Metal roofing is considered as a fairly common element of buildings for various purposes. Such a roof can be used in private and apartment buildings, high-rise buildings, as well as in industrial enterprises. Due to the fact that metal can be classified as not the most stable material since it is noticeably susceptible to destruction, it needs high-quality hydrophobic treatment. In this article, we will talk about how to protect a metal roof from atmospheric precipitation and, accordingly, preserve the integrity of the entire structure.

Types of metal roofs

To date, there are several types of metal roofs that differ from each other in external and operational characteristics. The material for waterproofing and the technology of its implementation is selected depending on the type of roof chosen for a particular structure. Consider the most common types of metal roofs.

Profiled flooring

The basis of profiled flooring – is metal sheets, which form the roof. The profiled sheet is covered on both sides with a polymer composition that improves resistance to various influences but does not affect its thermal insulation properties. For this reason, the profiled flooring is necessarily insulated before installation. However, the insulation still does not protect the metal surface from moisture, so the profiled flooring needs additional waterproofing treatment.

The advantages of profiled flooring compared to other materials are that it is easy to install, serves for a long time, and is highly resistant to atmospheric and mechanical influences, as well as it is characterized by a low price and a rich color scheme. This material is suitable for buildings of various purposes, including private houses with a pitched, flat, stepped, semicircular, or complex roof shape. Moreover, since the sheets of profiled flooring have a minimum number of fixation points, and are easily sealed together, profiled flooring is considered one of the most reliable waterproofing materials that do not leak moisture.

Metal tiles

The following material is also metal sheets. However, in comparison with profiled flooring, metal tile has slightly less valuable characteristics. One of the most important features of these materials is the fact that metal tile sheets are more difficult to seal and have more fixation points, so more moisture will inevitably penetrate between them. And the consequence of such a feature of metal tiles— is the need to install a high-quality waterproofing membrane.

A unique feature of metal tiles — is the ability to imitate natural ceramic tiles, so this material is often chosen for decorative reasons. The average thickness of metal tile sheets is 0.5-0.6 mm, and the weight is 3.5-5 kg. as a rule, metal tiles are covered with a zinc or polymer composition, which ensures their resistance to rust formation.

Other advantages of metal shingles — include rigidity and strength, which make them one of the main materials not only for the design of metal roofs but also for the manufacture of snow holders, stairs, lighting protection devices, and elements of gutters.

It is important that the minimum slope angle for the construction of a metal roof is at least 14 degrees. Otherwise, there are no differences between profiled sheets and metal tile sheets, even in the requirements for waterproofing material: in both cases, you can stop at the same thing. The most common waterproofing options will be considered later.

You can read more about waterproofing metal roofing in the following articles:

- Waterproofing of metal roofing: Materials and technology of their installation under metal roofing of cold and warm roofs

- Repair of metal roofing: Technology and prices

Sheet metal, aluminum, and copper

The most popular type of metal roof is the material of the sheet structure. The connection of the transverse panels with each other is carried out along the line of their edges by coupling the bent edges into the lock. Such a connection ensures the strength and durability of the roof, and high-quality waterproofing allows you to increase the service life of the roof to at least 50-100 years.

Non-ferrous materials are often used as roofing. For example, aluminum, from which metal sheets are made, has an acceptable cost and low weight, so it does not create an additional load on the structure.

Aluminum does not oxidize upon contact with oxygen and does not corrode, so this material protects the structure from air and moisture while maintaining its excellent appearance. The only drawback of aluminum — is the lack of resistance to low temperatures. When the temperature drops, aluminum loses its plasticity and becomes brittle, so its installation is carried out in the warm season.

Copper metal sheets, as manufacturers guarantee, with proper care will be able to last at least a hundred, or even two hundred years. Despite the fact that copper is still corroded, this does not lead to the destruction of the material, but only to a change in its color. The oxide film covering the metal prevents the manifestation of other corrosive effects and also protects the copper from the effects of liquids.

The only drawback of copper metal sheets – is their cost, which, as a rule, exceeds the value of two thousand rubles per square meter. However, it is worth mentioning another indisputable advantage of this coating: copper sheets rarely need constant professional inspection and repair. Regular inspection of such a roof is not required.

