One of the most common roofing materials today is metal roofing, characterized by an attractive appearance, strength, and reliability. Such material, if previously subjected to high-quality waterproofing treatment, is able to last for many years and not allow those who live indoors to suffer from purges or roof leaks.

And yet, sometimes there are situations in which the metal tile is partially or entirely damaged, and there is a need for repairs, capital, or current. Why there may be a violation of the integrity of metal tiles, what features are characteristic of all types of professional repair of such a roof, and what rules should be known to everyone who has decided to install metal tiles, and will be discussed in this article.

What is metal tile and how does it work

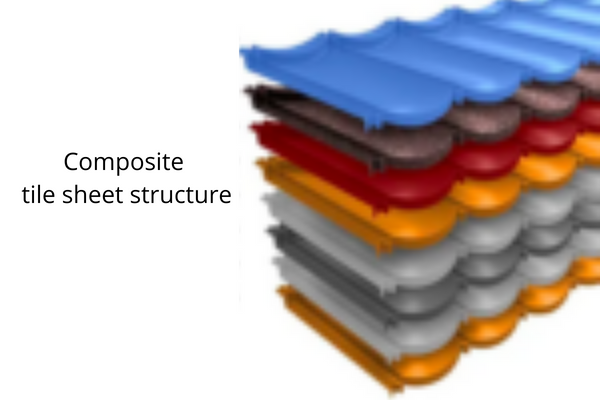

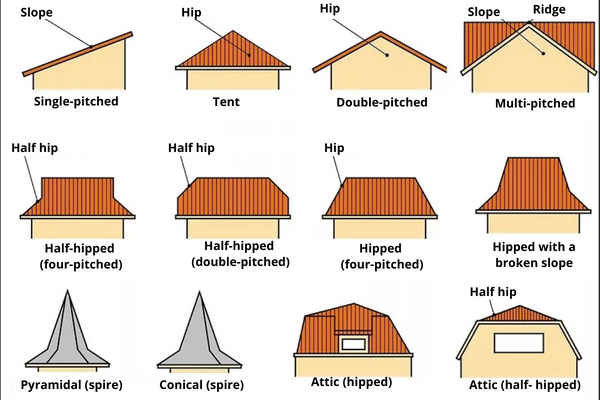

First of all, it should be said that metal tile is a material made of zinc-coated steel. Zinc protects the roof tiles from corrosion and allows you to preserve the appearance of the material for a long time. Profiled metal sheets imitate standard ceramic tiles and are currently sold in a wide variety of colors. A rich assortment, versatile dimensions, lightness, and ease of installation have made metal roofing one of the most popular roofing materials in the construction market.

In addition, metal tiles are characterized by an acceptable cost, which is why today it is used for coating:

- Single-pitched,

- Double-pitched,

- Tent,

- Hip,

- Half-hipped roofs and not only.

Before purchasing the material and installing it, it is imperative to consult with a specialist in the field of construction, who will be able to give an accurate answer to the question of whether a metal roof is suitable for a particular design.

After that, the installation and, if necessary, dismantling of the metal roofing is carried out, the technologies of which differ from each other depending on the purpose of the building, the roof of which is covered with metal tiles.

Why do defects and leaks appear in the metal tile structure?

Although metal tile is considered to be quite durable and resistant to various influences, it is still subject to both surface and deep damage. Violation of the integrity of the material can occur for absolutely different reasons, and a large percentage of damage is provoked either by the builders installing the roof or by the residents of the house. What exactly is going on?

- One of the most common causes of defects is considered to be the improper operation of the roofing structure. The roof made of metal tiles should perform exclusively protective and decorative functions and cannot be used, for example, as an object for events. It is strictly forbidden to place and fix various structures on the roof of metal tiles, such as swimming pools, golf courses, greenhouses, kindergartens, and others. This is due to the fact that metal tile is a fragile material that is not sufficiently resistant to regular high loads.

