Table of Contents

- Why is concrete floor waterproofing necessary?

- How to properly waterproof a concrete floor?

- Types of materials and methods of their application

- Waterproofing of the floor price for work

- Waterproofing the floor with your own hands: step-by-step instructions

- Repair of waterproofing of concrete floors

When we talk about waterproofing and protecting the concrete floor in a private residential building or commercial building, we usually do not mean a screed, but a base plate, which serves not only as a rigid base on which we talk but also as a cut-off between the ground and the living space. In this article, we will tell you in detail about the methods of waterproofing this structure.

Why is concrete floor waterproofing necessary?

Concrete — is a porous structure that absorbs water and moisture like a sponge and can pass through itself into the room. For this reason, in the absence of high-quality waterproofing, moisture, groundwater, and surface water can freely penetrate the concrete, thereby provoking the following consequences:

- Destruction of concrete– Water contains salts, minerals, and various impurities that negatively affect any concrete;

- Formation of cracks in the floor – water is absorbed into the concrete base of the floor and leads to a gradual growth of capillaries and pores in the concrete, which eventually leads to the formation of microcracks, and then full-fledged cracks in the floor;

- The appearance of mold and mildew-In the absence of insulation, the floor slab will always be wet, as it absorbs water, which leads to increased humidity in the room. In turn, increased humidity promotes the growth of fungus and mold in the room, which greatly harms human health;

- Flooding – If the floor does not have properly made waterproofing then water can go through it and floor the house, basement, or other structures.

How to properly waterproof a concrete floor?

To properly perform waterproofing of a concrete floor, it is necessary to understand not only what kind of materials you need to use for this, but also how to position it correctly. In some cases, the protection of the floor made of concrete should be located not only on it but also under it, to prevent the water under the house from affecting the concrete and thereby destroying it over time.

Waterproofing under a concrete floor or waterproofing of the floor on the ground

It is necessary to apply waterproofing under the future floor when it comes to a field in the basement of a private house or commercial building.

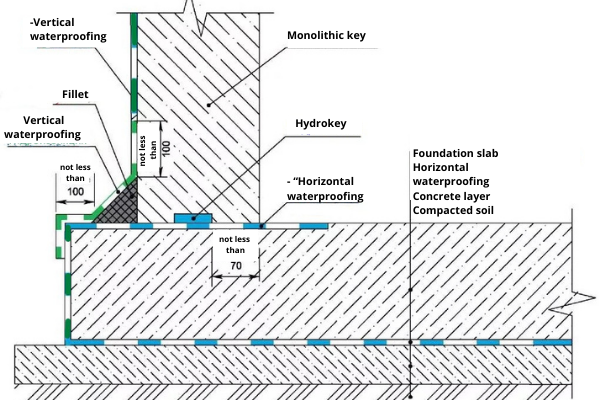

The main waterproofing of the floor should be located under it so that the water under a private house or commercial building. The main waterproofing of the floor should be located under it so that the water under a private house or administrative building could not affect and soak into the concrete floor itself. To do this, you should first make a concrete preparation, and then apply waterproofing to it. After applying to waterproof, a reinforced frame is made and a plate is poured, which serves as the main floor. Waterproofing is not done on the ground, but is done on concrete and serves as floor protection from water and moisture in the ground.

Important: The most common mistake when installing waterproofing under the floor is that waterproofing is applied directly to the ground or another unstable base so that it quickly becomes unusable since it does not withstand the dynamics of the soil base. Waterproofing should be applied to a rigid and stable foundation, which is why the first thing under the construction of the floor is concrete preparation, which is applied waterproofing

The scheme of the waterproofing installation under a monolithic floor:

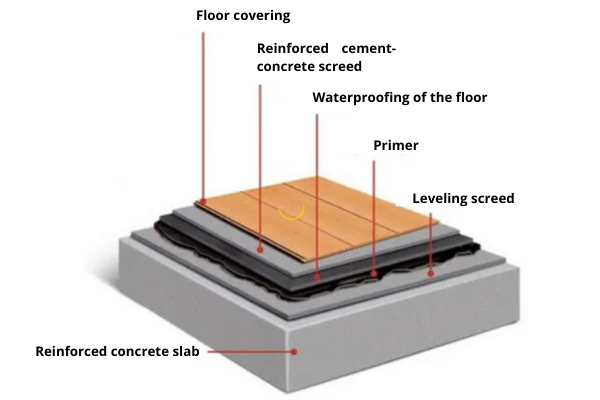

Waterproofing over the concrete floor and under the screed

Waterproofing over the concrete floor is recommended to be applied before the screed installation in the following cases:

- When it comes to the impoverished wet zone, where the kitchen, bathroom, line-by-line, workshop or other premises related to the use of water will be located;

- When it comes to the basement of a private residential building, building, or structure.

