Table of Contents

- How do water and moisture affect the foundation of the house and does it need waterproofing?

- Waterproofing of the foundation structure from groundwater and water

- Vertical and horizontal waterproofing of the foundation

- Materials for waterproofing the foundation

- Auxiliary elements for long-lasting protection of the foundation from water

- Proper waterproofing of the fire foundation and how best to make the foundation waterproofing – from the outside or from inside?

- Waterproofing of the foundation price per m2 and cost of work

- Repair work and waterproofing installation, depending on the type of foundation

- Make waterproofing of the foundation of the private house with your own hands

How do water and moisture affect the foundation of the house and does it need waterproofing?

Waterproofing of the foundation is not just important, but very important and it should be done, otherwise you risk the gradual destruction of your foundation and the possible occurrence of cracks on it. Basically, the foundation is destroyed due to the impact of water, moisture, and an aggressive environment on it.

If it is not properly protected, the structure of concrete (or brick) from which it is made will absorb moisture and water, which will freeze in winter at subzero temperatures and thaw in spring, forming pores, voids, and microcracks in the concrete. These microcracks and voids will increase with each season and subsequently lead to the formation of more serious cracks and destructions.

It is important to know here that if waterproofing works are carried out correctly outside the structure and materials are correctly selected, then water will not be able to penetrate the concrete and, accordingly, will not be able to destroy the foundation from the inside.

Concrete is a sponge for water, it absorbs it, which will subsequently not only negatively affect it but also lead to the destruction of metal fittings. Which, in the end, will lead to a drop in the strength of the foundation, as well as the penetration of moisture and liquid into the premises of your house.

Waterproofing of the foundation structure from groundwater and water

Groundwater can be different. They can be classified according to the degree of aggressiveness to concrete and to metal. In all highly aggressive environments, it is necessary not only to make horizontal protection of the foundation from them but also to use water-resistant grades of concrete in its construction. It is possible to determine the level of aggressiveness in groundwater by setting up laboratory tests. To protect the structure from ground rivers, it is necessary to make properly and timely horizontal insulation of the concrete base and foundation slab, for this there are different types of materials and methods that you will learn about in the continuation of this article.

What factors should be taken into account when creating a foundation design?

When properly designing the waterproofing of a house below ground level, both vertical and horizontal, it is necessary to take into account a number of factors:

- Concrete grade;

- Groundwater level;

- Degree of soil moisture;

- Type and depth of the foundation;

- The tendency of soils to frost heaving;

- Heterogeneity of the soil composition.

Vertical and horizontal waterproofing of the foundation

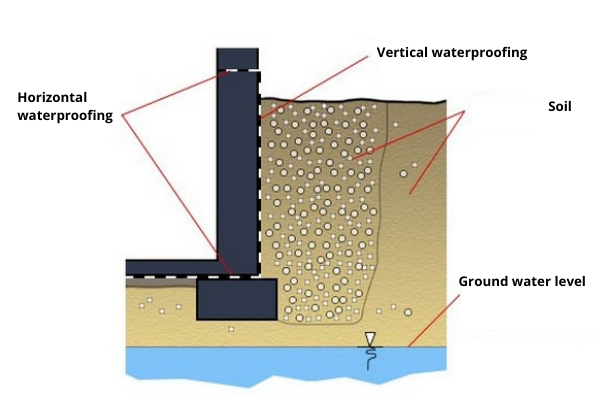

When installing protection and waterproofing of concrete or any other foundation, it is necessary to take into account two types of insulation. Vertical protection and horizontal one.

At the moment, waterproofing can be divided into several types. The first type is vertical. The second type is horizontal. And the third type is internal.

Important: It is recommended to apply any insulating compounds only from the inside only if it is not possible to perform waterproofing from the outside.

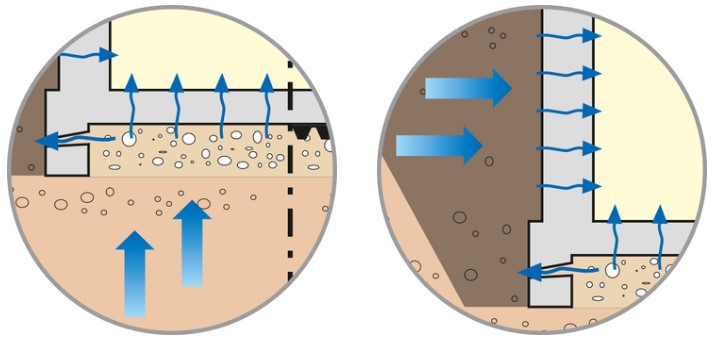

Experts distinguish between horizontal and vertical waterproofing. In this case, the terms horizontal and vertical refer to the direction in which the waterproofing material is applied, which primarily depends on what moisture you want to protect the house from. It can be ascending moisture, also known as capillary moisture, then we will talk about the installation of horizontal insulation. If the water presses from the side, then we will talk about the installation of vertical insulation.

In any case, with proper and comprehensive protection of the foundation of your house or building, you need to perform both horizontal and vertical waterproofing. In each case, the type of waterproofing and the technology of its installation will be selected, taking into account the operating conditions of the foundation. What is usually provided for by the project of a house or building.

Horizontal or cut-off waterproofing of the foundation

Horizontal waterproofing — is the so-called cut-off waterproofing. At the construction stage, it is carried out with the help of special membranes separating the foundation and walls. At the stage of repair and operation, cut-off waterproofing is most often performed by injection and its risk is to create a cut-off or barrier for moisture and water. The cut-off can be done both from the outside of the building and from the inside. Basically, we are talking about cases of lifting capillary moisture from the foundation slab up the walls. In such cases, the so-called cut-off waterproofing is performed– the cold seam of the abutment is stitched (the installation of the indenting) then it is compacted in layers with a non-shrink compound or an expanding sealant, and then injected. Injection resin is injected into the cold seam, thereby forming a horizontal cut-off that prevents capillary moisture and water from rising up the wall.

At the construction stage:

Materials for waterproofing the foundation

The most popular methods and materials for vertical and horizontal waterproofing of foundations— are:

- Pasted and surfaced

- Mounted

- Coating

- Liquid rubber

- Penetrating

- Injection

Pasted and surfaced

Surfaced roll waterproofing according to the type of surfaced bitumen materials from Technonicol – this type of insulation is applied or deposited in several layers mainly from the outside and has obvious disadvantages, such as the presence of seams, which is a weak point.

The material is also characterized by the absence of 100% adhesion to the surface. Accordingly, the deposited membranes have cavities and voids where the liquid can stagnate and walk. The material is installed on the surface using a burner and a fire.

Important: When installing surfaced materials, it is very important to select those materials that are suitable for being below ground level and have resistance to the appropriate environment saturated with various minerals and salts.

This type of waterproofing refers to rolled materials, which you can read more about in the article – “Roll waterproofing installation with detailed installation instructions“.

Types of pasting and surfacing materials for the foundation and their main characteristics:

| Name | Mounting method | Maximum tensile force (along/across) | Water absorption within 24 hours by weight | Heat resistance | Price per 1m2 in % |

| Surfaced waterproofing Izoplast П EPP 4 (10х1m) | Surfaced | 360 H | 1 % | 120 °C | starting from 10 |

| Surfaced waterproofing Izoplast К EKP 4.5 grey(10х1m) | Surfaced | 600 H | 1 % | 120 °C | starting from 11 |

| Icopal ICOPAL Н | Surfaced | more than 600 H | less than 1% | more than 95 °C | starting from 10 |

| Icopal ULTRANAP | Surfaced | more than 900 H | less than 1% | more than 100 °C | starting from 18 |

| Surfaced waterproofingTechnonicol Technoelast Terra EMP (10х1 m) | Surfaced | more than 900 H | less than 1% | more than 100 °C | starting from 20 |

| Surfaced waterproofing КРЗ Hydroizol XPP (9х1 m) | Surfaced | 294 H | 1 % | 70 °C | starting from 5 |

| Surfaced waterproofing Technonikol Uniflex ЭКП slate (10х1 m) | Surfaced | 500 H | 1 % | 95 °C | starting from 10 |

| Bicrost TPP (15х1 m) | Surfaced | 600 H | 1 % | 80 °C | starting from 6 |

Mounted or membrane

This type of insulation is mounted on the surface with the help of special clamping elements, for example, slats. The most popular material in this category are TPO and PVC membranes. Different pieces of membranes are connected thanks to a construction hair dryer and hot air. In most cases, PVC membranes are applied in 1 layer.

Seams and a complete lack of adhesion make this material very vulnerable to water penetration.

You can read more about membrane waterproofing in the article – “Membrane waterproofing: Types of materials and methods of their installation“.

Types of membranes for waterproofing the foundation:

| Name | Mounting method | Manufacturer |

| Sikaplan WP 1100-15HL | Mounted | Sika |

| Sikaplan WP 1100-20HL | Mounted | Sika |

| Sikaplan WP 1200-16 C | Mounted | Sika |

| SikaProof A+ 12 | Mounted | Sika |

| Icopal TERANAP | Mounted | Icopal |

| PVC membrane LOGICBASE V-SL 2,0 mm | Mounted | Technoniсol |

| PVC membrane ECOBASE V 2,0 mm | Mounted | Technoniсol |

Surfaced coating waterproofing

The basic principle of surfaced coating materials is that they can be applied by coating the surface with a brush or roller. There are several types of coating waterproofing that differ from each other by their main components and the principle of operation. As a rule, all coating compositions are supplied in the form of mastic in special metal or plastic buckets of different sizes. These mastics are applied in several layers from the 1st to the 4th.

Виды обмазочных мастик:

- Coating bitumen waterproofing – these compositions are made on the basis of bitumen and are applied externally in 2-3 layers. The reliability and durability of bitumen mastics depend on the quality of bitumen, added polymers, and the manufacturer (the more expensive, the better and more reliable the material will be). You can read more about bitumen mastics in the article – “Bitumen waterproofing: types, characteristics, and technology of the installation.“

- Polyurethane compositions – This type of mastic is made on the basis of polyurethane with the addition of various polymers. Both bitumen and polyurethane systems are applied to the foundation surface using a brush and roller. You can read more about polyurethane mastics in the article – “Polyurethane waterproofing“.

- Cement compositions – are cement, plaster, and polymer-cement compositions. The main component of cement waterproofing will be cement with the addition of various polymers. Like other coating systems, cement and plaster are also applied with a brush, roller, and spatula. You can read more about polyurethane mastics in the article – “Cement-based waterproofing: Features, types, and methods of its application“.

Liquid rubber

Double-component and single-component FlexLock type liquid rubber from HYDRO – is an elastic and seamless coating that is applied by spraying and has 100% adhesion to the surface. It is the most effective and most reliable material for waterproofing concrete surfaces from the outside, such as a concrete slabs or walls located below the zero level.

Advantages of liquid rubber:

- No seams;

- Material resistant to the aggressive environment;

- High coefficient of elasticity;

- Can be applied to an uneven surfaces;

- 100% adhesion to the base;

- Environmentally friendly;

You can read more about liquid rubber in the article – “Waterproofing with liquid rubber“.

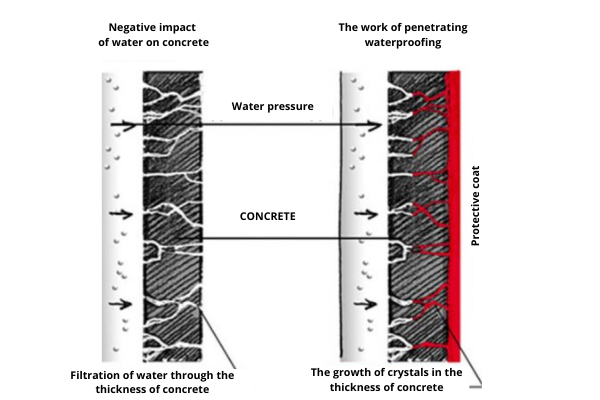

Penetrating – Waterproofing of the foundation with a penetration

To seal the foundation from the inside, you can use different penetrating technologies and compositions, including materials of Penetron brand, but do not forget that Penetrating mixtures that have the properties to form a so-called crystal film do not work in all cases and do not on all grounds. Non-Penetron and other penetrating compounds will not work on a brick base, blocks, and poorly vibrated sections of concrete, as well as on areas of reinforcement coupling with concrete. For the above reasons, before using such materials, it is necessary to study their characteristics very carefully, as well as consult with a contractor specialized in waterproofing (preferably with a company that deals with all types of waterproofing and not just Penetron-it is such a company that will be the most objective).

you can read more about penetrating waterproofing in the article – “Penetrating waterproofing: A detailed description of its work on concrete, types of materials and application technologies“.

