If you find defects in the existing waterproofing coating or leaks in your home, building or any other structure, then you need to repair the waterproofing made earlier. This article will tell you in detail how to perform properly repair work on various constructs such as the basement, roof, walls, so as to do ot once and forever.

Repair of waterproofing of buildings and various structures

Very often there are situations when the waterproofing made, after a certain time, becomes unusable and requires repair. If the completed waterproofing is located where there is access to it, for example, the finishing layer of the roof or excavated foundation walls, then its repair will entail much less costs than where the insulation requiring repair is hidden and located underground or under other layers of finishing (tile, screed, insulation, etc…).

Which elements of the building and its structures most often require waterproofing repairs:

- Roof – Basically a flat roof of a building or house. A flat roof is subject to a large amount of precipitation, while the necessary slopes are not always observed there, which leads to stagnation of water and pressure on the structure;

- Basement underground part – Basically we are talking about the underground part of the basement, as it is exposed to groundwater, as well as water and moisture absorbed into the ground after rain or melting snow.

- Socle – Is exactly the underground part of the socle.

- Foundation – The foundation of the building is affected by both groundwater and rainwater.

- Walls – If the walls of the building are below ground level, it means that they are subject to constant exposure and water in the ground.

- Balcony and terrace – As in the situation with the roof, balconies and outdoor terraces are exposed to a sufficiently large amount of precipitation, as well as the dynamics (movement) of the structure.

For what reasons does the waterproofing coating begin to leak water?

- The service life of the waterproofing material has expired.

- The wrong method or type of material was chosen for the installation and the performance of the work. For example, when installing waterproofing of a roof, when choosing a material, UV resistance was not taken into account (in the case when it comes to waterproofing as a finishing coating).

- Waterproofing was performed with violations of technology.

Important: The most common reason why waterproofing requires repair is a violation or non-compliance with its installation technology. If you do not want to spend a lot of money on repair and restoration, then to perform such important work as waterproofing, you need to choose a large and experienced company whose specialization is waterproofing.

From what the restoration of waterproofing should be started?

It is necessary to start restoring waterproofing with the involvement of an experienced company whose specialization is directly waterproofing work and work related to drainage and discharge. To determine the optimal method of restoring the protective coating, as well as the material necessary for this, the contractor’s engineer should come to your facility and make the necessary inspection.

After the inspection, the arriving engineer draws up a detailed technical specification, where he makes a detailed description of all the technology necessary for repair, after which the estimate department makes a detailed estimate for you, where all the work and materials are taken into account.

To restore and repair waterproofing, a specialist needs to start with:

- Determining the potential location of a leak or the root of the problem;

- Studying the features of a building, house or structure;

- Determining where it is better to carry out repairs – from inside the room or outside;

- Determining the possibility of performing local repairs or the need for a complete replacement of the protective layer;

- Choosing the best method for performing works related to the protection of the building from water;

- Selection of the most suitable insulation for the arrangement of the repair activities.

Methods of waterproofing repair

The method by which you can repair or restore the waterproofing coating depends directly on the structure of the building, its features, the nature of leaks and the method by which the existing waterproofing coating was made.

To determine the most effective repair technology, it is best to invite an experienced engineer to your facility. It is the experience and knowledge of various constructs, waterproofing technologies and materials that will help him choose the best option, so that you are guaranteed to have no more problems with leaks.

Important: When the existing waterproofing is made of rolled or membrane sheets, it is very difficult, and sometimes even impossible, to determine the exact location of the leak, since these membranes do not have 100% adhesion to the surface and water can enter from the outside in one place, walk under the element and exit inside in a completely different place, as a rule, in the weakest. If you want to get a guarantee about the absence of future leaks, then the above circumstance does not allow you to perform local or spot repairs and replacement of all external waterproofing is required for a guaranteed water stop.

To date, there are several basic methods of waterproofing repair, then we will consider in detail each of these methods.

Liquid rubber

Waterproofing of LR – When sprayed forms a seamless coating with full adhesion to the surface and an elasticity coefficient of 600%. It is perfect for repairing any bitumen-based coatings, such as surfaced rolls or bitumen-based mastics. When performing repairs in order to avoid leaks, the treated surface should be completely covered with liquid rubber. Liquid rubber is perfect for performing repairs outside the building, on such constructs of foundation and walls.