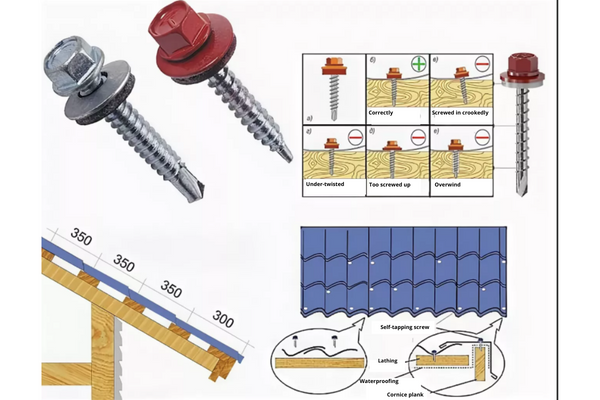

- Another problem may be the mistakes made by the craftsmen during the installation of metal tiles. The use of low-quality tools, for example, bad screws, can lead to roof leaks — an extremely unpleasant phenomenon for all residents of the house. The presence of gaps and voids between the sheets of material can also lead to negative consequences. That is why it is necessary to contact only trusted companies for construction work.

- The wear of roofing material can occur without the participation of builders or residents of the house. For example, this happens in cases when the metal tile was treated with not too high-quality atmospheric paint, which eventually lost its appearance and performance characteristics. In the absence of proper care, the metal also deteriorates, which may cause scuffs, traces of corrosion, and even cracks. Complete or partial wear of the roofing coating requires the intervention of specialists to restore the integrity of the material.

- Another problem that leads to a violation of the integrity of metal shingles — is the lack of regular inspections and other roof maintenance activities. As a result, ice growths, liquid accumulations, or even areas interacting with harmful chemicals from on the coating. However, not only the absence of such measures can damage the coating, but also excessive care in their implementation. It can lead to damage to the zinc coating of the roof tiles and, as a result, to a deterioration in the appearance of the roof.

Careful selection of the material, builders for installation, proper operation and regular maintenance— is a guarantee that your metal roof will serve for many years to you!

What can be the consequences in the presence of roof defects

Regular professional inspections of metal roofing are necessary just in order to detect damage to the material in time and deal with them in a turnkey manner. However, some owners of private houses, as well as developers, neglect the necessity, which leads to unpleasant consequences. What kind of consequences we are talking about?

If the damage to the material is not deep, but, on the contrary, superficial, it is unlikely that it will lead to serious consequences. Such damages include, for example,

- scuffs,

- light scratches,

- paint slipping and other minor defects.

However, if a crack has formed in the tile, then there can be many consequences.

- either, the moisture that has penetrated through the crack to the rafter system forms areas of dampness and leads to roof leaks,

- or the liquid that has got into the cracks in the cold season freezes, and expands (after it thaws), and continues to destroy the roofing.

Thus, the most serious consequences of metal tile damage can be considered as roof leaks and structural failure, which sooner or later will happen if the problem is started.

In order to avoid significant problems with the integrity of not only the roof, but also the entire structure, it is important to order professional inspections of the roof condition from a proven construction company at least twice a year and correct all defects in a timely manner if they occur.

Types of metal roof repair for administrative buildings and private houses

To date, there are three main types of roofing repairs that are also relevant for metal tiles. The types of repair work differ from each other in the equipment required for repair, in the area of the surface to be restored, and not only. Let’s consider each of the types of roof repairs in more detail.

Emergency roof repair

Emergency or spot repairs are performed in cases where the roof damage occurred unexpectedly and could not be detected in advance. As a rule, such damages include emergency leaks or damage to roofing elements due to natural disasters.

Also, emergency repairs are necessary when loosening the fastenings of the roof sheets to the work surface and if the protective coating is damaged. It is best to entrust the repair process to professionals because in this case, the quality of life in the room directly depends on the speed and quality of the work performed.

