Table of Contents

- Common causes of leaks on outdoor balconies

- Balcony waterproofing methods and materials applied to them

- Waterproofing of an open balcony outside – what should be done to prevent leaks?

- Waterproofing the balcony of a private house with your own hands

- Waterproofing of the balcony from the inside

- Waterproofing of the balcony. Price

- Calculator of the cost of waterproofing the balcony

The greatest number of waterproofing violations is observed on balconies and terraces, and especially on the floor. Although the design criteria in many of these structures take into account the need for waterproofing, not all balconies are properly protected from water.

Without proper protection, leaking balconies can have devastating consequences for a private home or commercial building, and this should worry any private homeowner or builder.

Common causes of leaks on outdoor balconies

Below are some of the main and most common causes of leaks on an open balcony of a house, including a private one, outside and inside:

- No waterproofing of the floor or the open part of the balcony.

- In the absence of a slope for drainage, rainwater accumulates on the floor, penetrates into the finish coating and, when temperatures change (from negative to positive), destroys concrete from the inside, it does not matter whether it is a private house or a commercial building.

- No drainage or drain funnels.

- Natural movement and shrinkage of a building or house lead to open cracks in the concrete or to deformation of an incorrectly selected waterproofing coating, through which water can then seep.

When balconies or terraces of a private house are being built, then at the stage of preparation for waterproofing work, it is necessary to observe the correct technology. In order to provide a long-term solution to the problem of open balcony leaks, it is necessary to familiarize yourself with the correct technology of work and use the appropriate materials to protect the house, as specified in the current production and construction standards.

Important: When builders and contractors do not have much experience in the work related to waterproofing, they are likely to perform their work poorly both from the inside and outside, since they are unfamiliar with the necessary technologies/materials and do not see the whole picture.

Such risks include:

- Damage to the structural component of the open balcony of a private house, which will lead to a possible leak.

- Expensive repair of an open balcony, which will require reinstalling the structure and related finishing materials.

- Disputes between neighbors or private owners or landlords, lead to possible litigation.

- The formation of mold poses a serious health hazard.

Leaks of an outdoor terrace can lead to various problems, including final losses, loss of property value, destruction of the interior decoration of the interior of a private house, as well as a threat to health and safety.

Taking into account all the consequences of improperly performed waterproofing, when performing these works, it is recommended to contact a large company whose specialization is waterproofing at home. It is such a company that will be able to determine correctly the right material for outdoor protection of open spaces from water, as well as properly perform drainage and drain funnels in a private house.

Balcony waterproofing methods and materials applied to them

To protect balconies from water penetration, there are various methods from traditional surfaced bitumen roofing materials to ultra-reliable seamless polyurethane materials.

The main types of waterproofing suitable for use in outdoor balconies:

1. Polyurethane waterproofing:

When it is applied, a homogeneous elastic coating is obtained without a single seam and with 100% adhesion to the base. The material is resistant to mechanical loads and solar radiation, which makes it an ideal composition for the final floor covering on the balcony.

Materials:

- Polyurethane 2-double-component mastic – Applied manually and by spraying.

- Polyurethane 1-single-component mastic – Applied manually.

2. Liquid rubber:

Waterproofing with liquid rubber is a high-quality solution suitable for application on the base slab or on the floor screed, provided that the coating is further protected from ultraviolet radiation. The seamless elastic membrane does not allow water to affect the concrete, and during the dynamics of the structure, it stretches without damaging the integrity of the coating.

Materials:

- 2-double-component liquid rubber – Applied manually and by spraying.

- Single-component liquid rubber – Applied manually.

3. Polymer-cement materials:

After polymerization, a homogeneous insulating coating is obtained without seams and joints. This insulation is resistant to mechanical loads and has 100% adhesion to the concrete base.

Materials:

- 2-double-component polymer-cement mixtures – Applied manually and by spraying.

You can read more about cement waterproofing in the article – “Cement-based waterproofing: Features, types, and methods of its application“.

4. Roofing materials and surfaced insulation materials

This type of waterproofing provides for the deposition of bitumen insulation material in several layers. The presence of seams, the lack of full adhesion, and minimal elasticity make this type of protection not the most suitable for open-type balconies.

Materials:

- Roofing material – Is deposited on the surface by a hot method using fire.

- Rolled surfaced bitumen-based membrane – Is deposited on the bases using a burner.

- Adhesive insulation – Mounted by gluing.

You can read more about roll waterproofing in the article – “Roll waterproofing arrangement with detailed installation instructions“.

5. PVC membranes

When installed, it lies on the surface like a carpet and has no adhesion with it. Through numerous seams, water can penetrate under the made carpet and move from one place to another, damaging from the base.

Materials:

- PVC membranes — This type of membrane is fixed with slats and stitched together with hot air.

You can read more about membrane waterproofing in the article – “Membrane waterproofing: Types of materials and methods of their installation“.

6. Coating waterproofing

Numerous bitumen-based mastics are applied to the base with devices such as brushes and rollers. The quality of such mastics is determined by the components mixed in bitumen and the quality of the bitumen itself. In most cases, we are talking about low-quality materials (hence the low price).

7. Polyurea

After mixing the components, polyurea is sprayed through a special installation. When spraying, a UV-resistant coating is formed without any joints.

You can read more about polyurea in the article – “Waterproofing with polyurea“.

Important: The choice of the right method and material is best entrusted to professionals with extensive experience in the field of waterproofing.

A table with the advantages and disadvantages of each type:

In the following table, you can see a comparison of the characteristics of each of the above-mentioned materials and make the necessary conclusions.

View the table

| Liquid rubber | Polyurethane waterproofing | Polymer-cement | Surfaced waterproofing | PVC membrane | |

| Mounting method | Non-firing | Non-firing | Non-firing | Firing with the burner | With the help of a hair dryer and mechanical fixation |

| The availability of seams | Not available | Not available | Not available | Available | Available |

| Adhesion to the base | 100 % | 100 % | 100 % | 40 % | No adhesion |

| Coefficient of elasticity | 600-800% | 300-800% | 100-300% | 10-20% | 10-20% |

| UV resistance | Not available | Available | Not available | Available | Available |

| The warranty period for works | 7 years | 7 years | 7 years | 3-5 years | 1-2 years |

Ideal waterproofing material for waterproofing floors and slabs on the balcony

Good, and most importantly, durable and reliable waterproofing should have the following qualities:

- No seams. Seams between waterproofing membranes or sheets are the weakest points in the coating, and they are the first to fall into disrepair. Moreover, the correct gluing of seams is the most painful place for almost all builders, respectively, the human factor plays a very strong role here.

- 100% adhesion to the surface. A good composition will have 100% adhesion to concrete or other surface, so as not to let water stand and pass in cavities and voids, between the protective membrane and the base.

- Elasticity. A high coefficient of elasticity is always welcome since it is he who does not allow the waterproofing to crack or disperse at the seams, with the dynamics of the structure or shrinkage of the building.

- Warranty. Contractors give a guarantee of 6-7 years for high-quality waterproofing materials.

- No seams. Seams between waterproofing membranes or sheets are the weakest points in the coating, and they are the first to fall into disrepair. Moreover, the correct gluing of seams is the most painful place for almost all builders, respectively, the human factor plays a very strong role here.

- 100% adhesion to the surface. A good composition will have 100% adhesion to concrete or other surface, so as not to let water stand and pass in cavities and voids, between the protective membrane and the base.

- Elasticity. A high coefficient of elasticity is always welcome since it is he who does not allow the waterproofing to crack or disperse at the seams, with the dynamics of the structure or shrinkage of the building.

- Warranty. Contractors give a guarantee of 6-7 years for high-quality waterproofing materials.

If we are talking about the finishing coating: It is best to use double-component polyurethane waterproofing of the PolyFlex type by the (by German company HYDRO). This composition has all the above qualities, as well as UV resistance. Another advantage of PolyFlex is that it comes in different colors, so you can always choose the color you like.