You can read more about this composition in the article “Waterproofing with liquid rubber“.

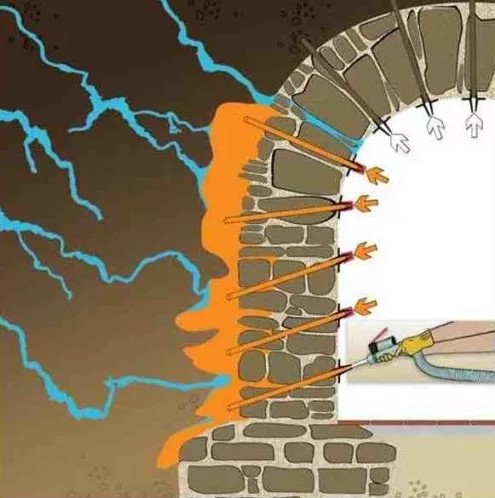

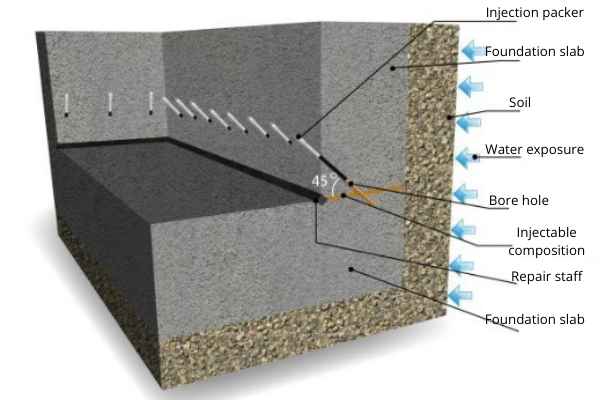

Injection waterproofing

Injection waterproofing is used mainly from inside a building or a private house, and is designed to repair and seal joints, junctions and the body of the structure – Special compounds are injected under pressure into the bases using an injection pump. The injection compound penetrates into all possible pores, voids and microcracks of concrete, block, brick and fills them, thereby sealing them.

You can read more about injection in the article “Injection waterproofing”.

Repair scheme using injection technology:

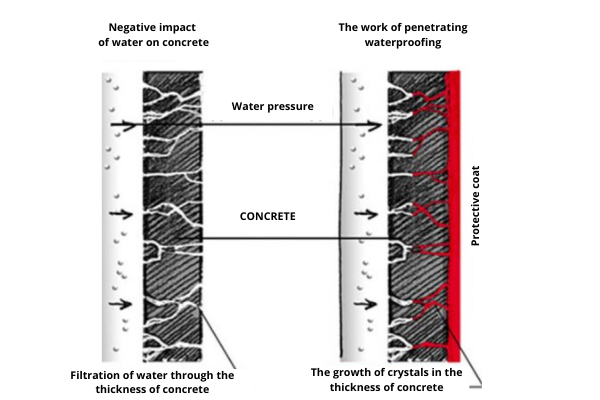

Penetrating

Penetrating insulation arrangement – Applied with a roller or brush, thanks to abundant moisture penetrates into the structure of concrete and forms a protective film. The protective film is formed due to the connection and growth of crystals inside the concrete.

You can read more about penetrating waterproofing in the article – “Penetrating waterproofing: A detailed description of its work on concrete, types of materials and application technologies“.

Repair scheme using penetrating compounds:

Polymer-cement compositions

Polymer cement waterproofing – These compounds are applied with a brush or roller and work on negative water pressure from the outside to the inside. That is why they are best used from the inside of the basement or socle.

Polyurethane

Polyurethane waterproofing consists of various polyurethanes and can be either single-component or double. When applied, it forms a seamless coating with 100% of adhesion to the substrate and a high coefficient of elasticity. Polyurethane compounds are UV-resistant in most cases and are excellent for waterproofing a roof, terrace or balcony as a finishing layer.

This method is mainly used for carrying out work outside and is suitable for repairing existing polymer, surfaced roll coatings or when performing a major repair of the base with a complete replacement of the old coating with a new one.

You can read more about polyurethane spraying in the article “Polyurethane waterproofing“.