In the basement, after the protection installation under the future floor, the monolithic floor itself is poured directly. Despite the cut-off waterproofing located under the made floor, it is also recommended to apply waterproofing to the floor itself before the screed installation. It is recommended to apply waterproofing under the screed, especially if we are talking about wet areas or a field in the basement or socle, under which there is a ground layer. This additional protection under the mounted screed serves as a second waterproofing circuit and will be very useful if the first circuit eventually begins to let water pass into the basement or socle of the house.

Types of materials and methods of their application

To qualitatively make the future protection of the floor made of concrete, it is necessary to choose the right waterproofing materials. Next, we will study the main types of materials.

Important: When choosing a suitable material, you should not choose according to the principle of the cheaper the better. In most cases, higher-quality materials are more expensive, since higher-quality ingredients are used in their manufacture and expensive components are added in a higher proportion than those of cheap analogs. Do not forget that if the waterproofing is violated, the cost of its alteration will be at least 2 times more expensive than initially making high-quality insulation. This is not counting the cost of possible repairs due to flooding.

Pasting

This category includes roll-up gauntlets that have an adhesive base and are mounted by the existing adhesive base to the surface. The pasting panels are mounted overlapping each other in 1-2 layers.

You can download detailed installation instructions by clicking on the link – Installation instructions for pasting insulation

You can read more about roll systems in the article – Roll waterproofing installation.

Coating

We are talking about various kinds of mastics based on bitumen, polyurethane, or acrylic. These compositions are applied using a roller or brush in 2-3 layers. When applying each subsequent layer, it is necessary to wait for the previous one dry. The most popular material in this category is bitumen-based mastics.

Surfaced

Here we are talking about surfaced roll materials. These systems are deposited on the surface using a burner. When the bitumen layer melts, the rolls are glued to the base, creating a barrier for water and moisture. When it comes to the field of a basement, the roll-on insulation is applied in 1-2 layers, depending on the presence or absence of groundwater. The rolls should be overlapped on top of each other and when the second layer is overlaid, the seams of the previous one should be overlapped.

You can read more about roll systems in the article – Roll waterproofing installation.

Liquid rubber

Liquid rubber — is a bitumen-latex emulsion. Liquid rubber is applied manually by coating it or by spraying it. When applying the LC, a seamless, elastic coating with 100% adhesion to the base is formed on the surface. The absence of seams and high elasticity make this type of insulation extremely effective and durable. High-quality liquid rubber is capable of serving at least 50 years.

You can read more about the liquid rubber in the article – “Waterproofing with liquid rubber“.

Cement

Cement compositions — are those materials that have a cement base to which various polymers are added. Cement and polymer-cement compositions are applied by coating in 2-3 layers on a dry or slightly damp concrete surface. High-quality polymer-cement compositions can withstand negative water pressure from the outside to the inside.

You can read more about cement insulation in the article – “,“.

Waterproofing additives in concrete

Additives in concrete help to improve its properties in terms of strength and water resistance. Additives in concrete should be added at the time of its preparation, clearly following the instructions.

Important: No additives and additives to concrete can change its porous structure and make it completely waterproof, that is why when using any additives, it is necessary to do waterproofing.

Comparative table of materials

This table shows the advantages and disadvantages of the main materials mentioned above. Studying them will help you better understand each material and make the right choice.

| Liquid rubber | Bitumen-based coating mastic | Surfaced and pasted membranes | Cement | |

| Work on negative water pressure from outside to inside | Not available | Not available | Not available | Available |

| The ability to apply to a wet surface | Not available | Not available | Not available | Available |

| Seams and joints in waterproofing coating | Not available | Not available | Available | Not available |

| 100% adhesion to the base | Available | Available | Not available | Available |

| High coefficient of elasticity | Available | Not available | Not available | Available |

| Efficient operation at high ground waters and in an aggressive environment | Available | Not available | Not available | Available |

| Warranty period for works | 7 years | 3-5 years | 3-5 years | 7 years |

Conclusions

For the installation of a high-quality waterproofing coating under the floor, it is best to use seamless waterproofing systems with a high coefficient of elasticity and 100% adhesion to the base (so that there are no voids and cavities under the material), and with the dynamics and movement of the structure, it does not tear and does not diverge at the seams, but stretches.

