Table of Contents

- What is penetrating waterproofing

- Types of penetrating compounds and their characteristics

- How penetrating sealers work on concrete

- Advantages and disadvantages of penetrating sealers for waterproofing

- Where penetrating materials can be used

- Crystalline waterproofing technology and application of penetrating sealer

- Overview of the most famous brands:

- Prices for penetrating sealers and their application

- Frequently asked questions about penetrating sealers and the principles of crystalline waterproofing.

- Video about how penetrating sealers and crystalline waterproofing works

Many builders and owners of private houses have heard about penetrating waterproofing, but most of them do not understand exactly how this type of insulation works and where it is better to use it and where not. This article will tell in detail everything you need to know about penetrating waterproofing to anyone who is thinking of performing waterproofing works using penetrating compounds.

What is penetrating waterproofing

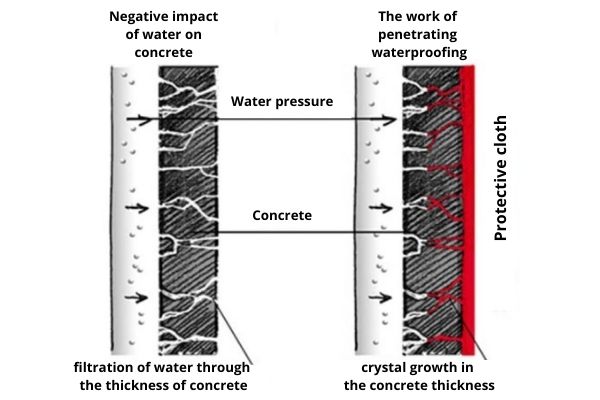

This is a waterproofing that penetrates deep into the concrete, by chemical reaction with the base. Penetration goes inside the existing pores and voids, thereby forming a waterproof barrier in it. Deep penetration is what distinguishes penetrating compounds from standard waterproofing materials, such as coating, roll and membrane, since they all protect only the surface without penetrating deep into the element. When penetrating, the penetrating compounds form a kind of integral whole with concrete and, unlike standard insulations, can be destroyed or damaged only when the concrete itself is destroyed.

Penetrating insulation materials help to solve the problems associated with:

- Waterproofing of porous bases – Consists in protecting concrete and other structures with porous surfaces from excessive moisture and water exposure. Without reliable protection, they are at risk of damage, mold growth and other problems. A high-quality penetrating product will repel both water and various chemical elements, salts and oils, while at the same time allowing the concrete to breathe.

- Protection of porous substances from destruction – Excessive porosity in cement and other substances can lead to damage over time. The penetrating sealant protects the treated structure, significantly reducing the amount of chemical elements and water penetrating and affecting it.

Penetrating materials consist mainly of special cements, quartz sand and additives such as sodium silicate and lithium silicate, Silicate or Silane-Siloxane. These special additives distinguish some penetrating products from others.

Types of penetrating compounds and their characteristics

Not all penetrating sealants are the same. Some of them have fine particles that provide deep penetration into the cement base and a longer service life. Understanding the different types and when one of them may be preferable to the other is certainly useful. The most common types of penetrating coating materials include:

Types of penetrating materials:

- Made on the basis of sodium silicate and lithium silicate – give unique advantages to concrete by improving it, as well as providing reliable water resistance and resistance to various minerals. They have a relatively long service life.

- Made on the basis of Siliconates – provide excellent protection against porosity. They contain medium-sized particles that penetrate deep into porous places. They are great for preventing excessive absorption of water and oil in the long run.

- Produced on the basis of Siloxane – Siloxane contains larger particles, which makes it less able to penetrate deep into the pores of concrete. However, it can be a cost-effective solution for those who are on a budget.

- With the addition of Silanes – Silane is a good choice if you are looking for a compound that penetrates deep into the cement base. It may not improve the appearance as much as silicate, but it can last more than five years and has excellent water resistance.

- Fluorinated – Many prefer fluorinated penetrators and consider them more effective. However, they are often less accessible and tend to be more expensive.

There are several main types of penetrating systems, which differ mainly in the way they are manufactured and the presence of a particular component in them. All these types penetrate concrete to different depths, forming a chemical barrier that protects against moisture and chemicals. As a rule, they provide invisible protection without changing the appearance of the surface and most of these products breathe, allowing moisture vapors to escape.