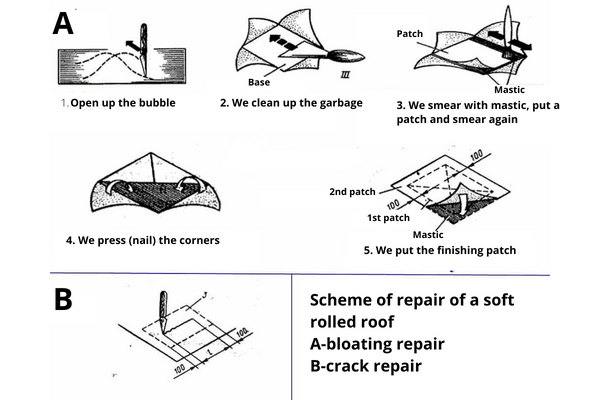

Roll surfaced

Roll-on waterproofing – if we talk about repairs, then it is carried out by the method of patching on damaged areas. The technology of repair using bitumen rolls is suitable exclusively for the repair of the same bitumen rolls, which eventually became unusable or were incorrectly laid.

Below is a detailed instruction for the local repair of roll-on-roll insulation using the patch installation method:

See the detailed instructions for the patch installation

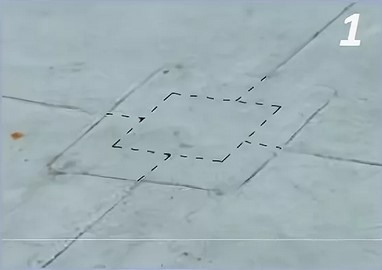

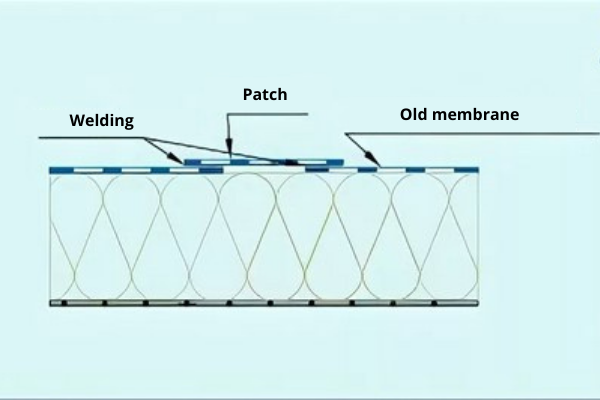

Membrane insulation

Repair with PVC and TPO membranes is possible only as a patch installation on the same membranes, preferably from the same manufacturer. Otherwise, the completed patch may not have adhesion to the old membrane, and it will lose its effectiveness.

You can read more about membrane waterproofing in the article – “Membrane waterproofing: Types of materials and methods of their installation“.

Repair instructions using PVC membranes:

View detailed repair instructions

Veil waterproofing

It is used exclusively from inside the room, mainly in underground structures such as basements, underground parking lots and tunnels. The task of the veil technology— is to restore the waterproofing protection from the outside of the wall or foundation by performing work from the inside.

Veil waterproofing – Is an injection technology where the injection compound is injected from the inside, behind a wall foundation, thereby forming a new protective layer between the ground and the wall.

You can read more about the veil method in the article “Veil waterproofing”

Repair scheme using the veil injection technology:

The cost and prices of the waterproofing repair installation

The prices listed below reflect the average cost of repair work, but the cost may vary depending on the complexity of the work and the materials used.

The price for repairs outside:

| Description of works | Unit of measurement | Price in $ |

| Repair of surfaced waterproofing | m2 | 20 |

| Repair of self-adhesive insulation | m2 | 14 |

| Repair of PVC membrane | m2 | 30 |

| Application of polyurea | m2 | 30 |

| The installation of coating waterproofing | m2 | 8 |

| The application of liquid rubber by spraying | m2 | 8 |

| The application of liquid rubber manually | m2 | 10 |

| Repair of polyurethane waterproofing | m2 | 20 |

Prices for interior repairs:

| Description of works | Unit of measurement | Price in $ |

| Sealing of cold joints: -Works on the installation of the indenting -clearing the indenting -layer-by-layer sealing of non-shrinkable composition | running meter | 20 |

| Sealing of interblock joints: -Works on the installation of the indenting -clearing the indenting -layer-by-layer sealing of non-shrinkable composition | running meter | 15 |

| Sealing of expansion joints: -Works on the installation of the indenting -clearing the indenting -sealing of the elastic profile -sealing of non-shrinkable composition -complex of works on injection | running meter | 160 |

