Table of Contents

- Features of underground parking and its waterproofing

- When parking waterproofing is necessary and why leaks occur?

- Solving problems at the construction stage of the facility

- Waterproofing technology and methods in the operation and repair of underground parking:

- Waterproofing of the roof of the parking area or stylobate

- Waterproofing of the parking floor

- The cost of parking waterproofing services – price per unit

Features of underground parking and its waterproofing

Nowadays, there is a lot of talk about the importance of maintaining the parking structure and its quality. In recent years, technologies for the construction and protection of underground parkings and parking areas have improved significantly, giving operators and owners more control over the protection and preservation of their facilities, as well as encouraging more active and successful maintenance strategies. In addition, as a result of the recent economic downturn, many owners and management companies are looking for new opportunities to protect and maintain their existing parking lots and similar assets, rather than to build new facilities.

Today, most parking areas are located in shopping malls, business centers and new residential complexes, where management companies and Homeowner Associations monitor their reliability and operation.

There are two main categories of maintenance of such parking areas:

- Planned/preventive

- Repairing/Replacing.

The first is carried out on a regular basis to constantly maintain the quality of parking areas or car parks and the safety of the structure. It includes sweeping, garbage removal, flushing and periodic inspection of joints, doors, mechanical systems and other components. Any parking operator or employee can perform these tasks. A carefully constructed maintenance program will help to implement a consistent and regular maintenance schedule.

The second category — is the repair of the structure. The concept of repair includes a lot of aspects and technical problems that arise with the time of operation. One of the most common problems in such parking areas is the problem associated with water leaks in various sections of the structure, such as:

- Walls;

- Floor slabs;

- Parking roof (stylobate);

- Deformation and cold seams;

- Delivery points of communications.

When parking waterproofing is necessary and why leaks occur?

Leaks in the underground parking structure occur for several reasons:

- High-quality waterproofing was not done outside.

- The completed waterproofing has become unusable due to the end of its service life.

- The waterproofing made from the outside was done poorly.

Water penetration is one of the most harmful problems for parking or underground parking and it leads to premature destruction of the foundation, walls and floor slabs. Concrete is the main material used in the construction of underground parking areas, so the damage that humidity can cause is serious.

Moisture damage can sometimes be difficult to determine until it’s too late. There are situations when a certain parking area has been exposed to water from the outside, it has no problems. However, this opinion is erroneous and such a negative impact of humidity on concrete can lead to the formation of a small, and then large crack, the repair of which can be very expensive.

If cracks and leaks are ignored, this can lead to leaching and destruction of concrete, which occurs when water passes through it and begins to destroy it from the inside. If the process is started, it will take considerable time and money to eliminate the damage caused by such leaks.

Cracks in the floor can also lead to deterioration of the quality of floors and ceilings at lower levels, causing the upper concrete to peel off, creating potential safety deficiencies. In order to fully protect the concrete structure of the parking area in the event of leaks, it is necessary to perform work related to the waterproofing of the object without delay.

The most frequently in need of maintenance sections of the underground parking structure are:

- Supported entrance and exit ramps, spirals and turning lanes;

- Floor slabs;

- Cold concreting joints;

- Deformation seams.

- Communication entry points

These areas are most often at risk of cracking, leaking, leaching and chipping due to water damage.

Important: In the absence of high-quality and durable waterproofing on the outside of concrete, moisture is absorbed into concrete, freezes in winter, and thaws in spring, forming more and more microcracks and pores in concrete every year. If you ignore the moisture entering the concrete structures of the underground parking area, then sooner or later you risk getting a serious crack in the wall or the base of the parking area, which will require a lot of money for restoration work.

Solving problems at the construction stage of the facility

Poor waterproofing of underground parking in general and various concreting joints in particular are often the cause of damage to the structure of underground parking or parking areas. These shortcomings lead to the fact that water affects the building material and, accordingly, worsens its condition, which eventually leads to more serious consequences and leaks.

For high-quality parking protection at construction stage, it is necessary to pay attention to the following tasks:

- To ensure the construction of a parking area from the outside with good and durable protection from water, for example, with a seamless waterproofing of the type of liquid rubber;

- Take care of the correct sealing of cold joints, for example, with the use of hydraulic seals and sealants;

- Take care of sealing the deformation joints;

- Pay attention to all places where communications are entered

Waterproofing technology and methods in the operation and repair of underground parking:

If wet spots or leaks appear in the parking area, the maintenance service should respond immediately, since ignoring such serious problems can lead to deterioration of the underground parking area and the formation of destruction and microcracks in concrete, which eventually turn into serious cracks threatening the integrity of the underground parking structure as a whole.