Penetrating mixtures based on sodium silicate and lithium silicate

In the category of silicate penetrating sealants, there are silicate compositions with the addition of sodium and silicate compositions with the addition of lithium. Potassium silicate is on the market, but not of high enough quality for masonry work. Penetrating mixtures made on the basis of sodium and lithium silicates penetrate into the base, where they react chemically with free lime and calcium in the pores. The reaction forms a permanent calcium silicate hydrate structure that resembles a crystalline structure. The purpose of silicate components is to increase the strength and density of cements.

Penetrating Silicone sealants

Penetrating sealants made of Siliconates Silicate mixtures are water-repellent, which react chemically under the surface, forming a hydrophobic barrier inside the pores. This is a very effective solution to reduce the damage caused by the absorption of water, snow and ice, as well as various salts. If applied excessively to highly porous or colored substrates, this material can leave behind a white precipitate. Silicate water repellents are great for use on white or light gray planes.

Penetrating insulation materials based on Silane or Siloxane

Penetrating insulation materials based on Silane or Siloxane Silane and siloxane components are water-repellent sealants that react chemically under the surface, forming a hydrophobic barrier inside the pores. They are very common for industrial use, such as sealing roadways and bridge decking. In addition, homeowners prefer to use them for waterproofing their driveways, patios and garage floors. They help to reduce the deterioration of concrete quality caused by water absorption, and help to reduce the formation of mold and efflorescence. It is important to understand that the hybrid silane/siloxane product does not work at all like silane or siloxane material. Silane and siloxane materials have several weaknesses when used independently.

How penetrating sealers work on concrete

Concrete is porous, that is, it contains small holes that can leak moisture. Over time, moisture can cause problems such as leaks, efflorescence, mold and cracks in concrete. The materials penetrating into concrete are designed to protect it from water and moisture by forming a chemical barrier from a waterproof composition.

The surfaces of reinforced concrete structures can be effectively protected by applying special coatings. Penetrating coatings are able to penetrate inside, which makes them useful for performing not only as primary sealers, but also for performing repair work. Manufactured in the form of a dry mixture with penetrating properties, products based on mineral binders are used for waterproofing concrete bases with developed capillary porosity (reinforced concrete, brickwork, etc.).

The principle of work for penetrating sealers is as follows:

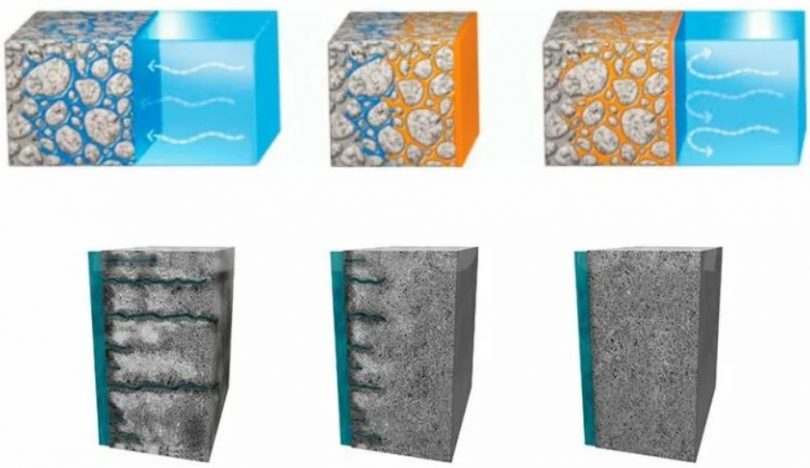

During application, penetrating polymers for concrete (made of silane or siloxane polymers) penetrate into the voids and capillary pores of concrete and react with the alkalis that are in it with the formation of hydrophobic compounds in the pore structure.

Chemically active substances penetrate into the pores and capillary paths of concrete, where they react with free lime and sediment on the surface of the pores. Pores (or microcracks) are filled, reducing permeability and helping to make the substance waterproof. If the structure comes into contact with water molecules, the reaction resumes and the compaction process moves deeper into the concrete. The same process underlies the” self-healing” of microcracks. When applied, the coating creates a film inside, filling voids and capillaries. Within 10-30 days, the material will begin to crystallize, keeping voids and capillaries filled with crystals that attach to the concrete, retaining water and high humidity.

