Table of Contents

- What are a metal roof and the features of its structure?

- Is waterproofing necessary to be arranged for metal tiles?

- Materials for waterproofing the roof of metal tiles

- What kind of waterproofing is better to choose for a metal roof

- Waterproofing for cold roof metal tiles

- Waterproofing under metal tiles of a warm roof

- The technology of installation of waterproofing under metal tiles

- Prices for the waterproofing installation for metal tiles

Metal roofing — is one of the most common types of metal roofs in modern construction. The high strength of the material, its durability, as well as its attractive appearance, have led to the fact that today metal tiles are used in the construction of private and apartment buildings, high-rise buildings, and industrial enterprises.

However, it is not enough just to buy such a roof in a warehouse store, it is important to understand how to care properly for metal tiles so that it does not lead to roof leaks and rust in the near future. For this purpose, waterproofing is used, and installed on the roof, as a rule, at the stage of construction of the roof of the building. How to properly conduct waterproofing and what materials are best used for this, and will be discussed in this article.

What are a metal roof and the features of its structure?

Metal tile – is a material designed for the installation of high-quality and reliable roofing. This roofing material is supplied in the form of sheets of thin steel, aluminum or copper coated with a polymer protective compound. The roof made of metal tiles is very similar to natural tiles, but at the same time differs from it in its characteristics. Metal tile is used as a coating for pitched roofs with a minimum slope angle of 14°.

Main characteristics of metal roofing:

- Lightness – The specific weight of 1 м² metal tiles is plus or minus 5 kg;

- Strength – The basis of the material is metal;

- Safety – No toxic and environmentally harmful components;

- Different color scheme – You can choose different colors for the roof;

- Installation at subzero temperatures – Metal tiles can be installed all year round.

Important: These characteristics may vary depending on the quality of the metal tile. Less high-quality sheets will lose their appearance and performance characteristics faster.

Is waterproofing necessary to be arranged for metal tiles?

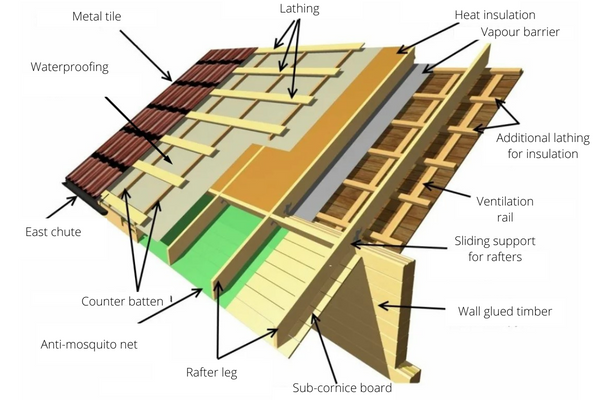

The roof made of metal tiles has a rather complex structure, but the interaction of all structural elements of the roof is not enough to protect the structure from water penetration. Before we outline why waterproofing is still necessary, let’s study the structure of the roof made of metal tiles:

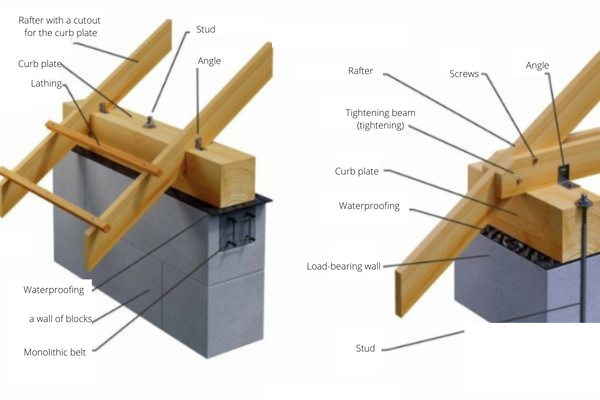

- Any roof has a base that serves as a support for the upper part of the building and helps to distribute the load from the roof side to the entire structure. Metal tiles based on the walls of the house and on a beam installed around the perimeter are no exception. It serves to distribute pressure on the walls and is called a curb plate.

- The lower layer of the roof is a truss system designed and manufactured individually for each building. The main material of the rafters is traditionally considered rolled metal or lumber. The service life of the entire structure depends on the reliability of the rafter system and the correctness of its installation, so need to approach the issue of choosing and buying rafters very carefully.

