Table of Contents

- Advantages and disadvantages of metal roofs

- Types of metal roof

- Metal roof construction: installation technology and materials used

- Prices for the arrangement of metal roofing

Metal roofing — is the most common type of roofing used in the modern construction of buildings and structures. This type of roofing has found wide application due to its versatility, a large number of manufactured sizes, and extensive color scheme. Depending on the type of metal, the roof may be suitable for a complex roof structure. It is also attractive for its price.

Advantages and disadvantages of metal roofs

During the construction of buildings, an important stage is considered to be the installation of the roof. The market offers a wide range of roofing coverings made of various materials. The most common are roofs made of metal sheets. Like any other roofing material, metal roofs have their advantages and disadvantages.

The advantages of metal roofing include:

- Environmental friendliness of the materials used – different types of metals from which sheets of metal roofing are made are non-toxic and safe for humans during operation.

- Wear resistance and durability – with the right roof arrangement, the roof made of metal sheets can serve for a long time, without additional repairs.

- Architectural possibilities – depending on the metal of the roofing sheets, it is possible to cover roofs of various configurations, with different colors and textures.

- Lightweight – the light weight of metal sheets makes it possible to lighten the roofing sheet and, when calculating the truss system, allows you to increase the interval between the truss elements or the elements of the lathing, which saves material consumption.

- Smooth surface – facilitates the cleaning of the roofing sheet from precipitation in winter, the snow cover slides off the roof under the influence of gravity.

- Fire safety — metal roofing is capable of resisting the effects of fire and high temperatures for a long time, and is not flammable by itself.

- Strength – metal roofs have a fairly high strength index, with a metal sheet thickness of more than 0.5 mm, they are able to withstand loads from precipitation and be resistant to external factors without deforming.

- Resistance to temperature changes – roofs of this type are able to withstand temperature changes in the range of 20 degrees without changing the size and maintaining the integrity of the sheeting.

- Ease of installation – the installation of a metal roof can be done without special qualifications and expensive equipment, it is important to observe the technology of work, ensuring the tightness of the roofing sheet.

The disadvantages include:

- High thermal conductivity — it is necessary to arrange a thermal insulation layer to prevent heat loss at low temperatures.

- Low sound insulation — when installing a roofing sheet, it is necessary to additionally lay a sound insulation layer in the roof structure, which can be combined with thermal insulation.

- Additional installation of snow holders – to ensure safety on the roof with a metal coating, it is necessary to install snow holders to prevent rapid snowfall in a large layer.

Types of metal roof

Despite the large selection of metals from which sheets for metal roofing are produced, most roofs made of metal sheets are divided into types:

- Seam roofs – have such a name, due to the connecting lock “Seam”, which provides a reliable fastening of metal sheets together, the use of seam materials allows you to reduce the number of joints, which provides additional tightness of the roofing sheet.

- Roofs made of the profiled sheet – this type of roofing has found wide application in various fields of construction and is excellent for covering public, administrative and residential buildings. It is also used in the construction of industrial buildings and structures. This material is suitable for roofs with complex configurations.

- Roofs made of metal tiles – textured sheets that repeat the contour of small-sized tiles. This type of roofing is widely used due to its attractive architectural appearance and a wide variety of color palettes.

Read more about the arrangement of various types of roofs in these articles:

- Installation of the roof of a house and a turnkey building: Types, materials, construction technologies, and installation prices;

- The roof of the house and building in use: methods of installation, materials used, and installation prices;

- Installation of a soft roof: technologies, materials, and prices for work;

- The arrangement of the surfaced roof: Types of rolled surfaced materials and the technology of their installation.

The metal roof is made of corrugated board

When choosing materials for the installation of profiled roofing, it is necessary to take into account several parameters so that the roofing will serve for a long time without additional repairs. The slopes of the inclines are taken into account, which should be more than 12 degrees, if the roof structure is flatter, then it is necessary to install a reinforced rafter system, the rafters should withstand the load from the snow cover.

The installation of the truss system and the lathing is carried out with a certain set step, depending on the calculated load on the roofing sheet, taking into account all the characteristics, the brand of the profiled sheet is chosen. It is worth nothing that the higher the profile, the tougher the profile sheet will be, it is worth considering this feature when choosing a profile sheet brand.

Let’s consider the marking of a metal profiled sheet:

- Н — is a load-bearing corrugated board, has the high load-bearing capacity, and is suitable for the installation of flat roofs.

- С — the wall corrugated board, is the lowest profile sheet, mainly used for fence or wall installation.

- НС — universal profiled flooring, used for the arrangement of pitched and straight roofs, is a universal type of profiled flooring.

