Table of Contents

- Why it is necessary to do waterproofing for the walls of a house and a building

- Waterproofing of basement walls and exterior walls from groundwater and high water-how to do it correctly

- Horizontal and vertical waterproofing of walls outside

- Waterproofing of walls: materials and methods

- Waterproofing of the wall from the inside

- Waterproofing of brick wall and block walls

- Waterproofing arrangement of walls – how to perform properly the work and prepare the surface

- Waterproofing of walls. Price per m2 and work rates

- Wall waterproofing repair

- Waterproofing of walls with your own hands

The walls of a private house or commercial building can be made of concrete, brick, FBS blocks and other materials. Regardless of what material the walls are made of, all elements of the building located below ground level should be covered with waterproofing. Waterproofing of the walls prevents their destruction and prevents water from entering the room.

Why it is necessary to do waterproofing for the walls of a house and a building

In the absence of properly made horizontal and vertical waterproofing of walls, all walls of a house or building that below ground level (ground level) will be exposed to water and aggressive environment, which will eventually lead to their destruction, as well as to the penetration of water and moisture into rooms located underground, for example, basement or socle.

It does not matter what kind of walls we are talking about-concrete walls or brick, all these substances absorb moisture and water. Waterproofing and horizontal protection of the walls outside the house is very important even in the absence of groundwater, the soil absorbs moisture from melting snow or heavy rain. Moist soil gives this moisture to concrete or brick, which in turn absorb it very well and transfer it inside the basement, socle and any other room.

Destruction occurs for several reasons:

- The impact of an aggressive environment on concrete and brick-there are various impurities in the ground and other water that can affect these materials and subsequently lead to their destruction.

- Temperature difference-water is absorbed into concrete and brick walls. In winter it freezes, and in spring it thaws, thereby destroying the foundations forming microcracks and voids.

The lack of proper waterproofing of exterior walls of the room can subsequently lead to:

- Leaks in the basement and socle

- Cracks formation

- Mold and mildew dangerous to human health

- Wet walls and the destruction of the finish

Waterproofing of basement walls and exterior walls from groundwater and high water-how to do it correctly

Socle or basement, as a rule, is located underground and, accordingly, is most exposed to water. As mentioned above, protecting the exterior walls of the basement from water is a necessary measure and it needs to be done correctly. It is better and more correct to make waterproofing even at the stage of building a house and erecting a basement.

When it comes to proper waterproofing of the basement, it is necessary to take into account the following nuances:

- Cut-off waterproofing – horizontal cut-off waterproofing of the basement, which will serve as a barrier between the walls of brick, block or concrete being erected (monolithic walls) and the foundation.

- Waterproofing of the joints of the abutment of the slab (foundation) and wall – Sealing of cold joints can be done with a swollen cord or a water stop (when it comes to pouring monolithic concrete walls).

- Vertical waterproofing – the arrangement of the protective coating of the walls. The vertical protection of the basement should be properly done so that it docks with the horizontal insulation of the foundation in the form of hydraulic lock.

Important: If at the stage of building a house waterproofing is done incorrectly or will not be done at all, then its repair or a new device will cost 3 times more expensive, since for this it will be necessary to re-dig out the house or basement, break the blind area, dismantle the insulation, rebury the house, etc… Considerable expenses will be added for the repair of the unfit finishing of the basement or socle.

You can read in detail about how to make waterproofing in the complex in the article – Turnkey integrated waterproofing.

You can read more about basement waterproofing in the following articles:

- How to do properly waterproofing of the basement from the outside

- Waterproofing of the basement from the inside: Methods, materials and stages of work

- Elimination of basement leaks once and forever

- Waterproofing of the basement floor of the house: Methods, technologies of installation and materials

- Fungus and mold in the basement of a private house: Causes and how to get rid of it once and forever?

