Table of Contents

A lot depends on the quality of installation and operation of the foundation of the building, starting from the appearance of the structure and ending with its service life. At the stage of foundation construction, it is important to strengthen the foundation, properly perform reinforcement, and load calculation, carry out its reliable waterproofing, if necessary, equip the site with a drainage system, and also make sure that the construction work was carried out in compliance with all documentary norms and professional recommendations.

If you neglect at least one of these points, you may encounter such a problem as the need for additional strengthening of the foundation and sealing of the cracks formed in it. In some cases, this process is carried out using the injection method, which will be discussed in detail in this article.

When the foundation injection should be done

The injection of the foundation involves filling the pores, voids, and other defects of the material with a high-quality composition. This method of working with the foundation allows you to extend its service life or to improve the quality of the concrete from which it is made by filling the pores and capillaries.

Injection work should be carried out in the following cases:

- Cracks. Microcracks or cracks appeared in the foundation. In any case, they should not be filled superficially, but inside a concrete or brick structure, and this can be done exclusively by injecting special compounds into the body of a concrete or brick structure by injection.

- Foundation leaks. It is worth noting that any brick or concrete has a porous structure, so this material has the ability to absorb photos and in the absence of high-quality external waterproofing, it begins to pass water and moisture into the room, which leads not only to flooding but also to the gradual destruction of the foundation. The most effective way to solve this problem is— to use injection.

Strengthening the foundation by injection

The main advantage of repair by injection is considered to be the high speed of this process. For this reason, injection is most often used only in cases where damage to the foundation is of an emergency nature. In other situations, owners of private houses, administrative buildings, or residents of apartment buildings prefer more “traditional” methods.

The injection method makes it possible to make repairs effective since the foundation treated in this way is not prone to the formation of new deformations. However, it is worth nothing that the injection of the foundation cannot be carried out independently. It is carried out only by specialists using equipment capable of pumping mortar under the base of the building in case of subsidence of the foundation or into the body of the structure in case of repair of cracks or other damage.

Strengthening the foundation by injection is a necessary measure in the following situations:

- Cracks began to appear in the foundation (for example, made of concrete) due to the impact of precipitation, negative temperatures, corrosion, and other environmental factors on the base of the structure;

- Subsidence of the foundation or seismic activity on the territory of the area led to the formation of deep cracks in the foundation: in this case, it is necessary to strengthen the foundation as soon as possible;

- Urgent repairs are also necessary if the exterior walls of basements or other rooms located underground are damaged;

- If leaks appear in the house or building and it is not possible to eliminate them by repairing the waterproofing coating from the outside;

- If the foundation is made of rubble stone, then over time it may collapse or exfoliate: as soon as such damage has been detected, it is necessary to contact the injection company and order repair work;

- Injection of the base of the building can also be carried out for preventive purposes: for example, in order to stabilize the subsidence properties of the soil on which the foundation is located.

Important: In the described situations, the strengthening of the base by injection should be carried out as soon as possible. Otherwise, the damage may worsen, and then it will not be necessary to repair the foundation, but its complete restoration.

Waterproofing of the foundation by injection

However, the injection can be used not only for repairs but also for waterproofing the foundation. As a rule, the injection method can perform the following type of protection of the structure from water:

- Injection into the body of the foundation structure, walls, and other elements. With this method, the injection composition using special injectors under pressure is fed into the thickness of the desired places of the structure, thereby filling all available voids, capillaries, and microcracks, preventing water and moisture from passing.

You can read more about this injection method in the article – “Injection waterproofing”

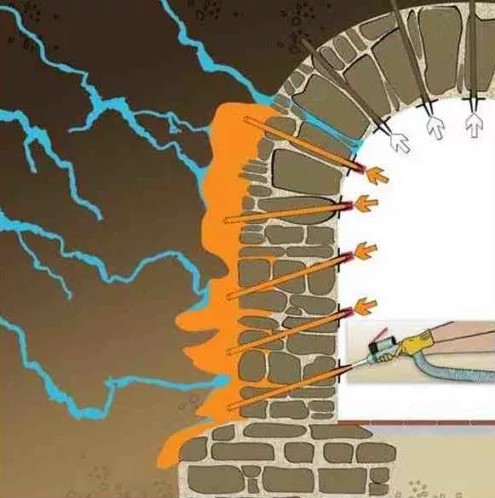

Diagram of the arrangement of injection waterproofing into the body of the structure:

2. Veil injection

With this method, the injection composition is fed not into the thickness of the foundation structure, but behind it. In fact, a strong and reliable waterproof “cushion” is formed between the foundation and the external environment (for example, the ground), capable of protecting the base of the building from the effects of precipitation, groundwater, moisture, and other factors за неё.

