Table of Contents

- Why is it necessary to do waterproofing of bricks and masonry walls?

- The technology of waterproofing the walls of the socle of brickwork and its stages

- Waterproofing of the socle wall made of brick

- Materials for waterproofing of bricks

- Cost of work

- Conclusion

Why is it necessary to do waterproofing of bricks and masonry walls?

Brick is quite a popular material in construction. Bricks have many advantages, and, accordingly, disadvantages. One of these disadvantages is that brick acts as a sponge for water, it is strongly exposed to moisture and water, absorbing them into itself. Due to the presence of various minerals in the water, as well as due to the temperature difference, without a high-quality waterproofing that can protect the brick from contact with water and moisture, the completed masonry can be severely destroyed.

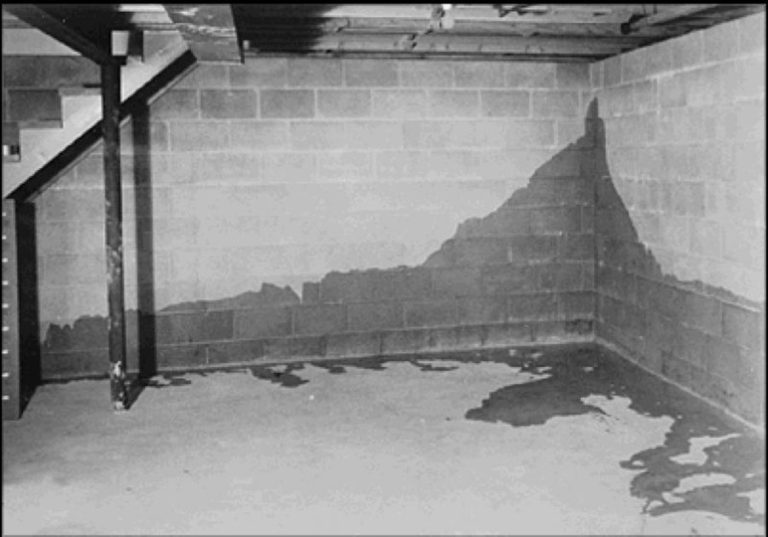

Consequences of improperly performed waterproofing of brick walls

If the brick or other masonry is not protected from the penetration of water from the outside, then water and moisture will be absorbed into the brick. In winter, this water will freeze in the structure of the brick and in spring it will thaw and thereby lead to the formation of microcracks, voids, pores and destroyed areas in the completed masonry.

As a result, you will most likely face the following consequences:

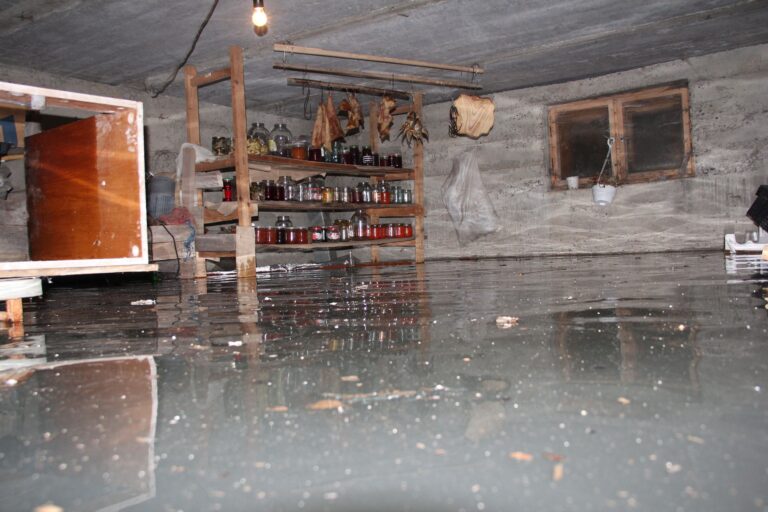

- Leaks in the socle or basement

- Wet surfaces and increased moisture in the socle or basement room

- Formations of mold and mildew dangerous to health (due to constant humidity)