- Waterproofing of the socle: Recommended materials and technologies

Horizontal and vertical waterproofing of walls outside

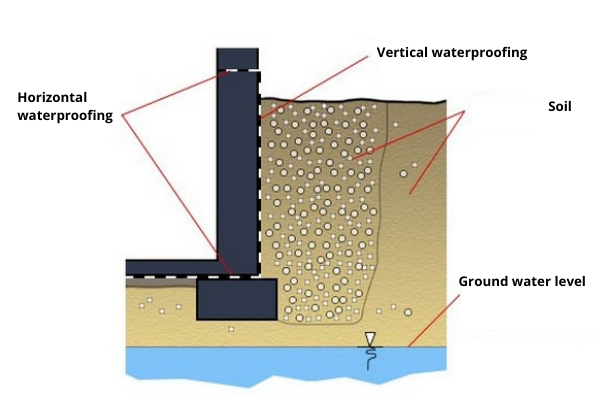

The walls of the building below level zero should be protected both with a horizontal insulation arrangement and with a vertical one.

Horizontal waterproofing – is designed to protect a building from water penetration from below, especially when it comes to high groundwater.

Important: Horizontal protection is needed not only at a high ground waters, since the soil around the house or building in any case is saturated with moisture from rain and high water, which in turn negatively affects the foundation of the building.

Vertical waterproofing – its arrangement is designed to protect the outer walls of the basement from water falling on the walls from the side vertically. We are also talking about groundwater and rainfall. The soil around the building is saturated with moisture and gives it to the foundation and walls of the basement or socle, thereby negatively affecting them.

You can read more about vertical and horizontal waterproofing in the following articles:

- Horizontal waterproofing of the foundation: The technology of the installation and the materials necessary for this

- Vertical waterproofing: materials and methods of its installation

Waterproofing of walls: materials and methods

Today there are many different methods of waterproofing on the market, including walls. A large selection of waterproofing materials is attached to each method of protecting the house from water. Below are the most popular methods and materials for waterproofing works:

- Coating

- Pasting

- Surfaced roll

- Mounted roll or membrane

- Injection waterproofing

- Liquid

Coating waterproofing of walls

This type includes various bitumen-based and polyurethane-based mastics. The most popular coating materials are bitumen mastics from technonikol. However, do not forget that waterproofing is not done for 1 day or even for 1 year. Accordingly, it is not necessary to choose cheap bitumen compounds as the main waterproofing. In addition to cheap bitumen mastics from Technonikol, there are also a number of professional waterproofing compounds on the market, such as FlexLock Pro or PolyFlex from the German manufacturer Hydro.

You can read more about bitumen waterproofing in the article – “Bitumen waterproofing: types, characteristics and technology of the installation“.

Pasting waterproofing of walls

The pasting materials include different bitumen-based membranes. Their main difference- is that they are glued to the surface using a special adhesive base. Advantages:

- Low price

- Market availability

- Simple installation that can be done with your own hands

Disadvantages:

- Poor protection quality

- Short service life

- Low resistance to aggressive environment

- The presence of seams

Roll waterproofing of walls

Roll waterproofing is supplied in rolls that are sewn together on the surface of the walls. This type includes PVC membranes and surfaced roll membranes on a bitumen basis. PVC membranes are stitched together with a special hair dryer and lie on the surface with a kind of carpet. The presence of seams and the complete lack of adhesion to the base of the walls makes these materials very unreliable. The surfaced membranes are connected to each other by means of a hot fire (burners are used). The main disadvantages of these materials are the presence of seams (that is why it is necessary to apply these membranes in at least 2 layers) as well as the lack of 100% adhesion to the base (which forms voids and cavities).

You can read more about surfaced and roll waterproofing in the following article – “Roll waterproofing arrangement with detailed installation instructions”.

Injection waterproofing of walls

In most cases, the injection is used to carry out work from the inside. This is a very effective way to eliminate leaks and repair, but also quite expensive. You can read more about this method in the continuation of this article.

Liquid waterproofing for walls

Liquid waterproofing includes such premium compounds as liquid rubber and polyurea. Liquid rubber — is a special material that forms an elastic, reinforced seamless membrane with 100% adhesion to the surface. This material is widely used for durable wall protection installation.

Important: When choosing waterproofing materials, do not forget one well-known proverb “It does not happen cheap”-When buying a product, a person chooses: to take a cheap thing or a high-quality, reliable one that will last well and for a long time.

The best waterproofing of walls

If we are talking about the best waterproofing of walls, then it is best to choose materials with the following qualities:

- Lack of seams – seams are the weakest point in any waterproofing coating.

- Adhesion to the base – good adhesion indicates that when cracks or holes are formed in the protective coating, water will not be able to pass under it, stagnate and walk there.