The scheme of penetrating sealer effect

Important: Penetrating materials work only in areas where there are small pores, microcracks and capillary channels. Penetrating coating materials will not work in areas where there are large voids, cracks or empty spaces at the interface with the reinforcement.

Advantages and disadvantages of penetrating sealers for waterproofing

Advantages:

- Provides reliable waterproofing;

- Provides protection against various minerals and salts;

- 100% adhesion to the base;

- Withstands both positive and negative water pressure from outside to inside; · Does not affect the appearance;

- Prolongs the service life of concrete;

- It is securely held in the thickness of the structure and collapses only if the structure itself is destroyed.;

- Restrains hydrostatic pressure;

- Allows concrete to breathe. Repelling water, salts and chlorides, the base remains breathable, so that the water vapor inside can evaporate;

- Incombustible;

- Environmental friendliness.

Disadvantages:

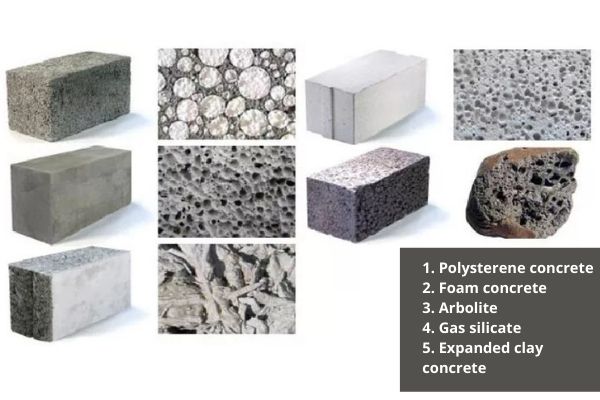

- Penetrating coating does not work on all concrete structures – In places where there are large voids, pores or cracks, penetrating insulation will not work, since it cannot fill a large space. Unfortunately, most problems with leaks are formed just in such problem areas, which makes the penetrating effect there useless;

- Large voids form in poorly ventilated concrete, where penetrating insulation does not work;

- Can not be used for waterproofing large-porous products: Poorly ventilated and destroyed concrete, asbestos cement slabs, aerated concrete, foam blocks, expanded clay concrete blocks and brickwork;

- The need for additional waterproofing – Since the penetrating coating works only on small voids and small capillary channels, it is necessary to additionally apply other types of waterproofing, for example, polymer cement, to close larger voids;

Where penetrating materials can be used

Penetrating mixtures are widely used to protect concrete foundations and restore their operational properties. They can be applied both from the outside of the structure and from the inside, mainly due to their ability to penetrate and withstand negative pressure. Application areas:

- Basements and basement floors;

- Walls of basements and foundations;

- Foundations of buildings and private houses; · Water tanks;

- Underground parking and parking lots;

- Collector;

- Sewage treatment plants;

- Hydraulic structures, such as piers, dams, docks, etc.

Penetrating method to waterproof a basement from the inside

Penetrating systems are often used for waterproofing basements from the inside when detecting problems with the entry of moisture or active leakage through the walls or floor of the basement after completion of construction. With the help of penetrating coating systems, builders are trying to make a barrier for water from inside the basement, thereby saving on the restoration of external waterproofing.

Important: When performing any waterproofing from the inside of the basement, you do not solve the root of the problem, namely its impact and the destruction of the walls and foundation of your basement from the outside. Destruction occurs mainly due to temperature differences, water is absorbed into concrete like a sponge, freezes in winter, and thaws in spring, thereby forming microcracks and pores. Unfortunately, no penetrating system will protect your basement from such impacts for a long time.

- In addition to performing repair work with the help of coating penetrating components, these mixtures are also used as primary waterproofing of walls and basement foundations. At the same time, it is worth noting that the use of materials of this type outside as primary insulation is not always beneficial, since today there are more reliable materials for this, such as liquid rubber or polymer cement waterproofing. When repairing and eliminating basement leaks from the inside, the following systems can be used as an alternative:

- Injection waterproofing

- Polymer cement waterproofing

You can read more about the methods of waterproofing basements in the following article – “Waterproofing the basement from the inside: Methods, materials and stages of work”.

