Table of Contents

- What consequences are hidden in the construction of a pond without waterproofing

- The main methods of the installation of artificial reservoirs

- Waterproofing methods for artificial ponds and reservoirs made of concrete

- Waterproofing methods for ponds on a soil base

- Repair of waterproofing of artificial ponds

- Prices for pond waterproofing

- Waterproofing services of reservoirs

Not only country hotels and holiday homes have equipped ponds and reservoirs on their lands, but today many owners of private houses also equip artificial reservoirs on their plots for fish breeding, recreation, or as a decorative element. However, many people and even construction companies providing pond construction services absolutely forget to take care of reliable and high-quality waterproofing of their offspring.

What consequences are hidden in the construction of a pond without waterproofing

If you do not take care of the installation of high-quality waterproofing of an artificial pond, reservoir, or basin, then this structure can expect several adverse consequences:

- Withdrawal of water from the reservoir – This is applied to both artificial concrete reservoirs and ponds made on a soil base. The filled water will gradually pass either through the soil or through microcracks and pores in concrete (with a concrete base), which will entail constant inconvenience and the need for constant filling of the pond with water, which costs a lot of money;

- Formation of cracks in the artificial concrete base of the reservoir and the violation of the integrity of the concrete bowl – This is mainly due to the temperature difference since in the absence of waterproofing, the water in the concrete bowl is absorbed into the concrete like a sponge, freezes in winter, and thaws in spring, destroying concrete by forming microcracks, pores, and voids in it. It is important to understand that the described effect occurs even if the owner has artificially pumped out all the water from his reservoir before the onset of frost since it is difficult to hide completely the concrete trough from rainwater and high water.

- The ingress of unwanted groundwater into the artificial structure of the reservoir from the outside.

The main methods of the installation of artificial reservoirs

There are several methods by which you can make a pond or arrange and artificial pond on the site:

- The installation of a concrete pond – the excavated bowl of the future pond is reinforced, and then filled with concrete;

- The arrangement of the pond is based on the soil – an artificial bowl is dug out for the future pond, ennobled, protected by waterproofing, and filled with water;

- By installing a finished plastic or polymer container.

Depending on the chosen method of the installation, the method of waterproofing of the made structure is also selected.

Further in the article, you will be able to familiarize yourself with various materials suitable for concrete and soil foundations. Some materials can be used in both cases.

You can read more about the construction of ponds and reservoirs in the article – “Construction of artificial reservoirs and ponds: Installation technology with step-by-step instructions“.

Waterproofing methods for artificial ponds and reservoirs made of concrete

The installation of reservoirs made of concrete is a costly and rather laborious occupation, however, such reservoirs turn out to be more durable and long-term, and the water in them is easier to control in terms of cleanliness and level.

During the construction of concrete reservoirs for their waterproofing, the technologies and materials described below can be used.

Waterproofing of the pond with liquid rubber

Liquid rubber — is a bitumen emulsion mixed with latex and other polymers. When liquid rubber is sprayed onto the concrete surface of the pond bowl, a rubber coating with certain characteristics is formed.

- Characteristics and properties of liquid rubber:

- No seams;

- Full adhesion to the concrete base;

- Environmental compatibility and safety in contact with humans and even drinking water;

- High elasticity, which does not allow the rubber to disperse or crack when the structure shrinks or its dynamic movement.

Installation technology:

- Preparation of the concrete surface – cleaning of concrete from dust, dirt, sharp corners, and peeling elements;

- Primer of the base – A special primer is applied to the surface, thanks to which the waterproofing coating is made to better grasp the surface;

- Preparation of the material – Barrels with rubber mix well and prepare the component B consisting of water mixed with calcium chloride;

- Spraying – Liquid rubber is sprayed onto the base using a special installation forming a homogeneous rubber membrane on the surface with 100% adhesion to the surface;

- Drying time – the rubber rises within 3 minutes, but the final set of the material occurs within 3-4 days after application;

- Filling the reservoir with water – Then the reservoir can be filled with water.

Liquid polyurethane waterproofing

Polyurethane waterproofing, as well as rubber, is applied by spraying or manually using rollers.

When installing a polyurethane coating on the concrete base of an artificial structure, a high-quality insulating coating with premium properties is obtained.

