Table of Contents

- Types of materials for waterproofing various roofs and their characteristics

- How to choose the right waterproofing material for the roof?

- Types of roofs and materials suitable for waterproofing

- Roof waterproofing installation – how to perform properly installation work so that you don’t have to redo everything later

- Prices for work on the installation and assembly of roof waterproofing

- Roof waterproofing services

The roof of an administrative building or a private house is an important and complex structure, the purpose of which, among other things, is to protect the structure from the effects of various atmospheric precipitation.

It is necessary to approach the waterproofing of the roof with responsibility and professionalism, otherwise, you risk not only paying twice for the work, but also for restoring the finishes destroyed as a result of leakage and damaged furniture.

Types of materials for waterproofing various roofs and their characteristics

There are many options on the market for professional waterproofing systems that differ in the following aspects:

- Purpose – each material has its own purpose and place in the roofing layers. For example, there are materials that are perfect for installation as an interplayer in a roofing layers or as the first layer of insulation, but at the same time, they are absolutely not suitable for installation as a finishing coating of the roof, since, for example, they do not have resistance to ultraviolet and solar radiation.

- Quality – different materials have a different quality in most cases, it directly depends on the price of a particular material (the cheaper, the worse the insulation quality).

- Characteristics – by the presence of seams, adhesion, elasticity, flammability, water resistance, etc.

- The principle of operation – each system works in its own way and requires a different number of layers.

- The complexity of installation – the installation of some systems requires special equipment or long-term training and experience in the production of such works.

- Deadlines of work – for example, sprayed compositions can be applied 3 times faster than mounted or surfaced.

- Warranty – not only the manufacturer’s warranty of a particular material is important here, but also the warranty of the company that performs the work on the waterproofing installation itself.

- Product prices – different compositions have different prices, on which, as a rule, the quality of the composition also depends.

- Installation prices – different works have different complexity and, accordingly, the price of installation.

Important: The guarantee for the absence of future leaks of the roof can only be given by the company performing work on the waterproofing installation, and not by its manufacturer. That is why it is very important to listen to the recommendations of a professional company that performs waterproofing in a complex, and not specializing in a certain type or one material.

Roll waterproofing

This type of protection consists of rolled sheets of different quality, which are based on bitumen. The rolls are deposited on the prepared base by heating the binder bitumen layer, live-fire using a burner.

The installation of roll-deposited insulation should be performed in 2-3 layers overlapping the seams of the previous one.

Advantages:

- The main advantages of surfaced waterproofing —are its relatively low cost and availability of materials.

Disadvantages:

- The presence of seams;

- Lack of adhesion to the base;

- Relatively low coefficient of elasticity;

- Difficulties in bypassing various junctions during installation;

- The great influence of the human factor on the quality of work and installation.

The most famous manufacturers of this type of membrane are:

- Technonicol company

- Icopal

Important: When installing a surfaced system, it is very important to choose a professional contractor, since in most cases unqualified and inexperienced personnel make many mistakes during installation, which eventually leads to leaks and subsequent alterations of the work performed. One of the most common mistakes during work is excessive heating of the bitumen layer in the area of the joint (seam), which leads to burning of bitumen and weakening of the adhesion of the seams (through which water later gets under the waterproofing carpet).

By clicking on the link, you can download detailed instructions for the installation of roll-on-roll insulation –Instructions for the installation of waterproofing of a flat roof made of surfaced bitumen-polymer roll materials.

You can read more about roll waterproofing and the features of its installation in the article – Roll waterproofing installation.

Bitumen mastics

Various waterproofing compounds are based on modified bitumen. These mastics are applied to the bases by coating them with a brush, roller, or spatula. Mastics are applied in 2-3 layers with a mandatory interval when each layer dries.

This type of waterproofing is rarely used on roofs due to its unreliability and fragility. Most bitumen mastics are not resistant to solar radiation and can quickly crack or become unusable if you do not take care of their protection by installing subsequent layers.

You can read more about bitumen waterproofing in the article – Bitumen waterproofing: types, characteristics, and technology of the installation.

Film and membrane materials

Membranes consist of various polymers and come in different types, for example, single-layer or two, or three-layer.

