Table of Contents

- Technologies and methods of Terrace and balconies waterproofing

- Materials

- The arrangement of terrace waterproofing with your own hands- recommendations on how to make waterproofing properly

- Flat terrace waterproofing

- Terrace waterproofing and repair services

- Prices for waterproofing application

A terrace is a kind of exploited plane that can be built in a private residential building or in an administrative building. Terraces can be open without a canopy or roof, or closed with a roof. Terraces may be located above the living space or it may not be under them. Some terraces are located on an elevation as balconies or exploited roofs, and some at ground level. The most vulnerable constructions of terraces in terms of the impact of water and precipitation on them are structures made in an open way (without a roof). It is the outdoor terraces that most need high-quality waterproofing, since a large amount of precipitation falls on them.

Technologies and methods of Terrace and balconies waterproofing

Waterproofing should be applied to the floor slab or foundation at the time of construction of the house. There are several basic methods of waterproofing balconies and outdoor terraces:

- The installation of seamless systems with 100% adhesion to the surface – This category includes waterproofing materials that form a single coating with 100% adhesion to the base without seams and joints. The most famous materials in this category are liquid rubber, polymer-cement compounds, polyurethane mastics and polyurea.

- Arrangement and installation of various roll and PVC membranes – This category includes all possible roll materials, bitumen and PVC membranes. These materials have seams and do not have 100% adhesion to the base.

Materials

When it comes to waterproofing balconies or terraces, it is important to choose the system most suitable for the existing situation, regardless of whether it is a new design or repair of a previously existing balcony. Today, there are masses of materials on the market for the protection of terraces, exploited roofs and balconies, but it is important to understand that different compositions are suitable for different situations and methods of protection.

Liquid rubber

Waterproofing with liquid rubber, can be applied by spraying or manually. The application of high-quality liquid rubber is mainly when the applied material is not a finishing coating, since not all liquid rubbers are resistant to ultraviolet (solar radiation). Liquid rubber is best applied to the floor base when additional elements such as insulation, screed, etc. are mounted on top of it.

Bitumen mastic

Made on the basis of bitumen. Bitumen is a solid composition insoluble in water, which is a mixture of hydrocarbons and their nitrogenous, oxygenated, sulfurous and metal-containing derivatives. The density of bitumen is 0.95-1.50 g/sm3, its properties depend on the quality of the oil and other additives included in the mixture. Fairly cheap and primitive materials, which in most cases will not withstand water pressure for a long time.

Polymer systems and polyurea

They are ideal for waterproofing arrangement as an intermediate and finishing coating, as they have the following qualities:

- No seams

- 100% adhesion to the base

- Resistance to mechanical impact and damage

- Resistance to UV and solar radiation

- Subject to tinting in different colors.

You can read more about these waterproofing systems in the following articles:

Polymer-cement compositions

Polymer cement waterproofing is great for the arrangement on the terrace floor or before installing tiles. If a tile is planned to be installed as the final finishing element, then unlike other waterproofing systems, it can be placed directly on the polymer-cement waterproofing without the need to protect it with a screed.

You can read more about cement types of waterproofing in the article – “Cement-based waterproofing: Features, types, and methods of application“.

PVC Membranes

It is not the most successful material for protecting the terrace from water penetration, since the material lies on the surface of the carpet and has joints between the rolls. When water passes through a weak joint, it enters the membrane carpet and begins to stagnate there, moving from one corner to another.

You can read more about membrane waterproofing in the article – “Membrane waterproofing: Types of materials and methods of their arrangement”.

Surfaced bitumen membranes

As in the situation with the PVC system, bitumen surfaced rolls have seams and do not have 100% adhesion to the surface. Due to the presence of such weak elements as seams, water will sooner or later pass under the waterproofing layer, which will lead to a violation of the integrity of the coating and its deformation.

Comparison table between different materials and their main characteristics:

| Liquid rubber | Polyurethane waterproofing | Polymer cement | Surfaced waterproofing | PVC membrane | |

| Mounting method | Non-firing | Non-firing | Non-firing | Firing with a burner | With a hair drier and mechanical fixation |

| Availability of seams | Not available | Not available | Not available | Available | Available |

| Adhesion to the base | 100% | 100% | 100% | 40% | No adhesion |

| Coefficient of elasticity | 600-800% | 300-800% | 100-300% | 10-20% | 10-20% |

| UV resistance | Not available | Available | Not available | Available | Available |

| The warranty period for works | 7 years | 7 years | 7 years | 3-5 years | 1-2 years |

Ideal waterproofing material for terrace waterproofing:

Ideal material for waterproofing arrangement should have the following characteristics:

- Absence of seams and joints. The weakest node in any waterproofing is the seams and joints, since they diverge first, respectively, a good composition, when applied, will not form seams.

- Adhesion or adhesion to the surface. A good composition will always have maximum adhesion to the surface so that cavities and cracks do not form under it, through which moisture can walk or stagnate.

- Elasticity. A good composition will have a high coefficient of elasticity. It is the elasticity of the material that prevents its further rupture during shrinkage of elements or dynamics (mobility) of the structure).

- UV resistance. This is important if the waterproofing coating is an open finishing layer.

If the waterproofing coating goes as a finish:

If we are talking about waterproofing as a finishing open coating, then it is best to use polyurethane waterproofing compounds of the PolyFlex type (German manufacturer HYDRO). Since they have no seams, they have 100% adhesion to the surface, a high coefficient of elasticity, resistance to ultraviolet (solar radiation), as well as different colors (which are ideal for finishing an open layer).

