Table of Contents

- Methods and types of waterproofing of the basement outside

- Materials

- Perform waterproofing of the basement from the outside with your own hands: Detailed instructions and stages of work

- Prices for waterproofing work outside

- Wall waterproofing technology

In the basement, you can place a lot of things, a restroom, a cellar, a wardrobe, a storage space, etc… But there is one thing no one needs in their basement – it’s water.

If you haven’t done waterproofing of your basement properly from the outside, rain and groundwater can find multiple ways into your home and cause damage to the building, your health, and your belongings. To solve problems with water and moisture in a basement, you need to make good waterproofing outside your basement. Proper waterproofing should take into account all the nuances and features of your structure, soils, ground and surface waters, and other factors.

The most correct and thorough approach to waterproofing, in general, is to perform waterproofing works and a set of auxiliary measures precisely outside the buried part of your house or building. This approach will prevent water, moisture, and an aggressive underground environment from affecting the concrete or any other material from which your foundation and walls are made.

Methods and types of waterproofing of the basement outside

The main task of the waterproofing of the underground parts of the building — is to protect the house from the effects of water and not only ground, but also surface. For this purpose. There are several basic methods of waterproofing and remembering structures.

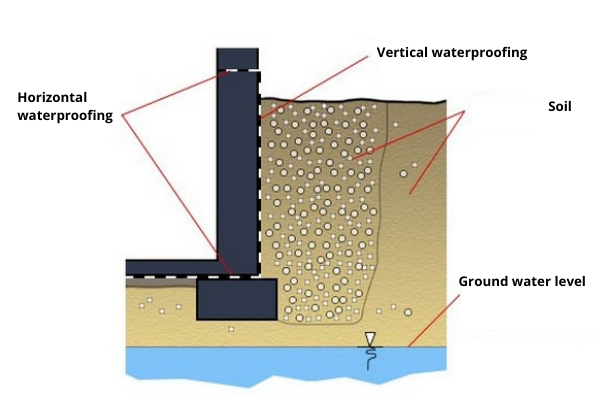

For reliable protection of the basement at the stage of construction or repair from the outside, it is necessary to provide the following types of protection:

- Vertical waterproofing – Resists the ingress of water into the basement of the house through vertical surfaces, such as the foundation or foundation slab. Vertical insulation also serves as a shut.

- Horizontal waterproofing – Resists the impact of the water on horizontal surfaces such as walls.

The main types of waterproofing:

To perform vertical and horizontal waterproofing on the outside of your foundation and basement, there are the following waterproofing systems:

- Surfaces and rolled – This includes all taped and fire-surfaced membranes, such as roofing material and other bitumen-based membranes.

- Membrane – is when the surface is complete with a strong membrane layer bonded together by hot air. At the same time, this membrane has no adhesion to the surface (to lie down like a carpet). The fastening of such a membrane to the walls and foundation is carried out using a special clamping bar.

- Liquid rubber – is a super-quality waterproofing system. Forms an elastic rubber coating on the surface with full adhesion to the base. Rubber is applied by spraying or by manual method. After polymerization, the rubber coating made has no seams, which guarantees high-quality and durable protection against water penetration.

- Coating – This includes all possible mastics and coating compositions. The most popular coating compositions are mastics based on bitumen, polyurethane, and cement. Most of the coating mixtures are applied with a brush, spatula, or roller.

- Penetrating – The main meaning of penetrating insulation is that when applied, it penetrates the concrete surface and creates an insulating membrane that protects the wall from moisture penetration.

- Injection – Hydrophobic materials are pumped into the problem area of the wall, seam, or foundation, filling all voids. Thus, the problem area stops letting water pass through. This type of waterproofing is an idea for high-quality solutions to problems with leaks from inside the basement, socle, or other premises.

Auxiliary structures to protect the basement from the outside:

- Drainage system – Designed to drain water from a house or building. The deep drainage installed below the foundation slab will take not only the water suitable for the house but also the groundwater, located under it.

- Storm sewer – Diverts water flows from the roof of the house.

- Blind area – Diverts water from the walls of the house.

Materials

Each of the types of insulation described above has its suitable materials. Each of them has its characteristics, features, disadvantages, and advantages.

Recommendation: The task of any builder is to find the optimal solution for durable and high-quality protection of the basement from water, and there is such a solution! If you have the opportunity to make waterproofing from the outside, then you need to choose a material with the following qualities: 1. Lack of seams – This characteristic will betray maximum reliability to your waterproofing since seams are one of the weakest points in any waterproofing system. 2. Maximum adhesion to the surface (adhesion) – In the presence of such quality, water will not be able to stagnate under the waterproofing coating and walk under it, which will provide easy and inexpensive repairs in the event of a hole. 3. Stretching – A high percentage of elasticity and tear during dynamic movement or shrinkage of the building. 4. Reliability and service life – Maximum service life at the ground and other water pressure. All these characteristics correspond to two types of waterproofing materials – Liquid rubber and Polyurethane waterproofing. According, they are best suited for performing waterproofing work outside.

Penetrating waterproofing

These mixtures penetrate the concrete and form a barrier to moisture penetration. These compounds are best suited as auxiliary measures, rather than the main waterproofing since they do not work on all types of bases.

You can read more about penetrating waterproofing in the article – “Penetrating waterproofing: A detailed description of its work on concrete, types of materials and application technologies“.

Roofing material and rolled surfaced materials

A membrane, made of bitumen with various additives. When heated, bitumen melts and is thus glued to the walls of the foundation slab. Different roofing materials have different characteristics, some are suitable for gluing on foundations and basements below ground level, and some for internal use. To carry out waterproofing of underground structures, it is better to use the “Technonikol foundation” from the company Technonikol. However, do not forget that all Roofing materials and surfaced materials have two main disadvantages: The presence of seams and the lack of 100% adhesion.