For more information about this method of injection, its advantages, and disadvantages, you can read the article – “Veil waterproofing“.

Diagram of the arrangement of the veil injection:

Injection waterproofing will be extremely useful in the following cases:

- There are dry or wet cracks in the structure that need to be repaired;

- It is necessary to carry out waterproofing o structural, deformation, or working seams, as well as junctions present at the junctions of the walls with the floor;

- Sealing and hydrophobic treatment are necessary at the points of entry of communications (for example, cable or pipeline);

- Under the wall masonry, it is required to install a cut-off type waterproofing;

- It is necessary to eliminate active leaks and thereby protect not only external, but also internal structural elements from the effects of liquid;

- Repair or internal waterproofing of hydrophobic membranes that are adjacent to the outer surface of the walls of the building is required.

Also, injection is necessary in cases where, due to poorly executed waterproofing between the foundation and the wall, an increase in the groundwater level is observed. And the problem here is not only the effect of the liquid. Groundwater contains a large percentage of salts, acids, and other chemical compounds that negatively affect the condition of the construction material. Such an effect harms not only the integrity of the building but also the health of the people. In this case, it is necessary to resort to the organization of work on the implementation of injection waterproofing.

It is worth noting that injectable compositions themselves have many useful properties. For example, they contain chemicals that can protect the foundation from the formation of mold and mildew, increase its mechanical strength, and reduce the impact of corrosion on the material. The repair or waterproofing composition has the property of penetrating into all cracks, irregularities, or pores of the foundation material (for example, concrete) and when in contact with moisture, turns into the smallest crystallohydrates, which creates a reliable waterproof barrier.

You can read more about the injection method, the problems it is used to solve and its effectiveness in various situations in the following articles:

- Cut-off waterproofing and its arrangement technology

- Waterproofing and sealing of cracks in concrete, brick and other bases

- Sealing and waterproofing of joints – concrete, cold and deformation ones

Injection materials

In modern construction, numerous materials with useful properties are used to inject the foundation. However, it should be understood that the direct reinforcement of the base of the building and its waterproofing requires the use of various compositions. Let’s take a closer look at the types of injection materials, depending on their purpose.

Materials for strengthening and reinforcement of the foundation

To strengthen the foundation by injection, the following materials are most often used:

- Cement-based compositions, in most cases supplied with valuable additives in the form of polymeric substances. Such compositions perfectly penetrate into any cracks or holes formed in the foundation and after solidification forms a very durable coating that can last for several decades.

- Micro-cements – Mixtures-based on finely dispersed mineral binders.

Strengthening the foundation using concrete or cement mixtures allows you to increase the strength of the foundation, and increase its resistance to temperature changes and corrosion. This significantly extends the service life of such buildings.

Main characteristics of cement-based injection materials:

| Indicator name | Indicator value |

| Compressive strength MPa 1 day: 30 days: | 25 MPa 55 MPa |

| The spreadability of the cement dough does not begin earlier than end no later than: | 30 minutes 8 hours |

| Linear expansion in a limited state | not less than 0,05% |

| Water separation | not more than 3,5% |

| Water resistance | not less than 8 atm. |

| Frost resistance | not less than 200 cycles |

Materials for injection waterproofing arrangement

To protect the structure from water, as a rule, the following types of materials are used:

- Polyurethane compositions – have different coefficients of elasticity, expansion, and solidification time.

- Helium compounds – are very elastic materials in the form of a gel, which are used mainly where there is a large dynamics and movement of the structure, for example, in deformation seams or where there is a risk that the base may collapse when using more viscous materials.

The choice of building compounds used for injection waterproofing is based on several factors:

- For which elements of the foundation, it is planned to carry out the hydrophobic treatment? These can be foundation walls, seams, or cracks

- The presence of active water intake or its absence.

- What material is the foundation base made of, and where will the injection be applied – concrete, brick, FBS blocks, etc…

Important: The main task of builders is to select an injection composition with suitable technical characteristics that will allow the material to best fulfill its role in specific operating conditions.

Main characteristics of injectable polyurethane materials:

| Indicator name | Indicator value |

| Viscosity | 220 MPa |

| Elongation at break Water-filled crack: Wet crack: Dry crack: | 71% 10% 39% |

| Adhesion to concrete Water-filled crack Wet crack Dry crack | 0.30 MPa 0.17 MPa 0.20 MPa |

| Tensile strength | 0,9 MPa |

| Relative elongation | 55 % |

| Resistance to water pressure | 0,2 MPa |

Main characteristics of injectable helium materials:

| Indicator name | Indicator value |

| Viscosity | 4,2 mPas |

| Elongation at break | 1000 % |

| Adhesion to concrete Water-filled crack Wet crack Dry crack | 0.50 MPa 0.20 MPa 0.28 MPa |

| Swelling coefficient | 100 % |

| Resistance to water pressure | 0,2 MPa |

Foundation injection technology

The method of injecting the foundation has many advantages over other methods of working with the foundations of buildings. Among them, for example, the ability to use this method for any soil and for any type of building, as well as high-quality reinforcement or waterproofing of not only the base of the structure but also floors, vaults, as well as load-bearing elements of the building.