Scheduled repairs

Scheduled repairs belong to the category of planned works that are carried out at approximately the same time of the year. The need for such repairs is established during a regular professional inspection of the roof, designed to identify possible damage to the roofing.

However, planned work can also be carried out in cases where the integrity of the coating is not violated. Then the roof protective coating is updated, as well as special measures are carried out that can extend the life of the roof.

Major repairs

The last type of work, namely major repairs, implies a complete replacement of the existing roofing, and in some cases even the rafter system. Capital works are necessary in cases where the total area of the damaged roof elements is more than 40% of the total coverage.

The order of work in such a situation is as follows:

- first, the old roofing is dismantled,

- then the working surface is cleaned and prepared for the application of a new roofing material

- and finally, the direct laying of a new roof.

- the overhaul is being completed with surface finishing, that is, the elimination of residual surface defects and the fixation of all additional roof elements.

Repairs of any kind are not recommended to be carried out independently. Entrust it to professionals, most reliable companies, in addition to competent work, will provide you with a quality guarantee!

Metal roof repair: Technologies and materials

Professional repair of metal roofing can be carried out using various technologies and materials. For example, in modern construction, the use of both liquid and rolled roofing materials is widespread. Let’s talk a little more about ways to restore the roof from metal tiles.

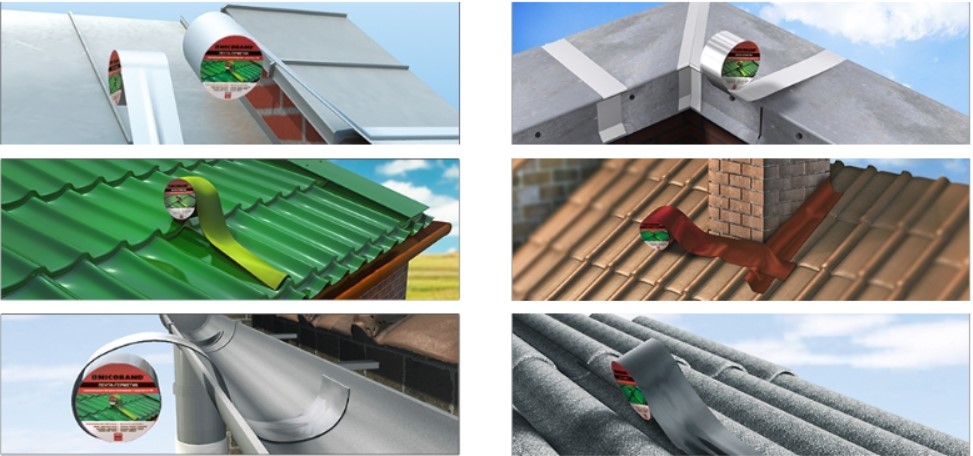

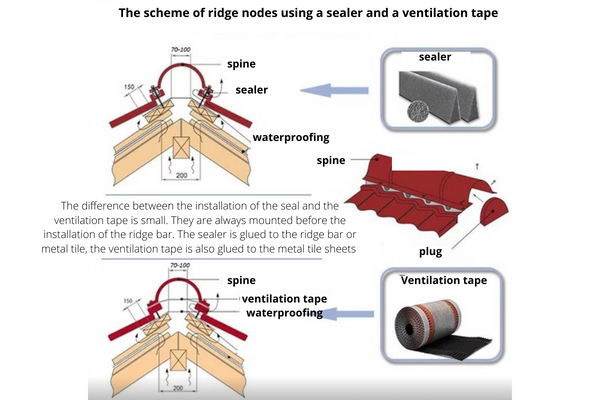

The use of tape for the repair of metal tiles

For the repair of roofs made of metal tiles, sealing tapes are widely used, which are universal, profile, and self-expanding. The sealer itself — is an excellent material that can compensate for minor damage to the roofing. For metal tiles, as a rule, profile tapes are used, which are made on the basis of foamed polyethylene. The profile sealer is even specially equipped with ventilation holes that allow air to pass through and prevent the accumulation of moisture in the under-roof space, as well as the formation of condensate harmful to metal tiles.