The main types of membranes for roofing are:

- PVC

- Thermoplastic Polyoleofin

- Ethylene Propylene Dien Monomer

The installation of the membrane on the roof consists in laying it on the surface, fixing it along the perimeter with a clamping bar or a special rail, and stitching the seams between the sheets in such ways as sealing with special glue or stitching with hot air.

Advantages:

- It is possible to carry out installation work in various weather conditions, including in winter at subzero temperatures;

- Roofing membranes are resistant to UV radiation.

Disadvantages:

- The presence of seams;

- Lack of adhesion to the base – the membranes are laid on the surface like a carpet and in case of the slightest divergence of one of the seams, water penetrates under the membrane and begins to spread in different directions and manifest itself in the premises in the weakest place;

- It is very difficult to perform high-quality work on waterproofing of various junctions;

- A great influence of the human factor on the quality of installation (the slightest flaw at the seams and water penetrates under the membrane).

The most famous manufacturers of this type of membrane are:

- Technonicol company

- Sika

- Resitrix

- Plastfoil

You can read more about membrane systems and methods of their installation in the article – Membrane waterproofing: Types of materials and methods of their installation.

Polyurethane waterproofing

Polyurethane waterproofing is one of the most reliable protection against water and moisture penetration. In fact, this is a seamless coating that is applied to the roof by spraying or manually and adheres to it 100%, not allowing water to penetrate under the waterproofing carpet.

Polyurethane can be applied both on a concrete base and on a metal one.

Advantages:

- 100% no seams;

- 100% adhesion to the surface;

- 100% resistance to ultraviolet solar radiation (when using a protective varnish), which allows the use of polyurethane as a finish;

- 100% resistance to mechanical pressure, you can walk on the coating, install various equipment or elements of the operated roof on it;

- The ability to color polyurethane in various colors according to the Ral line;

- High coefficient of elasticity.

Disadvantages:

- Relatively high price.

You can read more about polyurethane systems and the rules for working with them in the article – Polyurethane waterproofing

Liquid rubber

Liquid rubber — is a bitumen latex emulsion with the addition of various polymers. Waterproofing with liquid rubber is a reliable and durable protection of the roofing structure. Liquid rubber forms a homogeneous seamless coating with 100% adhesion on a base of concrete, metal or bitumen rolled sheets.

Advantages:

- No seams;

- 100% adhesion to the surface;

- High coefficient of elasticity;

- Can be applied to the surfaced or self-adhesive waterproofing.

Disadvantages:

- Relatively high price;

- Not all liquid rubbers are resistant to sunlight and are more suitable as a lower waterproofing layer for the floor slab (on which the roofing layers is laid).

You can read more about liquid rubber in the article – Waterproofing with liquid rubber.

Polyurea

Polyurea is very similar to polyurethane waterproofing. In fact, polyurethane foam – is a double-component organic polymer material. The component B– isocyanate, which is an ester of isocyanic acid, is related to polyurethane foam (PUF). In fact, waterproofing with polyurea is no worse and no better than polyurethane, it forms the same reliable seamless coating with 100% adhesion to the surface.

Advantages:

- 100% no seams;

- 100% adhesion to the surface;

- 100% resistance to ultraviolet solar radiation (when using a protective varnish), which allows the use of polyurethane as a finish;

- 100% resistance to mechanical pressure, you can walk on the coating, install various equipment or elements of the operated roof on it;

- The ability to color polyurethane in various colors according to the Ral line;

- High coefficient of elasticity.

Disadvantages:

- The price is more expensive than polyurethane systems with the same efficiency;

- Working with polyurea is difficult and requires some experience and skills;

- Some types of polyurea are applied only with the help of specialized equipment.

You can read more about polyurea in the article – Waterproofing with polyurea.