You can read more about roll waterproofing in the article – “Roll waterproofing installation with detailed installation instructions“

Polymer membranes

Here we are talking mainly about various PVC membranes. As in roofing material, there are also seams and there is no adhesion to the base. If water penetrates under the waterproofing carpet through a small gap in the seam, which eventually diverged, then it will accumulate under the membrane and exit in the basement at the weakest point, which in fact may be at the opposite end from the entry point. To carry out repairs from the outside, it will be necessary to dismantle completely the entire coating.

You can read more about the membrane in the article – “Membrane waterproofing: Types of materials and methods of their installation”

Liquid rubber

Waterproofing with liquid rubber implies an elastic, homogeneous rubber coating that repeats the shape of the surface and how the glue adheres to every millimeter of it. One of the most high-quality and well-known liquid rubbers is FLexLock Liquid rubber from the German manufacturer of industrial waterproofing materials HYDRO.

Liquid glass

This is a composition that is made from an aqueous alkaline solution of sodium or potassium silicate. Liquid glass is supplied in liquid form and is sometimes used as a waterproofing compound. It is not recommended for use as the only waterproofing measure, since it has rather low characteristics and will not be able to withstand moisture or liquid for a long time.

Bitumen mastics

These are bitumen-based mastics, to which various polymers are added to improve their characteristics in terms of resistance to water, elasticity, and adhesion. The more expensive the bitumen mastic, the better it is, since most likely more polymers are added to it, improving its properties. Most mastics can be applied with your own hands using brushes or rollers.

You can read more about bitumen mastic in this article – “,“.

Cement waterproofing

This method includes various polymer-cement mixtures. These mixtures can be single-component or multicomponent. They form a dense, reliable waterproofing film with 100% adhesion and without seams when applied. However, not all cement insulations have a high coefficient of elasticity and resistance to aggressive environments. In the absence of elasticity, there is a risk of cracking of the material when moving the house due to soil or its shrinkage. If we talk about high-quality industrial compounds with high elasticity, then one of them is the German polymer-cement material HydroPaz from the Hydro group.

You can read more about cement compositions in the following article – “,

Injection waterproofing

Injection materials — are mainly polyurethane resins of various viscosity, expansion coefficient, and hardening rates. The selection of the necessary resin depends on the nature of the leak or the problem to be solved. It is unlikely to be possible to determine the necessary injection on your own since you need a lot of experience and knowledge of all existing injection formulations. To perform injection waterproofing it is best to call a specialist from a large and professional organization.

Perform waterproofing of the basement from the outside with your own hands: Detailed instructions and stages of work

- Surface preparation – Using a metal brush, water pressure (through the Kercher facility), and rags, clean the surface from any kind of dirt and dust.

- Fillet – If you have a protrusion of the foundation slab and you will raise the waterproofing from the foundation to the wall, then at the transition from the horizon to the vertical you need to make a fillet of cement-sand screed (CSS), to make a smooth transition, but not 90 degrees.

- Primer – Apply a primer to the surface. To do this, you need to use a roller or brush. Wait a certain time until the primer dries or grabs the surface according to the manufacturer’s instructions.

- Waterproofing – Apply waterproofing following the manufacturer’s instructions. If you do not comply with the necessary standards, you risk the formation of leaks and the need to replace the completed waterproofing in 2-3 years.

- Protection – If necessary, protect the waterproofing coating made of the mechanical damage during filling. During the subsequent installation of the insulation, in no case attach the insulation to fungi, as you can damage the integrity of the waterproofing. To protect the work done and for the installation of additional drainage, it is recommended to attach a sike-shaped drainage membrane to the walls as a finishing layer.

Here you can read more information about the waterproofing of the basement:

- How to do waterproofing of the basement properly from the outside?

- Fungus and mold in the basement of a private house: Causes and how to get rid of it once and forever?

- How to make a basement recess properly below the sole of the foundation

- Waterproofing of the socle: Recommended materials and technologies

Prices for waterproofing work outside

| Name of works | Unit of measurement | Price in $ |

| Installing melting waterproofing on horizontalontal surface | m2 | 16 |

| Installing melting waterproofing on vertical surface | m2 | 18 |

| Installing a self-adhesive membrane on a horizontal surface | m2 | 16 |

| Installing a self-adhesive membrane on a vertical surface | m2 | 18 |

| Installing PVC membrane on a horizontal surface | m2 | 19 |

| Installing PVC membrane on a vertical surface | m2 | 21 |

| Application of polyurea | m2 | 28 |

| Application of mastic waterproofing | m2 | 17 |

| Application of liquid rubber spraying | m2 | 17 |

| Applying liquid rubber manually | m2 | 16 |

| Application of cement-mineral 2-component waterproofing | m2 | 22 |

| Application of polyurethane waterproofing | m2 | 22 |

| Application of penetrating compounds | m2 | 22 |

| Applying the primer | m2 | 15 |

Calculator for self-calculation of the cost of waterproofing

Wall waterproofing technology

Most builders are used to doing work to protect the walls of the basement and the foundation from the outside, roll-on-roll insulation, however, as modern practice shows, this is not the best choice and not the most durable. To make high-quality and durable waterproofing of walls from the outside, it is recommended to choose materials with the following characteristics:

- Minimum number of seams in the waterproofing coating

- Good grip on the surface.

- Large coefficient of stretching.

You can read more about waterproofing walls in the following articles:

- Waterproofing of the ribbon foundation: Technology and materials

- Waterproofing of foundation blocks and walls

- Waterproofing of bricks and masonry