It is necessary to perform waterproofing works in the room if there is a risk that water may leak out of it or water or moisture from the outside will penetrate into it. This is relevant for the following types of premises:

- Basements and ground floors are located below ground level (bordering the ground).

- Rooms located under the roof, balcony, or terrace

- Rooms with wet areas such as baths, bathrooms, swimming pools, saunas, kitchens, and food shops – when there is a risk that water or moisture will pass from this room to others.

If we are talking about the fact that the structure is located underground, then it is necessary to provide waterproofing from the outside of the foundation and walls. Sometimes there are cases when such waterproofing has not been done or has become unusable and there is no way to fix it (from the outside). In such situations, it is necessary to perform waterproofing inside. In such situations, it is necessary to perform waterproofing inside – Waterproofing the basement from the inside: Methods, materials, and stages of work.

Works on waterproofing of premises

Works on waterproofing of premises can be done with your own hands (independently) or with the help of a specialized organization. Such responsible work is best done with the help of a professional company since it is professionals who see the whole picture and can choose the right material and method for performing waterproofing work so that later they do not have to redo everything or do double work.

Important: Waterproofing of premises — is a responsible and important job that requires experience and skill. If such work is carried out with violations, you risk the formation of leaks, which can lead to violations of finishing, cracks, fungus and mold. In case of problem with leaks in your home, it will cost at least 2 times more to redo a poorly done job that to do it well initially, and this does not take into account the costs of repairing damage due to broken insulation.

In the article “Contractors, companies, and firms for waterproofing and drainage”, you can learn about the 7 rules – How to find a professional waterproofing company or contractor and not make a mistake.

It does not matter whether you decide to perform work related to protecting your premises from water yourself or with the help of a professional firm, these works will include the following stages:

- The choice of waterproofing method

- Selection of the required material

- Surface preparation

- Applying the selected insulation according to the manufacturer’s instructions

- Protection of the work performed from mechanical damage

Recommendations: If all these elements have access from the outside, it is best to perform their waterproofing from the outside. In the absence of such a possibility, protection should be performed inside, using compositions working on negative water pressure (from the outside to the inside) or perform a clamping element (a clamping screed or wall).

Features of various constructions and types of premises and recommendations on the choice of their waterproofing method

Indoors, if necessary, waterproofing is applied to the following structures and bases:

- Walls

- Floor

- Ceiling (if you want to avoid the risk of flooding from the area above the ceiling)

- Floor slab

- Places of communications entry

- Cold joints and concreting joints

Further, we will consider in detail the waterproofing of some of the above elements.

Waterproofing of walls of premises

Waterproofing of walls indoors. The walls of rooms, located underground should be protected from the penetration of moisture and water, otherwise, you risk due to constant humidity, at least the formation of mold and mildew (dangerous to human health) and at most flooding of these rooms, the destruction of walls and the formation of cracks in them (moisture penetrates the walls, in winter it freezes, thaws in the spring, thereby destroying the substance of the wall, forming microcracks, voids, and pores).

If there is access to the walls from the outside, it is best to put a protective barrier on them using liquid rubber. Liquid rubber is one of the most reliable compounds, as it has 100% adhesion with substances such as concrete and brick. In addition to good adhesion, when applying liquid rubber, an elastic seamless coating is obtained (it looks like rubber). Thanks to the adhesion, elasticity, and absence of seams, this composition will reliably protect the walls of your room for at least the next 30 years.

If there is no access to the walls from the outside, then you need to perform waterproofing of the basement walls from the inside. Further, let’s look at exactly how it is best to perform waterproofing of the walls of the room inside.

Waterproofing of the floor on the premises

Floors should be protected from water in 2 cases:

- Wet zones – For example, if there are water-related communications in the room, such as a bathroom, bath, kitchen, etc. – When it comes to the fact that there is a risk that there may be water leaks on the floor in a certain room, which, in the absence of good floor insulation, will leak down and flood (or will damage) other premises.

- Production and food shops – in such areas, it is assumed that there is water on the floor due to the production process.

- Leaks from under the floor. If there is groundwater under the building or there is no proper insulation of the foundation slab and/or cold joints, then water can enter the room from the floor. To avoid getting the floor wet, excessive moisture, destruction, and flooding, it is recommended to apply a waterproof compound working on negative water pressure to the floor, according to the type of polymer-mineral elastic waterproofing.

Waterproofing of wet areas and wet rooms

Waterproofing wet rooms and wet areas – is one of the first steps that should be taken when such a room is being built. It involves installing a waterproof barrier around the walls and floor in the bathroom to protect the structure of the house from moisture, water, and leaks. Insulation is best done in stages.

Some steps are taken before the floors and walls are completely laid, some after everything is done, including the floor screed. The most important areas are where the walls meet the floor. Any cracks into which water can leak can lead to serious structural damage, the repair of which is very expensive.

Bitumen mastics, polyurethane, and mineral cement can be used for the installation of a waterproof barrier. First, a primer is used, then the first layer is applied from left to right (horizontally). The subsequent layer is then applied up and down (i.e. vertically) to catch any small holes missed in the first layer. The above formulations usually take about a day to dry.

Waterproofing indoors from leaks, dampness, and fungus

When considering the issue of insulation inside your premises, it is necessary to pay attention to the following parts of your building, basement or socle:

- Walls

- Floor

- Abutment seams or interlocking seams

All these elements can be a weak point and let water pass into your room. Usually, the weakest points in any structure are seams, and it is the sealing and waterproofing of seams that should be given the main attention.

If we talk about complex and durable waterproofing made inside the building itself, then the following recommendations should be followed:

- Protection of cold and interblock seams:

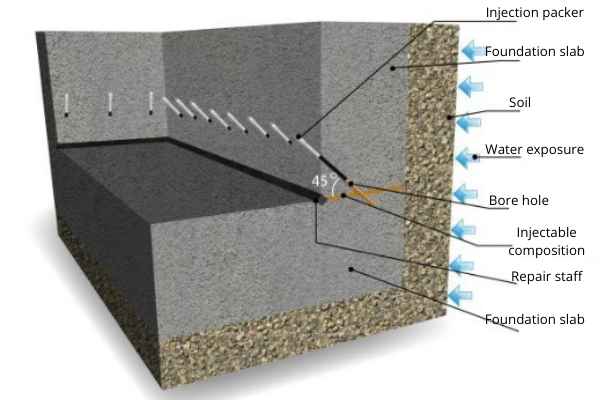

As a rule, cold seams are unstitched (s small 3х2sm indenting is made), and a non-shrink or expanding sealant is compacted there in layers. After that injection waterproofing is performed – a double-component polyurethane resin of the HydroInject type penetrates into concrete or brick under pressure, filling all existing voids, microcracks, and pores, making this area waterproof.

2. Double-component cement-mineral or Polymer-mineral elastic waterproofing is applied to the floor and walls. This composition works on negative water pressure and that is why it is ideal for insulation of the floor and walls of the room from the inside.

Diagram of the injection waterproofing arrangement of the cold seam slab-wall:

Waterproofing of residential premises

When it comes to residential premises – we mean exploited areas where people can stay and live, for example, exploited basements or socle floors. Waterproofing of residential premises is extremely important since its absence will lead to disastrous consequences, such as:

- The formation of mold and mildew on the walls, floor, and ceiling of residential areas, threatening human health;

- Flooding of living space;

- Excessive humidity in the living room;

- The destruction of walls and the formation of cracks will lead to the fact that this area will be impossible or unsafe for use as a residential area;

As already mentioned earlier, waterproofing of residential premises can be performed both outside and inside, depending on the structure of the building or house.

Waterproofing of basement, socle and underground premises

When waterproofing a building, all underground rooms, such as the basement and plinths, should be protected from water and moisture penetration. As mentioned earlier, it is better to protect the walls and foundation of the basement, socle, or other underground room from the outside, so you will prevent the penetration of water into the underground building elements even when it approaches.

Why it is better to perform work on the installation of a waterproof coating outside the basement or socle, how to perform them correctly and how best to do them from the inside (if there is no access from the back), you can find in the following articles:

- How to do waterproofing of the basement from the outside properly

- Waterproofing of the basement from the inside: Methods, materials, and stages of work

- Elimination of basement leaks once and forever

- Waterproofing of the basement floor of the house: Methods, technologies of installation, and materials

- Fungus and mold in the basement of a private house: Causes and how to get rid of it once and forever?

- How to make properly a basement recess below the sole of the foundation

Materials for waterproofing

In order to successfully perform work to protect various rooms from water, it is necessary to choose the right materials. As a rule, they are divided by the type and method of their installation.

Basic waterproofing materials:

- Surfaced or rolled

- PVC and TPO (Thermoplastic Polyolefin) membranes

- Coating

- Painting

- Sprayed

- Penetrating

- Mineral-cement

- Injection

The choice of materials for waterproofing has advantages and disadvantages:

Each room has its own characteristics, tasks, and problems, respectively, materials should be selected individually based on the characteristics of the structure. Here are the most popular materials with which waterproofing works are carried out, their main disadvantages and advantages:

1. Rolled surfaced bitumen-based membranes – Are supplied in rolls, fastening to the surface and stitching seams, occurring with the help of a hot fire (burner), melting the bitumen layer. Surfaced membranes are recommended to be applied in at least 2 layers in order to cover the seams

Cons: The availability of seams, the absence of 100% adhesion (adhesion) to the surface

Pros: Relatively inexpensive price

2. PVC membranes – Come in rolls, are fastened with a special strap, and the seam is stitched with hot air using special dryers or more professional equipment.

