Table of Contents

- How a monolithic foundation slab and its layers are arranged

- Is it necessary to make waterproofing the foundation slab and the consequences of its absence?

- How to make properly the waterproofing of the foundation slab and under it?

- Methods of waterproofing installation and materials used for them

- Waterproofing installation of the foundation slab rates with prices per 1m2

The foundation slab is the foundation of a future building, structure or private house and the reliability of the future structure depends on the quality of its installation. That is why it is necessary to take seriously the construction of this part of the future structure and observe all technical norms and rules when installing it, including in the waterproofing section.

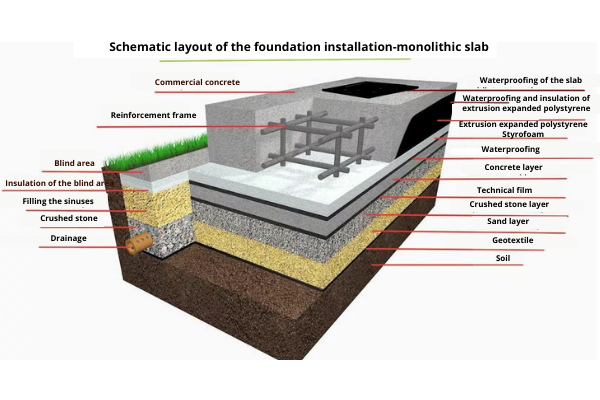

How a monolithic foundation slab and its layers are arranged

The slab foundation of ready – mixed concrete or monolith is arranged as follows:

- Compacted soil;

- Geotextile – as a separating layer and a material that contributes to the hanging strength of the base;

- Sand-rammed sand is designed to filter groundwater, evenly distribute loads, and reduce possible vibrations;

- Geotextile – necessary for additional strengthening, exclusion of interpenetration of different layers, and protection from silting;

- Crushed stone – generally has the same purpose as a sand cushion, further reducing the likelihood of soil moisture rising up;

- Geotextile or technical film – serves as a separating layer, protects against the mixing of layers, and contributes to the reinforcement of previous layers;

- Concrete preparation is a very important component of the foundation cake, as it serves as the basis for the device of future waterproofing. In addition to waterproofing, concrete preparation contributes to the correct installation of the metal frame and the correct arrangement of the future geometry of the plate;

- Waterproofing – serves as a cut-off of the monolithic slab located below and protecting it from water;

- Geotextile – as a separator;

- Thermal insulation – in some solutions there is no thermal insulation, which is not a violation. Thermal insulation is designed for insulation;

- Geotank;

- Reinforced frame – installed in 2 levels and provides a high load-bearing capacity of the future foundation;

- Commercial concrete is the pouring of a monolithic slab, the thickness of which depends on the type of structure and future loads.

The scheme of installation of the foundation slab:

Is it necessary to make waterproofing the foundation slab and the consequences of its absence?

Is it necessary to make waterproof the slab?

The answer to this question is: Of course, it is necessary. The durability of the foundation, its reliability, and its indestructibility directly depends on the quality of the waterproofing performed.

In addition to the fact that waterproofing protects the slab itself from the effects of water, aggressive environment, and moisture, it also protects your future home or structure from the penetration of water and moisture inside. Since concrete has a porous structure and absorbs moisture like a sponge, this moisture is able to move through the pores and capillaries inside the concrete and exit on the concrete inside your structure.

Consequences of the lack of high-quality waterproofing:

- Cracks in the slab – In the absence of waterproofing under the slab, water is absorbed into the concrete, freezing in it in winter and thawing in summer. This cycle gradually leads to the destruction of concrete, and the formation of pores, voids, and microcracks, which can later turn into serious cracks threatening the integrity of the entire foundation.

- Flooding of the basement or basement – Concrete can pass water into the room through the voids, capillaries, fittings, and microcracks existing in it. Without proper waterproofing, capillaries and microcracks grow, which eventually leads to an increase in the volume of water in the basement.

- Fungus and mold in the basement – The constant humidity of the slab due to the lack of waterproofing, contributes to increased humidity in the room, which in turn contributes to the growth of mold, threatening not only the house but also human health.

How to make properly the waterproofing of the foundation slab and under it?