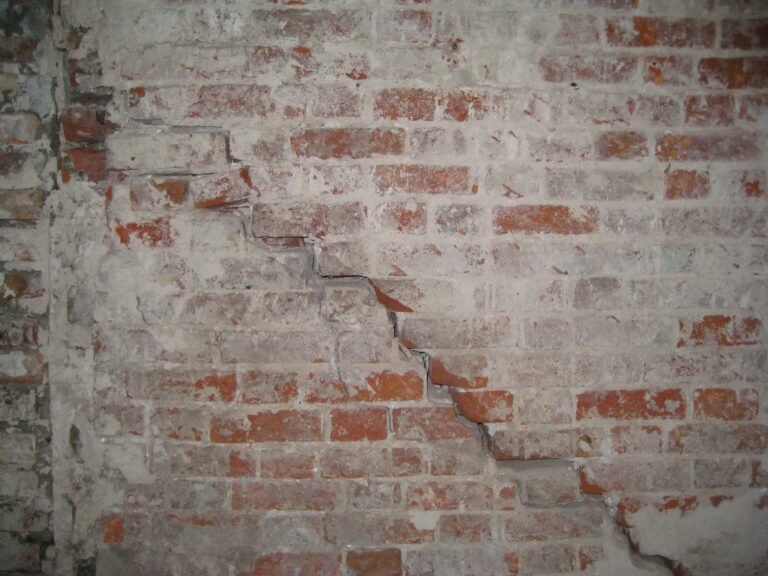

- Formations of cracks of different sizes in the masonry itself

The technology of waterproofing the walls of the socle of brickwork and its stages

Today there are several basic technologies for waterproofing the walls of a house made of brick. The choice of waterproofing technology or method depends on several factors:

- Primary insulation or repair –Works to protect against water penetration are carried out at the stage of construction of the house or after its commissioning.

- The condition of the walls – In what condition are the walls of the socle. The presence of cracks and destroyed bricks.

- Access to the walls outside the house-If the house can be dug out along the perimeter and there is access to the basement walls, then waterproofing is best done on the outside.

Choosing the right method for performing waterproofing works is best left to professionals. It is an experienced company whose specialization is waterproofing itself that will be able to choose the right technology and materials for durable and high-quality protection of your basement from water.

Stages of works performance:

- Inspection of the object by a waterproofing engineer;

- Definitions of method and material;

- Preparation of the brick surface;

- Carrying out waterproofing works outside or inside the room.

Surface preparation-What should be done with masonry walls before waterproofing?

It does not matter whether you protect the socle from the outside or from the inside, before applying the insulation coating, you need to prepare the surface. In order for the waterproofing coating to be laid properly on the surface, the contractor should take the following two steps:

- Repair of any physical chip, crack or irregularity in the masonry;

- Caulking holes and voids in the seams of masonry between bricks;

- Cleaning the surface from dust and dirt.

Let’s see each of these points in detail.

Recovery of physical damage

Weathering, moisture, aggressive environment and age have their effect on brick and masonry. The most common damage is the wear of the joints of the mortar from the inside and outside. Replacing the missing or damaged mortar will improve the appearance and structural integrity. Similarly, cracked or missing pieces of brick should be replaced.

If the work is carried out from the inside, and you want to preserve the texture of the brick as a finishing element, then you will have to spend time searching for the right bricks. It can be difficult to find a brick that matches the existing masonry, so this issue should be resolved as soon as possible.

If we are talking about several pieces, probably the homeowner has reserves stacked behind the barn or in the basement. If we are talking about major repairs or additions, then the best solution is to find the original manufacturer.

When an exact match is not found or is impractical for a particular action, the contractor should find a replacement of the same size and texture and as close as possible to the original color.

The exact coloring can be adjusted later in the process. Keep in mind that the color of the mortar should also be precisely matched, since it is able to represent a significant part of the surface (up to 20%) and will have a significant impact on the apparent color of the brick.