| Injection waterproofing of seams / cut-off waterproofing -Works on the installation of the indenting -clearing the indenting -layer-by-layer sealing of non-shrinkable composition -Works on the installation of boreholes and assembly of packers -a complex of works on injection -dismantling of packers and sealing of injection holes | running meter | 80 |

| Injection waterproofing in concrete body -marking, Works on the installation of boreholes and assembly of packers -a complex of works on injection -dismantling of packers and sealing of injection holes | m2 | 80 |

| Injection waterproofing in brick body -marking, Works on the installation of boreholes and assembly of packers -a complex of works on injection -dismantling of packers and sealing of injection holes | m2 | 80 |

| Polymer-cement waterproofing | m2 | 20 |

| Penetrating waterproofing | m2 | 20 |

| Waterproofing of communication entry points: -Works on the installation of the indenting -clearing the indenting -layer-by-layer sealing of non-shrinkable composition -Works on the installation of boreholes and assembly of packers -a complex of works on injection -dismantling of packers and sealing of injection holes | piece | 250 |

Calculator for self-calculation of the cost waterproofing

Open the waterproofing calculator from the outside

Calculation of waterproofing cost

The total cost of waterproofing

Open the calculator for calculating suture and injection waterproofing

Calculation of the cost of injection and suture waterproofing

The total cost of waterproofing

Waterproofing repair materials

The reliability and durability of the waterproofing and protective layer depends on the correct choice of material. For this reason, you should not choose economy class materials, in most cases they quickly become unusable and require replacement or repair, and this can be associated with a lot of associated costs, such as dismantling the waterproofing layers (screeds, tiles, plaster, insulation), digging up the soil and its subsequent backfilling (if we are talking about the basement), etc…

The main types of waterproofing materials for repair:

- Injection polyurethane resins – Are used to protect concrete, walls made of blocks and bricks. When injected into the bases under pressure, polyurethane foam or resin expands, thereby filling all existing voids.

- Injectable helium compounds – Are used where there is dynamics and polyurethane resins can crack, for example, deformation seams.

- Expanding sealant – Used for sealing joints and places of entry of communications.

- Liquid rubber – Sprayed with special equipment or applied manually forming a seamless elastic coating with excellent adhesion.

Where to start the repair and how to do it once and forever?

In order to perform properly the repair, the first thing you need:

- Not only to determine the location of the leak, but also to understand why it is occurred and where its root is;

- To understand the structure, the existing waterproofing and its features, various nuances of the structure of your foundation, basement or other structure. This is what will help you to understand whether it is possible to perform local repairs and thereby protect yourself from leaks, or after patching a certain area, the water will immediately go to the next weak point, which will eventually make your local repair absolutely useless;

- Choose the best repair method;

- Choose high-quality material;

- Perform the work efficiently.

In order to carry out all the above measures, it is recommended to contact experienced professionals.

To do everything correctly and not to redo in the future, you should follow 3 simple rules:

- Find a good company that specializes in the field you need;

- Call the engineer to your facility so that he can properly access your situation and offer a technically sound and correct solution regarding repair methods;

- Sign a contract with professionals and do not engage in amateur activities, hiring workers of questionable qualifications from bulletin boards and service aggregator sites.

Further, in this article, you can familiarize yourself with some of the features of repairing various constructs, such as foundations, basements, walls and roofs. Each of these structures needs its own approach and method of repair.

Repair of waterproofing of the roof, balcony and terrace

If you find leaks in the roof, terrace or balcony, then you need to perform urgent repairs. In most roofs, membrane or roll-on insulation is made, which makes it impossible to determine the exact place of water entry from the outside. As we said earlier, the place of leakage from inside the building is simply the weakest point in the structure, and it does not always determine the place where the water flows from the outside.

There are several options for performing repair work and eliminating leaks:

If you perform work locally, you can use the following methods:

- For PVC membrane insulation – patches are made on damaged areas. If the coating is old, then it is not always possible to weld or glue a new membrane to it well. In this case, the site is covered with a special mastic that has adhesion with a PVC membrane.

- For roll surfaced – The top layer of the damaged or swollen area is cut out, if the bottom layer sits tightly, then a primer is applied to it and a new sheet of 2 layers is deposited on top in order to overlap the seams.