Not all types of profiled flooring are suitable for roofing, below we will consider the brands of profiled flooring and their characteristics that are used for roofing:

| Grade of profiled flooring | Thickness, mm | Weight, running meter, kg | Weight, m2, kg |

| Bearing profiled flooring | |||

| Н57 | 0,7 | 6,5 | 6,87 |

| Н57 | 0,8 | 7,4 | 9,87 |

| Н60 | 0,7 | 7,4 | 8,76 |

| Н60 | 0,8 | 8,4 | 9,94 |

| Н60 | 0,9 | 9,3 | 11,01 |

| Н75 | 0,7 | 7,4 | 9,87 |

| Н75 | 0,8 | 8,4 | 11,2 |

| Н75 | 0,9 | 9,3 | 12,4 |

| Н114 | 0,8 | 8,4 | 14 |

| Н114 | 0,9 | 9,3 | 15,5 |

| Н114 | 1 | 10,3 | 17,17 |

| universal profiled flooring | |||

| НС35 | 0,55 | 5,9 | 5,9 |

| НС35 | 0,7 | 7,4 | 7,4 |

| НС44 | 0,55 | 5,9 | 5,9 |

| НС44 | 0,7 | 7,4 | 7,4 |

| wall profiled flooring | |||

| С21 | 0,5 | 5,4 | 5,4 |

| С21 | 0,55 | 5,9 | 5,9 |

| С21 | 0,7 | 7,4 | 7,4 |

In addition to the above markings, a feature of this type of roof is the size of the profile sheet. The table shows the dimensions of the profile sheet corresponding to the brands.

| Profiled flooring grade | Trapezoid width (upper side), sm | The gap between the inner faces of the trapezoids, sm | The gap between the trapezoids on the lower face, sm | Step size, sm |

| С8 | 5,25 | 6,25 | 5,25 | 11,5 |

| С21 | 3,5 | 6,5 | 3,5 | 10,0 |

| НС35 | 7,0 | 13,0 | 7,0 | 20,0 |

| НС44 | 7,5 | 7,5 | 10,0 | 25,0 |

| НС57 | 9,3 | 9,45 | 4,4 | 18,75 |

Metal tile and its elements

Metal tile – a kind of profile sheet with a contour of a small-sized tile. It has a relatively low price, while it has an attractive appearance. When designing a roof made of metal tiles, the angle of the slope is calculated more than 14 degrees, this optimally distributes the load from precipitation over the entire surface of the roof. After calculating the bearing capacity of the roof, they proceed to the choice of the metal tile profile, the main types will be considered below:

- Monterrey – is the most common type of metal tile, which repeats the contour of ceramic tiles, but with the characteristics of a metal profiled sheet.

- Cascade – strict geometry is observed in this model of metal tile, the advantage of this model is a smaller number of connecting seams, which creates a more hermetic web.

- Joker – has a similar configuration to the view of Monterrey, the contour also repeats the shape of natural ceramic tiles, but has more denominated geometric lines.

- Athena – corresponds to its name, is one of the most beautiful types of metal tiles, and has a noble architectural appearance, thanks to the smooth alteration of the wavy profile with the flat lines of the base.

Metal tiles are made in sheets of various shapes and different sizes depending on the manufacturer. The range of sizes of the produced metal tiles is very extensive and can be created according to individual orders, the main sizes are presented below:

- Width: 116-118 sm;

- Length: 50-900 sm;

- Thickness: 0,04-0,06 sm;

- Distance between waves: 35 sm.

For regions with increased precipitation, it is recommended to use metal tiles with a thickness of 0,5 mm, this will allow the roofing to serve for a long time without additional repair costs.

The main parameters, characteristic of a metal roofing sheet made of metal tiles, corresponding to the type of coating:

| Parameters | Polyester | Brushed polyester | Pural | Placizol |

| Type of coating | smooth | matte | smooth-matte | ribbed |

| Coating thickness | 27 | 35 | 50 | 200 |

| Max operating temperature of the roof | 120 | 120 | 120 | 60 |

| Resistance to external factors | 3 | 3 | 4 | 5 |

| Resistance to corrosion damage | 4 | 4 | 5 | 5 |

| UV resistance | 5 | 5 | 5 | 4 |

You can read more about metal roofing in the following article – Repair of metal roofing: Technology and prices