Cleaning from dust and dirt

When cleaning masonry made of bricks, the contractor should use the softest method that allows you to perform this task well. Sometimes a bucket and a brush -are the only tools needed. Mold and other growths need to be removed with a special solution and this should be done before applying insulation.

Further, you can familiarize yourself with the basic methods of waterproofing masonry made with the use of bricks.

Waterproofing for bricks outside

Waterproofing of the socle or basement from the outside can be done by several different methods. Each method has its own advantages and disadvantages, as well as its ow warranty period for the work performed.

Basic methods:

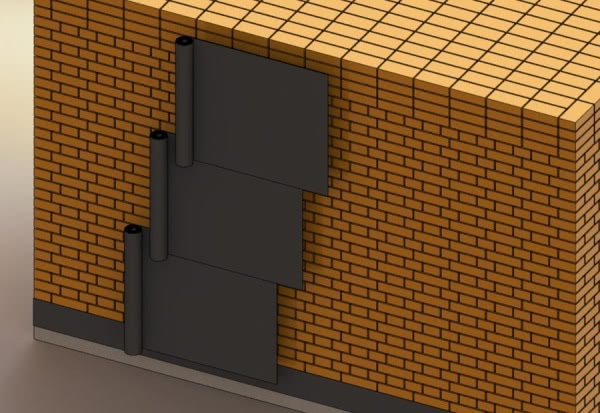

- Surfacing of rolled types waterproofing on the surface – Rolled surfaced insulating membranes are applied by fire with a burner in 2-3 layers, overlapping the seams and joints between the rolls.

- Arrangement of PVC membrane – Is rarely used for basement rooms made of masonry, since when installing PVC membranes, seams (joints between rolls) are formed and it has no adhesion to the surface.

- Coating waterproofing – Various mastics are applied to the surface in 2-3 layers using a roller or brush, forming a protective layer.

- Waterproofing with liquid rubber – It can be applied by cold spraying or using a roller. When spraying, rubber repeats any surface irregularities and fills small voids, which is ideal for waterproofing bases such as bricks. When installing insulation using liquid rubber, a homogeneous seamless, elastic coating with 100% adhesion to the surface is obtained.

The following table compares liquid rubber with the main types of waterproofing membranes for outdoor works:

| Liquid rubber | Surfaced bitumen-based membrane | PCV membrane | |

| Mounting method | Non-firing | Firing, with the help of the burner | With a hair dryer and mechanical fixation |

| The availability of seams | Not available | Available | Available |

| Adhesion to the base | 100 % | 40 % | No adhesion |

| Coefficient of elasticity | 600-800% | 10-20% | 10-20% |

| Installation speed m2/per day | 400-600 | 20-50 | 30-60 |

| Warranty period for works | 7 years | 3-5 years | 1-2 years |

Waterproofing of bricks from the inside

If for some reason you do not have the opportunity to protect your socle or basement from the outside, then issues with leaks and waterproofing can be solved from the inside of your room.

Important: If possible, it is recommended to perform waterproofing from the outside of a brick or other wall. By performing high-quality waterproofing from the outside, you solve the root of the problem, namely, the penetration of water into the structure of the brick and its further destruction. When arranging waterproofing from the inside, you are mainly struggling with the consequences of broken external insulation, and not solving the root of the problem.

When installing insulation from the inside, you need to choose the right technology for the insulation itself, otherwise, water will continue to flow into your basement. You have to be very careful in choosing, since there are many different methods and types of waterproofing systems on the market.

Each situation has its own material and method. Before you decide on the material and type of sealing of your foundation, it is best to call one of the major waterproofing companies operating in your city so that engineer comes, looks and gives you the necessary recommendations.

You may want such a company to do all the necessary work itself, saving you from unnecessary hassle and possible alterations, since you are still a laymen.

Basic methods:

- Polymer cement waterproofing – Applied to a brick using a roller or brush in 2-3 layers. With the right choice of material, this type of protection will keep negative water pressure from the outside to the inside.