Comparative table of the main types of waterproofing, their advantages, and disadvantages

| Surfaced sheets | Membranes | Polyurethane | Liquid rubber | |

| The availability of joints and seams | Available | Available | Not available | Not available |

| Adhesion to the concrete base | 10 % | Not available | 100 % | 100 % |

| Adhesion to the metal base | 10 % | Not available | 100 % | 100 % |

| Possibility of mounting on thermal insulation boards | Not available | Available | Not available | Not available |

| The convenience of working with junctions and reliability of completed nodes | Low | Low | High | High |

| Installation in negative temperature | Not available | Available | Not available | Not available |

| Elasticity | Low | Low | High | High |

| Resistance to solar radiation | When using an armored layer | Available | Available | Not all types of rubber |

| Resistance to mechanical pressure | Available | Available | Available | Available |

How to choose the right waterproofing material for the roof?

The difference between waterproofing materials to protect the roof from materials for the installation of underground waterproofing:

Although roofing and underground waterproofing are similar, there are important differences between them that should be taken into account by designers, architects, and contractors performing the work. Both have some similar functional requirements, but are also completely different. For optimal performance, it is important to understand the different loads and stresses that underground waterproofing systems are exposed to compared to roofing systems.

The operating conditions of waterproofing underground and on the roof have several differences. As a result, the physical properties that are important for underground protection do not necessarily coincide with those properties that are required for the roof.

Some of these differences are summarized below.

- Availability for repair and replacement. Unlike roofing insulation, it is impractical and expensive to excavate around foundation walls or dig slabs below ground level to replace or repair waterproofing. Roofs are generally easier to access and easier to repair in case of problems.

- Constant contact with water and its pressure. Depending on the amount and level of water in the ground, the waterproofing system may be in constant contact with groundwater and moist soil. Roof systems, if properly constructed with a sufficient slope to drains, are usually exposed to water only for a short time. In addition, the hydrostatic pressure to which they are subjected is much less than that of systems that are located underground. Even a heavy and poorly drained roof with 2 inches (50 mm) of surface water is subjected to a pressure of only approximately 0,07 psi (0.5 kPa).

- The waterproofing barrier should withstand the effects of chemicals in the ground. The chemical effects to which the underground insulation is exposed differ from those to which the roofing structure is exposed. The soil often contains acids, alkalis, salts, and many other pollutants that cause the destruction of waterproofing materials. Unlike roofing insulation, the selected waterproofing system for underground installation should be able to withstand the effects of these chemicals during the expected service life.

- The waterproofing barrier should resist abuse during construction. Unlike the roof surface, waterproofing coatings for foundations and walls, as a rule, need protection from mechanical damage until the excavation work is completed (for example, gravel, debris, and other sharp materials may be dumped during backfilling).

- Waterproofing of foundations and walls, unlike the roof, should be able to withstand certain dynamics. Concrete walls and foundations can settle and dry out. The roof structure may experience thermal movement and load deflection. The waterproofing coating should be able to overcome small cracks and to some extent resist rupture from thermal expansion and compression. It should be noted that the volume of traffic below the zero level is significantly less than during the construction of roofs. For this reason, properties such as extensibility and tear resistance are very important for the roof.

- Exposure to sunlight, precipitation, and wind erosion. Waterproofing of the roof should be resistant to UV rays, otherwise, over time it will crack and lose its properties.

It is extremely important that designers, architects, and contractors understand the differences and similarities between different waterproofing materials in order to choose the right materials and perform the work once and forever.

Types of roofs and materials suitable for waterproofing

There are two main types of roofs – flat and pitched. Each of these types has its own subspecies, advantages, disadvantages, and various nuances related to the complexity of installation, the cost of work and materials, and various other aspects.

Flat roofs

This is a roof structure that represents a surface on which equipment can subsequently be placed or made an operational area. Such a roof is any roof with a slope of less than 10°.

The surface without a strong slope should be qualitatively protected from the effects of precipitation, water, and moisture by the waterproofing installation.

You can read more about waterproofing of flat roofs in the following articles:

- Waterproofing of a flat roof. Recommended materials, methods of installation, and prices for work

- Roof waterproofing repair: Methods, materials, and prices

When a Flat roof is necessary?

- The desire of the owner of a building or a private house to use the roof area to accommodate equipment or to organize an operational area and useful space;

- Urban planners or other regulations do not allow the height required for a pitched roof;

- The desire of the owner or architect to have a certain appearance of a building or a private house;

- Limited budget.