Self-expanding tapes, or PSUL (Pre-Compressed Sealing Tape), are considered to be an equally common type of sealing tape. This material is great for roofs with a ridge structure. With its help, joints are sealed, which are characterized by uneven surfaces, and cracks and gaps are removed, that is, such damages, are compensated for by planned repairs. Moreover, the self-expanding seal is a “breathable” material capable of providing air exchange between the under-roof space and the street.

Also, sealing tapes are characterized by a complete repetition of the shape and waves of the roofing, so that they fit snugly to the metal tile and protect the entire roofing layers from the penetration of dirt, and precipitation, hazardous chemicals, pests, including birds. This property has a positive effect on the noise of the under-roof space, but also in the living space.

Sealing tapes are sold in hardware stores in the form of highly compressed rollers covered with a layer of glue. Before application, the adhesive composition is released from the protective strips and connected to the work surface.

Repair of metal tiles with liquid rubber

Minor surface damage and divergence of joints between metal tile sheets can be compensated with liquid rubber. It is a plastic viscous material that is evenly distributed over the work surface. Filling cracks, holes, or gaps with liquid rubber will not be difficult even for the most experienced builder.

Liquid rubber is made on the basis of bitumen and latex and is suitable not only for the restoration of roofing but also for the repair of roads, tunnels, downpipes, swimming pools, and many other structures. Excellent compatibility with any coating makes liquid rubber a reliable material suitable for repairing metal tiles. This composition can be applied using special spray equipment or manually.

Don’t look for cheap compounds. The quality of the selected material depends on its durability, resistance to precipitation, elasticity and adhesion to the substrate.

You can read more about liquid rubber in the article – Waterproofing with liquid rubber.

Repair of metal tiles of polyurethane waterproofing

Polyurethane, as well as liquid rubber, can be applied using special spray equipment or manually (relevant for small volumes). The main difference between polyurethane compounds and liquid rubber is:

- Higher resistance to UV radiation, which is especially important when finishing the coating;

- The ability to choose the right color for the RAL line, which is impossible for rubber, since in most cases it has an exclusively black color.

You can read more about polyurethane waterproofing in the article – Polyurethane waterproofing.

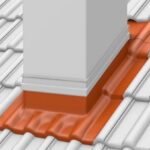

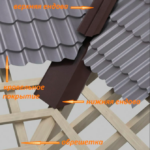

Repair of the endowment of metal tiles

The design of the inner corners of the roof is considered an extremely responsible process, and sometimes even experienced builders are completely illiterate. For this reason, after a fairly short period of time, there is a need to repair the endowment of metal tiles, carried out in several stages.

First, you need to find the vulnerabilities of the roofing. After that, it is important to ensure the optimal distance from the cutting line of the metal tile sheets to the endow center line: it should be at least 12 sm. The tile is fixed close to the endowment so that there are no cracks and gaps. The holes from the screws, as well as all the side overlaps of the roofing material sheets, need to be treated with a polyurethane sealant.

The distance between the metal tile sheets and the end wall, due to the increase in which roof leaks occur, is foamed with construction foam. Such a dense layer of protective material will protect the under-roof space from liquid and ice entering it. It is recommended to cover the construction foam with a layer of bitumen paint and seal it qualitatively.

These measures will help to get rid of shallow damage to the roofing for a while. However, in the near future, when the ambient air reaches optimal temperatures, it is recommended to reinstall the metal tile, paying special attention to the processing of the ends.

Repair of holes in metal tiles

A number of reasons can lead to the formation of an undesirable hole in the metal tile. For example, errors in the installation of ventilation of the roof and under-roof-space, excessive mechanical effects on metal tils, as well as incorrect fastening of metal tiles to the work surface can have a negative impact on the condition of the roofing.