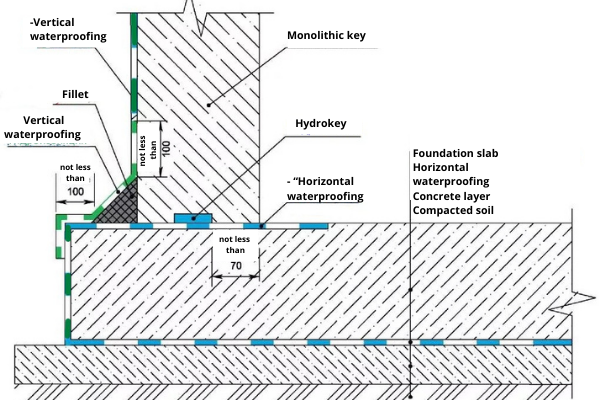

It is necessary to approach the issue of waterproofing a monolithic foundation comprehensively by performing the main waterproofing under the slab, as well as an additional one on it.

- The first and most important contour of waterproofing protection passes under the slab and serves as a cut-off protecting it from the effects of the surface, groundwater, and moisture from the soil located under the structure. Waterproofing under the foundation should be applied to a rigid and durable foundation, namely concrete preparation. Otherwise, the waterproofing made will be useless, since it will not be sealed and will simply disperse at the seams due to the constant dynamics of the soil.

- The second waterproofing circuit is located horizontally on a monolithic slab and is performed after the concrete has completely risen and dried. When erecting walls, it is necessary to make a small indentation from the edge of the slab inside, so that the future vertical waterproofing of the walls could form a hydraulic lock with horizontal insulation.

Important: The main mistake of builders is that they forget to make concrete preparation under the foundation, which makes it impossible to install high-quality waterproofing under the slab, since any waterproofing should lie on a rigid and reliable foundation. The lack of waterproofing under the slab makes it possible for water and moisture under the foundation to soak into the concrete base and gradually destroy it, as well as to rise capillarly up the concrete and manifest as wet spots on the floor or in the area of cold joints (joints of the slab and walls).

Additional measures:

For additional protection of the foundation from the effects of water, it is recommended to install a high-quality drainage system located 30-50 sm below the foundation mark of a house or building.

This arrangement of the drainage contributes to the fact that it can take both the water that approaches the monolithic base from the side and the one that will be under it, thereby reducing the pressure and impact of water on the base plate.

You can read more about the drainage system and the methods of its installation in the article – “Turnkey drainage installation around the house: Proper drainage, its types, installation technologies, materials, schemes, and prices“.

Methods of waterproofing installation and materials used for them

The insulation of the foundation from the top and bottom of the monolith can be done using a large number of different methods and – materials, but not all materials are equally effective.

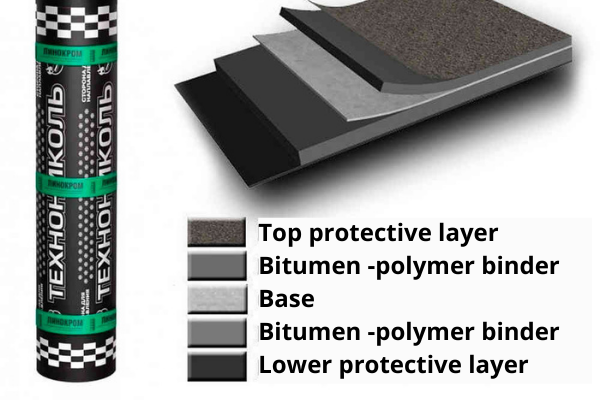

Surfaced roll waterproofing

We are talking about special rolled materials, which are mounted by their hot deposition method on a concrete preparation erected under a monolithic foundation base, as well as on the slab itself after it is poured

The surfaced membranes are supplied in rolls. The material is deposited on the surface primed with a primer by means of a burner and a fire at the time of melting of a special bitumen layer available in rolled materials.

The material is recommended to overlap in 1-2 layers so that the second layer overlaps the seams of the previous one.

You can download detailed installation instructions by clicking on the link – Installation instructions for a waterproofing membrane made of bitumen-polymer rolled materials.

You can read more about roll insulation in the article – “Roll waterproofing installation”.

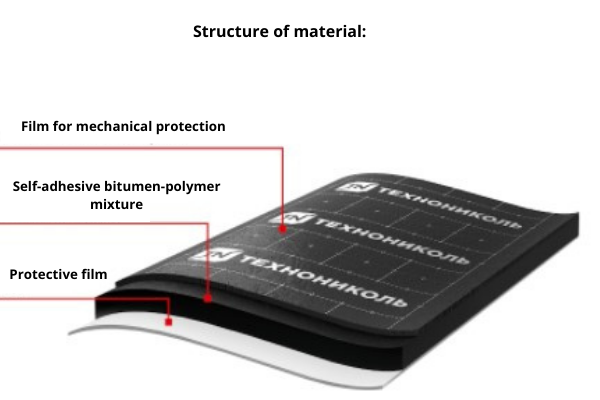

Self-adhesive roll

Roll insulation based on self-adhesive sheets is supplied in rolls, as well as surfaced, but its difference is that it does not need to be surfaced using a burner. To install self-adhesive rolls, they simply need to be rolled out on a pre-primed bitumen surface and secured on the upper edge with a metal edge rail.

