Table of Contents

- Is it necessary to make waterproof the concrete surface?

- Types of waterproofing materials for concrete and methods of their construction

- The best waterproofing of concrete

- How to make concrete waterproofing – concrete waterproofing arrangement with your own hands in stages

- Waterproofing of concrete works

- Waterproofing of concrete price for work

- Repair of concrete waterproofing

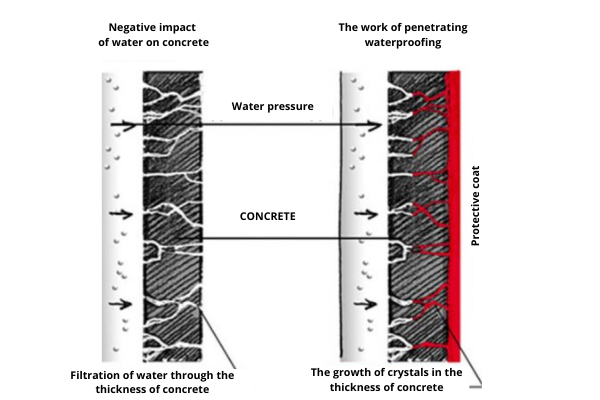

Concrete– is a permeable and porous compound that absorbs water. Pollutants and chemical elements carried by water cause deterioration of the quality of concrete, after which cracks may form in it, and it may become unusable. Waterproofing of concrete is the application of waterproofing material to concrete to protect it from water penetration. It is thanks to the waterproofing installation that the structure made of concrete remains protected without letting moisture pass into the room.

Is it necessary to make waterproof the concrete surface?

The answer to the question “is it necessary to do waterproofing of concrete?”, is unambiguous – of course, it is necessary, otherwise the concrete may collapse over time.

Advantages of a waterproofing installation for a surface made of concrete:

- The absorption of liquids by concrete will be reduced.

- Preventing the formation of cracks on the concreting surface.

- Increasing the service life of the concrete structure.

- Prevent rusting of fittings.

- Prevention of dampness inside the building.

- Prevent water seepage from the ceiling and walls.

- Reduction of building maintenance costs.

- The value of the property will be increased because no one wants to buy a house with water leakage problems.

The main advantages of performing waterproofing works described above relate to external waterproofing since it is the performance of work outside that guarantees the protection of concrete from moisture penetration into its structure.

Waterproofing should be applied to all concrete foundations that are underground and/or exposed to water and moisture:

Types of waterproofing materials for concrete and methods of their construction

Waterproofing of any surface, including concrete, should be done at the construction stage of a private house, building, or any other structure. When performing repairs and works related to the elimination of leaks, certain types of waterproofing can be applied, including from the inside.

Types of waterproofing materials:

- Penetrating;

- Liquid additives in concrete;

- Coating;

- Surfaced, glued, and mounted;

- Sealants;

- Liquid rubber.

Penetrating materials

Crystal-based systems are usually available in the form of dry powder. Crystal systems actually use water to grow crystals inside the concrete, effectively closing the way for moisture, which can damage the concrete itself, forming a kind of water barrier. Penetrating mixtures are mainly used as auxiliary ones since in most cases they will not work where the concrete has voids, is poorly vibrated, or damaged, and these are exactly the places that, as a rule, are prone to leaks.

You can read more about this type of waterproofing in the article – “Penetrating waterproofing: A detailed description of its work on concrete, types of materials and application technologies“.

Waterproofing additives in concrete

Additives, are added to concrete in a certain proportion at the factory at the manufacturing stage or directly when working on site. The substances enter into a chemical reaction inside the concrete, which turns the concrete itself into waterproof. Integral concrete waterproofing systems can be seals, water-repellent substances or crystalline impurities.

The main additives are:

- Hydrophobizers

- Waterproofing additives

Hydrophobizers

Hydrophobizers — are various additives and impregnations that make concrete hydrophobic. They are based on silicates, organic solvents, and water.

These additives can improve the properties of concrete in terms of:

- Frost resistance;

- Elasticity;

- Service life;

- Waterproof;

- Resistance to chemical influences.

Hydrophobizers are supplied in a liquid state in the form of concreting or ready-to-use compositions and are used in two ways:

- They are added in the process of making a concrete mixture.

- They are applied to the finished surface.

Waterproofing additives

These additives improve the water-resistance of concrete, making it less susceptible to absorption and penetration of moisture and water. Additives are added to the concrete at the stage of mortar preparation and are divided into several types:

- Polymer;

- Plasticizing;

- Colmatating.

Coating waterproofing and mastics for concrete

This method includes materials applied to the surface by a coating method. Coating materials — are mainly mastics applied to the surface with a brush or roller.

The main types of coating compositions include the following mastics:

- Bitumen – Mastics, made on a bitumen basis with the addition of various polymers.

- Polyurethane – The main component of such mastics is polyurethane.

The main advantages of coating insulation:

- Absence of seams in the formed coating.

- Good grip on the surface.

Disadvantages:

- Cheap mastics available in construction markets and shops do not always have the necessary qualities for durable and reliable waterproofing.

- The slightest violation of the technology of mixing and applying the composition will lead to the loss of its properties.

Impregnations for concrete

Impregnations are applied to concrete with a roller or brush and are divided into 2 types depending on the composition:

- Organic polymer – when used, the fill the pores of the concrete, giving the surface the ability to repel water.

- Inorganic silicate – react with external molecular compounds. As a result, the strength and water resistance of the concrete surface are improved.

Today the most popular impregnations — are organic. They are divided into the following types:

- Acrylic – is made on the basis of acrylic and protects against moisture penetration.

- Polyurethane – More effective than acrylic. Provide concrete resistance to aggressive environment, chemicals and moisture.

- Epoxy– made on an epoxy basis with the use of a hardener as a second component. Epoxy impregnations improve the water-resistance and strength of concrete.

Glued and surfaced materials for waterproofing concrete surfaces

When we talk about surfaced and mounted insulation materials, we mean several basic types:

- Bitumen-based membranes – Rolled surfaced and self-adhesive membranes.

- PVC membranes

Bitumen-based membranes

Bitumen and roll membrane is one of the most popular methods of concrete protection. Bitumen membrane can be surfaced (its installation occurs with the help of a burner and a fire) and self-adhesive. For the installation of the surfaced membrane, fire is used. The fire is necessary for bonding with the surface, with the help of it the bitumen layer is melted and glued to the outer surface.

Self-adhesive membranes consist of asphalt, polymers, and various fillers. These materials are very sticky to the outer surface, viscous, and waterproof.

Advantages:

- Affordable and relatively inexpensive materials.

Disadvantages:

- When gluing rolls, seams are formed, which eventually diverge and begin to pass water.

- There is no full-fledged adhesion to the surface.

- The self-adhesive type has a low shelf life since the binders eventually become unusable and lose their protective properties.

- If the insulation technology is not followed, the effectiveness of the insulation coating will be catastrophically low.

You can read more about the different types of roll waterproofing in the following articles:

- Roll waterproofing installation with detailed installation instructions

- Membrane waterproofing: types of materials and methods of their arrangement

Sealants

Sealants are used mainly when it comes to sealing joints in the concrete foundation or walls. Sealants are also used to eliminate local leaks and cracks in concrete.

There are several different types of sealant:

- Polyurethane – designed for sealing seams. It has a water-resistant and viscous structure that does not allow it to flow down the wall, which makes it an ideal composition for sealing vertical concreting joints.

- Thiokol – basically contains polysulfides. They are resistant to chemical influences and have high elasticity.

- Acrylic – mainly used for interior work. With the use of these sealants, it is possible to seal up seams and small cracks in concrete. Since there are no solvents in the composition of this sealant, it can not be covered with an additional protective layer.

- Silicone– made on the basis of neutral silicone. The main advantage of silicone compounds will be high elasticity coefficients.

Liquid rubber

Liquid rubber – forms a coating in the form of a membrane, which usually consists of a primer layer and a layer of waterproofing film, which are applied by spray or roller to the surface. Liquid rubber provides serious protection against water penetration, forming an elastic and waterproof coating on the applied surface.

the durability of the protection depends on the type of polymer used to make the material.

Liquid rubber, is a bitumen mixed with latex. This method is best suited for protecting foundations, walls and other structures made of concrete, FBS blocks and bricks, as it has a number of advantages:

- No seams on the surface.

- 100% adhesion to the surface.

- Large coefficient of elasticity.

The best waterproofing of concrete

For each case and structure, its own method of protection is suitable, respectively, it is difficult to determine the best material or the best method of waterproofing. Nevertheless, a good material for waterproofing concrete from the outside should necessarily have the following properties:

- No seams. Seams— are the weakest points in any protection against moisture and it is the seams that are the fits to diverge and let the liquid pass through.

- Adhesion to the surface. A good material should have 100% adhesion or adhesion to the surface so that cavities and voids are not formed under it, in which water will walk and stagnate.