It is quite simple to repair the hole in the metal tile. First, the screws are loosened and turned out from the edges of the sheet, and the damaged element is cut out along the metal deformation line. After that, an overlay is cut out with a length of at least one step of the profile vertically: it will act as a patch, so it should be adjusted in size to the damaged section of the metal tile. Before installing the patch, the work surface is treated with a sealant and then covered with a patch. After the repair is completed, the patch is covered with aerosol paint or polyurethane composition.

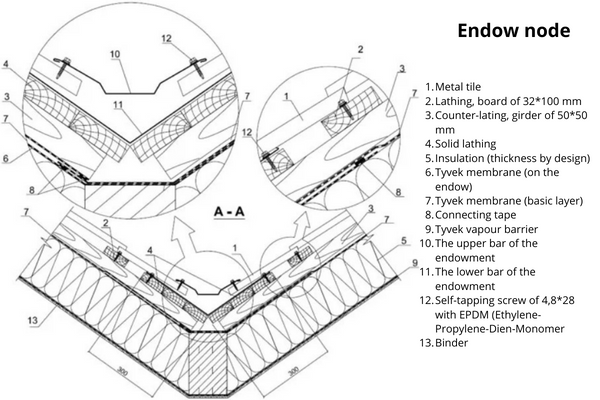

Repair of snow holders on the roof of metal tiles

Types of snow holders

The rules for working with snow holders consist of their competent installation on a metal roof. The main cause of all problems is precisely the incorrect fastening of such elements on top of sheets of metal material, which is why the snow holders periodically fail to cope with their task and break away from the work surface.

Their repair consists of the re-installation of products in compliance with all the rules for their installation, that is 50 cm from the edge of the roof and only using a high-quality screwdriver and screws.

Tightening and replacement of fasteners

Fasteners typical for many types of roofing materials, including metal tiles, may not cope with a sufficiently strong load. In order to prevent this from happening, it is necessary to calculate the load on all elements of the roof at the stage of drafting.

However, if unforeseen circumstances have led to loosening and tearing of fasteners, such a problem can be solved simply and quickly. If you find damaged or lost fasteners, purchase all the necessary materials from a hardware store and carefully twist or replace the element. Even an inexperienced builder will surely cope with such a task.

Possible errors when installing the lathing

Sometimes problems arise at the stage of installation of the roof lathing under metal tiles. The list of possible causes of such a defect is as follows:

- Profile sheets do not fit together;

- Installation of end and gable slats caused difficulties;

- Metal tile sheets are too loosely fixed to the lathing;

- The protrusion was made too large or, conversely, small.

Regular inspection will help to deal with such problems if you entrust it to professionals.

It is advisable to restore the lathing as soon as possible, without waiting for scheduled repairs!

Changing individual sheets

It is quite simple to replace individual sheets of metal tiles. To do this, the screws are unscrewed, the damaged element is carefully separated from the nearby sheets, the surface under it is cleaned and processed, and then a new part of the roofing is installed in its place.

Before installing a new sheet of metal tile, it is important to make sure of the integrity of the lathing and the truss system, which are necessarily restored in the presence of damage. The new part of the roof is also fixed to the surface with screws, and its coating is checked for any defects. If such defects have been detected, then the metal tile sheet is treated with protective enamel.