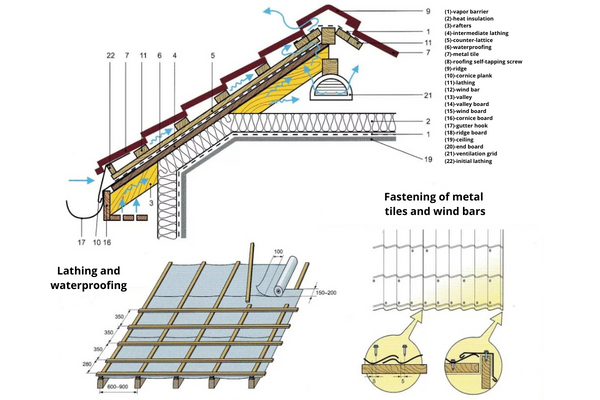

- Further, moving from the bottom up, elements such as a vapour barrier layer, a cornice bar, and an initial lathing can be found in the roof. The next layer of insulation is laid, as which mineral wool is often used. This material reliably fills all voids, does not pass moisture and cold air, and is also a high-strength, elastic, chemically resistant, and durable composition.

- The insulation layer is followed by lathing and counter-lathing. The first of them is worth talking about in more detail. The lathing serves as a base for mounting metal tiles on the roof. It is a construction of wooden bars or boards that are laid out on top of the insulation at a certain distance from each other, called the step of the lathing.

This parameter is selected taking into account the geometry of the roofing material and geographical features of the area. It is selected in such a way that a reduction in deformations of the structure during its operation is achieved. - The roof structure is covered by two upper layers – waterproofing and the metal tile itself.

Why is waterproofing so necessary, and why is it installed exactly as the top layer?

As can be understood from the structure of the main elements of the roof, the truss system, the lathing, the cornice bar, and the vapor barrier are not solid structures or waterproofing and therefore they let water pass through.

Waterproofing also provides reliable protection of all elements of the so-called under-roof space from wind and precipitation. Moreover, special hydrophobic material not only protects residential premises but also ensures the integrity of the materials of all layers of the roof, for example, insulation, wooden beams of the lathing, or metal elements of the rafter system.

In the roof layers, located under the roof, condensation also often accumulates, which is formed due to the temperature difference outside the structure and inside it. Over time, the accumulated moisture begins to affect negatively the roof materials and gradually destroys them, leading to purges and leaks of the roof. Installing high-quality waterproofing saves the owners of the house from such a nuisance.

Another convenient advantage of waterproofing is that a layer of hydrophobic material will simplify the conversion of the attic space into an attic room if the owner of the house has such a desire.

The absence of a waterproofing layer or its incorrect installation leads to the destruction of the roof, and damage to the load-bearing structures of the walls. Saving on waterproofing the roof leads to huge time and money losses in the future!

The scheme of the structure of the roof is made of metal tiles and the place of waterproofing in it:

Materials for waterproofing the roof of metal tiles

For hydrophobic treatment of metal tiles, it is necessary to choose only the most durable and reliable materials. Their main purpose is to protect all layers of the roof from the effects of wind and moisture. To do this, waterproofing materials should withstand the effects of heat and mechanical loads, be resistant to significant temperature changes and ultraviolet radiation, and also perfectly pass steam.

In addition, the materials are manufactured in such a way that they do not deteriorate upon contact with chemicals and microorganisms. And the waterproofing compounds used in the pitched type of metal roofing should be absolutely safe for human health since they have a direct impact on the quality of life of households.

Speaking of hydrophobic compounds suitable for the treatment of metal roofs, it is impossible not to mention one important property. The materials should work in such a way that the internal moisture evaporates, and the external moisture does not enter the living quarters. In other words, the materials should be characterized by high vapour permeability, especially relevant for buildings with an attic room. Vapour-permeable hydrophobic materials protect the interior from moisture and cold air and allow you to keep warm even in the place of the house, which is located under the roof.

Modern materials have different characteristics and differ in terms of resistance to light and temperature and to mechanical loads, as well as in their ability to maintain their original appearance for a long time. And now let’s take a closer look at the most common options for waterproofing materials supposed for the treatment of metal roofing.