- Elasticity. A high coefficient of elasticity will allow not to crack and not tear during shrinkage of the building or the dynamics of the structure.

- No seams. Seams— are the weakest points in any protection against moisture and it is the seams that are the fits to diverge and let the liquid pass through.

- Adhesion to the surface. A good material should have 100% adhesion or adhesion to the surface so that cavities and voids are not formed under it, in which water will walk and stagnate.

- Elasticity. A high coefficient of elasticity will allow not to crack and not tear during shrinkage of the building or the dynamics of the structure.

Another important recommendation regarding better protection – is that good materials cannot be cheap, since they should have high-quality components.

How to make concrete waterproofing – concrete waterproofing arrangement with your own hands in stages

1st step: Surface preparation

first of all, you need to clean the surface thoroughly from lagging elements, loose materials, dust, and oil. Surface cleaning plays a very important role in the arrangement of all waterproof coatings.

2nd Step: Applying the primer layer

Apply a primary layer of base paint (primer) to the surface of the structure. Different primers are suitable for different materials, for example, solvent-based or water-based primers are more suitable for bitumen membranes.

3rd Step: Applying waterproofing material

Work, related to the application of waterproof composition is one of the most important points in the insulation installation, respectively, before applying a particular material, you need to read the instructions for its arrangement and assembly.

4th Step: Protection

some waterproof coatings require protection from mechanical damage. For example, when filling walls or houses.

Waterproofing of concrete works

Considering the above, well-made concrete protection is very important. It is extremely important to choose the right waterproofing material, prepare the surface for work, and then apply this or that insulation. To do this, it is best to contact a large and professional company whose specialization is the waterproofing arrangement.

When contacting such a company, pay attention to the fact that this company works with different types of waterproofing, since if it works only with certain methods and materials, it will offer them sometimes even to the detriment of your interests. Do not skimp on materials and do not try to do the work yourself, since waterproofing from the outside of your structure is the basis of its reliability and one of the most difficult elements to pay attention to during the construction work, and not after its completion.

If the building has a basement then a poor-quality installation of waterproofing will lead to the fact that in a year or two you will have to dig out the old waterproofing and re-install and fill everything in, and this is a big expense, not to mention the interior decoration damaged as a result of leaks.

Waterproofing of concrete price for work

| Description of work | Unit of measurement | Price in $ |

| Work on the arrangement of surfaced waterproofing | m2 | 10 |

| Work on the arrangement of PVC membrane | m2 | 20 |

| Work on the arrangement of polyurea | m2 | 30 |

| Work on the arrangement of mastic waterproofing | m2 | 28 |

| Work on the arrangement of liquid rubber by spraying | m2 | 28 |

| Work on the arrangement of liquid rubber manually | m2 | 10 |

| Work on the arrangement of cement-mineral double component waterproofing | m2 | 60 |

| Work on the arrangement of polyurethane waterproofing | m2 | 60 |

| Applying the primer | m2 | 8 |

The exact price of waterproofing depends on many factors, including the type and cost of materials, the complexity of the work, distance from the center, etc… taking into account these factors, the prices for carrying out work to protect your home may vary. To obtain accurate calculations and quotations for the total cost and price per 1m2, it is recommended to call an engineer from a company specialized in these works.

Concrete Waterproofing Cost Calculator

Calculation of waterproofing cost

The total cost of waterproofing

Repair of concrete waterproofing

As we mentioned earlier, making concrete repairs — is an expensive undertaking that is best avoided. If your basement or rook is leaking, it means that there is no waterproofing on the outside of your concrete structure or it has become unusable. The method of repair depends on the method used for waterproofing.

Repair of surfaced waterproofing

If you were able to find the place of damage from the outside, then you need to repair it by removing the damaged area (cut-out criss-cross) and melting a new membrane. However, it is worth nothing here that it is not always possible to make repairs since with leaks in waterproof membranes, it is impossible to determine the place of damage and leakage of water from the outside, at the place of leakage inside, since the type of waterproofing has cavities and voids, respectively, water can flow in one place from the outside, and go out completely inside in the other– in the weakest place.

Repair of waterproofing of walls made of concrete

If your basement is leaking, the building has been built for a long time and there is no access to the walls from the outside, then repair work can be done with the help of so-called injection waterproofing or waterproofing substances working on negative pressure (water pressure from the outside) intended for work related to repair and elimination of leaks from the inside.

When performing work by injection, a special polyurethane resin is pumped into the thickness of the concrete wall and fills all the voids and pores of concrete under pressure, thereby making these places waterproof.