Examples of such systems:

- Liquid rubber – by the type of FlexLock. It is used as a layer between the concrete preparation and the floor, as well as between the floor and the screen. This material does not withstand negative pressure and, accordingly, requires clamping, for example, with a screed.

- Polymer cement system – HydroPaz Prime. It can be applied to a slightly damp base, which saves time waiting for the concrete to dry completely. It works on negative water pressure, which allows you to use this insulation without the need to press it with a screed, which allows the performer to use it as a finish and immediately put tile on it.

Waterproofing of the floor price for work

Prices for work depend on the complexity of their implementation and the selected material. The prices shown in the table may vary depending on the season, complexity, and distance to the object.

| Works description | Unit of measurement | Price in $ |

| Work on the installation of surfaced rolls in 1 layer | m2 | starting from 6 |

| Work on laying the pasting membrane in 1 layer | m2 | starting from 6 |

| Work on the installation of mastic insulation in 1 layer | m2 | starting from 3 |

| Works on the installation of liquid rubber | m2 | starting from 10 |

| Works on the installation of a cement system | m2 | starting from 10 |

| Works on the installation of polyurethane mastic | m2 | starting from 10 |

| Applying the primer | m2 | starting from 3 |

Calculator for self-calculation of the cost

Calculation of waterproofing cost

The total cost of waterproofing

Waterproofing the floor with your own hands: step-by-step instructions

If you want to do all the work on the insulation of the floor of a private house with your own hands, then you need to follow the following step-by-step instructions:

If there is a concrete floor:

- The floor surface should be cleaned of dust and dirt;

- The floor should be carefully primed with a special primer (it has its own for each material);

- Apply waterproofing acting strictly according to the instructions specified by the manufacturer;

- During the subsequent installation of finishing elements, it is recommended to apply a screed on the top of the insulation, and then install a tile or other finishing material on it.

When erecting a new concrete base slab as a floor (relevant in basements and underground socle floors of the house):

- First of all, it is necessary to make a rigid concrete base on which insulation will be applied to the ground. This base is recommended to be made in 8-10 sm with reinforcement with a metal mesh;

- It is necessary to lay or apply insulation on a rigid base with an approach to the vertical of the walls;

- To make a reinforced frame in 2 rows for poring the future slab, which will serve as the basement floor;

- To install a bentonite profile (swelling cord). This is necessary to seal future cold seams that are formed between the new slab and walls;

- To pour the concrete base with the addition of special additives that improve the properties of concrete;

- To make a second waterproofing circuit on top of the flooded slab.

The scheme of the waterproofing arrangement:

More information on the topic:

- Waterproofing of the foundation slab methods and materials

- How to make a basement recess properly from the bottom of the sole of the foundation

- ,

Where it is possible to buy high-quality waterproofing at low prices on my own?

If you need high-quality building materials, then going to construction markets, small shops along the road and various shops are not for you, since in all these places you can run into fake, expired goods that have lost their basic properties or simply low-quality products. As experts in our field, we recommend contacting only trusted suppliers and large construction hypermarkets.

As advantages of self-purchase of construction supplies in large construction stores, we can highlight the following aspects:

- Low prices

- Convenient online purchase

- Delivery to the construction site within 2 hours from the moment of online purchase.

Repair of waterproofing of concrete floors

Often, the floor made in the basement of a private building or house begins to let water pass into the house or building. If this is the case, it means the or the from the bottom (on concrete preparation) or on it. In this case, these nodes can be repaired in 2 ways:

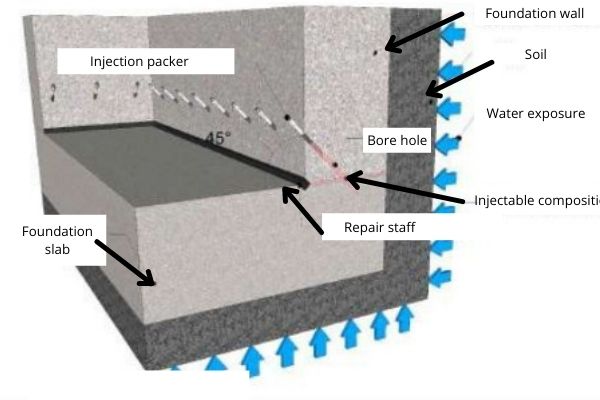

1. Injection waterproofing – with the help of injection, it is possible to seal cold seams effectively through which moisture and water enter in the first place since they are the weakest point of almost any structure.

2. Polymer cement or cement waterproofing working on negative water pressure-these compounds are applied to the floor with a small approach to the walls.

The scheme of repair of waterproofing of floors using injection: