Table of Contents

- What is cut-off waterproofing for?

- Capillary rise of moisture: How does cut-off waterproofing fight it?

- Materials for the arrangement of cut-off waterproofing and the main requirements for them

- The technology of assembly and arrangement of cut-off waterproofing

- Horizontal cut-off waterproofing

- Cut-off waterproofing price

In fact, the cut-off waterproofing is designed to perform the function of cutting off moisture coming from the outside and elements of the structure being erected over the cut-off zone. Cut-off waterproofing stops the capillary rise of moisture.

What is cut-off waterproofing for?

This type of barrier installation is suitable for both monolithic foundations and brickwork or masonry blocks.

Cut-off waterproofing can be performed both at the beginning of construction and after it. Of course, the most correct option for installing such insulation is its installation at the construction stage of a building or structure.

In what cases it is necessary to do a cut-off waterproofing?

Cut-off protection is needed mainly in places where construction is carried out below ground level (underground). Since the main danger to your structure is moisture released from the ground and absorbed into the concrete or brick foundation base. This moisture can rise capillary, destroying the elements of your structure from the inside.

And it absolutely does not matter whether there is groundwater on your site or not. Water and moisture in the ground and around your building is formed not only if there is high groundwater in your area, but also with every rain or snow melt.

In any area there is rain, and this means the upper water (water on the surface), which is absorbed into the soil saturating it with moisture. In the absence of proper waterproofing, this moisture is absorbed into concrete or brick, since these materials are a sponge for water.

How destruction happens:

- Aggressive environment. Groundwater may have impurities and substances that can harm concrete upon contact with it.

- Temperature difference. Moisture is absorbed into concrete, brick or other unprotected material. Further, at the onset of frost, this moisture freezes in the thickness of the structure, and thaws in the spring, thereby forming microcracks and pores in the concrete, which eventually leads to its destruction.

Consequences of the lack of properly performed cut-off waterproofing:

- Cracks in the wall – the temperature difference leads to the fact that the water trapped in the walls or foundation freezes and then thaws and thereby leads to the formation of microcracks and voids, which can later turn into a serious problem.

- Leaks of basement walls or socle – if water gets into concrete, it can eventually destroy it, which will lead to the formation of leaks.

- Mold and mildew formation indoors-capillary rise of moisture, can form wet spots on the walls, which will eventually lead to the formation of fungus and mold dangerous to human health.

Capillary rise of moisture: How does cut-off waterproofing fight it?

Capillary rise of moisture — is when moisture or water is absorbed into the bases of foundations and then rises along the foundation or wall, forming wet spots, microcracks and voids-in fact, destroying concrete or brick. Capillary moisture can rise to a height of up to 1.5 m, depending on the quality of concrete, block or brick. It is possible to deal with capillary moisture by the arrangement of a cut-off waterproofing.

It is possible to deal with capillary moisture by the arrangement of a cut-off waterproofing.

Cut-off waterproofing of the foundation and walls

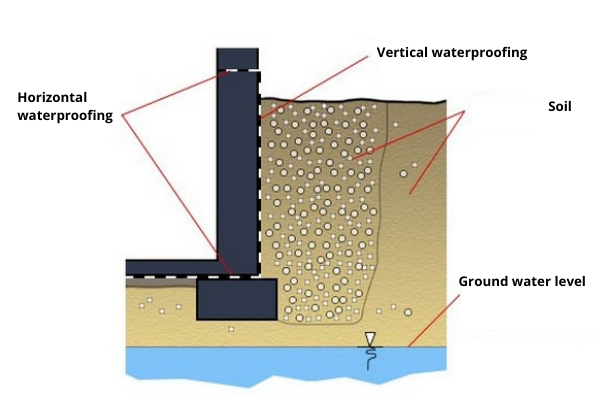

Cut-off waterproofing is primarily used to cut off the foundation or foundation slab from the subsequent stage of construction-the erection of walls. The arrangement of cut-off insulation serves to ensure that moisture entering the foundation bases does not go up the wall by capillary suction.

The cut-off installation allows you to protect the walls of the house from the penetration of water into them through the junctions with the foundation.

Cutting off with the use of waterproofing, it is necessary to perform not only when it comes to the foundation of a monolithic slab, but also when a ribbon foundation is being built.

Materials for the arrangement of cut-off waterproofing and the main requirements for them

The arrangement of the cut-off barrier can be made of various materials, the main thing is that they have the following qualities:

- Durability – service life of at least 20 years

- Elasticity – A high coefficient of elasticity will contribute to reliable operation and will not allow materials to break at the seams or crack when the foundation shrinks or its dynamics.