And now let’s take a closer look at the most common options for waterproofing materials supposed for the treatment of metal roofing.

Waterproofing films

The first material worth remembering is various types of waterproofing films. They include several layers, each of which performs a specific function. Reinforcing and absorbent layers are most common. The first protects the under-roof space from moisture penetration, and the second absorbs moisture from inside the building and thereby protects the entire film from condensation and mold formation. In most cases, a polyethylene coating is applied to both layers.

To date, there are several types of waterproofing films, namely classical, anti-condensate, and super diffusion options. What are their differences from each other?

- Classic or standard films, as a rule, have low vapor permeability. Therefore, in the case of installation of such material, double-circuit ventilation is necessarily arranged, assuming the location of gaps between it and the insulation layer.

In this case, gaps with a thickness of 3-5 sm are installed between the layers. Despite everything, standard films are quite common, because they are easy to install, suitable for the arrangement of a cold roof (we will talk about it later), and have an affordable price. - The next type of waterproofing film – is anti-condensate. This material also requires the installation of double-circuit ventilation, however, compared to the classic version, it copes better with the steam transmission, but still does not do it too well.

An additional moisture-absorbing layer of such a coating perfectly absorbs and retains moisture, thereby performing the functions of protecting the space under the roof from condensation. Anti-condensate films are characterized by a fleecy surface, rough to the touch, which is characterized by resistance to ultraviolet radiation and mechanical stress. - Waterproofing films of superdiffusion types – are the most expensive film composition. Every owner of a private house can hardly afford it since both the purchase of material and its installation require a lot of resources. Only an experienced builder armed with special equipment can cope with the installation of such waterproofing.

Among the obvious advantages of super diffusion, films are high vapor permeability (double-circuit ventilation is not installed), strength, elasticity, as well as resistance to temperature, moisture, wind, and various natural disasters.

Diffusion membranes

Diffusion membranes are a material similar in properties to films, but at the same time superior in quality. Diffusion membranes have high vapor permeability and therefore do not need additional ventilation, and are also characterized by high strength and elasticity. When fixing such material on the roof, it is important to leave gaps between it and the roofing. The only drawback of this material – is the high cost.

Standard diffusion membranes are a “breathable” material and perfectly protect the under-roof space from moisture, including condensation. They do not even allow the latter to form, releasing steam at the stage of its contact with the membranes. However, even the highest quality hydrophobic materials need good care.

If you regularly allow too much steam to pass through the membrane or incorrectly fold the layers of the roof, blocking the possibility of ventilation, then the entire under-roof space may suffer. For example, a layer of insulation will deteriorate, which will begin to cope much worse with the task of thermal insulation of the room. Another option — is the formation of condensate on the membrane due to excessive steam intake and the formation of areas of dampness, mold, and rot.

Also among the membrane materials, volumetric separation diffusion membranes are distinguished, which are excellent for tiles made of zinc, copper, steel, aluminum and other types of metal tyles. Such membranes are used on gentle slopes, the angle of which ranges from 3 to 15 degrees, and are often installed on roofs of complex shapes containing a larger than usual number of angles.

The volumetric lattice present in this material provides constant ventilation, that is why condensate does not accumulate in the space under the roof. For the proper functioning of the membranes, only a gap on the upper side is required, which it often does not need to be installed additionally.

What kind of waterproofing is better to choose for a metal roof

Often, owners of private houses, as well as builders of multi-storey buildings, have a question, what kind of waterproofing is best to choose for metal roofing. The most serious rivals at such moments, as a rule, are anti-condensate films and diffusion membranes.

- The membranes are mounted in the roof with only the gap – the upper one. It is installed between the membrane itself and the roof. In such cases, regardless of the shape and complexity of the roof, a layer of high-quality insulation should be applied, thanks to which the roof will retain heat indoors. Ventilation of steam and moisture at the top of the roofing layers should not interfere with the preservation of heat.

- Anti-condensate films are installed with two gaps – upper and lower. This material is considered much cheaper and therefore more common in modern construction. Films are relevant for waterproofing roofs of simple shapes with gentle or steep slopes.

