or from exposure to ultraviolet radiation.