- Reliability

- Adhesion – good adhesion to the foundation base

- Lack of seams and joints — seams are the weakest point in any waterproofing material. In most cases, when the foundation shrinks, the waterproofing diverges precisely at the seams.

Existing materials today:

- Cut-off waterproofing

- PVC membranes

- Bitumen-based waterproofing mastics

- Liquid rubber – forms a seamless coating with 100% adhesion to the surface of the foundation made of concrete or brick

- Injection waterproofing – Is injected into cold seams or the body of the structure using a special pump feeding the injection compound under pressure.

The technology of assembly and arrangement of cut-off waterproofing

Cut-off waterproofing is necessary both when installing walls made of brickwork and when pouring walls made of concrete. The arrangement of cut-off waterproofing is a very important and crucial moment in the construction of a house or building, respectively, when performing these works, you need to follow a certain technology.

Each material has its own instructions for use and its own installation technology. If this technology is not followed, the cut-off barrier simply will not work. That is why it is best to entrust the waterproofing arrangement to professionals with experience.

The technology of arrangement at the construction stage:

- Surface preparation – cleaning from dust and dirt

- Primer application – the primer is applied to improve adhesion (adhesion)

- Arrangement of waterproofing material

This technology is suitable for performing cut-off waterproofing at the time of construction of walls made of brickwork, FBS blocks or Gas concrete blocks on the foundation. The technology may change depending on the material used.

The technology of the arrangement at the repair stage:

When the walls or brick, block or concrete (monolithic walls) have already been erected and a cut-off is required, it is necessary to resort to the injection method of waterproofing described below.

The installation of waterproofing barrier using injectable resins and gels is carried out using the following technology:

- It is necessary to dismantle all the finishing elements in the work area in order to reach the base of the wall (if we are talking about seams, then to the base of the abutment of the slab and the wall). It is necessary to remove the plaster from the walls and the screed from the floor (if any).

- In the area where it is necessary to make an investment, holes are drilled in the wall as a cut-off and hollow tubes made of metal or plastic (injectors or packers) are inserted into them.

- Special equipment is connected to the injectors, which, under pressure, feeds the injection compound into the thickness of the wall, filling all microcracks and voids and thereby creating the very cut-off of the wall from the slab. This cut-off prevents capillary moisture from rising through the installed barrier.

- The mounted packers are cut-off and the holes are sealed with a special sealant.

If we are talking about cold joints of the foundation slab to the wall, then in order for the injection compound to get deep into the wall (into the thickness of the wall) and not come out in a weak place, the above measures are supplemented by work on:

- Expansion of the cold seam by the method of the borehole installation

- Layer-by-layer sealing of a special expanding sealant or a non-shrink compound.

You can read more about the injection method of waterproofing in the following article – “Injection waterproofing“.

Horizontal cut-off waterproofing

Horizontal waterproofing is obligatory, as it protects the future structure from leaks. Horizontal protection is applied to the foundation or foundation slab and thereby serves as a horizontal cut-off waterproofing protecting subsequent layers from leaks.

You can read more about horizontal waterproofing in the article – “Horizontal waterproofing of the foundation: The technology of installation and the materials necessary for this“

Cut-off waterproofing price

Below are the average prices for the work. Prices may vary depending on the selected material and depending on the complexity of the work. If you need to get the final prices or estimates, it is best to contact us by e-mail or call our engineer to inspect the object.

| Description of works | Unit of measurement | Price in roubles |

| Cut-off waterproofing of cold joints: -Works on the arrangement of the indenting -Cleaning the indenting -Layer-by-layer sealing of non-shrinkable composition | running meter | 50 |

| Waterproofing of interblock joints: -Works on the arrangement of the indenting -Clearing the indenting -Layer-by-layer sealing of non -Shrinkable composition | running meter | 35 |

| Cut-off waterproofing by injection: -Work on the arrangement of indenting -Clearing the indenting -Layer-by-layer sealing of non-shrinkable composition -Works on the arrangement of boreholes and installation of packers -Complex of works on injection -Demounting of packers and sealing of injection holes | running meter | 150 |

| Waterproofing of places for input of communications: -Work on the arrangement of indenting -Clearing the indenting -Layer-by-layer sealing of nonshrinkable composition – Works on the arrangement of boreholes and installation of packers – Demounting of packers and sealing of injection holes | piece | 350 |