Types of roofs with a minimum angle of inclination:

- The operated roof – is the roof that is constantly operated by people and it can have a large amount of equipment, a parking lot, or another operated area. This type is designed to withstand various loads.

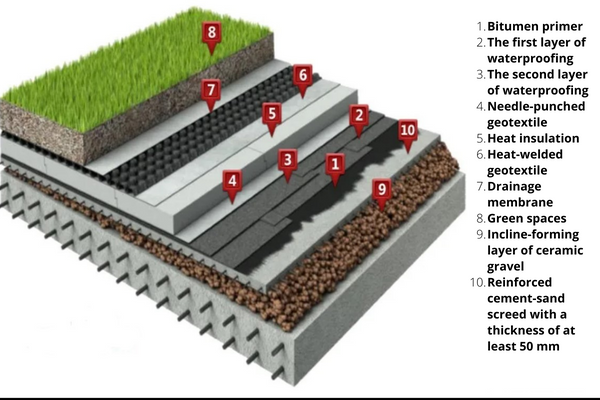

2. A green roof – This is an exploited roof, which is intended, among other things, for planting various plants and flower beds on it. In addition to the standard functions of the operated roof, there is also drainage and special protection from the roots of various plants that can damage the waterproofing layer of such a roof.

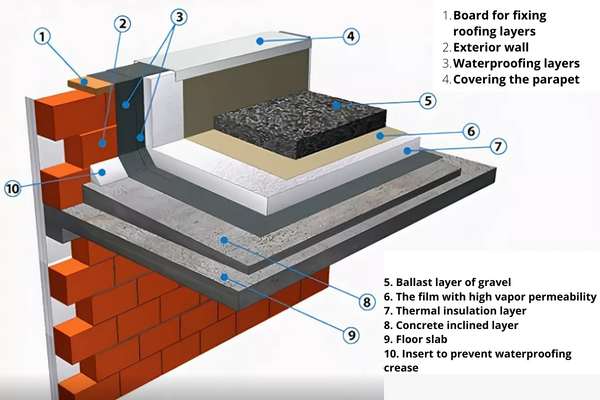

3. Inversion roof – This type of roof can be both operated and not operated. The distinguishing feature of the inversion roof is that the final layer is the insulation installation on top of which the ballast is being installed, for example, gravel.

4. Unused roof – in this variant, the roof is not designed for continuous operation and to withstand various loads, such as the installation of large ventilation units and other structures. As a rule, this type of roof is installed in warehouse and garden buildings.

Methods of waterproofing flat roofs and the materials used for this:

For waterproofing roofs with a small angle of inclination, the following types of waterproofing can be used:

- Rolled surfaced materials – These membranes are deposited on the surface using a burner in 2-3 layers with overlapping seams of the previous one. When installing such membranes, it is necessary to take into account their variety and to use armored membranes with a special sprinkling to protect against solar radiation for the installation of the finishing coating.

- Liquid rubber – Applied by airless spraying or manually forming an elastic, seamless coating.

- PVC membrane – Work on fixing the membrane is carried out by fixing it around the perimeter with railings and strips, and the seams between the sheets are usually stitched with hot air using special dryers or devices.

- Polyurethane – applied manually or using a special spray system, forming a seamless, elastic coating on the surface with 100% adhesion and resistance to sunlight.

Additional measures to protect the roof without a slope from water:

In addition to works related to waterproofing, there are a number of auxiliary measures that weaken the water pressure on the performed waterproofing, so that it can last 5 times longer.

- The installation of a screed with a slope – If all the standards of the slope are met, the water will not stagnate on the roof, but will slow down the slope towards the drain funnels.

- The installation of a high-quality drain – Thanks to the mounted drain funnels and the drainage system, the water entering the roof will not stagnate on it, creating additional pressure and impact on the waterproofing system.

- Roof and drain heating installation – Installation of the heating system will not allow the funnels and pipes to freeze, through which water should drain as a result of snow melting.