- For coatings made of mastic, polyurethane and liquid rubber – The damaged area is cut out, the surface is cleaned, a primer is applied to it, and then a patch is applied in one or more layers.

If we solve the issue thoroughly:

If you want to solve the issue of leaks thoroughly with a guarantee of their absence in the future, then in the case of membrane or roll insulation, it is recommended to dismantle the entire layers to the base plate and make waterproofing a new one. The new insulation can be made from:

- PVC membranes;

- Surfaced bitumen-based insulation in 2 layers;

- Liquid rubber

- Polyurethane waterproofing

- Waterproofing of polyurea;

- Polymer-cement compositions.

When installing a new waterproofing it is recommended to use materials according to the type of polyurethane waterproofing, since it has the following advantages:

- No seams and joints;

- 100% setting (adhesion) with the surface;

- High coefficient of elasticity and stretching;

- UV resistance.

You can read more about the repair of various types of roofs in the following article – “Roof waterproofing repair: Methods, materials and prices”.

You can read more about roof waterproofing in the following articles:

- Waterproofing of the roof: methods of its arrangement and types of materials for performing high-quality work

- Waterproofing of a flat roof. Recommended materials, methods of their installation and prices for work

- Waterproofing and repair of pitched roofs

Repair of waterproofing of the foundation and walls

If the insulation of the foundation is broken, then it should be restored. Vertical waterproofing is best restored from the outside in order to protect the foundation from the effects of moisture and water contributing to its gradual destruction. To perform external repair measures, it is best to use seamless compositions with 100% adhesion, according to the type of liquid rubber.

To restore the horizontal waterproofing of the foundation and walls, it is best to use injections, since finding horizontal protection makes it difficult to repair it when walls are erected.

Scheme of restoration and repair of horizontal waterproofing of the foundation and erected walls:

Repair of basement and socle waterproofing

If you find leaks or wet spots on the walls in your basement, it means that the waterproofing from the outside of the basement is missing or broken. In this case, it requires repair. Repairs can and should be carried out from the outside, but sometimes there are situations when it is impossible to do this from the outside and it is necessary to deal with leaks from the inside.

If the water protection from the outside is made of surfaced bitumen or PVC membranes, then by the nature of leaks inside it is impossible to determine the exact place of entry of water under the insulating coating from the outside (for its local repair), since the above materials do not have adhesion to the base and if water gets under them, then it can freely move from one place to another, the other is under it.

Important: If leaks are detected in the basement, it is recommended to repair the insulation outside the basement. In this case, the root of the problem will be solved – water and moisture will not have access to the walls of the basement or socle.

Renovation of the basement outside:

To do this, it is necessary to gain access to the basement from the outside and perform a number of necessary measures:

- Dismantle the old waterproofing;

- Clean and prepare the surface;

- Apply new waterproofing.

Renovation of the basement from the inside:

Here you can use several technologies, the choice of which depends on the nature of the leak. In most cases, when performing work from the inside, it is worth paying attention to the most problematic and weak points in any structure, namely cold, interlocking and other seams and joints. To repair and seal joints, it is best to use the technology of injection of polyurethane resins.

If leaks and broken insulation are detected in the body of the wall, in addition to injection, polymer-cement compositions working on negative water pressure from the outside, such as German HydroPaz or similar analogues, can be used for repair.

Important: Bitumen surfaced sheets, PVC membranes and various kinds of polyurethane and bitumen mastics do not work on separation, respectively, when applied from the inside, these materials should be pressed with a pressure wall or screed.

You can read more about basement waterproofing in the following articles:

- How to do waterproofing of basement properly from the outside

- Waterproofing of the basement from the inside: Methods, materials and stages of work

- Elimination of basement leaks once and forever

- Waterproofing of the basement floor of the house: Methods, technologies of the installation and materials

- Fungus and mold in the basement of a private house: Causes and how to get rid of it once and forever?

- How to make properly basement recess below the sole of the foundation

- Waterproofing of the socle: Recommended materials and technologies

Repair of floor waterproofing

When it comes to the repair of floor insulation in wet areas, then waterproofing is mainly produced using various bitumen mastics. If we are talking about a field, a production kitchen or a workshop where a sufficiently large amount of water is assumed, then it is best to use polymer cement or polyurethane compounds for the production of floor waterproofing.

If you have a problem with leaks in the basement floor due to the presence of cracks or other defects, then it is best to use the injection method.