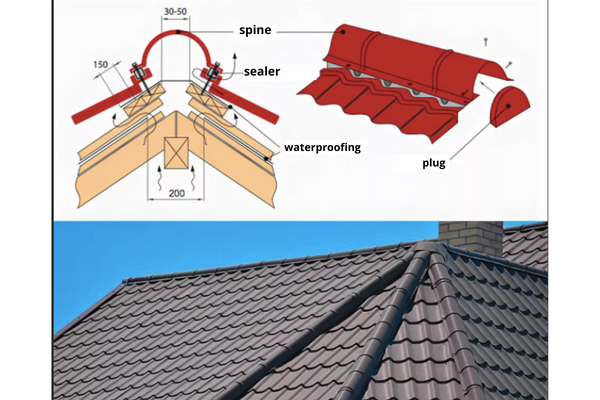

Ridge repair and roof geometry correction

The ridge structure of the roof implies the fastening of the roof elements on a special solution, which eventually begins to deteriorate and crack. Moisture can get into the cracks, freezing in winter and turning into ice, which continues to destroy the roofing. To restore the roof, lime-cement mortar or roofing mastic is used, covering the imperfections of the surface. Skates whose integrity is broken can be replaced completely.

However, there are situations in which the geometry of the roof is violated. And this happens because the tile presses on the roof with its weight and violates the shape of its skeleton, as a result of which there is a need for additional reinforcement. For this:

- the tile is removed together with screws, clamps, and staples,

- using a nail cutter, the bars of the lathing is removed,

- the waterproofing material is cut out,

- then the bars are fixed to the rafters,

- waterproofing fits into place,

- and the joints are sealed with roofing tape.

- The process is completed by fixing the removed lathing and laying metal tiles in their place.

Spine repair and installation scheme:

The ridge structure of the roof implies the fastening of the roof elements on a special solution, which eventually begins to deteriorate and crack. Moisture can get into the cracks, freezing in winter and turning into ice, which continues to destroy the roofing. To restore the roof, lime-cement mortar or roofing mastic is used, covering the imperfections of the surface. Skates whose integrity is broken can be replaced completely.

However, there are situations in which the geometry of the roof is violated. And this happens because the tile presses on the roof with its weight and violates the shape of its skeleton, as a result of which there is a need for additional reinforcement. For this:

- the tile is removed together with screws, clamps, and staples,

- using a nail cutter, the bars of the lathing is removed,

- the waterproofing material is cut out,

- then the bars are fixed to the rafters,

- waterproofing fits into place,

- and the joints are sealed with roofing tape.

- The process is completed by fixing the removed lathing and laying metal tiles in their place.

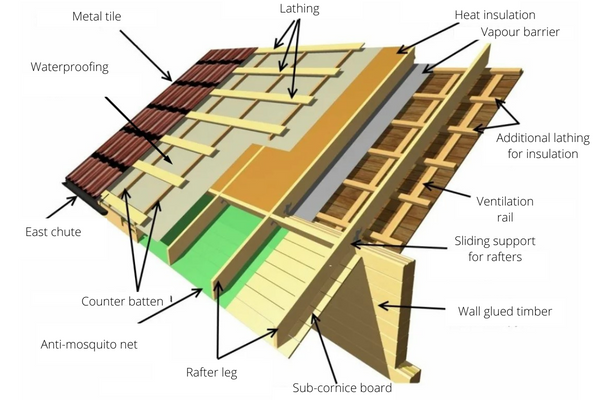

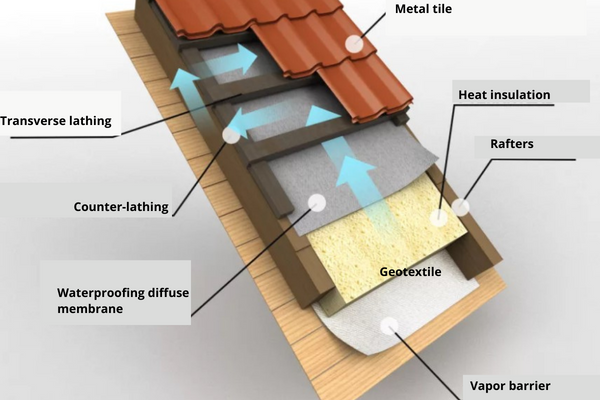

Replacement of vapor barrier and waterproofing of the roof

Layers of hydro- and vapor barriers, as a rule, are mounted in the depth of the roofing layers, therefore, a number of difficult manipulations will be required to replace them. Most often, such work is entrusted to representatives of specialized construction companies.