Important: Unlike rubber, polyurethane coating is more resistant to UV radiation and can be tinted in almost any color, which makes it one of the most attractive and effective materials used as waterproofing for structures such as concrete artificial ponds, reservoirs, or basins.

Characteristics of polyurethane waterproofing:

- One-piece homogeneous coating — no seams and joints;

- 100% adhesion to the base;

- Resistance to solar UV radiation;

- The possibility of tinting in any color according to the RAL catalog, is great for the installation of artificial decorative reservoirs.

Application method:

- Preparation of the foundation;

- When using double-component materials, before starting work, the components should be mixed in the right proportion strictly following the manufacturer’s instructions;

- Applying the primer;

- Spraying of polyurethane composition in 2 layers with the drying of each;

- Filling the pond with water.

Polymer-cement compositions

Polymer-cement compositions have high cohesive strength and can accept both static and dynamic loads. The coating forms structurally indissoluble bonds with the base, as it fills and seals all pores. Some polymer-cement compositions are grasped with the surface in the form of a film formed on the surface with insulating properties, and some polymer-cement compositions penetrate the structure of concrete, such materials are called penetrating.

Properties of polymer cement insulation:

- No seams;

- Can be applied on a wet base;

- 100% adhesion to the base;

- Environmentally friendly material;

- Some formulations withstand negative water pressure from the outside to the inside.

You can read more about cement compositions in the article – “Cement-based waterproofing“.

Waterproofing methods for ponds on a soil base

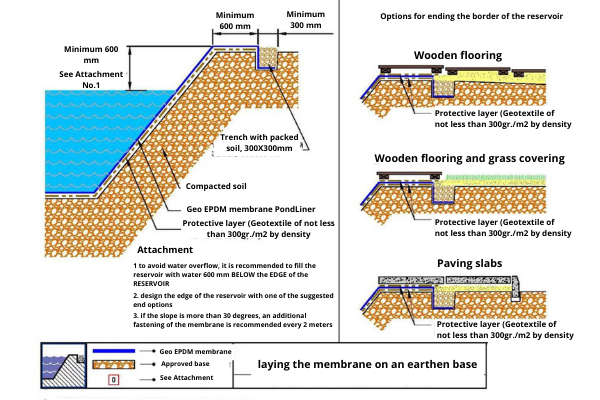

Most large ponds are not concreted, which means that waterproofing for such structures should not be laid on a soil foundation, but on soil, clay, or another type of loam. Insulating films or membranes are mainly suitable for waterproofing such structures.

Membranes and films

Waterproofing of most ponds where there is a soil or clay base is performed using various roll membranes having different qualities. Nevertheless, all membrane materials intended for waterproofing reservoirs are laid similarly.

The technology of laying:

- Removal of roots, stones, and other interfering elements;

- Ramming of the ground base;

- Installation of the membrane web, taking into account the sealing of the joints.

- Laying the canvas of the auxiliary trench along the perimeter of the reservoir for its fixation.

You can read more about membrane waterproofing in the article – “Membrane waterproofing: Types of materials and methods of their installation“.

Methods of hermetical connection of seams between the rolls:

- Cold method – The membranes are overlapped in 10-15 sm and glued together with a special glue;

- With the use of tape – The edge zone of the sheet is cleaned with a special compound and then treated with a primer, after which two sheets are overlapped and connected with a self-adhesive tape.

- Hot vulcanization – The joint is stitched at a temperature of 500-600 degrees with special equipment. This method is considered as the most effective.

PVD (Polyethylene of High Pressure) and PND (Polyethylene of Low Pressure) membranes:

Geomembrane HDPE (PND): PND — means low-pressure polyethylene. These are polyethylene materials produced from durable low-pressure polyethylene with a thickness of 0.5-4mm, which, due to its unique properties and catalytic processing, has a higher density and can withstand chemical waste in addition to water. These materials are quite rigid and inelastic, respectively, they are best laid in a flat base.

Geomembrane LDPE (PVD): These membranes are made of artificial polyethylene of high pressure and low density. LDPE membranes are of double-layers polymer roll materials. This material is elastic enough and is suitable for laying on an uneven or raised surface.