Penetrating Sealer Application for foundation waterproofing

The foundation slab and walls, as well as the whole basement, can be coated with with penetration sealers, however, as in the situation with the basement, such technology is not always justified, including due to the complexity of its actual application and due to the complexity of the subsequent care, namely constant moistening for 5-8 days.

If you wish to perform waterproofing work by applying penetrating Sealer, you should perform the following steps:

- Cleaning the surface to an ideal condition without dust, dirt and microcracks;

- Abundant hydration

- The device of the 1st layer of waterproofing sealer, and then the application of the 2nd after 2-4 hours;

- Abundant hydration of the work performed several times a day for 5-9 days.

Alternative systems to apply for high-quality foundation waterproofing from the outside:

- Liquid rubber;

- Polymer – cement;

- Polyurethane waterproofing; You can read more about the methods of waterproofing foundations in the following article – “Horizontal foundation waterproofing:

The technology of the device and the materials necessary for this”.

Penetrating sealer to apply on floors and walls

Penetrating sealer for floors and walls in the basement, it is possible to apply it as coating. However, when carrying out work related to waterproofing to floors and walls, attention should be paid to the fact that materials with has a penetrating effect will not always be able to help protect the basement and its structures from water, since they do not work on those areas of concrete where there are large voids, cracks and places of interface with reinforcement.

When installing protection or waterproofing for walls made of concrete or blocks, you should also pay attention to the interlocking seams (if available) and cold seams of the plate at the junction of the floor and wall. In most cases, these places will leak in the first place, since seams are the weakest places in any structure and no penetrating coatings will help here.

For waterproofing cold and ecpension joints, it is best to use injection waterproofing and special expanding sealants. You can read more about waterproofing of walls in the following article – “Waterproofing of basement and house walls from the outside and from the inside – Methods, materials, prices, and technology”.

Crystalline waterproofing technology and application of penetrating sealer

Different brands of penetrating compounds may have different application technology and devices, but there are some general rules for the device of penetrating types of coatings that must be followed.

Step-by-step application technology

- It is necessary to remove all peeling elements from the work area and heal the existing cracks.

- Concrete must be cleaned of any plaque, efflorescence, dirt, dust, oil, grease, wax, rust, or paint.

- Moisten the desired area before application to improve the penetration of the composition into the concrete during its coating;

- Apply the first layer with a special brush or spray equipment. The application should be carried out on a wet base;

- Apply the second layer to the fresh, but already gripped the first layer after 1-4 hours. Before applying the second layer, the base must be re-moistened;

- Moisten the surface in areas where work has been carried out several times a day for 5-9 days;

- Protect the places where the work was carried out from exposure to ultraviolet rays of the sun, mechanical loads, sub-zero temperatures, and precipitation for 6-9 days (each manufacturer has its own setting time). The application of subsequent finishing elements can be carried out no earlier than 8 days after the primary insulation device.

Important: Application to freshly cast concrete can be done when its luster disappears and it will be possible to walk on it without leaving any traces, as a rule, this happens within the first 36 hours after the completion of pouring.

Overview of the most famous brands:

Today, in the market of waterproofing systems with a penetrating effect, there are a lot of manufacturers offering different versions of these materials. Most of them differ in their characteristics and composition.

Next, let’s look at the most popular manufacturers and the difference between them:

- HYDRO Pro is a high-quality penetrating product from a German manufacturer of waterproofing products that supplies it all over the world, including in Russia. HYDRO is mainly known for the high quality of its products and participation in the supply of its products to large industrial and infrastructure facilities, such as the construction of metro lines and hydraulic structures.

HYDRO Pro has properties to penetrate deep into the structure of concrete, is environmentally friendly and has high water-repellent properties. In addition to waterproofing properties, the compositions of this brand are able to improve the quality of concrete and protect it from chemical elements, salts, petroleum products and various minerals. - Lahta (Lahta) – Lakhta is a product manufactured by the Russian company RASTRO. Lahta is a composition of penetrating action to increase the water resistance of building structures. One-component composition, which is a dry gray construction mixture, which includes Portland cement, quartz filler and active chemical additives. Complies with GOST R 56703-2015. Detailed instructions with a technological description of all stages of work using Lahta can be downloaded from the following link – Lahta -Instructions for work. The instruction is provided by our partners of the company “CJSC RASTRO”.