It is worth remembering that for the hydrophobic treatment of metal roofing, it is not recommended to use bitumen mastic hydraulic barriers Preference should be given to waterproofing films of membranes. Moreover, at the stage of visiting a construction store, it is better, first of all, to think about the quality of the coating, and not about its cost. Following this advice, most owners of country houses prefer diffusion membranes of super diffusion films.

All the characteristics of the compositions are indicated on the edge tapes framing the material. The standard form of membrane release — is rolls of 50 meters long and 1.5 meters wide. At the same time, the density is approximately 140 grams per cubic meter. One of the best materials for waterproofing metal roofing is considered to be Isospan AM or AS.

Sometimes metal roofing is also used for roofs of non-residential premises, such as greenhouses, sheds, baths, and other structures. In such situations, when the quality of the installed waterproofing does not directly affect the quality of life of the household, you can save a little and buy cheaper materials, for example, those based on bitumen. The most common of them, namely roofing material and parchment, will be discussed a little later.

Waterproofing for cold roof metal tiles

A cold roof made of metal tiles is common in many, as a rule, non-residential premises. Its peculiarity lies in the fact that there is no layer of insulation in the layers of the roof. This to some extent has a positive effect on the condition of the roof. The heat-insulating material does not interfere with ventilation, and therefore it is not necessary to think about buying an expensive vapor-permeable composition for waterproofing. Therefore, roofing material is often used to process a cold roof made of metal tiles.

Roofing material — is a roll-type material, which is considered practically the cheapest option on the construction market. It is made on the basis of paper soaked in bitumen solution. Also, for waterproofing installed under the metal roof of a cold roof, pergamine is used, which is a bitumen cloth. This composition is quite cheap and is excellent for processing roofs of non-residential premises. It is characterized by resistance to water, temperature changes, and ultraviolet radiation.

The installation of standard waterproofing films on cold roofs that need double-circuit ventilation was no exception. The correct installation of such coatings provides long-lasting protection for cold roofs made of metal tiles from the penetration of excess moisture, as well as from the accumulation of condensate, which can significantly spoil all layers of the roof.

Waterproofing under metal tiles of a warm roof

Another option is a warm roof, installed in most residential premises and in need of high-quality waterproofing. In this case, it is better not to save on good materials, because the quality of life in the house directly depends on its operational properties.

An excellent option will be the already considered standard or anti-condensate waterproofing films, as well as diffusion membranes. These materials, if given due attention at the installation stage, have high vapor permeability and moisture resistance, and are also extremely frost-resistant.

In the case when there is a heater in the under-roof space that can interfere with ventilation to one degree or another (this situation is relevant for all warm roofs), it is important to make sure that the waterproofing material copes well with steam transmission and moisture absorption. Neglect of this factor is unacceptable, since the result of an inattentive attitude may be the destruction of the rafter system, as well as moldy or even roofing materials. Over time, this process will inevitably lead to the collapse of the roof.

Diffusion and super diffusion membranes, noticeably superior to waterproofing films in cost, cope best with the task of passing steam and absorbing moisture. However, for simple buildings, standard films may be suitable, for which it is necessary to provide high-quality double-circuit ventilation, that is to install gaps in the upper and lower parts of the film.

The waterproofing material, used for the installation of warm roofs should necessarily cope well with the transmission of steam and moisture absorption. Neglect of this point will necessarily lead to the collapse of the roof!

The technology of installation of waterproofing under metal tiles

As already mentioned, waterproofing is practically the top layer in the roofing layers. Therefore, before installing it, it is necessary to perform a number of preparatory works, namely, fixing the system of rafters and installing the cornice and end boards.

If the roof treatment is carried out with your own hands and without the help of specialists, it is important to prepare the following tools:

- Scissors;

- Roulette;

- Hammer;

- Marker;

- Screwdriver;

- Construction stapler;

- Bars and screws.

