Most modern buildings have such an important structural element as a foundation. It helps elevate the structure above the ground, ensure its stability, and protect it from negative impacts from soil and precipitation. However, in order for the foundation to cope with the task of protecting the house from moisture penetration into the room, it is necessary to conduct its waterproofing at the construction stage. This article discusses what materials and methods are used to seal the pile foundation and grillage.

Is it necessary to do waterproofing the pile foundation?

The pile foundation is highly reliable and, in this indicator, surpasses the equally common ribbon foundation. For this reason, piles are installed in areas with mobile soils. The choice of piles is based on how aggressive and frequent the impact of groundwater on buildings is observed in a particular area. Piles are also popular in the construction of multi-story buildings in problem areas with high dynamics.

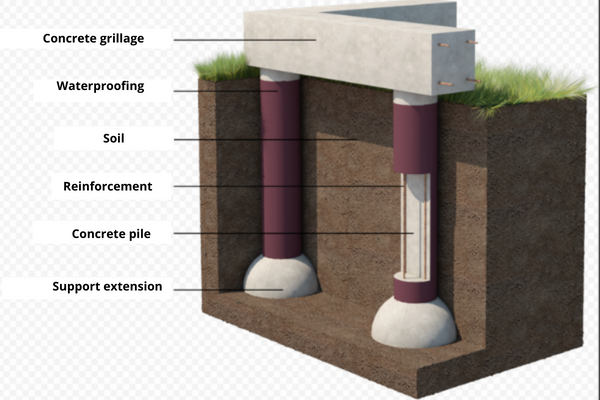

So why does the pile foundation, characterized by reliability and high resistance to moisture and air, need waterproofing? The fact is that in the pile foundation, in addition to the piles themselves, there are other elements that need to be protected from the effects of water and moisture, namely a foundation slab or a strip of monolith or sides, which is located in the ground.

The destructive effect of moisture begins immediately after the installation of the pile foundation, despite the fact that extremely it becomes noticeable not so quickly. The main problem areas in the foundation of piles are concrete products that come into contact with the ground, which means that they can absorb moisture and be destroyed by salts and minerals in groundwater or by temperature differences due to the freezing of water in the pores and microcracks of concrete and its subsequent expansion when a positive air temperature occurs.

The above process can not only locally destroy sections of concrete, but also lead to more serious consequences, such as the formation of microcracks, and full-fledged cracks in the foundation. That is why the pile foundation needs high-quality waterproofing of all parts below ground level

In addition to protecting the above elements, pile structures also need a cut-off waterproofing arrangement, located between the piles and other elements. Such waterproofing is necessary so that water and moisture cannot rise by capillary method, through the installed piles up to other elements of the foundation, for example, a slab or ribbon.

Waterproofing materials for grillage and piles

For the processing of piles and grillage, the same materials are used for most parts as for waterproofing, for example, other types of foundations, roofs, or panels of a panel building. The most popular technologies are roll and coating, and the most common materials — are roofing material in rolls, bitumen mastic, and liquid rubber.

Roofing material in rolls

Roofing material is considered an effective means for waterproofing both horizontal and vertical methods. Recall that vertical sealing is performed for walls and foundations in the bottom—up direction after the construction of the structure, and horizontal-by introducing waterproofing material into small holes of the working material before the structure is installed. Insulation of buildings is carried out in similar ways.

For waterproofing, it is not recommended to use roofing material on cardboard basis, since it does not have high waterproofing performance. However, if the material was purchased in advance, it can also be adapted for processing grillage and piles, if you lay it in several layers on bitumen mastic.

Other types of roofing material, for example, a polyester or fiberglass basis, protect the foundation from the effects of temperatures and moisture much better and are traditionally considered better than some types of coating waterproofing. Such roofing materials are quite expensive materials, but they differ in strength and durability.

Bitumen mastic

Mastics, made on the basis of bitumen, is perfect for waterproofing in a vertical way. The material is applied over plaster, which includes sand and cement. Despite the fact that plaster is sometimes used as a waterproofing material, it is strictly forbidden to process pile foundations and grillage with it. Plaster in this case is used only as a base, on which bitumen mastic is subsequently applied with a roller or brush.

A waterproof shell is formed on the surface of the mastic after its application, protecting the foundation from any effects of moisture and penetration of microorganisms into the material. The application of bitumen mastics is considered one of the most expensive methods of waterproofing and is also used for processing columnar foundation.

You can read more about bitumen waterproofing in the article – “Bitumen waterproofing: types, characteristics, and technology of the arrangement“.

Liquid rubber

Liquid rubber is a viscous material that resembles mastic in consistency. The rubber is distributed using industrial machinery or a special sprayer, but can also be applied with a standard roller. However, manual laying can lead to the formation of voids that can pass moisture.

Therefore, the method of pressure spraying is mainly used for piles and grillage. Liquid rubber includes polyurethane, acrylic, and bitumen, thanks to which it hardens quickly enough. Also, the material is resistant to mechanical stress and wear over time. The only drawback of rubber can be considered the only the high cost of the composition.

You can read more about liquid rubber in the article – “Waterproofing with liquid rubber”

Waterproofing technology of pile foundations of various types

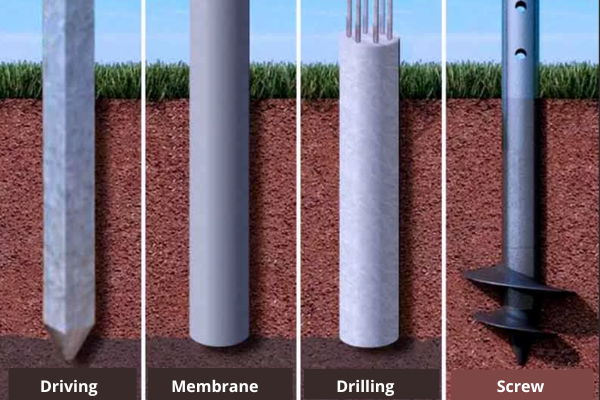

The pile foundation, as well as any other structural element, can be made of various materials. Depending on the composition of the pile, specific technology is selected for the installation of waterproofing, which helps to process piles at the highest level. Let’s look at what techniques are used in specific cases.