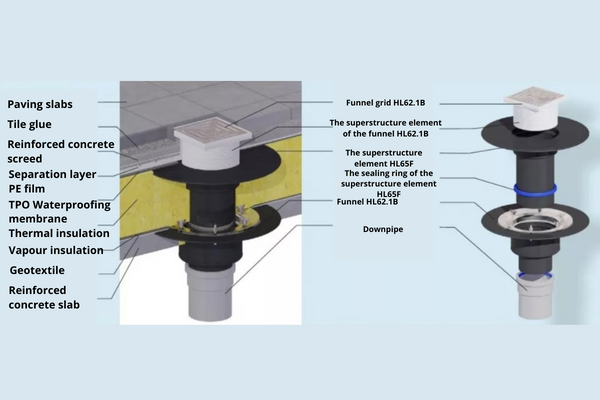

Installation diagram of the roof funnel:

Scheme of the roof heating installation in problem areas:

Pitched roofs

The main two methods of installation of pitched roofs are:

- Cut roof: The traditional method of cutting wood on site and erecting a roof using rafters, beams, girders, ridge boards, etc.

- Truss roof: Prefabricated trusses that are delivered to the facility and mounted.

- There are also a number of other frame structures, such as portal frame roofs.

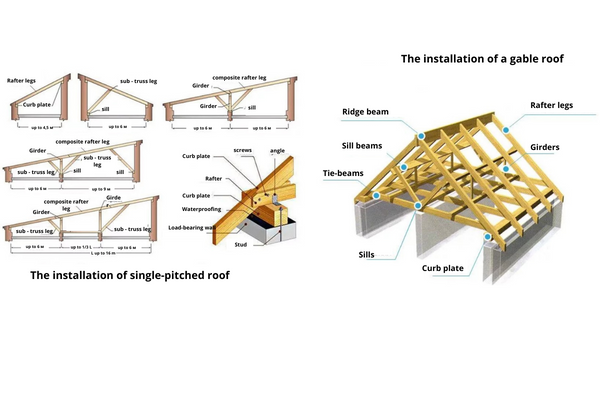

Diagram of the ramp installation:

Types of pitched roofs:

- Single-pitched roof – in this form, the roof slope goes only one way. As a rule, a ramp of this shape is made in small buildings.

- Gable roof – In this form, the roof is installed, so that the slope from it goes in two different directions, and the so-called ridge is installed in the middle.

- Hip roof and half-hipped roof – Hip or four-pitched is when there are 2 slopes located opposite each other. In fact, it is a complex shape with four ramps. The semi-palm shape is very similar to the hip shape, but unlike it, in triangular slopes, there is a pediment that starts from the ridge or from the cornice.

- Tent roof – This type may have a large number of ramps that have the shape of isosceles triangles and converge at one point

- Multi-gable roofs – Are formed due to the connection of numerous ramps.

- Spire-shaped (pyramidal) roofs – Spire-shaped (pyramidal) roofs consist of several triangle slopes connecting at the top.

- Vaulted roofs – Vaulted roofs in cross-section can be outlined by an arc of a circle or other geometric curve.

Methods of waterproofing of pitched roofs and materials used for this:

For pitched roofs, tracking types of waterproofing are suitable:

- Roll pasting waterproofing;

- Rolled roof tiles;

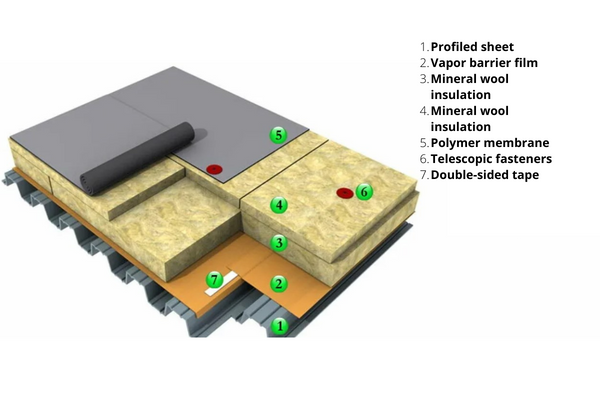

- Membrane waterproofing;

- Metal tiles.

Roof waterproofing installation – how to perform properly installation work so that you don’t have to redo everything later

In order to make waterproofing once and forever, you need to follow two very important rules:

- To hire for this work a professional specializing in the field of waterproofing and having a respectable portfolio of complete works.