The roof covering and the lathing are removed from the roof, and then the vapor barrier and waterproofing films are fixed. However, it is also possible to preserve the integrity of the roof: for this, it is necessary to install steam and waterproofing materials from inside the living room, affecting only the elements of interior decoration…

Prices for the repair of a roof made of metal tile

Below are the prices for certain types of work related to the repair of the roof consisting of metal tiles. All prices are preliminary.

| Description of works | Unit of measurement | Price in $ |

| Roof repair | ||

| Arrangement of anti-condensate film | m2 | starting from 20 |

| Arrangement of classic film | m2 | starting from 20 |

| Arrangement of superdiffusion film | m2 | starting from 30 |

| Arrangement of diffusion membrane | m2 | starting from 40 |

| Sealing joints with a special tape | running meter | starting from 30 |

| Repair of metal tiles with polyurethane | m2 | starting from 60 |

| Repair of metal tiles with liquid rubber | m2 | starting from 60 |

| Sealing tape arrangement | running meter | starting from 80 |

| Tightening and replacement of fasteners | m2 | starting from 40 |

| Work on the repair of individual elements of the roof made of metal tiles | ||

| Dismantling of roofing | m2 | starting from 15 |

| Dismantling of lathing | m2 | starting from 30 |

| Dismantling of the rafter system | m2 | starting from 25 |

| Dismantling of thermal insulation | m2 | starting from 25 |

| Dismantling of waterproofing | m2 | starting from 5 |

| The arrangement of the truss system | m2 | starting from 80 |

| Arrangement of lathing | m2 | starting from 25 |

| Arrangement of counter-lathing | m2 | starting from 25 |

| Arrangement of thermal insulation | m2 | starting from 20 |

| Metal tile arrangement | m2 | starting from 60 |

| Expertise and design | ||

| Preparation of design documentation | piece | starting from 4500 |

| The expertise of metal roofing | piece | starting from 200 |

Repair the roof of a private house with your own hands

Repair of the roof of a private house can be carried out without the help of specialists from a construction company. To do this, it is enough to identify damage to the roof, purchase new materials in the required amount, prepare tools, and then carefully perform all the steps of restoring the roofing. Do not rush to lay a new roof immediately after removing the old one: first, you need to make sure of the integrity of all roof elements, including the truss system. Only after that, you can start the repair work.

Metal tiles are considered to be quite fragile material, that is not only easily damaged, but can also cause serious harm to the health of people who happen to be near the house in case of a fall. Therefore, for the transportation of materials (in case of major repairs), it is necessary to use a self-made movable platform on which metal tiles are laid out.

Only if all safety recommendations are followed, the repair can be carried out successfully.

Repair of the roof of an administrative building and an apartment building

Often the roofs of administrative buildings are covered with metal tiles, therefore, such buildings periodically need professional repair. It is necessary to trust the restoration of the roofing of administrative buildings only to proven construction companies are involved in servicing a significant part of city buildings. For the period of work, fences are installed that do not allow bystanders to potentially dangerous areas.

It is also necessary to carry out regularly scheduled inspections of the roofs of administrative buildings, namely, to hire specialists for this at least 2-3 times a year. Then all the damage to the roofing will be detected on time, and the planned repair of the roof will not take much time.

Conclusion

Modern metal tile — is a beautiful, reliable, and durable material for covering the roofs of both private and administrative buildings. However, sometimes even such a durable material can be damaged as a result of improper operation or errors made at the installation stage.

In order to avoid roof repairs or damage to the building itself due to the destruction of the roof, carefully choose metal tiles, builders who will install it, regularly inspect and prevent by a professional team of roofers. Well, if repairs are necessary, choose contractors who will not only competently perform the necessary work, but also provide a quality guarantee.