Cons: There is no adhesion to the surface at all, the membrane lies on the base, like a carpet. The availability of seams, and the seams — are the weakest point in any insulation.

3. Coating and sprayed insulation according to the type of liquid rubber or polyurethane waterproofing (mastic).

Cons: The price is more expensive than that of simply surfaced membranes.

Pros: No seams, 100% adhesion (adhesion) to the base, and high coefficient of elasticity (is not torn or cracked during dynamics or shrinkage of the building).

4. Penetrating.

Cons: It does not work in places where there is poorly vibrated concrete or voids in concrete, as well as at the joints of reinforcement and on such a basis as bricks or blocks. Because of these disadvantages, these materials are almost not applicable anywhere, since, in places of leakage, where, in fact, waterproofing is necessary, concrete most likely has voids and microcracks where penetrating mixtures will not work.

5. Mineral-cement mixtures (single or double-component).

Cons: The price is more expensive than that of simple surfaced materials.

Pros: No seams, 100% of adhesion (adhesion) to the base.

6. Injection waterproofing.

Cons: the high price for performing work by injection as well as for the injection materials themselves (if we are talking about high-quality components).

Pros: An effective way to solve problems with leaks, inside a problem room, building, basement and walls.

When choosing the right waterproofing composition, it is necessary to take into account:

- What part of the building do you want to protect – underground basement, foundation, socle and etc..;

- What exactly do you want to protect – floor slabs, floor, ceiling;

- Where exactly the work is carried out – inside or outside the structure;

- On which surface it is necessary to apply a waterproofing barrier – brick, concrete, metal and etc. and in what condition it is (the degree of destruction);

- In what condition is the problem place – basement, foundation or socle.

Important: To determine accurately the right material and type of work, it is best to invite a specialized waterproofing company.

Price for waterproofing of premises

The price for performing work outside:

| Description of work | Unit of measurement | Price in roubles |

| Work on the arrangement of surfaced waterproofing | m2 | 10 |

| Work on the arrangement of PVC membrane | m2 | 18 |

| Work on the arrangement of polyurea | m2 | 30 |

| Work on the arrangement of mastic waterproofing | m2 | 8 |

| Work on the arrangement of liquid rubber by spraying | m2 | 8 |

| Work on the arrangement of liquid rubber manually | m2 | 10 |

| Work on the arrangement of cement-mineral double-component waterproofing | m2 | 20 |

| Works on the arrangement of polyurethane waterproofing | m2 | 20 |

| Application of primer | m2 | 5 |

The price for the work performance from the inside:

| Description of work | Unit of measurement | Price in roubles |

| Waterproofing of cold joints: -Work on the installation of indenting -clearing the indenting -layer-by-layer sealing of non-shrinkable composition | running meter | 20 |

| Waterproofing of interblock joints: -Work on the installation of indenting – clearing the indenting -layer-by-layer sealing of non-shrinkable composition | running meter | 15 |

| Waterproofing of expansion joints: – Work on the installation of indenting – clearing the indenting -sealing the elastic profile -sealing of non-shrinkable composition -complex of works on injection | running meter | 160 |

| Injection waterproofing of seams / cut-off waterproofing –Work on the installation of indenting -clearing the indenting -layer-by-layer sealing of non-shrinkable composition -Work on the installation of boreholes and installation of packers -a complex of works on injection -dismantling of packers and sealing of injection holes | running meter | 50 |

| Injection waterproofing into the concrete body -marking, Works on the arrangement of boreholes and assembly of packers -a complex of works on injection -dismantling of packers and sealing of injection holes | m2 | 60 |

| Injection waterproofing into the brick body -marking, Works on the arrangement of boreholes and assembly of packers -a complex of works on injection -dismantling of packers and sealing of injection holes | m2 | 60 |

| Cement-mineral waterproofing | m2 | 20 |

| Penetrating waterproofing | m2 | 20 |

| Waterproofing of communications entry points: -Works on the arrangement of indenting -clearing the indenting – layer-by-layer sealing of non-shrinkable composition – Works on the arrangement of boreholes and assembly of packers -a complex of works on injection -dismantling of packers and sealing of injection holes | piece | 250 |