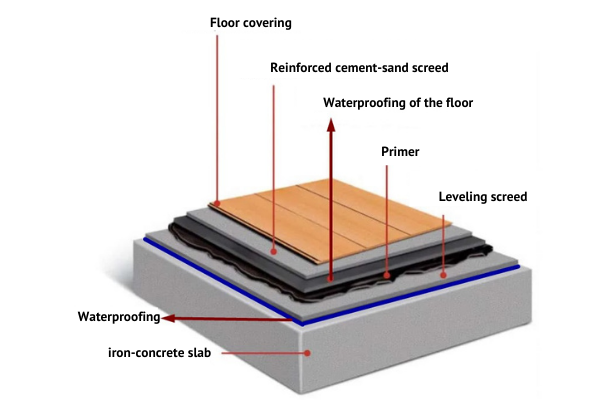

If the waterproofing coating is part of the layers:

If the waterproof material is in the layers itself, then it does not have to be UV-resistant and have a different color palette, respectively, in this case, for the arrangement and installation of a reliable waterproofing layer, it is best to use double or single-component liquid rubber, like FlexLock or FlexLock Pro or double-component cement-mineral compositions like HydroPaz.

These materials have no seams, have 100% adhesion to the surface, as well as a large coefficient of tension. And they look good in an open space.

The arrangement of terrace waterproofing with your own hands- recommendations on how to make waterproofing properly

Half measures:

When detecting leaks of the terrace, one of the most economical solutions is to apply waterproofing on top of the finish coating, tile, or screed, without dismantling the entire layers,

to the base plate. When choosing this solution, you save on dismantling and garbage removal, as well as on restoring the floor screed and insulation. But this method has a rather big drawback – the water that has penetrated into the layers of your terrace has not gone anywhere, it has remained in the layers, respectively, it can continue to form wet spots on your ceiling for quite a long time, despite the new waterproofing layer.

Recommended:

If we are talking about an existing terrace that is leaking, then to eliminate leaks, you will need to dismantle all existing elements of the floor finishing, up to the base plate – tiles, screed, insulation, etc. After that, when installing waterproofing, it is recommended to touch on 2 important structural elements in your outdoor terrace – the seams and the base plate.

- The joining seams of the slab wall are the weakest points in any structure, and special attention should be given to their waterproofing. To protect the seams, it is recommended to point them up (make a swallow-shaped hole), and seal the expanding sealant in layers in the resulting cavity according to the HydroExpand type, thus strengthening the weakest point. The second option is the installation of a special waterproofing tape or reinforced fillet with an additional layer of waterproofing, at the seams of the junction.

- Base plate – The selected composition should be applied to the base plate, having previously prepared the surface depending on the selected waterproofing coating. When preparing for most of the components, it is recommended to perform the so-called fillet (small baseboard) at all junctions to the constructs (walls, steps, etc.), so that the transition of the waterproofing material from the vertical to the horizon is smooth (and not 90 degrees). Thus, the floor-wall coating will not disperse and will not crack when moving from the horizon to the vertical.

Flat terrace waterproofing

To choose the right waterproofing, first of all, it is necessary to decide whether it needs to be carried out anew or whether it is a question of restoring an existing waterproofing coating of a balcony or terrace. This assessment allows you to understand which method is best to apply, and which services to order. In order to make a balcony or terrace waterproof, first of all, it is necessary to assess the existing conditions of the treated surface because depending on the state of preservation of the surface of the terrace on which you want to apply to waterproof, those decisions and various steps that will need to be performed for high-quality waterproofing of both the walls and the floor of the balcony depend.

The first thing to assess is the condition of the existing terrace floor covering, that is, its visible layer. This assessment can be carried out, for example, by checking all the seams visible on the floor, as well as the seams of the floor-wall junction, because in most cases it is from the seams of the floor that water begins to seep.

Consequently, the water that penetrates through the seams will begin to penetrate into the structure of the outdoor terrace, soaking into the elements of the layers (screed, insulation, stove, etc.), which will lead to serious damage to all elements, both the floor and the walls. In parallel, you can check the condition of the floor, there are cracks, chips, and holes through which water can penetrate. After you have examined the surface of the floor or slab of your terrace, you need to decide which composition to use for the arrangement of a protective coating. It is also important whether this structure is open or not.

Terrace waterproofing and repair services

Waterproofing the terrace is a very responsible job, since it depends on the quality of this service, and whether you will have leaks in the future or not. That is why when choosing a contractor who will provide such services, it is worth choosing a large company whose specialization is waterproofing.

An engineer of such a company should come to your facility, see what its features are, make measurements, and draw up a technical specification, with a list of necessary measures and services for high-quality waterproofing. If we are talking about a large company, providing waterproofing services, then it is unlikely that an engineer who has arrived at your facility will have all the prices for the entire list of services.

Most likely, the technical task made by him will be transferred to the estimating department, which will calculate the cost of waterproofing services, and then send you a detailed calculation, where all the work and materials used will be listed. Whether it is open or closed type. If the contractor firm is confident in its abilities and in the quality of the materials used, then the guarantee for its services should be at least 6-7 years.

Prices for waterproofing application

Below is given the table for works, related to waterproofing. The indicated prices may change.

| Works description | Unit of measurement | Price in $ |

| Works on the arrangement of surfaced waterproofing | m2 | 5 |

| Works on the arrangement of PVC membrane | m2 | 8 |

| Works on the arrangement of polyurea | m2 | 12 |

| Works on the arrangement of mastic waterproofing | m2 | 3 |

| Works on the arrangement of the liquid rubber by spraying | m2 | 4 |

| Works on the arrangement of liquid rubber manually | m2 | 5 |

| Works on the arrangement of cement-mineral double-component waterproofing | m2 | 8 |

| Works on the arrangement of polyurethane waterproofing | m2 | 8 |

| Application of primer | m2 | 1,5 |