During operation, the repair and restoration of waterproofing can be done from the inside or outside. As a rule, digging out the construction of an underground garage from the outside is a long and expensive undertaking, respectively, most operating organizations carry out repair work from the inside.

Repair of waterproofing of parking outside:

When repairing the waterproofing coating from the outside, a number of waterproofing materials can be used, such as:

- PVC membrane

- Surfaced waterproofing materials of the Technonikol Foundation type

- Coating compositions

- Roll waterproofing

- Liquid rubber

Double-component liquid rubber

The most effective material for waterproofing walls, foundations and roofs of underground parking is FlexLock-type liquid rubber from the German manufacturer Hydro, since it has no seams, cavities and under it and it has 100% adhesion to the concrete surface. Another advantage of this material is a high coefficient of tension, which is important when the building shrinks and the dynamics of certain movements.

Waterproofing repair from the inside:

If the parking area has already been built and if leaks occur, it is not possible to dig it out to restore the waterproofing coating from the outside, then there are several methods of waterproofing from the inside the concrete structure of the parking area:

When performing work from the inside, it is very important to pay due attention to the following elements:

- Deformation and working seams

- Pipe entry points

Injection waterproofing

The most popular method of waterproofing from the inside is injection waterproofing. Injection waterproofing can be applied when sealing cold and deformation joints, as well as when wet spots and leaks occur in the body of the concrete itself.

This type of waterproofing is carried out with the help of special equipment that, under pressure, pumps the injection compound into the seams or body of concrete, thereby squeezing existing moisture and water out of it and filling all voids, pores, holes and cracks. One of the most well-known materials designed for this kind of work is the injection material HydroInject и HydroInject Gel (for dynamic seams).

More information about the injection method of waterproofing can be found in the article – “Injection waterproofing“.

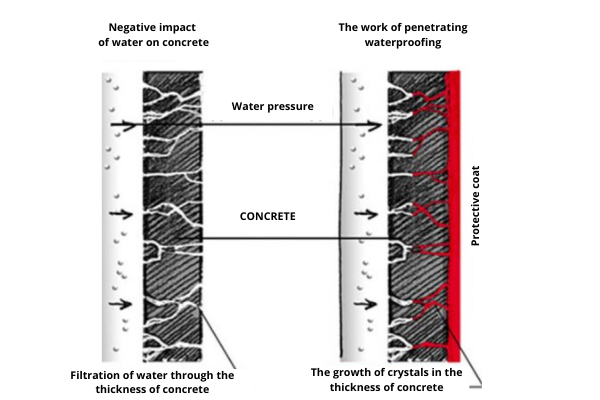

Penetrating waterproofing

This method involves applying a special penetrating material to the surface of concrete walls. Due to certain properties of penetrating insulation, the material penetrates into its structure with the help of abundant moisture of concrete, forming crystallized film. In real life, such materials are not very effective and cannot retain water in places of potential leakage.

You can read more about penetrating waterproofing in the article – “Penetrating waterproofing: A detailed description of its work on concrete, types of materials and application technologies“.

See the principle of operation of penetrating waterproofing:

Waterproofing of Deformation and working seams in the parking area

Another area, that is extremely important for protection against water penetration into the parking area is expansion joints and bends. These components cut through structures and allow movement as a result of expansion and compression of concrete due to temperature fluctuations. If these connections are not properly designed and installed, leakage into underground parking area may appear quickly enough, which will accelerate the destruction of the structure.

You can read more about penetrating sealing of various types of joints in the article – “Sealing and waterproofing of joints – concrete, cold and deformation ones“.

Insulation of places of output of communications

In any building there are places of entry of pipes of various diameters and places of passage of cables. These entry points should not only be properly mounted, but also carefully sealed. It is recommended to make passing the pipes through the sleeve or a special device.

If leaks are detected in the entry areas of pipes or cables, it is necessary to seal them using the following technologies:

- Injection of polyurethane resins

- Expandable sealants and hydraulic seals

- Installation of hydraulic seals

You can read more about the correct waterproofing technology of cable and pipe entry points in the article – Sealing and waterproofing of communication inputs into the building

Waterproofing of the roof of the parking area or stylobate

Another common problem in underground parking is the roof of the parking area. Often, the roof of the parking area is a stylobate part that is subject to dynamics and, accordingly, may leak due to poorly executed waterproofing of the roof.