Materials for waterproofing over metal roofs and the technology of their installation

Waterproofing of metal roofs is usually carried out with the application of waterproofing material on top of metal sheets of the roof or as a membrane under them. Various mixtures are used for waterproofing over metal, for example, polyurethane compounds, liquid rubber, waterproofing tape, as well as silicone, and thiocol sealants. For each of the listed materials, specific technology is used that allows you to protect products that are in various operating conditions. Let’s look at the most popular compositions in more detail.

Polyurethane compositions

The polyurethane composition used in the waterproofing of various structures has high elasticity and frost resistance and is also characterized by a long service life. Such compositions are characterized by excellent adhesion to metal and polymer compounds and, moreover, the ability to harden quickly.

Advantages:

- No seams in the final coating, and seams — are the weakest point in any waterproofing system;

- 100% adhesion to metal;

- High coefficient of elasticity;

- Suitable for application to various irregularities;

- Can be applied both manually and with the help of spray equipment;

- Resistance to ultraviolet solar radiation (with the addition of protective layers);

- The ability to combine the components in almost any color.

Disadvantages:

- Polyurethane compounds are considered extremely expensive;

- Requires careful surface preparation before application;

- Some compositions, for example, 2-ble components, are recommended to be applied by professional, experienced builders who specialize in waterproofing installation.

You can read more about polyurethane waterproofing in the article – “Polyurethane waterproofing“.

Liquid rubber

Sometimes the surface of a metal roof can be complex, and it is not possible to carry out waterproofing by simple coating. In such cases, the rolled material intended for standard metal roofs is not used. Then liquid rubber is used, which is a composition capable of providing a strong connection of surfaces made of any materials. Liquid rubber is often sued to repair old and equip new structures, as well as for waterproofing metal.

The process of applying liquid rubber, with a consistency resembling ordinary sealing mastic, is recommended to be carried out with the help of special equipment. Waterproofing using liquid rubber is best entrusted to specialists equipped with specialized equipment. Rubber hardens quickly and subsequently is not exposed to the harmful effects of air and precipitation. Double-component compositions of liquid rubber should be applied to the metal roof using a spray gun.

You can read more about liquid rubber in the article – “Waterproofing with liquid rubber“.

Waterproofing tapes

Sealing tape, the main component of which is butyl rubber, belongs to the category of self-adhesive tape materials and is convenient to use. The tapes have good adhesive properties with respect to metal, and also withstand temperature changes with an upper limit of up to 80-90 degrees Celsius. Also, these roll-type materials are very elastic and are not exposed to moisture and many chemical compounds.

The ease of installation and affordable price of waterproofing tapes allow them to be used for sealing roofs made of profiled sheets and metal tiles in places of overlap. Also, the tapes are able to perform the task of a sealer or serve as a basis or limiter for laying out other types of sealants on a work surface with steep slopes.

Silicone sealant

Silicone sealant is considered a universal material capable of bonding with any kind of surface, including metal coating. Such sealants are characterized by elasticity, heat resistance, heat and frost resistance, as well as the ability to withstand the effects of ultraviolet radiation while maintaining their original properties. Moreover, silicone sealants are characterized by an affordable price, so anyone can buy the option they like in a hardware store.

Among the disadvantages of the considered sealants, it is possible to distinguish a fairly short service life relative to, for example, polyurethane options. Silicone sealants are also difficult to use on roofs with steep slopes, especially if the metal roof has a polymer coating. This is due to the reduced adhesive ability of silicone sealants to polymers.

Thiokol sealant

The following sealant is several times superior to other materials in terms of resistance to temperature. Thiokol sealant is able to tolerate heating up to 140 degrees Celsius, and also is not changed under the influence of moisture. Its service life is at least 15 years. Such a composition is often used for the repair of non-metallic roofs, as well as for metal processing at the stage of construction of the structure. A strong layer of sealant perfectly protects the roof from leaks.

However, Thiokol sealant has such disadvantages that even its low cost is not compensated. For example, it takes a lot of time to dry it, which does not allow construction work to be carried out promptly. Sealants from some manufacturers take several days to completely solidify, and they should be applied in several layers. That is, the process of installing waterproofing can take even a week.