The material is applied in 1 layer at low groundwater and in 2 layers at high.

Structure of self-adhesive rolls:

You can download the detailed installation instructions by clicking on the link – Installation instructions for the adhesive insulation.

PVC Membranes

PVC membranes have high resistance to aggressive environments and high strength. PVC rolls are rolled out on the surface and attached to the edges using a special clamping rail. PVC rolls are sewn together with special glue or hot air. Such membranes do not require a special primer and are mounted in 1 layer.

Detailed installation instructions can be downloaded by clicking on the link – Installation instructions for the waterproofing system of the foundation of PVC membranes.

You can read more about membrane waterproofing in the article – “Membrane waterproofing: types of materials and methods of their installation“.

Coating insulation

There are several types of coating insulation on the market:

- Bitumen – Based bitumen;

- Polyurethane – Based on various polyurethanes and additives;

- Polymer-bitumen;

- Cement;

- Polyurea;

- Liquid rubber.

When performing work with coating materials, it is necessary to choose compositions resistant to aggressive environments, salts, and minerals located underground. The coating compositions are applied using a roller or brush in 2-3 layers. Some products require pre-priming of the substrate to improve adhesion.

Liquid rubber

Liquid rubber consists of modified bitumen, latex, and various polymers. Due to its unique properties, the material has a high percentage of elasticity, as well as high resistance to aggressive environments. Liquid rubber can be applied both manually and by spraying using special spray installations. When applying, the surface should be pre-primed.

Additives in concrete

Additives in concrete are a great way to improve the waterproofing and other properties of concrete, but it is important to understand that no additive will replace real waterproofing, since it cannot change the porous structure of concrete. Additives are added to the concrete at the time of preparation of the solution in an amount regulated by the manufacturer of a particular additive.

Comparison between materials in the table

| Liquid rubber | Surfaced-bitumen based membrane | Self-adhesive rolls | PVC membrane | |

| Mounting method | No firing method. By spraying or coating | Firing with a burner. Mechanical rail mounting | Rolling on a primed base and mechanical fastening | With a hair drier and mechanical attachment |

| Seams availability | Not available | Available | Available | Available |

| Adhesion to the base | 100% | 40% | 40% | No adhesion |

| Coefficient of elasticity | 600-700% | 30-40% | 30-50% | 10-20% |

| Installation speed m2/per day | 300-700 | 20-50 | 50-80 | 30-60 |

| The warranty period for works | 7 years | 3-5 years | 3-5 years | 3-5 years |

Recommendation: The most effective way of waterproofing

When studying the above table, the advantages and disadvantages of each of the discussed isolation methods are clearly visible. The most effective method of waterproofing is the application of liquid rubber since it is this material that has unique properties that contribute to the durability and reliability of the waterproofing coating of the foundation for 30-40 years.

Advantages of liquid rubber in the waterproofing of the foundation:

- A high percentage of stretching – when the building shrinks, the material will not crack and will not disperse (like roll insulation), but will simply stretch;

- No seams – unlike rolled materials, rubber does not have such weak points as seams and joints, since it is applied with a single coating;

- 100% adhesion to the base – unlike the membrane and roll insulation, the rubber is joined to the base 100%, so that there are no cavities or voids under it through which water can pass and where it can stagnate.

Waterproofing installation of the foundation slab rates with prices per 1m2

The prices shown in the table are preliminary ones for works related to the waterproofing of the monolith foundation base. The prices indicated in the table may change if there are special conditions or difficulties in performing the work.

| Works description | Unit of measurement | Price in $ |

| The installation of surfaced waterproofing in 1 layer | m2 | starting from 50 |

| Installation of self-adhesive insulation in 1 layer | m2 | starting from 50 |

| Installation of PVC membrane | m2 | starting from 100 |

| Application of bitumen mastic in 1 layer | m2 | starting from 40 |

| Application of liquid rubber by spraying | m2 | starting from 40 |

| Applying of liquid rubber manually | m2 | starting from 40 |

| Applying a primer | m2 | starting from 10 |

Calculator for self-calculation of the cost