Metal roof made of seam panels

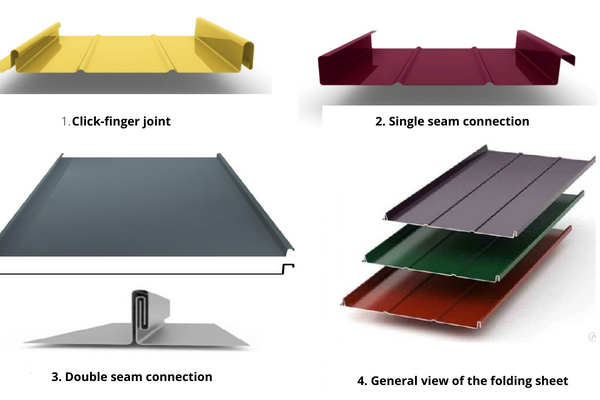

A feature of the folding roof is the reliable adhesion of metal sheets to each other due to the folding lock. Such a roof provides additional sealing of the roof, the main thing — is to ensure the high-quality installation of seam panels. The seam roofing is divided according to the type of connecting seam (lock):

- Double-leaf joint – is the most common type of folding lock. Due to the perforation on a special shelf, it is securely fixed to the elements of the lathing. This type of fastening is easier to install, metal panels can be installed by pressing the foot on the connecting lock, while creating a tight connection for a long time, significantly increasing the operational properties of the roof and its durability.

- Double seam connection – this type of connection has proven itself as one of the most reliable types of coupling metal sheets of a seam roof with each other. The tightness of the roofing is ensured, this type has found wide application in regions with increased precipitation. To install a roof with this type of connection, you will need a professional tool: automated or manual.

- Single seam connection – is a less common type of connecting lock, suitable for installation in places with moderate precipitation. This type of seam joint greatly facilitates installation work and saves time when installing roofing.

The features of the seam roof include:

- Tightness of the roofing;

- Corrosion resistance;

- Light weight.

Characteristics of the folding sheets used for the installation of the roofing sheet:

| Type of seam connection | Thickness, mm | Length, sm | Thickness, sm | Weight, kg | |

| common | working | ||||

| Click-finger joint | 0,45-0,7 | 120-900 | 54,5 | 51 | 2-5 |

| Double connection | 0,45-0,7 | 120-900 | 62,5 | 55 | 2-5 |

| Single connection | 0,45-0,7 | 120-900 | 62,5 | 55 | 2-5 |

When calculating the load-bearing load on the rafter system, it is necessary to take into account the mass of the roofing fabric, which will affect the rafter elements. Depending on the thickness of the metal sheet and the type of metal used, the mass of the metal web may vary. For the arrangement of a reliable roofing sheet with a high-quality metal coating, it is worth using sheet material with a thickness of at least 0,5 mm.

You can read more about the seam roof in the following article – Installation of a seam roof: Arrangement technology and materials used

Metal roof construction: installation technology and materials used

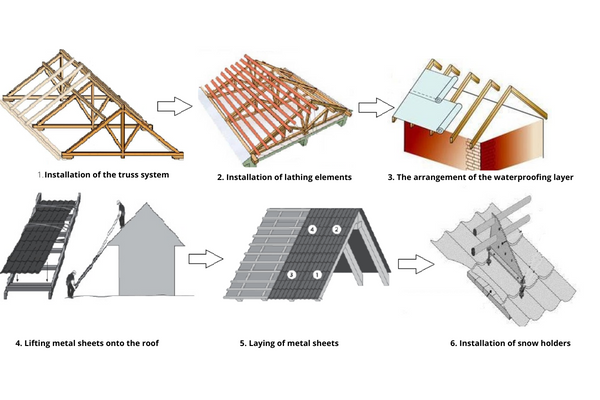

The peculiarity of the installation of a metal roof is considered to be the simplicity of laying metal sheets, it is possible to independently mount a roof arrangement made of metal sheets, observing the production technology. Let’s consider the technology of installing a metal roof in stages:

- Installation of a truss system – the arrangement of any roof begins with the arrangement of a truss system. The installation of the rafters is carried out with a certain step, according to the technological scheme. Due to the fact that the metal roof has a small weight– this allows you to install rafters infrequently, but to maintain an average step between them.

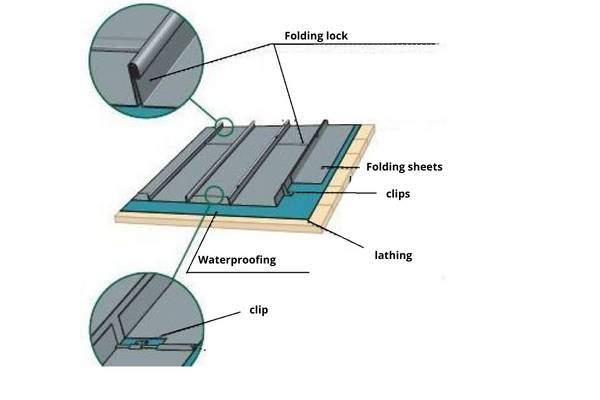

- Installation of lathing and counter-lathing – installation of elements of a lathing and a counter-lathing allows to prevent of deformation of roofing sheets from metal during operation.