How to make a repair and waterproof a metal roof over an existing foundation properly

When it is necessary to make reliable waterproofing on top of an existing metal base, without dismantling it, it is recommended to do this as follows:

- Clean the metal from rust, peeling elements, dirt, and dust;

- Treat all seams and joints with a special sealing tape, since it is the seams and joints that are weak points in the structure, and without their additional protection with a special tape, leaks may form in these places over time;

- Apply a special primer to the metal base to improve the adhesion of the future waterproofing system;

- Apply a seamless waterproofing compound having 100% adhesion to the base and a high coefficient of elasticity. Such composition can be polyurethane waterproofing or liquid rubber;

- Protective coating arrangements. This is a special finishing coating that should protect the applied composition from the effects of ultraviolet radiation.

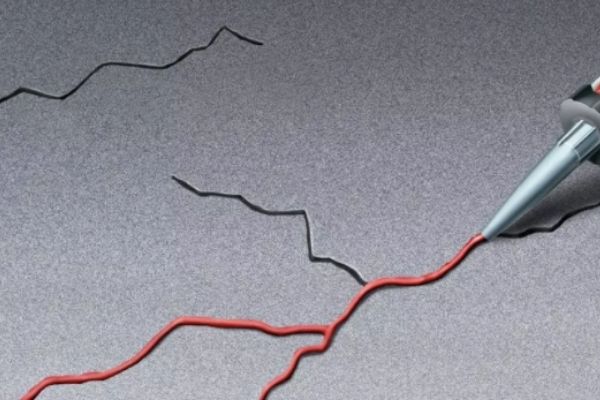

Waterproofing of metal roof seams

Seams and joints — are the weakest point in any roofing, including metal one. For sealing joints and junctions, as a rule, it is best to use special sealing tapes that are glued to the joint with epoxy glue or that have their own adhesive base.

There are many different sealing tapes on the market today:

- With one adhesive layer;

- With two adhesive layers (the adhesive layer is located on both sides of the tape);

- UV resistant;

- Width from 2 to 50 sm.

Important: For the repair and sealing of various seams and joints of roofing metal structures, it is recommended to use only tapes that are resistant to UV radiation.

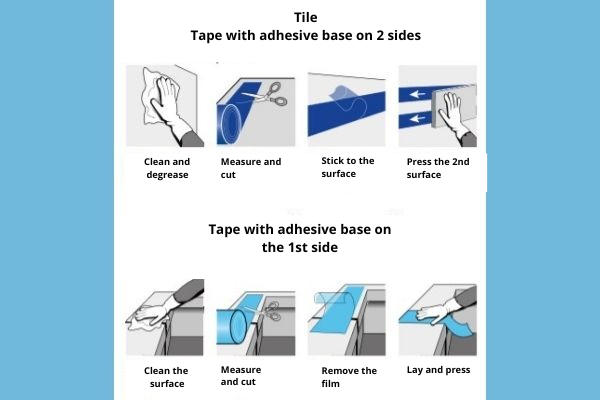

Instructions for applying most sealing tapes for seams in metal bases:

Most tapes should be applied at a surface and material temperature above +5 degrees. At temperatures below, it is necessary to warm up the base with a construction drier before arranging the tape.

For tapes with 1 (one) working surface:

- Clean and degrease the surface;

- Measure and cut the desired amount;

- Remove the protective film;

- Stick to the surface;

- Press the 2nd surface.

For tapes with 2 working surfaces:

- Clean and degrease the surface;

- Measure and cut the desired amount;

- Remove the protective film;

- Lay and press so that there are no creases and voids under the tape.

The cost of a metal roof waterproofing installation

The cost of the work, indicated in the table below is the preliminary price for 1m2. The preliminary price indicated in the table may change depending on the complexity of the work and other important factors.

| Description of work | Unit of measurement | Price in % |

| Preparation of the foundation | m2 | 1 |

| Primer of the base | m2 | 5 |

| Application of liquid rubber | m2 | 40 |

| Waterproofing with polyurethane | m2 | 80 |

| Application of UV resistant coating | m2 | 40 |

| Sealing of seams and joints with a special waterproofing tape | running meter | 60 |

| Tightening and replacement of fasteners | m2 | 40 |

| Replacement and reconstruction of metal tiles | m2 | 60 |

| Replacement and reconstruction of sheet metal | m2 | 60 |

| Replacement and reconstruction of metal with a folding lock | m2 | 90 |

| The installation of the lathing and counter lathing | m2 | 60 |

| Thermal insulation installation | m2 | 20 |