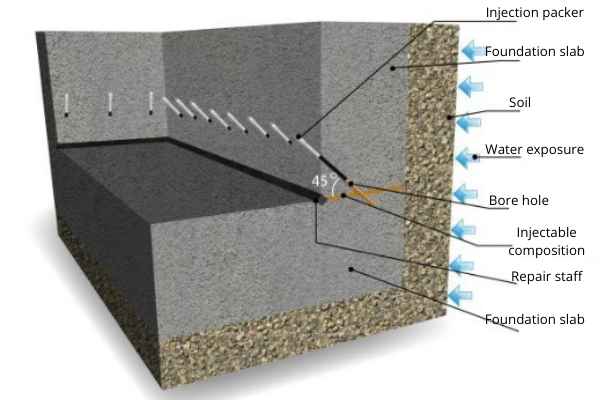

Injection waterproofing of the foundation

To perform injection work, holes in concrete are drilled from the inside (so-called boreholes), packers are inserted there (hollow tubes through which injection resin is injected) and a double- or single-component polyurethane compound is injected into the concrete under pressure (with special equipment), filling all cracks and voids.

Injection waterproofing is used both to protect the concrete body and to seal cold joints and foundation concreting joints inside the building itself.

Comparative table of the main characteristics of materials for waterproofing the foundation

For work-related to waterproofing, there are a number of different materials that differ in the method of installation, characteristics, properties, compounds, reliability, durability, and price.

To understand the main differences between the most famous waterproofing systems, as well as the examination of their advantages, you can study the following table:

| Liquid rubber | Bitumen-based coating mastic | Surfaced bitumen-based materials | PVC membranes | Penetrating compositions | |

| Mounting method | Non-firing By spraying Manually with a roller or brush | Non-firing Manually with a roller or brush | Burner and live-fire Special roller | Hair dryer and hot air Mechanical fastening with straps With a special roller | Non-firing Manually with a roller or brush |

| Work on negative water pressure | Not available | Not available | Not available | Not available | Available |

| Number of layers | 1 layer for double-component 2 layers for single-component | 2-3 layers | 2-3 layers | 1 layer | 1-2 layers |

| The need for pre-priming | Available | Available | Available | Not available | Not available |

| Seams and joints in waterproofing coating | Not available | Not available | Available | Available | Not available |

| Adhesion to the base | 100 % | 100 % | 20 % | No adhesion | 100 % |

| Coefficient of elasticity | 600-800% | 50-200% | 10-20% | 10-20% | 0 % |

| Installation speed m2/ per 1 day | 400-600 | 20-50 | 20-50 | 30-60 | 20-50 |

| The warranty period for works | 7 years | 3-5 years | 3-5 years | 1-2 years | 1 year |

Auxiliary elements for long-lasting protection of the foundation from water

Following the waterproofing installation of all elements of the foundation, it is very important to provide special systems that will help divert excess water from the foundation and thereby weaken the water pressure on the waterproofing made.

Such additional foundation protection systems are:

- Drainage system

- Storm sewer and roof drain

- Blind spot

Drainage around the foundation

The task of a properly executed drainage system is to divert water from the foundation, thereby reducing its pressure on the completed protection. To do this, the drainage pipes should be mounted below the level of the foundation, so that the drainage takes over not only the water that approaches the foundation from the side but also the one that is under it. The task of drainage is to accumulate water and divert it in another direction, usually behind a plot into a ravine, forest, or village storm sewer.

Drainage consists of the following elements:

- Drainage pipe;

- Crushed gravel of fractions 20-40;

- Geotextile;

- Inspection of drainage wells;

- Coarse-grained river sand (for filling drainage).

For more information on how to make proper drainage so that it works, you can read in detail in the article – “Turnkey drainage installation around the house: Proper drainage, its types, installation technologies, schemes, and prices“.

Important: Thanks to the drainage system, the waterproofing made will last 5 times longer, since it will not be under constant water pressure.

Blind area, storm sewer, roof drain

Both drainage and blind areas, stormwater, and drainage systems are necessary to drain excess water from a building or house. These systems consist of gutters, PVC pipes, trays, funnels, and rain collectors. Water through funnels and rain collectors enters the wiring of PVC pipes and is diverted to the collector (storage tank), from which it subsequently flows by gravity or forcibly goes outside the site.

Proper waterproofing of the fire foundation and how best to make the foundation waterproofing – from the outside or from inside?

Of course, the most correct and comprehensive waterproofing option is to perform waterproofing on the outside of your foundation, because this solves the roof of the problem itself. If the base is not properly protected from the outside, moisture penetrates into it, in winter it freezes, and in spring it thaws, which gradually forms microcracks in the base of the cavity and destroys the structure of the concrete. When working outside, you not only eliminate leaks in the basement of your house but also protect concrete from moisture penetration into it, which solves the root of the problem.

When working from the inside, your basement will be dry, but the root of the problem has not been solved — the foundation of your house continues to stand in water and absorb moisture, which can gradually lead to its destruction and the formation of cracks.