- It is desirable to use high-quality materials with the least number of seams.

Flat roofs

The structure of this type of roof is most susceptible to water pressure since the water slope for this design is several times less than in the construction of a pitched roof. That is why waterproofing of such a surface should be given special attention.

The following recommendations will help to avoid mistakes and perform high-quality and durable waterproofing:

- When installing a protective screed, it is necessary to make a qualitative slope towards the drain funnels or gutters;

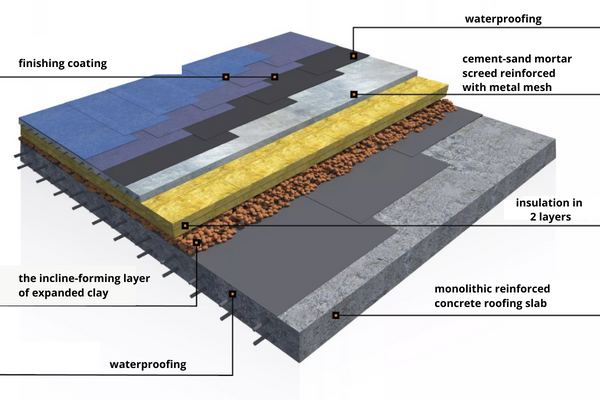

- It is recommended to perform 2 waterproofing circuits. The 1st contour is on the plate itself, and the 2nd contour is on the screeds. In the absence of insulation on the screed, it will eventually collapse, as water will be absorbed into it, freeze and thaw;

- It is necessary to install high-quality drain funnels and take care of their sealing;

- If the waterproofing coating is used as a finishing, then it is necessary to use UV-resistant materials during installation.

You can read more about the waterproofing of flat roofs in the article – “Waterproofing of flat roofs. Recommended materials, methods of installation, and prices for work“

Prices for work on the installation and assembly of roof waterproofing

Below there is a table with a description of prices for the installation of various types of waterproofing protection. The prices indicated are preliminary and may change depending on the complexity of the project and its other parameters.

If necessary, engineers can go to your facility, perform the necessary measurements and give the necessary advice on all possible options for protecting your home or building from water.

| Description of works | Unit of measurement | Price in $ |

| Waterproofing works | ||

| Installation of surfaced waterproofing in 1 layer horizon | m2 | starting from 10 |

| Installation of surfaced waterproofing in 1 layer vertical | m2 | starting from 15 |

| Installation of PVC membrane horizon | m2 | starting from 17 |

| Installation of PVC membrane vertical | m2 | starting from 20 |

| Works on the arrangement of polyurea | m2 | starting from 30 |

| Works on the arrangement of bitumen mastic | m2 | starting from 10 |

| Works on the arrangement of liquid rubber | m2 | starting from 10 |

| Works on the arrangement of polymer cement waterproofing | m2 | starting from 20 |

| Works on the arrangement of polyurethane protection | m2 | starting from 20 |

| Applying a primer or back paint | m2 | starting from 5 |

| Installation of tides | running meter | starting from 15 |

| Installation of drippers | running meter | starting from 10 |

| Монтаж сливных воронок | piece | starting from 120 |

| Roofing works | ||

| Installation of gutters | running meter | starting from 15 |

| Installation of thermal insulation | m2 | starting from 5 |

| The installation of fillets during the transition from the horizon to the vertical | m2 | starting from 20 |

| The device of galtels during the transition from the horizon to the vertical | running meter | starting from 5 |

Roof Waterproofing Cost Calculator

Calculation of waterproofing cost

The total cost of waterproofing

Roof waterproofing services

We specialize in performing waterproofing works of various types of roofs and the services we provide include not only the actual execution of the work but also the preparation of the necessary project documentation. Our professional team of engineers and designers is ready to come to your facility at any time and tell you how to build properly a roof from scratch, taking into account high-quality waterproofing, following all design and state standards, as well as how to properly repair existing waterproofing.

Roof waterproofing services include the following types of work:

- Roof waterproofing;

- Waterproofing repair;

- Design of roofs and roofing systems;

- Construction of roofs.