If we are talking about waterproofing between layers: Here you can use both polyurethane and other compounds. One of the most common materials is double-component cement-mineral compositions of the HydroPaz type, as well as double or single-component liquid rubber of the FlexLock type or FlexLock Pro (by the German company HYDRO). Liquid rubber has all the advantages described above, in addition to environmental friendliness and speed of application (when using cold spraying). When it comes to waterproofing a balcony, once and forever, it is recommended to call an experienced company whose specialization is waterproofing. The arrived engineer will inspect your facility and will be able to tell exactly how to eliminate the leak, which material and method of waterproofing to choose, taking into account all the features of your facility.

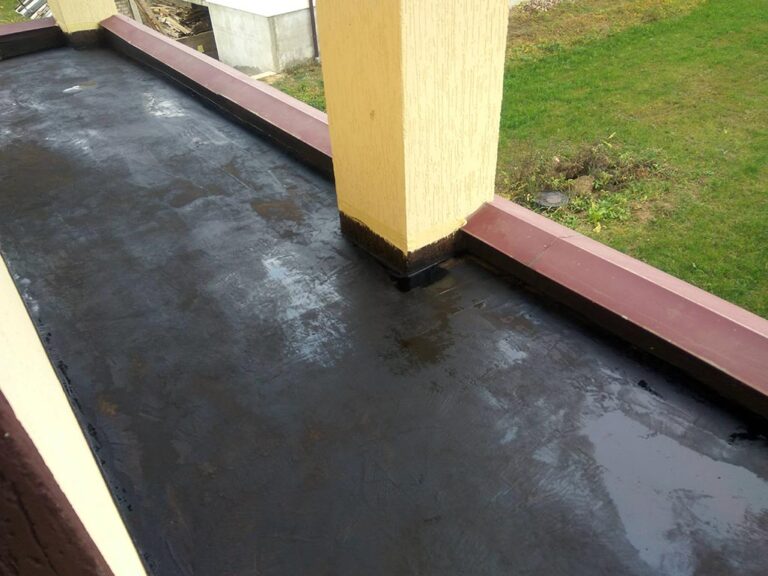

Waterproofing of an open balcony outside – what should be done to prevent leaks?

The design of each open balcony is unique, and the risk of water penetration is more likely if the insulation methods do not match the design and features of the balcony. Balconies require proper insulation from the outside, which does not allow water to affect the concrete. Water penetration usually occurs due to the fault of an inexperienced contractor or due to an incorrect choice of material for waterproofing the structure.

Important: When choosing a material, do not forget that cheap compounds are not just cheap, in most cases they are unreliable and in practice have a short service life, especially outside.

To protect properly the balcony from leakage, it is necessary to provide several things:

- Correct slope;

- Drainage and funnels;

- Additional protection of cold seams and joints adjacent to various structures (seams — are the weakest points);

- The right choice of material. Today there are many different materials. When determining the right material, it is worth considering the design features, service life, seasonality (in what weather a particular composition is applied), warranty period, and subsequent layers.

Waterproofing of the floor on the balcony

Most balconies will leak during their service life both from the outside and from the inside. Methods of construction of houses and outdoor areas have changed significantly in recent years, and this has had an impact on the effectiveness of waterproofing materials, including for the floor.

Today many builders build balconies in buildings, while they forget to take into account several important elements of the floor on these very balconies:

- A minimum slope of the floor screed. A balcony with an incorrectly executed slope of the floor is more susceptible to the accumulation of moisture between the waterproofing coating and the floor tiles, which creates constant water pressure on the waterproofing layer, and this reduces the service life of even the best waterproofing system, not to mention not very high-quality protection, which will quickly collapse. This leads to water leakage into the room.

- Drain funnels. The normal slope of the floor and properly installed drain funnels will not allow water to stagnate on the surface of an open floor or tile, which will subsequently reduce the water pressure on the waterproofing floor itself.

Waterproofing the balcony of a private house with your own hands

All the above works can be done with your own hands. Before waterproofing your balcony with your own hands, pay attention to the following things:

- Cracks in concrete;

- Problems with opening and closing balcony doors;

- Peeling or splitting of concrete;

- Weak structural joints in railings and posts.