- Service life – the material should not crumble in your hands after a year.

- Elasticity – the more elastic the material, the longer it will last, since the dynamics or shrinkage of the soil will not be able to destroy it (it will not crack and will not disperse at the seams).

Materials such as Liquid rubber (for example FlexLock) and Polyurethane waterproofing meet all the above qualities.

Waterproofing of the wall from the inside

Waterproofing from the inside is done mainly as measures to eliminate leaks in the basement or repair walls with broken or missing insulation from the outside, when there is no access to them from outside the house for some reason.

When performing wall repairs from inside the premises, the following technologies can be applied:

- Bitumen-based coating materials (various mastics) Surfaced roll plates and PVC membranes. All these materials do not work for negative water pressure (from the outside to the inside), respectively, when they are installed, they need to be pressed with a screed (if we are talking about horizontal insulation)-this method is not recommended when performing waterproofing from the inside.

- Materials, that work on negative water pressure-these compounds work precisely from the inside, when the water pressure goes from the outside into the room and they do not need to be pressed with anything. One of such compositions is HydroPaz from the German manufacturer HYDRO.

- Injection materials – are polyurethane and helium resins that are injected into the body of the structure or behind it. This technology is used mainly when it comes to work from the inside.

Injection waterproofing of walls from the inside

Injection waterproofing – is one of the most expensive and most reliable methods used to protect walls from inside a building.

The injection insulation method is suitable for both brick walls and walls made of blocks or concrete (monolithic walls). When performing work by injection, holes are drilled in the wall, into which packers (hollow tubes for injection resin wire) are inserted, an injection pump is connected to them, which under pressure feeds the composition into the thickness of the wall or beyond it. When injected resin or gel gets into the thickness of the wall, it fills all existing voids, microcracks and pores, thereby making the walls waterproof. The method of injection behind the wall is called veil waterproofing and is used in exceptional cases.

You can read the following article in detail – “Injection waterproofing“.

Waterproofing of brick wall and block walls

For waterproofing walls made of blocks or bricks, in fact, the same materials are suitable for a conventional monolithic concrete wall. The only nuance is the eveness of the surface on which the waterproofing will be applied. The waterproofing material should lie on a clean and flat surface.

The brick has many seams and in most cases they are minted unevenly, which leads to the fact that the surface of the walls where the membrane needs to be mounted requires alignment with special compositions.

If we are talking about waterproofing a brick wall from the inside, then before performing injection, the wall is covered with a special non-shrink compound so that the injection resin goes inside the walls, and does not come out through the seams between the bricks.

You can read more about waterproofing a brick wall in the following article – “Waterproofing of bricks and brickwork“.

Waterproofing arrangement of walls – how to perform properly the work and prepare the surface

The arrangement of a high-quality waterproofing coating begins with the correct choice of the method and type of waterproofing coating and ends with its proper protection from damage during filling or installation of subsequent layers (for example, insulation).

Here are the main things you should pay attention to when installing a high-quality waterproofing coating:

- The right choice of materials – for each structure (foundation, walls, basement, socle, roof), situation (there is groundwater or there are none, work from inside or outside, etc…) there is its best or at least suitable material. The wrong choice of waterproofing material will lead to a reduction in its service life or to future leaks.

- Surface preparation before waterproofing arrangement.

- The absence of angles under 90 degrees for the transition from the horizon to the vertical base (using a fillet or a special skirting board).

- Priming the surface with a special primer to improve adhesion.

- Arrangement and Application of waterproofing coating with exact observance of technology

- Protection of the performed work – it is important not only to do high-quality work, but also to protect it from future damage.

It is not an easy task to do waterproofing arrangement so that later would be no leaks in the room and nothing had to be redone. It is recommended to entrust this task to professionals-a large company whose specialization is directly waterproofing work.

Preparation of the wall surface for waterproofing

Proper surface preparation is a 50% success rate when applying insulation. If the wall surface is prepared with violations, this will primarily affect the adhesion (adhesion) of the material to the wall, and hence its reliability.

In order to prepare the walls properly, you need to follow the following recommendations:

- Seal all large holes, cracks, seams and cavities with cement mortar or non-shrink sealants;

- Remove all sharp protrusions, rebar ends and other protruding elements;

- Remove all outgoing elements from the surface;

- Clean the surface from dirt and dust using metal bristle brushes, rags and pressure water;

- Apply a primer (primer) to the surface.