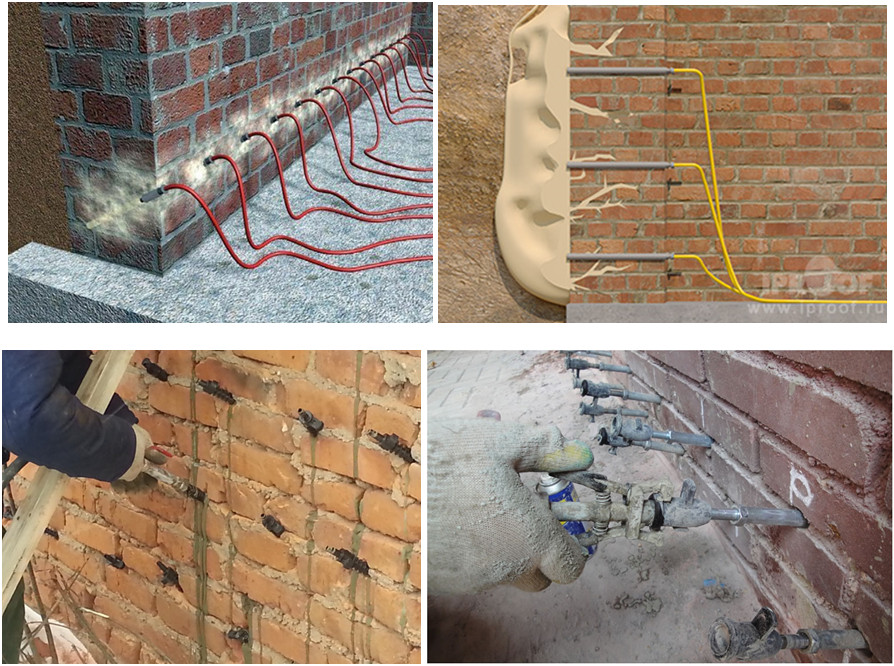

- Injection – Using an injection pump under pressure, polyurethane resins or gels are fed into the body of the brick, filling all existing microcracks, voids and pores. Injection waterproofing is one of the most effective ways to protect a house, socle or basement from the inside.

- Penetrating waterproofing – Suitable for carrying out work from the inside. The composition is spread on the surface with a brush or roller in combination with abundant moistening of the base. When penetrating into the structure of concrete or brick, the composition forms something like a crystalline film that does not allow water to pass. This method has extremely low efficiency.

- Veil waterproofing – Special polyurethane and other resins are injected not into the thickness of the walls, but behind them, thereby restoring the waterproofing layer between the ground and the wall. This type of insulation is quite expensive and is used only as a last resort or if there is a large budget for repairs.

Important: No matter what type of insulation and material you choose, the main thing is that it works under negative pressure, since you are doing work from inside the room, not outside. Surfaced, rolled waterproofing membranes, PVC membranes and coating bitumen mastics do not work at negative pressures. They all work on the clamp and they need to be mounted outside the socle or foundation. If you still decide to install this type of waterproofing from the inside, then in any case you will need to press it with an additional wall or screed (if on the floor).

Waterproofing of the socle wall made of brick

As we mentioned above, the choice of material, type and method of waterproofing of a brick base depends on where the waterproofing work will be carried out, from the inside to outside. If the work is carried out from the inside the socle, then it is better to protect the foundation with double-component polymer cement waterproofing. If we are talking about active leaks, then a set of measures is recommended here:

- Caulking of seams between masonry to non-shrink sealants;

- Preparation and cleaning of the surface from dust and dirt;

- Injection arrangement to eliminate active leaks in the brick wall, repair damaged seams and cracks in the brick;

- The arrangement of double-component polymer-cement membrane to protect the socle and foundation from further leaks and the appearance of wet spots that contribute to the formation of fungus and mold.

You can read more about waterproofing walls in the article – “Waterproofing of basement and house walls from the outside and inside– Methods, materials, prices and technology“.

Materials for waterproofing of bricks

Today, there are a large number of different compositions on the market for the arrangement of reliable waterproofing of bricks. Some of these materials are intended for installation exclusively from the outside of the structure, as they work on the clamp, and some can be used both from the outside and inside.