What is the best way to waterproof the foundation from the outside and from the inside?

Waterproofing of concrete and any other foundation can be done both from the outside and from the inside. There are effective methods for each case.

Waterproofing of the foundation from the outside

Among designers and firms specializing in waterproofing, the most popular way to protect concrete from the outside is to apply liquid rubber, as this is one of the most reliable methods of waterproofing concrete structures. Liquid rubber has a number of advantages, which allows you to give it the maximum warranty period:

- No seams – no seams, no potential leaks after a short period of time (seams tend to diverge).

- 100% adhesion to the concrete surface – there are no cavities and voids under the coating.

- Very high coefficient of stretching – this allows you to maintain the integrity of the coating during shrinkage of the building or its dynamics.

- Speed of application – LR is applied by cold spraying, which allows covering about 400m2 per day.

- Environmental friendliness and safety – LR — are eco-friendly materials that are absolutely safe for humans.

Scheme of drainage and waterproofing of the foundation from the outside:

Waterproofing of the foundation from the inside from moisture and groundwater

If there is no waterproofing outside your building or it has fallen into disrepair and for some reason, you cannot dig out the building and protect it from the outside, then waterproofing can also be done from the inside. The most effective way to protect your foundation from the inside — is to perform injection waterproofing with double-component polyurethane resin of the HydroInject type from the German company Hydro or injection materials from BASF.

For comprehensive protection of the walls and foundation of the house from the inside, it is also recommended to use special compositions that are designed to work on negative water pressure, that is, pressure from outside to inside. If you are looking for durable and reliable compounds that can be used from inside the room, then it is best to use HydroPaz or a similar line of construction chemicals from BASF.

Waterproofing of the foundation price per m2 and cost of work

All the prices listed below are average prices, and they may change depending on the volume, complexity of the work, the total cost for the entire estimate, the remoteness of the object from the center, etc…

The cost of performing work outside – Prices for various methods and technologies with a price per 1m2

| Name of works | Unit of measurement | Price in $ |

| Work on the device of surfaced waterproofing | m2 | 10 |

| Work on the installation of a PVC membrane | m2 | 20 |

| Works on the device of the polyurea | m2 | 30 |

| Work on the mastic waterproofing | m2 | 10 |

| Works on the device of liquid rubber spraying | m2 | 15 |

| Work on the device of liquid rubber manually | m2 | 18 |

| Works on the installation of cement-mineral 2-component waterproofing | m2 | 20 |

| Works on the device of polyurethane waterproofing | m2 | 20 |

| Applying the primer | m2 | 7 |

The cost of work from the inside – Rates and prices per meter

| Name of works | Unit of measurement | Price in $ |

| Waterproofing of cold joints: -Work on the device of the fine -cleaning of the fine -layer sealing of non-shrinkable composition | running meter | 20 |

| Waterproofing of interblock joints: -Work on the device of the fine -cleaning of the fine -layer sealing of non-shrinkable composition | running meter | 15 |

| Waterproofing of deformation joints: -Work on the device of the fine -cleaning of the fine -sealing of the elastic profile -sealing of the non-shrink compound -a complex of works on injection | running meter | 180 |

| Injection waterproofing of seams / cut-off waterproofing -Work on the device of the fines -cleaning of the fines -layer-by-layer sealing of non-shrinkable composition -Work on the device of boreholes and installation of packers -complex of works on injection -dismantling of packers and sealing of injection holes | running meter | 80 |

| Injection waterproofing into the concrete body-marking, -Work on the device of holes and installation of packers -complex of works on injection -dismantling of packers and sealing of injection holes | m2 | 80 |

| Injection waterproofing into the body of the brick -marking, Work on the device of holes and installation of packers -complex of works on injection -dismantling of packers and sealing of injection holes | m2 | 80 |

| Cement-mineral waterproofing | m2 | 20 |

| Penetrating waterproofing | m2 | 20 |

| Waterproofing of the places of entry of communications: -Work on the device of the fines -cleaning of the fines -layer-by-layer sealing of non-shrinkable composition -Work on the device of boreholes and installation of packers -complex of works on injection -dismantling of packers and sealing of injection holes | Unit | 300 |

Waterproofing of the foundation estimate

Above are some average prices for waterproofing work. The above total cost and unit prices may vary depending on complexity of the work, distance of the object from the city, the groundwater level (at high groundwater may need construction water supply) and etc.