Waterproofing of walls. Price per m2 and work rates

All prices and quotations are preliminary. If you are interested in the final cost, then you need to call our engineer to your facility. It is he, who will be able to determine the complexity of the work performed, from which the price may also depend.

Prices for work outside:

| Description of work | Unit of measurement | Price in $ |

| Works on the arrangement of surfaced waterproofing | m2 | 10 |

| Work on the arrangement of a PVC membrane | m2 | 20 |

| Work on the arrangement of polyurea | m2 | 30 |

| Works on the mastic waterproofing arrangement | m2 | 10 |

| Works on the arrangement of liquid rubber by spraying | m2 | 12 |

| Works on the arrangement of liquid rubber manually | m2 | 20 |

| Works on the arrangement of cement-mineral 2-component waterproofing | m2 | 20 |

| Works on the arrangement of polyurethane waterproofing | m2 | 20 |

| Applying the primer | m2 | 8 |

Price for work inside:

| Description of work | Unit of measurement | Price in $ |

| Waterproofing of cold joints: -works on the arrangement of indenting -clearing the indenting -layer-by-layer sealing of non-shrinkable composition | running meter | 20 |

| Waterproofing of interblock joints: -works on the arrangement of indenting -clearing the indenting -layer-by-layer sealing of non-shrinkable composition | running meter | 15 |

| Waterproofing of expansion joints: -works on the arrangement of indenting -clearing the indenting -sealing of the elastic profile -sealing of non-shrinkable composition -complex of works on injection | running meter | 200 |

| Injection waterproofing of seams / cut-off waterproofing -works on the arrangement of indenting -clearing the indenting -layer-by-layer sealing of non-shrinkable composition -works on the arrangement of boreholes and installation of packers -complex of works on injection -dismantling of packers and sealing of injection holes | running meter | 100 |

| Injection waterproofing into the body of concrete -marking, Works on the arrangement of boreholes and installation of packers -complex of works on injection -dismantling of packers and sealing of injection holes | m2 | 150 |

| Waterproofing in body of brick -marking, Works on the arrangement of boreholes and installation of packers -complex of works on injection -dismantling of packers and sealing of injection holes | m2 | 180 |

| Cement-mineral waterproofing | m2 | 20 |

| Penetrating waterproofing | m2 | 20 |

| Waterproofing of communications entries: -works on the arrangement of indenting -clearing the indenting -layer-by-layer sealing of non-shrinkable composition -works on the arrangement of boreholes and installation of packers -complex of works on injection -dismantling of packers and sealing of injection holes | piece | 200 |

Estimate of walls waterproofing

You can get a detailed estimate with all materials and works by contacting our organization by sending us an e-mail or by calling us by phone. If you are interested in the final version of the estimate with exact prices per m2 and detailed prices for the work, you can call our engineer to your facility.

The engineer will look at everything on his own, draw up a detailed technical specification and send it to the estimate department, where they will calculate everything in detail. In the estimate sent to you, you will find prices per m2 and total costs for all items of the estimate calculation.

Cost calculator for self-calculation

Calculation of waterproofing cost

The total cost of waterproofing

Wall waterproofing repair

Wall waterproofing repair is necessary when problems with water leaks and/or with increased humidity of the walls, fungus or mold (due to wet walls) have been found during the operation of a private house or commercial building.

Important: If water leaks are found in your house, basement or socle, this means that there is no vertical or horizontal waterproofing of the foundation or walls from the outside or has become unusable. Waterproofing repair are best done outside, as this will solve the root of your problem.

If you want to solve the problem with leaks once and forever, then the best solution is to make a good barrier outside, so that water does not penetrate into the structure of concrete or brick and does not destroy it. If it is impossible to carry out repair work from the outside, you can do it from the inside using the technology described earlier.

Waterproofing of walls with your own hands

If desired, you can perform all waterproofing work with your own hands, without resorting to the services of specialists, with the exception of work, related to certain specialized equipment such as injection waterproofing and spraying of liquid rubber. However, before you start work on protecting your home from water, it is recommended to study carefully the technology of work and gain relevant experience.