As well as waterproofing the foundation walls, waterproofing the roof of the parking area, can also be done from the outside and from the inside, depending on the situation. When performing repair work from the outside, it is necessary to disassemble the pir of the roof or the stylobate part to the base slab and re-perform its waterproofing, taking into account all structural elements including deformation and cold seams.

Recommendation: when performing waterproofing of a roof or stylobate, it is best to use materials that form a seamless coating with 100% adhesion to the surface. The absence of seams and cavities under the coating is a guarantee of the durability and reliability of the coating

Waterproofing of the parking floor

The floor slabs of parking areas are also affected by the negative effects of moisture, and a number of problems due to the effects of extreme severe weather conditions. The floor slabs are also affected by vehicles that create vibration and movement of the slabs. It is extremely important to regularly seal and waterproof all vulnerable areas of the parking structure, including the floor slabs, in order to avoid problems caused by moisture. In addition, parking floors should have appropriate positive drainage slopes so that water can properly enter the drainage zones and exit the parking area.

Waterproofing of floors during construction can be performed with various materials, namely:

In the parking overlap allows moisture and water to pass through at the time of operation, then this problem can be solved with the help of injection insulation and mineral cement. Special tapes and sealants can also be used to seal cold and deformation joints in the floor slab.

You can read more about the waterproofing of the floor slabs in the article – “Waterproofing of floor slabs: Methods and materials“.

The cost of parking waterproofing services – price per unit

The prices, shown in the table are average and do not take into account the complexity of the services provided. To obtain an accurate calculation, price and estimate, we need to familiarize ourselves with the detailed technical specification or send a qualified engineer to inspect your facility.

Our engineer will be able to determine the severity of damage of the complexity of the work, make a detailed technical specification and recommend the right material. Based on the compiled Technical Specification, our Estimate Department will make a detailed Commercial Offer for you, indicating the price for each individual type of work and the total cost of services.

Prices for the insulation arrangement from the outside:

| Description of work | Unit of measurement | Price in $ |

| The arrangement of the surfaced waterproofing horizontally | m2 | 10 |

| The arrangement of surfaced waterproofing vertically | m2 | 15 |

| The arrangement of a self-adhesive membrane horizontally | m2 | 10 |

| The arrangement of a self-adhesive membrane vertically | m2 | 20 |

| The arrangement of PVC membrane horizontally | m2 | 25 |

| The arrangement of PVC membrane vertically | m2 | 30 |

| Application of polyurea | m2 | 60 |

| Application of mastic waterproofing | m2 | 10 |

| Application of liquid rubber by spraying | m2 | 10 |

| Application of liquid rubber manually | m2 | 15 |

| Application of cement-mineral double-component waterproofing | m2 | 30 |

| The arrangement of polyurethane waterproofing | m2 | 30 |

| Application of penetrating compositions | m2 | 30 |

| Application of primer | m2 | 10 |

Prices for the insulation arrangement from the inside:

| Description of work | Unit of measurement | Price in $ |

| Waterproofing of cold joints: -Works on the arrangement of indenting -clearing the indenting -layer-by-layer sealing of non-shrinkable composition | running meter | 30 |

| Waterproofing of interblock joints: – Works on the arrangement of indenting -clearing the indenting -layer-by-layer sealing of non-shrinkable composition | running meter | 25 |

| Waterproofing of deformation joints: -Works on the arrangement of indenting -clearing the indenting -sealing of the elastic profile -sealing of non-shrinkable composition -complex of works on injection | running meter | 250 |

| Injection waterproofing of seams / cut-off waterproofing -Works on the arrangement of indenting -clearing the indenting -layer-by-layer sealing of non-shrinkable composition -Works on the arrangement of boreholes and installation of packers -complex of works on injection -packers demounting and sealing of injection holes | running meter | 60 |

| Injection waterproofing into the body of concrete -dimensioning, Works on the arrangement of boreholes and installation of packers -complex of works on injection – packers demounting and sealing of injection holes | m2 | 70 |

| Injection waterproofing into the body of brick -dimensioning, Works on the arrangement of boreholes and installation of packers -complex of works on injection -packers demounting and sealing of injection holes | m2 | 80 |

| Cement-mineral waterproofing | m2 | 30 |

| Penetrating waterproofing | m2 | 30 |

| Waterproofing of places for the input of communications: -Works on the arrangement of indenting -clearing the indenting – layer-by-layer sealing of non-shrinkable composition -Works on the arrangement of boreholes and packers assembly – complex of works on injection -packers demounting and sealing of injection holes | piece | 350 |