Polymer-cement waterproofing

Double-component polymer cement compositions are the most common and reliable way to seal the foundation of bricks and other foundation masonry. The most popular material among specialized waterproofing companies is HydroPaz Prime+ Acril, this composition is applied to the brickwork with special brushes and rollers, after which it penetrates into the structure of the brick and establishes a strong barrier. This barrier is able to withstand the negative pressure of moisture from the outside to the inside. Such compositions can be used both from the inside and outside.

You can read more about cement waterproofing compositions in the article – “Cement-based waterproofing: Features, types and methods of its application“.

Injectioning and injection waterproofing

This type of waterproofing is used mainly from inside the room when it comes to leaks in a brick wall, foundation or socle. Special holes are drilled in the brickwork, hollow tubes called packers are inserted into them, then injection resin is injected into the brick body through these packers, under pressure (using special equipment). For waterproofing of a brick base, helium compositions from BASF or such compositions as HydroInject Gel from the German company Hydro are mainly used. It can also be injected with polyurethane resin, but one should be careful, since it has the properties to expand and if the brick is destroyed or very weak, it can crack.

You can read more about injection waterproofing in the article – “Injection waterproofing”

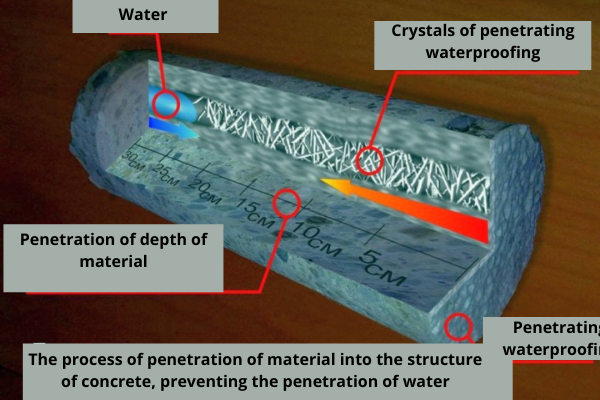

Penetrating waterproofing for bricks

This type of protection is suitable exclusively for interior work. Penetrating waterproofing, in its essence, should penetrate into the structure of the brick, forming a crystalline film, thereby stopping the water.

In fact, the method of penetrating insulation has not proven itself and is ineffective, since the brick is porous and in most cases has voids and microcracks, and penetrating compounds do not work in these areas, since there is, in fact, a void-but it is these areas that allow water to pass through.

View the scheme of the penetrating system

You can read more about the penetrating method in the article– “Penetrating waterproofing: A detailed description of its work on concrete, types of materials and application technologies“.

Coating waterproofing

Coating mastics based on bitumen or polyurethane do not work under negative pressure and are mainly used to perform work outside. The most popular manufacturers of such mastics are:

- Тechnonikol

- BASF

- German company Hydro

Each manufacturer recommends applying a certain number of layers and a certain thickness of these layers, depending on the characteristics of the proposed mastic. When performing work using coating insulation, it is recommended to perform at least 2 layers of insulation.

As we have already said, the coating sealing is mainly used from the outside of the wall, so that at water pressure, it works for clamping, and not for separation. There are many coating compositions on the Russian market, the best of them in terms of price and quality is single-component rubber, such as FlexLock Pro, which can be applied both manually and mechanized.

When selecting a coating mastic, it is best to make a choice in favor of more expensive compositions, since in most cases they last much longer than cheaper analogues.

Pasting

The most popular adhesive membranes are the membranes of Technonikol company. For the arrangement of protection and insulation of brickwork of walls located below ground level, it is recommended to use a rolled surfaced membrane “Technonikol Foundation” in 2-3 layers. Cheaper analogues will very quickly become unusable due to temperature differences, exposure to aggressive environments and various minerals in the ground and groundwater.