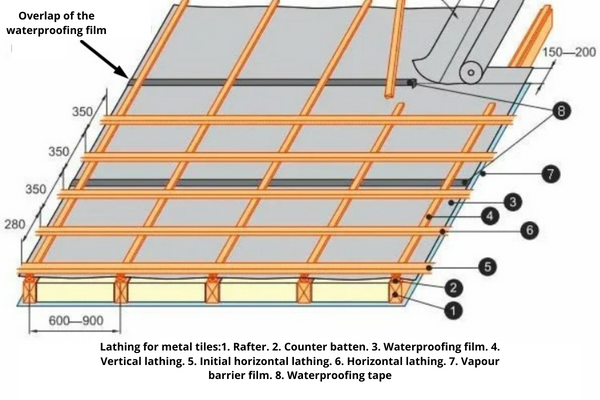

Immediately, before starting work, it is important to prepare the base on which the material will be fixed, as well as cut the film, membrane, roofing material, or any other composition into strips. It is in this form that the hydrobarriers will be installed. It is also important to remember that they are always installed in the bottom-up direction. So there is no water flowing through the sealing compound. And before installation, it is important to make sure that there is a layer of insulation in the composition of the roofing layers (when installing a warm roof).

Thermal insulation material is strictly forbidden to be laid out on top of waterproofing!

Installation of the waterproofing layer can be carried out in two ways.

- The first involves laying out hydrophobic material directly on the elements of the truss system. Laying is carried out in strips parallel to the cornice. At the stage of fastening the strips of material, their slight sagging between the rafters should be achieved. In the case when it is necessary to leave a small gap between the waterproofing and the roof, the strips are fixed on a counter-lattice reinforced above the rafter system.

- The second method of installing waterproofing involves laying the material perpendicular to the cornice. In this case, the strips are fixed to the lathing without any holes or sagging, that is, in a stretched state. Experts also recommend not to neglect the joints, even though all of them will eventually be pressed with tiles. For the reliability of waterproofing, it is best to glue all the joints with special sealing tape.

The scheme of the correct installation of waterproofing film

When installing waterproofing, it is important to consider the following nuances:

- Overlap between films or membranes in 15-20sm

- For the tightness of the waterproofing coating, it is necessary to install waterproofing tape at the joints between films or membranes.

If you responsibly approach the issue of waterproofing the roof of metal tiles, then the process will not be too energy-consuming. Moreover, most sealing materials are laid according to the same technology. The exception is roofing material, which should be rolled out a day before the start of work and left in the air. This will help to neutralize all defects of the coating and to level its surface as much as possible.

In addition to observing the installation technology, it is important to make the right choice at the stage of buying the material. It is best to purchase waterproofing in a proven construction store, in which you have never come across defective materials.

At the stage of choosing a product, it is necessary to study its length, thickness, tear resistance, expected service life, and other equally important characteristics. The decision to save on a hydrophobic material is not always correct, since damage to the waterproofing can lead to extremely negative consequences.

Prices for the waterproofing installation for metal tiles

The prices indicated in the price list below may change depending on the complexity of the work.

| Description of work | Unit of measurement | Price in $ |

| Waterproofing during construction | ||

| Installation of anti-condensate film | m2 | starting from 8 |

| Installation of a classic film | m2 | starting from 8 |

| Installation of the super diffusion film | m2 | starting from 10 |

| Installation of a diffusion membrane | m2 | starting from 12 |

| Sealing joints with a special tape | running meter | starting from 10 |

| Waterproofing during repair (without dismantling) | ||

| Repair of metal tiles with polyurethane | m2 | starting from 20 |

| Repair of metal tiles with liquid rubber | m2 | starting from 20 |

| Sealing tape arrangement | running meter | starting from 28 |

| Tightening and replacement of fasteners | m2 | starting from 25 |

| Work on the installation of individual elements of the roof made of metal tiles | ||

| Dismantling of roofing | m2 | starting from 8 |

| Dismantling of the lathing | m2 | starting from 10 |

| Dismantling of the rafter system | m2 | starting from 9 |

| Dismantling of thermal insulation | m2 | starting from 9 |

| Dismantling of waterproofing | m2 | starting from 5 |

| The installation of the truss system | m2 | starting from 25 |

| Installation of lathing | m2 | starting from 8 |

| Installation of a counter-lattice | m2 | starting from 8 |

| Installation of thermal insulation | m2 | starting from 7 |

| Laying of metal tiles | m2 | starting from 30 |

| Expertise and project | ||

| Preparation of project documentation | piece | starting from 2000 |

| Examination of metal roofing | piece | starting from 800 |