Waterproofing of the pile-grillwork foundation

The pile-grillage foundation is a structure of support pillars connected by a grillage, which is made of wood, reinforced concrete or metal. Depending on the type of binding, rolled or coated materials are used for waterproofing such a foundation.

Before starting work, each pile is impregnated with antiseptics and thoroughly cleaned of any contamination, after which a coating is placed on it. The next step is the application of waterproofing material. In the case of laying the binding on the heads, it can be bitumen or bitumen-rubber mastic. Distributed over the work surface with a wide brush. This material is applied in two layers.

Another material, rolled roofing material is necessary in situations where strapping is carried out with a channel or an I-beam. The roofing material is laid with an overlap of 8-10 sm with parallel straightening of the joints. Also, with a such a coating, it is possible to use coating mixtures famous for their hydrophobic properties.

If the grillage is made of reinforced concrete, the processing of the structure becomes two-staged. First, the grillage is covered with bitumen coating material, and after it is dried, it is processed using a rolled hydraulic layer. This method of waterproofing is considered extremely reliable for both residential and industrial buildings.

Waterproofing of bored piles

Often used in the construction of private houses, bored piles are considered to be the option that even a person who does not have special training can cope with waterproofing. In order to process such a foundation, the soil is turned into a formwork. This means that a small depression in the ground is drilled around each pile using a hand tool.

The resulting well is filled with concrete, in which the reinforcing frame is reinforced. For waterproofing, in this case, rolled materials are used, for example, roofing material, which is placed inside the well in a rolled-up form before installing a pile foundation.

Waterproofing of reinforced concrete piles

The following type of piles is common mainly in industrial construction, as well as reinforced concrete piles often form the basis of the foundation of multi-storey buildings. Fixing piles on the ground’s surface is carried out exclusively with the use of heavy machinery and cannot be performed by a person.

Supports for reinforced concrete piles are also made by pouring the material into molds and then installing a reinforcing frame. Such piles are characterized by a pointed tip, which makes it easy to immerse them in the ground or soil. The installation is carried out by the impact method, by driving piles into the ground. Waterproofing of reinforced concrete is carried out using penetrating technologies in which hydrophobic material is injected directly into the pile, and the most popular materials for such treatment are sealants made on the basis of bitumen, acrylic or polyurethane.

Waterproofing of screw piles

Screw piles are also in considerable demand, often used in the construction of simple structures, for example, baths, greenhouses or sheds. In most cases, screwing piles into the ground can even be done manually, using manual piles. The only exceptions are complex frame buildings, the installation of the foundation of which cannot be done without bulky industrial equipment.

The pile itself is a structure consisting of a trunk, a tip containing a screw blade, and a head. In the process of fixing the piles, the blades of the supports are immersed in the ground below the freezing point, the shanks are cut off, and the heads are put on and melted on top.

Waterproofing of screw piles is carried out with the help of compositions including bitumen. Such mixtures perfectly repel moisture and preserve the integrity of the building. Sometimes condensate can be accumulated inside the elements of the pile foundation. Filling the internal cavities of piles with concrete at the stage of laying the foundation helps to avoid this effect.

Waterproofing of pile-ribbon foundation

The next type of the foundation involves sinking piles made of reinforced concrete or steel into the ground and tying their supports with concrete tape. This method allows you to securely fix the piles in place and avoid their displacement during periods of seasonal soil movements.

At the stage of construction of the building, the hydrophobic treatment of the pile-belt foundation is caried out using bitumen. In some cases, concrete strips are protected by installing vertical or horizontal insulation. However, the final decision depends on the conditions in which the foundation will be operated. If a significant amount of standing groundwater is characteristic of a particular area, then the waterproofing of piles with bitumen is carried out together with the sealing of the connecting tapes.

The application of waterproofing materials can be carried out in one of two ways:

- First, dig a trench that is about half a meter wider than necessary, then pour concrete and wait it to harden. As soon as it happens, the form work is removed, and liquid rubber is sprayed on the walls of the piles or another composition is laid, for example, rolled roofing material.

- The second method supposes the use of non-removable formwork, which in this case is represented by extruded polystyrene foam. This material is waterproof and has excellent waterproofing properties, which contributes to the insulation of the basement and protects concrete from moisture.

In order to perform properly waterproofing of the pile foundation and grillage, it is important to study carefully all options for processing such structures. It is highly desirable to consult with a specialist and, quite possibly, order this work from a construction company. If it was decided to undertake the installation of waterproofing yourself, it is necessary to purchase all the required tools and materials in advance, which are best to buy with a margin.

Useful articles on the topic of foundation waterproofing:

By clicking on the links below, you can get acquainted with various constructs of foundations and methods of their protection from water and destruction:

- Foundation waterproofing arrangement: Methods, materials, prices and recommendations of specialists

- Waterproofing of the ribbon foundation: Technology and materials

- Waterproofing of foundation blocks and walls

- Horizontal waterproofing of the foundation: the technology of the arrangement and the materials necessary for this

- Vertical waterproofing: materials and methods of its arrangement

- Waterproofing of foundation slab. Methods and materials

- Waterproofing of basement and house walls from the outside and inside – Methods, materials, prices and technology

- Waterproofing of bricks and masonry