Butyl rubber of EPDM membranes:

Butyl rubber — is a reliable and widely used waterproofing material, including for waterproofing artificial and natural reservoirs or various ponds. Butyl rubber or EPDM (ethylene-propylene-diene-monomer/ EPDM) membrane is made based on polymerized synthetic butyl rubber with the addition of special polymers and vulcanizing components.

EPDM membranes are supplied in ready-made rolls and, if desired, rolls can be ordered at the factories according to individual size, which in turn will remove the seams between rolls or reduce them to a minimum, and the fewer seams in the coating, the greater its reliability.

Main characteristics and advantages of EPDM:

- Water-resistance;

- The coefficient of stretching is more than 300%;

- Resistance to mechanical stress;

- Possibility of installation at sub-zero temperature;

- Resistance to the aggressive environment;

- UV resistance;

- Environmentally safe;

- Large roll sizes allow the installation without seams.

Differences between the characteristics of different types of membranes in the table:

| Polyethylene (PVD, PND) | Butyl rubber (EPDM) | |

| Durability | Low | High |

| Coefficient of elasticity | 10-50% | 300-400% |

| Laying temperature | from -15 up to 35 ℃ | from -45 up to 200℃ |

| Protection against crease formation | Not available | Available |

| Ease of installation in points | 2 | 5 |

| Service life | from 1 up to 8 years | from 10 – 50 years |

| Resistance to mechanical influences | Not available | Available |

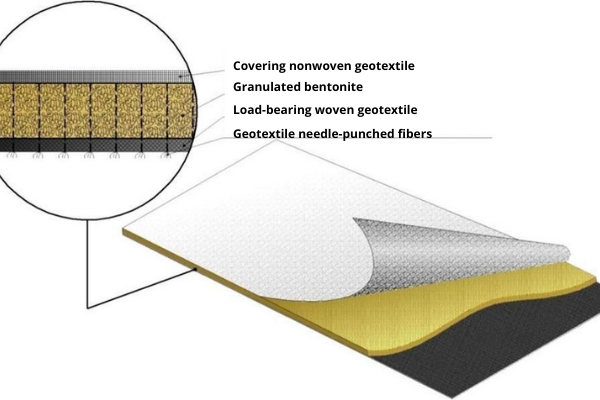

Bentonite mats for waterproofing

Bentonite mats — are a geosynthetic insulating material consisting of granulated bentonite (a natural clay-by the type of clay), which in turn is placed between two layers of woven and non-woven geotextiles, which provides bentonite mat with sufficient strength across the entire surface. Upon contact with water, the material swells and forms a waterproof layer of helium composition.

Characteristics and properties

- Unlike butyl rubber membranes and traditional film membranes, bentonite mats can recover independently, namely, independently eliminate various mechanical damage, for example, from tree roots;

- No welding or gluing of sheets is required during installation;

- Suitable for waterproofing dams, canals, reservoirs, and ponds;

- Suitable as a protective layer to prevent the penetration of waste or chemicals into groundwater. Bentonite can be used to seal the soil surface at landfills with various wastes, as it is resistant to various chemical elements, such as oils, oil, gasoline, etc.;

- The durability of use;

- Environmentally bladeless composition;

- Withstands unlimited cycles of freezing and thawing.

Installation technology:

- Cleaning of the concrete layer from dirt. When laying on the backfill, the backfill should be tamped;

- Bentonite mats are mounted on a vertical surface with special mounting dowels. The mats overlap on the horizontal base and do not require any welding of seams.

Waterproofing of the pond with clay

Clay — is a sedimentary rock having a fire-grained structure. When wet, the clay becomes plastic and does not pass through water. Even though clay does not let water pass through, it still absorbs moisture.

In the past, many people used clay as a waterproofing compound, but they did it not because of its over-reliability, but because at that time people did not have a high-quality alternative.

Important: If you want to use clay for waterproofing, then you need to use not the first available, but high-quality blue clay. But even such clay is recommended to be used exclusively as an auxiliary element, and not the main waterproofing. If you want to perform the work following the design and technical standards, then for durability and reliability, it is recommended to install membrane waterproofing of the selected type on top of the clay lock.

Installation of a plastic container

If the size of the artificial structure is small enough, then instead of concreting the reservoir with subsequent waterproofing or installing a membrane on the ground, you can install a ready-made plastic container created by the type of a small decorative pond. This container does not require waterproofing, as it is completely made of plastic.