- Kalmatron is a waterproofing capillary penetrating product from the Russian manufacturer of construction chemicals company KALMATRON.

- Penetron –Penetron) is a Russian manufacturer of insulation for various purposes.

The penetron is designed for application on various monolithic bases. Like other similar products, the Penetron does not require drying of the base when applied. Detailed instructions with a technological description of all stages of work using Penetron can be downloaded from the following link – Penetron – Instructions for use. The instruction is provided by our partners of the Penetron Russia company. - SikaSeal – Penetrating, coating insulation based on certain cements from the company Sika. Sika is a Swiss concern for the production of waterproofing and chemicals for construction and industry. SikaSeal is a one-component waterproofing based on cement, with the use of penetrating components that crystallize in the pores of concrete and increase water resistance. You can download the instructions with the technological description of the device from the link – Sikaseal-Technical description of the product. The instruction is provided by our partners of the company “SIKA”.

Comparison table between the main brands of penetrating materials

| The Name of the Indicator | BASF | Ceresit | Mapei | sikaseal |

| Consumption of dry mixture with two-layer application, kg/m2 * smooth surface * relief surface | 1,2-2 | 0,8 – 1,2 | 1,4-1,6 | 2 kg of ready-made solution per 1m2 per 1mm thickness |

| Viability of the solution, min | 30 | 30 | 15 | 30 at a temperature of 23°C |

| Increase of the grade of waterproofness of concrete treated | 3 – 5 stages (up to W20) | 4 stages (delta W8) | 2 – 4 stages (up to W20) | 3 – 5 stages (up to W20) |

| Increasing the strength of treated concrete % | 18 | 10 | 4 | 12 |

| Increasing the grade of concrete for frost resistance | Increase by 200-350 cycles | from F100 up to F200 | at least 50 cycles | Increase by 150-250 cycles |

| Vapor permeability, mg/(m*h*Pa) | Does not worsen | 0,0137 | 0,0122 | does not worsen |

| Resistance of the coating to the action of light and dark petroleum products | persistent | persistent | persistent | persistent |

| UV resistance of the coating | persistent | persistent | not available | persistent |

| Chloride-ion content, %, less | 0,03 | 0,05 | 0,1 | 0,03 |

| Application temperature (ambient), °C | +5 up to +35 | +5 up to +35 | +5 | +8 up to +30 |

| Warranty period of storage, months | 18 | 12 | 12 | 12 |

| Packing | Buckets of 20 and 25 kg | Paper bags with a polyethylene liner (5, 10 and 25 kg | Paper bags of 25 and 5 kg | Bags of 20kg, buckets of 7 and 15 kg |

Prices for penetrating sealers and their application

The prices of materials indicated in the table may vary depending on the season and the exchange rate of foreign currencies. To clarify the price, you can contact us by e-mail or by the phone number specified in the contacts.

| Price per kg in US dollars | Packing in kg | Unit price in US dollars | The cost of 1m2, taking into account the average consumption | |

| Ceresit | 9 | 25 | 225 | 14 |

| BASF | 12 | 25 | 300 | 26 |

| sikaseal | 18 | 25 | 450 | 28 |

| Mapei | 6 | 25 | 150 | 7 |

| Calmatrone | 4 | 25 | 100 | 8 |

Application of penetrating sealers and how much it will cost

To perform waterproofing work, it is recommended to call specialists who have experience working with different waterproofing systems, since not always all problems can be solved with one penetrating effect, sometimes you need to skip a set of measures. To obtain the final price, it is recommended to contact our office to obtain a preliminary estimate or to order the departure of our engineer to your facility to provide advice, measurements and preparation of technical specifications for the estimate department.