- Seams and joints;

- Drainage and funnels;

- Slope.

When it comes to carrying out work with your own hands, it is best to choose waterproofing those materials that can be applied with your own hands without using additional equipment, such as installing cold spraying or special hair dryers for stitching seams between membrane sheets. To perform the work on their own and own hands, you can use single-component liquid rubber or polyurethane mastic. At the same time, it is best not to save money here, but to choose expensive mastics, preferably of foreign production, since they are more reliable and durable. When performing waterproofing on your own, do not forget that improperly mixed or applied material will not work, and it absolutely does not matter what quality it is.

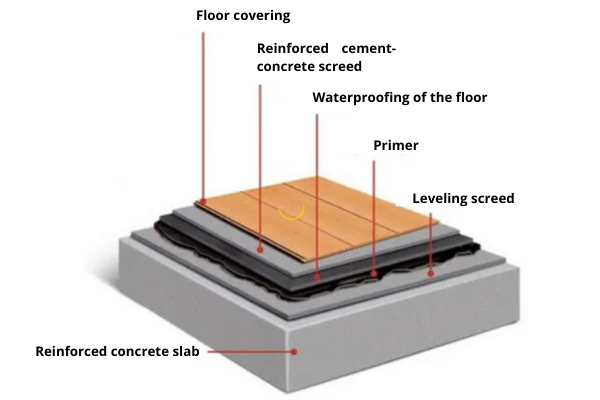

Stages of works performance:

- Surface preparation – cleaning from dust and dirt;

- Fillet arrangement on the abutments;

- Applying a primer (base paint);

- Waterproofing arrangement (base slabs);

- Separation layer of geotextile;

- Arrangement of insulation;

- Separation layer of geotextile;

- The arrangement of the leveling screed taking into account the slope marks;

- Floor waterproofing arrangement;

- Separation layer of geotextile;

- The arrangement of reinforced cement-sand screed with a slope;

- Arrangement of tiles or finishing.

A diagram of all the necessary layers for the construction of a concrete balcony:

Waterproofing of the balcony from the inside

Of course, waterproofing is always recommended to be performed outside the structure, but sometimes it is impossible or very expensive since the terrace is finished outside, tiles, screed, insulation, etc… are installed, and dismantling this is not easy and expensive. If it is not possible to perform work from the outside, the leak can be eliminated from the inside of the balcony or room, by injection, of polyurethane compounds such as HydroInject. In fact, if we are talking about eliminating leaks from the inside, then it is necessary to inject a polyurethane compound either into cold seams (having previously embroidered them from the inside and compacted them with special expanding sealants) or into the concrete body (finishing elements are cleaned or dismantled) from the inside. When performing works using injection waterproofing and injection into concrete or seam, all voids and cavities existing in concrete are filled with polyurethane, which in turn expands and squeezes out all water and moisture from the concrete, thus strengthening it and making it waterproof. When using this method from inside the room, do not forget that you have not solved the problem of waterproofing from the outside – this means, that water continues to pass through the broken layer of waterproofing, and penetrate into the upper layers of concrete and destroy it. Accordingly, sooner or later leaks will disappear.

Waterproofing of the balcony. Price

Below is a table of prices for works related to waterproofing. In the table, you can see the prices and the total cost of waterproofing works, depending on the method of their execution and the material used in this case (type).

| Description of works | Unit of mesurement | Price in roubles |

| Works on the arrangement of surfaced waterproofing | m2 | 10 |

| Works on the arrangement of PVC membrane | m2 | 20 |

| Works on the arrangement of polyurea | m2 | 30 |

| Works on the arrangement of mastic waterproofing | m2 | 10 |

| Works on the arrangement of liquid rubber by spraying | m2 | 15 |

| Works on the arrangement of liquid rubber manually | m2 | 20 |

| Works on the arrangement of cement-mineral double-component waterproofing | m2 | 30 |

| Works on the arrangement of polyurethane waterproofing | m2 | 30 |

| Application of primer | m2 | 9 |