Comparison table between the main waterproofing technologies

In this table you can see the advantages and disadvantages of the materials described above in comparison with each other:

| Liquid rubber and liquid polyurethanes | PND and EPDM membrane | Bentonite mats | Polymer-cement waterproofing | |

| Availability of seams | Not available | Available | Available | Not available |

| Negative pressure | Not withstand | Not withstand | Not withstand | Withstands |

| Permissible temperature for application | from +5 up to +40 | from -25 up to +40 | from -5 up to +40 | from +5 up to +40 |

| Adhesion to concrete | 100 % | Not available | Not available | 100 % |

| Can be applied on a ground base | Not available | Available | Available | Not available |

| Can be applied on a ground base | Available | Available | Available | Available |

| Resistance to aggressive environment | Available for polyurethane | Available | Available | Available |

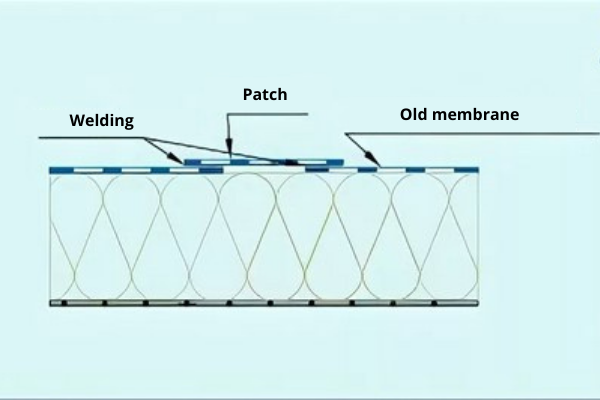

Repair of waterproofing of artificial ponds

If the waterproofing was done with violations, then sooner or later it may require repair.

Waterproofing repairs may be related to the fact that:

- Groundwater began to flow into the finished pond, disrupting the ecosystem of the pond or deforming the laid membrane.

- The broken integrity of the waterproofing carpet and water began to leave the pond constantly, lowering the water level in it.

Anyway, the broken waterproofing requires repair. The method of performing repair work mainly depends on the base of the pond bowl and existing waterproofing.

Liquid waterproofing materials:

If we are talking about materials such as rubber or polyurethane insulation, then repair is possible by applying an additional layer of waterproofing to the damaged area. This layer will serve as a kind of damage patch, when applied it is necessary to use a material similar to the existing type of components polyurethane, polyurea, or rubber.

Membrane or film:

The membrane or film is repaired by the method of patching in the body of the coating itself or at the joints. When performing repairs, it is necessary to select a material, similar to the laid one, otherwise, there may be problems with the adhesion of the new coating with the previous one.

Repair scheme of membrane insulation:

Prices for pond waterproofing

The table below with prices does not take into account the prices of the material and reflects only the prices of the work.

The prices, given for the work are approximate. To obtain an accurate and final estimate of prices for our company’s services, you need to contact us by email or by the phone number specified in the contacts.

| Works description | Unit of measurement | Price in $ |

| Services on laying bentonite mats | m2 | starting from 10 |

| Works on the installation of PVC membrane | m2 | starting from 9 |

| Works on the arrangement of EPDM membrane (Ethylene-Propylene-Diene Monomer) | m2 | starting from 9 |

| Works on application of liquid rubber by spraying | m2 | starting from 5 |

| Works on application of liquid rubber manually | m2 | starting from 6 |

| Services on installation of polymer-cement waterproofing | m2 | starting from 10 |

| Works on the application of polyurethane waterproofing | m2 | starting from 10 |

| Works on the installation of pond basins | m2 | starting from 150 |

Waterproofing services of reservoirs

Professional companies provide professional waterproofing services for such structures as:

- Reservoirs

- Ponds

- Swimming pools

- Basins

- Foundations

- Basements

- Roofs

- Terraces

- Balconies

- Other facilities

They work with all types of waterproofing materials and the services provided by our company do not focus on a specific type of material, but focus on waterproofing in general. When choosing a particular material for the provision of services, companies should be guided by the needs of a particular object and choose the material that will work most efficiently and for a long time in a particular case.

Also, companies confident in their professionalism, when performing work, provide an official guarantee of 3 years for the services provided.