The technology of foundation injection has its own characteristics, without which it is impossible to carry out construction or repair work competently. First of all, it is important that professionals are engaged in injecting the structure, who should first carry out a number of necessary calculations. The process of injection treatment of the foundation includes the following steps.

The process of injection treatment of the foundation includes the following steps:

- The creation or drilling of wells is performed at an angle of 45 degrees to the horizon. It will not be possible to perform such work without the use of special construction equipment.

- Injectors are inserted into the drilled wells, through which the solution will be supplied in the future;

- The resulting wells are filled with a solution that is evenly distributed throughout the entire volume of the crack, hole, or other types of space and acquires a thick consistency within 24 hours.

- The injectors are removed and the holes are sealed with a non-shrink compound.

However, the process of injecting the foundation has many subtleties that should be taken into account by the builders carrying out the work. When working with the foundations of old buildings, it is preferable to use cement as an injection solution, since it is considered a more durable composition.

Foundation injection technology for reinforcement and strengthening

Injection technology is most often used to strengthen foundations decorated with brick or masonry, as well as monolithic foundations and structures made of blocks made on the basis of concrete. The composition of building materials for such foundations includes acrylate gels, as well as solutions of micro-cements.

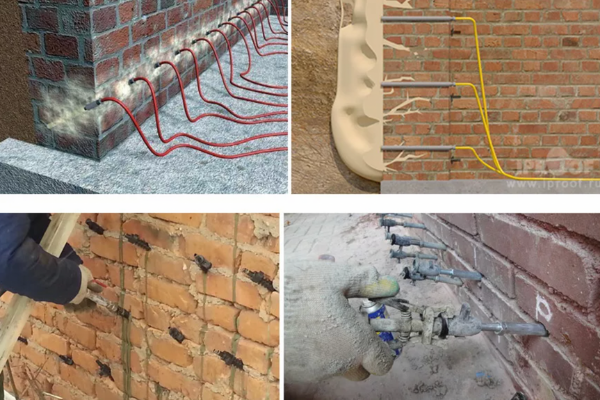

Consider, for example, the technology of strengthening the walls of the foundation. It includes the following obligatory steps:

- A damaged or unprotected section of the foundation wall is selected: it is carefully examined for damage, contact with groundwater, and other indicators. In this area, holes are drilled staggered and necessarily at an angle of about 45 degrees. The distance between the resulting holes should be at least 20 cm and not more than 30 sm.

- Then, with the help of a compressor, the holes are cleaned of dust, after which compression packers or specialized scoring injectors made of plastic or metal are mounted in them, which will be useful in the process of pumping micro-cements.

- A pressure hose of the pump (manual or electric) is inserted into the installed packers, through which the injection of construction chemicals is carried out. This process should be carried out in a diagonal direction: from the lower left injector to the upper right one. It is also important not to forget that the work is carried out under pressure conditions not exceeding 3-5 atmospheres. There is necessary in order not to damage structures characterized by not too high strength.

- The working process is completed by cutting the injectors and caulking the holes, however, the final stages of strengthening the foundation by injection can be carried out only after the injection composition has completely solidified.

Technology of foundation injection for its repair and waterproofing

If we talk about repairing or protecting structures from water and moisture, then the method of work depends directly on what exactly needs to be protected and what material the base is made of. For example, to seal joints and cracks in the foundation, you need to use one method of work, and to repair or waterproof the foundation body another. Further on, let’s look at each method separately.

Seams and cracks in the foundation:

- Reinforcement and sealing – before performing injection at the locations of seams or cracks, these zones are stitched, using the arrangement of small indenting (3х2sm), and a special expanding sealant is sealed in layers into the cavity formed. Thus, when performing the injection, the composition will go inside the structure, and will not begin to exit from the outside through a weak seam or crack.

- Installation of packers – boreholes (holes) are made along the perimeter of the sealed zone, and packers are installed in them.

- Injection – The necessary chemical composition is injected through the installed packers into the work area, under pressure through special equipment.

- The final stage – After the injection gets up, as a rule, it takes 1-2 days, the packers are removed, and the injection centers are caulked.