| Name of works | Unit of measurment | Price in US dollars |

| Penetrating sealer | m2 | starting from 11 $ |

| Polymer cement waterproofing | m2 | starting from 11 $ |

| Waterproofing of cold joints: -Work on the device of the fine -clearing of the fine -layer-by-layer sealing of non-shrinkable composition | running meter | 16 $ |

| Waterproofing of interblock joints: -Work on the device of the fine -clearing of the fine -layer-by-layer sealing of non-shrinkable composition | running meter | 11 $ |

| Injection waterproofing of seams / cut-off waterproofing -Work on the device of the fine -clearing of the fine -layer-by-layer sealing of non-shrinkable composition -Work on the device of boreholes and installation of packers -a complex of works on injection -dismantling of packers and sealing of injection holes | running meter | 32 $ |

| Injection waterproofing in concrete body-marking, Work on the device of holes and installation of packers – complex of works on injection – dismantling of packers and sealing of injection holes | m2 | 51 $ |

| Injection waterproofing into the brick body-marking, Work on the device of holes and installation of packers – complex of works on injection – dismantling of packers and sealing of injection holes | m2 | 51 $ |

| Waterproofing of places where communications are entered: -Work on the device of a fine -clearing of the fine -layer-by-layer sealing of non-shrinkable composition -Work on the device of boreholes and installation of packers -a complex of works on injection -dismantling of packers and sealing of injection holes | piece | starting from 400 $ |

Frequently asked questions about penetrating sealers and the principles of crystalline waterproofing.

If you still have questions about how penetrating sealers work, what they consist of, methods and technologies of application, then for an exhaustive answer, you can contact our office by e-mail info@construction-engineer.ru, by calling the phone number listed on our website or try to find an answer to your question in the list of frequently asked questions listed below.

- Question: Is it true that penetrating insulation materials can penetrate to a depth of up to 6 cm?

- Answer: Penetration is determined not by the properties of the materials, but by the porosity of the surface on which the penetrating solution is applied. Dense bases, such as polished monolith, do not absorb much moisture, so the sealant penetrates only 0.2- 1sm. On porous terrain, solutions can penetrate to a depth of 1-3sm.

- Question: How long does the penetrating moving effect last?

Answer: Penetration occurs as a result of a chemical reaction caused by a silicate and a permanent. The film formed inside the structure can be removed only when the concrete itself is destroyed. - Question: Do different penetrons change the color of monolith walls?

Answer: No. In some cases, white crystals may form on the surface, but this is infrequent when used correctly. - Question: Is it possible to apply penetrating solutions to bricks or paving stones? Answer: Yes, some mixtures can be applied, but this is highly discouraged, since in addition to the lack of desired waterproofing, excessive use can become a serious problem for bricks and lead to its destruction. compatibility and coverage.

- Question: Are all the penetrating materials the same?

Answer: The chemical reaction that occurs during the transition from one silicate to another is identical, but the silicate materials themselves are not the same. Many manufacturers sell silicates that are pre-diluted, while some manufacturers sell them in concentrate and allow the buyer to dilute them with water before applying. - Question: Can penetrating systems stop radon?

Answer: No. Despite the fact that some manufacturers use this statement as an advantage to sell the product, in fact it is a lie. Radon is a gas, and silicates breathe. Gases that got into the concrete before sealing will still pass through it after sealing. The most effective way to reduce radon levels is to install a special installation designed to reduce radon levels. - Question: Are the materials using silicate the same as those using silicate?

Answer: No! Silicate ones are used to harden and seal concrete and do not repel external water, silicone ones repel water and do not harden and do not seal concrete. - Question: Is it possible to apply one penetrating product on top of another if they are different (for example, one is based on silicones and the other is made of silicates)?

Answer: Yes, you can, after 5-7 days - Question: Is one penetrating material, for example, based on silicate, better than another, for example, based on siloxane?

Answer: One is neither better nor worse than the other, but in some cases the use of one kind is more appropriate than the other. For example, silicone types work best when applied to very light concrete surfaces. Applying them to dark or very porous ones, such as bricks or paving stones, can lead to the formation of a white precipitate. Silane-Siloxane types are popular in industrial applications such as waterproofing roadways and bridges, and are also excellent for waterproofing porous substances such as paving stones and bricks. - Question: How long do penetrating silicone products work?

Answer: Silicate sealants provide a service life of up to 7-10 years. - Question: Will silane-siloxane species always absorb water?

Answer: No. A certain component of silane-siloxane species disappears after 2-12 months, but the product continues to work in pores for up to 10 years. - Question: Are all silane-siloxane materials the same?

Answer: No, in fact there is a big difference in the formula from one manufacturer to another. For example, some contain from 2 to 8% solids (active), while others contain from 20 to 40% solids (active). The more active substances, the better – to a certain extent. In domestic use, the solids content should not exceed 40% to avoid darkening.