In order to understand accurately the cost of work related to the insulation of your foundation, basement or walls, it would be right to call an experienced engineer from a specialized company that deals directly with waterproofing. It is a professional hydraulic engineer who will be able to determine which is the best technology to use and which is the best material to apply in your particular case.

The engineer who has come to you will definitely draw up a detailed technical specification describing all the necessary processes for the subsequent preparation of a detailed estimate, which will describe all the work and materials used. Compiled by technical assignment the engineer passes the assignment to the estimate department, which makes detailed calculations of the final cost of the estimate, indicating the price and pricing for each position. After that you get a detailed estimate.

Waterproofing cost calculator

Калькулятор гидроизоляции фундамента

Итоговая стоимость гидроизоляции

Repair work and waterproofing installation, depending on the type of foundation

It is best to entrust the work on the installation of proper waterproofing to an experienced and professional organization, exactly it is who will be able not only to choose the right method for the installation or repair of the waterproofing coating, but also to perform its installation correctly.

It is the correctness of compliance with the installation technology that determines how well the foundation of your building will be protected and how long this protection will serve to you without the need for its repair or replacement. Do not forget that if the waterproofing is installed incorrectly, it will most likely have to be repaired after a year or two, and this is a serious additional cost associated with the following works:

- Dismantling of the maid blind area (if available)

- Development of the soil around the underground part of the house, to its full depth

- Dismantling of wall insulation (if available)

- Dismantling of the old waterproofing coating

- Installation of new waterproofing

- Reverse installation of insulation

- Backfilling of the soil and restoration of the blind area

Important: Most waterproofing coatings are not subject to local repair, since it is impossible to determine where the water gets from the outside at the place of leakage from the inside, respectively, it is necessary to completely change the entire coating.

7 rules on how to find a professional waterproofing company or contractor and not to make a mistake, you can find in the article — Contractors, companies and firms for waterproofing and drainage

Waterproofing of ribbon foundation

The ribbon foundation can be made of FBS blocks or poured from concrete.

When installing the insulation, it is necessary to take into account both horizontal and vertical waterproofing.

Horizontal protection is installed on the horizontal surface of the ribbon made of FBS blocks or concrete and serves as a cut-off between the ribbon foundation and the future walls of the house. Such a cut-off will not allow capillary moisture to rise and soak into the walls

Vertical protection is applied to the vertical surface of the ribbon located below ground level.

The following materials can be used as a waterproofing compound:

- Surfaced;

- Coating;

- Liquid rubber– recommended;

- PVC membranes;

Waterproofing of columnar and pile foundations

In this type of structures, it is necessary to provide only horizontal protection. Installation of waterproofing is carried out on the surface of grillage or support element. The main task of the insulation of pile foundations is to prevent the capillary rise of moisture and its further impact on the walls of the house.

For this type of structures, you can use materials such as:

- Surfaced insulation;

- Coating mastics;

- Membranes;

- Liquid rubber.

Monolithic slab foundation

When installing this type of foundation, it is necessary to provide high-quality and reliable waterproofing of the horizontal base, since in the future it will be impossible to repair the protection made.

For waterproofing of a monolithic slab, the following materials can be used:

- Surfaced bitumen membranes;

- PVC membranes;

- Bitumen mastics;

- Liquid rubber – recommended.

Important: When installing any type of foundation, it is recommended to install a high-quality drainage system around it at a depth of 0.3-0.5 m below the level of its occurrence. The drainage system located just below the foundation will take over the water that will approach it from the side and the water that is under it. This will weaken the water pressure on the concrete and increase the service life of the waterproofing system.

Make waterproofing of the foundation of the private house with your own hands

Protecting the foundation of a building or a private house from groundwater is very responsible job, but if desired and with proper knowledge of technology, the owners of private houses and cottages will be able to do it with their own hands, for this they will need to take the following steps:

- Choose the appropriate technology and material, the installation of which does not require the use of special equipment (for example, a plant for spraying liquid rubber or polyurea);

- Study the technology carefully and the manufacturer’s instructions for installation, repair or installation of a particular coating;

- Take all measures to organize the workplace and safety measures when carrying out work with your own hands;

- Carefully prepare the surface before self-waterproofing installation;

- Most materials require prior application of a primer (back paint, to improve the adhesion of the waterproofing coating to the surface);

- Apply the waterproofing coating with your own hands, clearly following the manufacturer’s instructions;

- Protect the waterproofing layer from subsequent mechanical damage (for example, during filling);

- Install the necessary auxiliary systems for removing water from the foundation and reducing its pressure, for example, the installation of a drainage system.