Liquid rubber

When carrying out works related to the protection of the foundation and brick walls from the impact and penetration of moisture, it is best to use double-component liquid rubber by the type of FlexLock or single-component liquid rubber, depending on the volume. This material is ideal for bricks, since liquid rubber has no seams, has an elasticity of 800% (it will not break when the structure shrinks or its dynamics), has 100% adhesion (adhesion) to the surface (this means that there will be no voids under the waterproofing layer, through which water can walk and stagnate).

When using LC, it is important to clean the surface from dust and dirt, then apply a special primer that improves the adhesion of the composition to the surface.

Important: When choosing the right material for waterproofing, you should not chase the low price of the material. As a rule, the cheaper the composition, the worse its characteristics and actual service life.

Cost of work

Below are the average prices for the complex of works. If it is necessary to get an accurate price for materials and works, it is recommended to call our engineer to inspect the object and draw up a technical task that will take into account all nuances that can affect the price of work.

Works from the outside:

| Description of works | Unit of measurement | Price in $ |

| The arrangement of surfaced waterproofing on the horizon | m2 | 20 |

| The arrangement of the surfaced waterproofing on the vertical | m2 | 30 |

| The arrangement of self-adhesive membrane on the horizon | m2 | 25 |

| The arrangement of self-adhesive membrane on the vertical | m2 | 35 |

| The arrangement of PVC membrane on the horizon | m2 | 40 |

| The arrangement of PVC membrane on the vertical | m2 | 45 |

| Application of polyurea | m2 | 70 |

| Application of mastic waterproofing | m2 | 20 |

| Application of liquid rubber by spraying | m2 | 20 |

| Application of liquid rubber manually | m2 | 25 |

| Application of cement-mineral double-component waterproofing | m2 | 40 |

| The arrangement of polyurethane waterproofing | m2 | 40 |

| Application of penetrating compositions | m2 | 40 |

| Application of primer | m2 | 10 |

Works from the inside:

| Description of works | Unit of measure ment | Price in $ |

| Waterproofing of cold joints: -Works on the arrangement of indenting -clearing the indenting -layer-by-layer sealing of non-shrinkable compositions | running meter | 20 |

| Waterproofing of interblock joints: -Works on the arrangement of indenting -clearing the indenting -layer-by-layer sealing of non-shrinkable compositions | running meter | 15 |

| Waterproofing of expansion joints: -Works on the arrangement of indenting -clearing the indenting -sealing of the elastic profile -sealing of non-shrinkable composition -a complex of works on injection | running meter | 160 |

| Injection waterproofing of seams / cut-off waterproofing -Works on the arrangement of indenting -clearing the indenting -layer-by-layer sealing of non-shrinkable compositions -Works on the arrangement of boreholes and installation of packers -a complex of works on injection -dismantling of packers and sealing of injection holes | running meter | 40 |

| Injection waterproofing into the body of concrete -marking, Works on the arrangement of boreholes and installation of packers -a complex of works on injection -dismantling of packers and sealing of injection holes | m2 | 50 |

| Injection waterproofing into the brick body -marking, Work on the arrangement of holes and installation of packers -a complex of works on injection -dismantling of packers and sealing of injection holes | m2 | 50 |

| Polymer-cement waterproofing | m2 | 20 |

| Penetrating waterproofing | m2 | 40 |

| Waterproofing of communication entries: -Works on the arrangement of indenting -clearing the indenting -layer-by-layer sealing of non-shrinkable composition -Works on the arrangement of boreholes and installation of packers -a complex of works on injection -dismantling of packers and sealing of injection holes | piece | 160 |

Cost Calculator for online calculation

Calculation of waterproofing cost

The total cost of waterproofing

Conclusion

Brick — is a good building material, however, the presence of many seams when laying, as well as its exposure to water and moisture, makes an underground structure (basement or socle) made of brick highly vulnerable to penetration and exposure to water.

When building a house using bricks, special attention should be paid to waterproofing the underground parts of the building, as they are subject to constant exposure to moisture and water.

To perform high-quality and durable protection of the house from water, it is recommended to contact specialists from a large and well-established company, since the subsequent repair of the commissioned building will cost 3 times more expensive than performing high-quality insulation during construction.