- The arrangement of the waterproofing layer – the waterproofing layer allows you to protect the internal structures of the room from condensation and lathing a sealed sheeting. With a properly selected waterproofing layer, excess moisture will be removed from the room, passing through all layers of the roofing fabric.

- Preparation of metal sheets – at the construction site, the sheets are cut to the required size for further installation on the roofing base.

- Installation of metal panels – before installing the panels, composite elements in the form of corners are fixed to the edge of the cornice to strengthen the structure and give it rigidity, which will allow metal sheets to be held on the roof during installation work.

The prepared sheet is lifted onto the roof and mounted near the gables, forming an overhang of about 5 sm, the sheet is leveled and a face of about 3 sm is left for the possibility of moving to the opposite side of the roofing sheet. Install clips for hidden fastening of metal sheets, starting from the second, and fix with screws.

Clips are fixed at a distance of 50 sm. After mounting the second sheet, it is connected to the first sheet, providing a tight connection. In regions with increased precipitation, it is recommended to additionally seal the connecting joints.

On the other side of the roofing sheet, clips are also installed and a third sheet is mounted on the surface of the pediment, secured with screws. The installation of the remaining metal sheets is carried out in a similar way. After mounting all the sheets of the roofing sheet, a ridge is installed at the top point of the two ramps and a drainage system is installed. - The arrangement of fencing and additional elements – for safety purposes, the detention of the descent of snow layers and their separation into smaller particles, and the installation of additional fences and snow holders is necessary. Installation is carried out with screws. Also, to ensure safety, it is necessary to install lighting protection, which is presented in the form of a metal pin or cable.

Features of the arrangement of the seam roofing sheet

The seam roof is considered the most difficult to install among metal roofs. Additional equipment and certain skills and qualifications of the employee may be required for the installation of sheets with a seam connection.

Installation of folding panels is carried out from the cornice, the main task when installing a roof of this type is to install a reliable connection of the panels to each other, depending on the type of lock, for example, for mounting panels with a double folding lock, an automated or manual machine is necessary to securely close the lock.

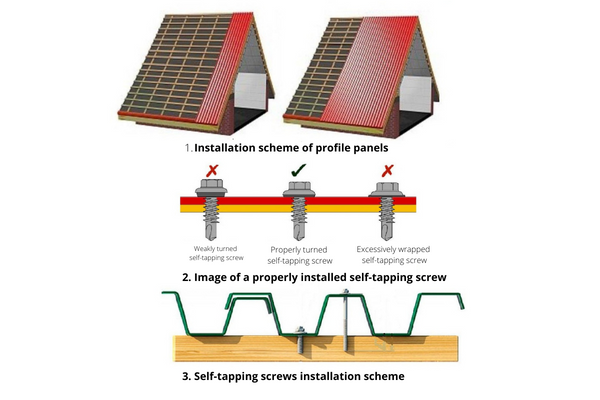

Features of the arrangement of a metal roof made of profiled flooring and profile sheets

The fastening of the profiled flooring is made by specialized roofing screws, for which a sealing gasket is provided. A properly installed self-tapping screw allows you to maintain the tightness of the entire fabric.

The profiled sheet is fixed to the elements of the lathing on the lower wave, placing the self-tapping screw in the center. Regardless of the size or shape of the profiled sheet, the installation is carried out by overlapping, tightly pressing the covering sheet to the bottom sheet, and pulling them together with screws.

Prices for the arrangement of metal roofing

Prices for metal roofing may vary depending on the type of metal panels, their number, and the installation of additional elements of the roofing fabric. Below are the prices for work on the installation of a metal roof.

| Type of works | Units of measurement | Price, $ |

| Installation of profiled flooring | m2 | 20 |

| Installation of metal tiles | m2 | 21 |

| Installation of folding panels | m2 | 60 |

| Installation of the truss system | m2 | 40 |

| Installation of lathing | m2 | 12 |

| Installation of waterproofing | m2 | 6 |

| Installation of the thermal insulation layer | m2 | starting from 15 |

| Processing of wooden roof elements with a specialized solution | m2 | 3 |

| Installation of the ridge | running meter | 30 |

| Installation of the endowment | running meter | 32 |

| Installation of a cornice or pediment | running meter | 27 |