You can read more about cracks and seams in the following articles:

- Waterproofing and sealing of cracks in concrete, brick, and other bases

- Cracks in the foundation of the house: Causes and methods of their repair

- Sealing and waterproofing of joints – concrete, cold, and deformation ones

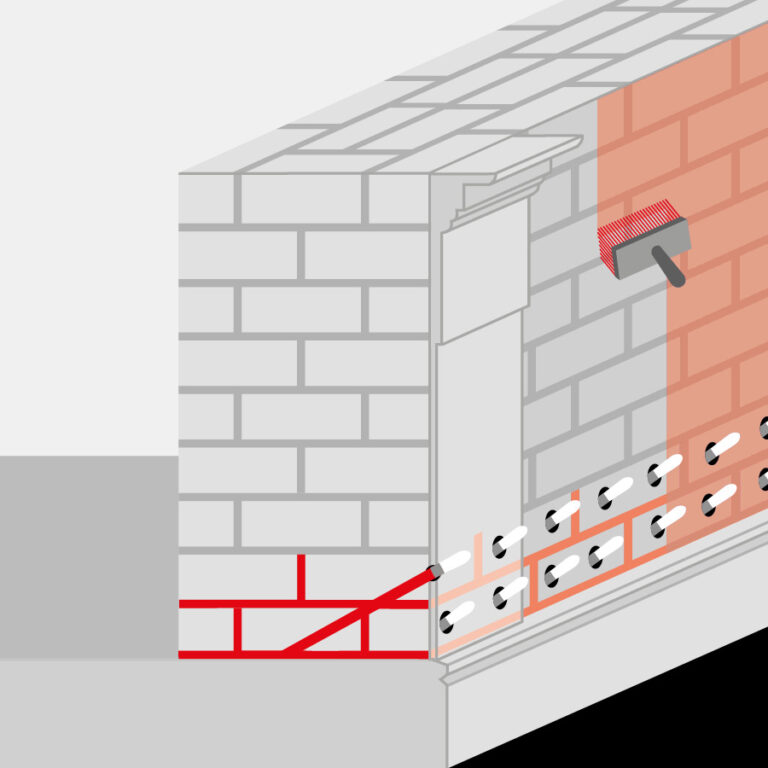

Scheme of work

The body of the foundation:

The method of injection into the body of the foundation differs from the technology of sealing cracks, and the location of the injectors, in this case, the injectors are arranged so as to cover not a linear meter, but a square one.

Important points:

- If the foundation is made of blocks, then before injection it is recommended to uncut all the interblock seams, seal them with an expanding sealant, and only then inject.

- If we are talking about a brick structure, then before injecting it is recommended to cover the brick with a special repair compound similar to plaster, and then inject it. Otherwise, during injection, most of the chemical composition may be distributed incorrectly and instead of dispersing inside the structure, it will simply come out through the inter-brick seams to the outside towards the room.

You can read more about these points in the following articles:

Scheme of works performance

Prices for foundation injection

| Description of work | Unit of measurement | Price in roubles |

| Waterproofing of cold joints: -arrangement of indenting -clearing the indenting -layer-by-layer sealing of non-shrinkable composition | running meter | 600 |

| Waterproofing of interblock joints: -arrangement of indenting -clearing the indenting -layer-by-layer sealing of non-shrinkable composition | running meter | 400 |

| Waterproofing of deformation joints: -arrangement of indenting -clearing the indenting -sealing the elastic profile -sealing of non-shrinkable composition -complex of works on injection | running meter | 4900 |

| Injection waterproofing of seams/cut-off waterproofing -arrangement of indenting -clearing the indenting -layer-by-layer sealing of non-shrinkable composition -the arrangement of boreholes and installation of packers -a complex of works on injection -dismantling of packers and sealing of injection holes | running meter | 1200 |

| Injection waterproofing into the concrete body -marking, the arrangement of boreholes, and installation of packers -a complex of works on injection – dismantling of packers and sealing of injection holes | m2 | 1900 |

| Injection waterproofing into the brick body -marking, the arrangement of boreholes, and installation of packers -a complex of works on injection -dismantling of packers and sealing of injection holes | m2 | 1900 |

| Cement-mineral waterproofing | m2 | 600 |

| Penetrating waterproofing | m2 | 600 |

| Waterproofing of entry points of communications: -arrangement of indenting -clearing the indenting -layer-by-layer sealing of non-shrinkable composition -the arrangement of boreholes and the installation of packers -a complex of works on injection -dismantling of packers and sealing of injection holes | piece | 6900 |

It should be understood that both calculations and the workflow itself performed by representatives of a construction company will cost the owners of a private country house or an administrative building quite expensive. As a rule, the final cost is significantly influenced by the type of materials used and their quality.

Important: Cheap injection compositions, as a rule, have a short service life and often require additional injection after a year or two. If the work is carried out in order to do everything efficiently and for a long time, then saving on injection material is not highly recommended.